V-PS Photoelectric Smoke Detector Installation Sheet: Description

Diunggah oleh

luisrruiz_123Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

V-PS Photoelectric Smoke Detector Installation Sheet: Description

Diunggah oleh

luisrruiz_123Hak Cipta:

Format Tersedia

• To ensure proper operation, schedule maintenance (regular or

selected) in accordance with the requirements of the authority

having jurisdiction. Refer to NFPA 72 and CAN/ULC-S536.

• To ensure proper operation, store the detector within the

recommended temperature ranges. Allow the detector to stabilize

to room temperature before applying power.

V-PS Photoelectric Smoke • Keep the dust cover (supplied) on the detector during installation

Detector Installation Sheet and remove it prior to commissioning and service. The dust cover

is not a substitute for removing the detector during new

construction or heavy remodeling.

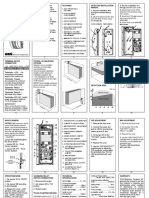

To install the detector:

1. Install and wire the detector base using the installation sheet

supplied with the detector base.

2. Connect the detector to the base by rotating the detector clockwise

until it snaps into the locked position. To remove the head turn it

counterclockwise.

3. If the head must lock to the base, break away the locking tab using

a pair of pliers. See Figure 1.

To remove the detector head after breaking away the locking tab,

insert a small screwdriver into the slot on the side of the base and

Description press in while simultaneously turning the detector head

counterclockwise.

The V-PS Photoelectric Smoke Detector uses an optical sensing

chamber to detect smoke. The detector analyzes the sensor data to 4. Remove the serial number label from the detector and attach it to

determine when an alarm should be initiated. the project documentation.

The detector continuously monitors changes in sensitivity due to the

environment (e.g., dirt, smoke, temperature, humidity) and notifies the Figure 1: Locking tab

loop controller of its condition. The detector issues a dirty-sensor

warning when it reaches its preset limit. This notifies the operator of

the need for service while the detector is still operating. The detector is

capable of performing comprehensive self-diagnostics and storing the

results.

LEDs: The V-PS detector uses a bicolor LED to show its status.

• Normal: Green LED flashes

• Alarm: Red LED flashes

Electronic addressing

The control panel automatically assigns addresses to the detectors.

Use a laptop computer to set custom addresses for the detectors. No

addressing switches are used.

(1)

Installation

(1) Locking tab

Install and wire this device in accordance with applicable national and

local codes, ordinances, and regulations.

Maintenance

Refer to Vigilant Detector Application Bulletin (P/N 3101109-EN) for

additional information on detector placement and spacing. When cleaning is necessary, the sensing chamber of the detector

easily unsnaps for field cleaning and service.

WARNINGS For warranty and return, see “Contact information” on page 2.

• Risk of system failure. This detector does not operate without

To clean the detector:

electrical power. As fires frequently cause power interruption,

discuss further safeguards with your local fire protection specialist. 1. Remove the detector from the base.

• Risk of system failure. This detector does not sense fires in areas 2. Insert a screwdriver in the small slot where the detector cap

where smoke cannot reach the detector. Smoke from fires in walls, connects to the detector body. See Figure 2.

roofs, or on the opposite side of closed doors may not reach the

detector. 3. Pry the detector cap off the detector body.

4. Squeeze the optical block chamber where the two arrows point,

Notes labeled “squeeze here.”

• Photoelectric detectors have a wide range of sensing capabilities, 5. Pull off the optical block chamber.

but are best suited for detecting slow, smoldering fires.

6. Blow off the optical block base in the detector body using clean

• Do not use a detector guard with this detector unless the compressed air.

combination has been evaluated and found suitable.

P/N 3101070-EN • REV 05 • ISS 24FEB16 1/2

7. Snap a new optical block chamber in place. Make sure you line up Specifications

the two arrows on the block chamber with the snaps on the optical

block base. Communication line 20 Vp-p max.

8. Connect the detector cap to the detector body by rotating the cap voltage

clockwise until it snaps into a locked position. Current

Normal operating 45 µA

9. Install the detector onto the base. Alarm 45 µA

Note: To verify the effectiveness of the cleaning, recalibrate the Smoke sensitivity

device and run a device maintenance report. Refer to the control UL 0.67 to 3.66 %/ft. obscuration

panel technical reference manual. ULC 0.74 to 3.70 %/ft. obscuration

10. Test the detector and verify sensitivity. Environmental Automatic

compensation

Figure 2: Detector disassembly Distance from ceiling 12 in. (305 mm) max.

(wall mounted)

Compatible bases

Standard B4U, B4U-LP

Relay RB4U

Isolator IB4U

(3)

Audible SB4U, SB4U-LF

(2)

Operating environment

(1) Temperature 32 to 120°F (0 to 49°C)

Relative humidity 0 to 93% noncondensing

XX

Storage temperature −4 to 140°F (−20 to 60°C)

XX

XX

XX

Regulatory information

(4) North American Meets: CAN/ULC-S529, UL 268

standards Follow: CAN/ULC-S524, CAN/ULC-S537,

(5)

National Building Code of Canada, National Fire

Code of Canada, and NFPA 72

(1) Slot to insert screwdriver (4) Detector body

FCC compliance This device complies with part 15 of the FCC

(2) Optical block chamber (5) Detector cap

Rules. Operation is subject to the following two

(3) Optical block base

conditions: (1) This device may not cause harmful

interference, and (2) this device must accept any

Testing interference received, including interference that

may cause undesired operation.

NFPA 72 and CAN/ULC-S537 require a calibrated sensitivity test upon

installation and following any modifications or additions to the system. Industry Canada This Class A digital apparatus complies with

compliance Canadian ICES-003.

The detector can perform this test and generate a system sensitivity

report.

To test the detector:

Contact information

1. Before initial testing, remove the dust cover from the detector and

For contact information, see www.kiddelifesafety.com.

notify the proper authorities that the fire alarm system is

undergoing maintenance and will be temporarily out of service. © 2016 Walter Kidde Portable Equipment, Inc.

All rights reserved.

2. Test the detector using Smoke-In-A-Can (model SM-200) canned

smoke. Carefully follow directions on the can to avoid damage to

the detector.

2/2 P/N 3101070-EN • REV 05 • ISS 24FEB16

Anda mungkin juga menyukai

- R04 V-PS Photoelectric Smoke Detector Installation SheetDokumen4 halamanR04 V-PS Photoelectric Smoke Detector Installation SheetDiegoBelum ada peringkat

- Manual Instalacion Detector de Humo EdwardsDokumen2 halamanManual Instalacion Detector de Humo EdwardsMatiasBelum ada peringkat

- 3102465-EN R003 KI-PD Intelligent Photoelectric Smoke Detector Installation SheetDokumen2 halaman3102465-EN R003 KI-PD Intelligent Photoelectric Smoke Detector Installation SheetAlejandro coronelBelum ada peringkat

- Kir PD Kidde Manual Instalacion SH IngenieriaDokumen2 halamanKir PD Kidde Manual Instalacion SH IngenieriaLuis RamirezBelum ada peringkat

- Installation Wiring Diagram for SD119 Series Smoke DetectorsDokumen2 halamanInstallation Wiring Diagram for SD119 Series Smoke DetectorsVictor PatsiBelum ada peringkat

- DMAX DH-4326 ManualDokumen2 halamanDMAX DH-4326 ManualMarcelo MachadoBelum ada peringkat

- Installation Wiring Diagram: DetectorDokumen2 halamanInstallation Wiring Diagram: Detectorparallax1957Belum ada peringkat

- Installation Sheet - SIGA-PD Intelligent Photoelectric Smoke Detector - Edwards Signaling ESTDokumen2 halamanInstallation Sheet - SIGA-PD Intelligent Photoelectric Smoke Detector - Edwards Signaling ESTChase GietterBelum ada peringkat

- TG - NB326 - S - Smoke DetectorDokumen2 halamanTG - NB326 - S - Smoke DetectordepozitankoBelum ada peringkat

- FIRECLASS Fire Detection System 4B Bases and AccessoriesDokumen12 halamanFIRECLASS Fire Detection System 4B Bases and AccessoriesMariusBelum ada peringkat

- Ficha-EN R001 SIGA-OSD Intelligent Photoelectric Smoke Detector Installation SheetDokumen2 halamanFicha-EN R001 SIGA-OSD Intelligent Photoelectric Smoke Detector Installation SheetYin VargasBelum ada peringkat

- 5151 - Manual - I56-5151 DHCDokumen2 halaman5151 - Manual - I56-5151 DHCmeribout adelBelum ada peringkat

- Eaton Halooutdoor Ms180 InstDokumen6 halamanEaton Halooutdoor Ms180 InstZar MtzBelum ada peringkat

- S W A N 1 0 0 0: Installation InstructionsDokumen2 halamanS W A N 1 0 0 0: Installation InstructionsLuisAlbertoSaldañaRmzBelum ada peringkat

- Notifier SD 651 SD 651A Low Profie Plug in Smoke DetectorsDokumen2 halamanNotifier SD 651 SD 651A Low Profie Plug in Smoke Detectorsด้วกส์ เอเชีย ไม่เคยเสียท่าใครBelum ada peringkat

- Hd912 ManualDokumen2 halamanHd912 ManualrhomadonaBelum ada peringkat

- VAR TEC FDR Series User ManualDokumen2 halamanVAR TEC FDR Series User ManualmicrajacutBelum ada peringkat

- Operating Instructions for Vibrating Level Switches Model NVIDokumen11 halamanOperating Instructions for Vibrating Level Switches Model NVIHasnaoui SamirBelum ada peringkat

- EDC-M9102 Detector Manual F3.780.1099ASY Issue1.01Dokumen2 halamanEDC-M9102 Detector Manual F3.780.1099ASY Issue1.01EDWIN100% (1)

- Wizmart: Installation Wiring DiagramDokumen2 halamanWizmart: Installation Wiring DiagramAlejandro CabreraBelum ada peringkat

- Manual de Instrucciones Reemplazo de Sensores Detector Multigas ALTAIR 4X - ESDokumen2 halamanManual de Instrucciones Reemplazo de Sensores Detector Multigas ALTAIR 4X - ESjaime saenzBelum ada peringkat

- 03 1 TD3100 Manual TraningDokumen38 halaman03 1 TD3100 Manual TraningPhit Nguyen Viet100% (1)

- GFE H ManualDokumen2 halamanGFE H Manualparallax1957Belum ada peringkat

- Man Leak Detector Pce LDC 15 en - 230627 - 070750Dokumen20 halamanMan Leak Detector Pce LDC 15 en - 230627 - 070750hrstgaBelum ada peringkat

- How To Install Ecoobee Smart SensorDokumen8 halamanHow To Install Ecoobee Smart SensorVamshi GuptaBelum ada peringkat

- Intelligent Photoelectric Smoke Detector Features Twin LED DetectionDokumen2 halamanIntelligent Photoelectric Smoke Detector Features Twin LED DetectionSeagull MarineBelum ada peringkat

- Installation Instructions for Swan 1000 Passive Infrared & Microwave DetectorDokumen2 halamanInstallation Instructions for Swan 1000 Passive Infrared & Microwave Detectorf041793Belum ada peringkat

- Installation CAS 1RA O Instructions and WiringDokumen4 halamanInstallation CAS 1RA O Instructions and WiringManielBelum ada peringkat

- XR2B Detector Installation/Removal Tool For Use With System Sensor Low Profile Intelligent DetectorsDokumen2 halamanXR2B Detector Installation/Removal Tool For Use With System Sensor Low Profile Intelligent DetectorsMarcelo OrtizBelum ada peringkat

- InstructionsDokumen8 halamanInstructionsAndré SilvaBelum ada peringkat

- Twin LED Sensor Light: Instruction ManualDokumen4 halamanTwin LED Sensor Light: Instruction Manualgortonm1Belum ada peringkat

- Manual Urz3366Dokumen40 halamanManual Urz3366Ionel LungeanuBelum ada peringkat

- Manual de Instalare Senzor de Miscare Digital Quad PIR DSC BV 501 12 M 360 Deg MLSP PDFDokumen2 halamanManual de Instalare Senzor de Miscare Digital Quad PIR DSC BV 501 12 M 360 Deg MLSP PDFDumitru BogdanBelum ada peringkat

- Important: 5-In-1 PRO+ Weather SensorDokumen8 halamanImportant: 5-In-1 PRO+ Weather SensorTaller KnettBelum ada peringkat

- Wireless Glass Break Detector JA-60BDokumen2 halamanWireless Glass Break Detector JA-60BDragus IonelBelum ada peringkat

- 3402 - LED Upgrade Instructions - 843J001 Rev D8 PDFDokumen14 halaman3402 - LED Upgrade Instructions - 843J001 Rev D8 PDFAris Bodhi RBelum ada peringkat

- Mag Retrofit Probe: Installation GuideDokumen10 halamanMag Retrofit Probe: Installation Guidesarge18Belum ada peringkat

- Manual Swan Quad CrowDokumen2 halamanManual Swan Quad CrowApex PredatorBelum ada peringkat

- Uvc 500Dokumen20 halamanUvc 500upadhyaysk97Belum ada peringkat

- Aprilaire 8051 Installation InstructionsDokumen2 halamanAprilaire 8051 Installation InstructionsYonathan ArdilaBelum ada peringkat

- Detector Geam SpartDokumen16 halamanDetector Geam SpartGabrielBelum ada peringkat

- Instruction Sheet 554 811: Radiation Protection, Administrative Requirements Safety NotesDokumen12 halamanInstruction Sheet 554 811: Radiation Protection, Administrative Requirements Safety NotesFrancisco Javier PérezBelum ada peringkat

- User's Manual: Micro-Portable ProjectorDokumen40 halamanUser's Manual: Micro-Portable ProjectorS. WANNANBelum ada peringkat

- Installation CAB300Dokumen2 halamanInstallation CAB300Yuri OliveiraBelum ada peringkat

- Nfx-Opt / Nfxi-Opt: EnglishDokumen4 halamanNfx-Opt / Nfxi-Opt: EnglishYves Sylvère YILIBelum ada peringkat

- Over Height Laser Scanner: Instruction ManualDokumen12 halamanOver Height Laser Scanner: Instruction Manualnikname08Belum ada peringkat

- RE316 Smoke and Heat Detector Wiring DiagramDokumen2 halamanRE316 Smoke and Heat Detector Wiring Diagramedwin_serpas2894Belum ada peringkat

- RE316 Smoke and Heat Detector Wiring DiagramDokumen2 halamanRE316 Smoke and Heat Detector Wiring DiagrammadhuBelum ada peringkat

- 1.1-MANUAL SENSOR DE RADICÓN SOLAR (Inglés)Dokumen8 halaman1.1-MANUAL SENSOR DE RADICÓN SOLAR (Inglés)WILLIAM TELLEZ / INSAKBelum ada peringkat

- Quick Start Quick Start Optimass 1400 Twin, Straight Tube Mass FL OwmeterDokumen4 halamanQuick Start Quick Start Optimass 1400 Twin, Straight Tube Mass FL OwmeterarBelum ada peringkat

- T-Rex Installation ManualDokumen2 halamanT-Rex Installation ManualVictor Bitar100% (2)

- JUPITER 1032 הוראות התקנהDokumen16 halamanJUPITER 1032 הוראות התקנהfreinlyxBelum ada peringkat

- F24 60 en (A4) V1.2Dokumen2 halamanF24 60 en (A4) V1.2dozer_kamilBelum ada peringkat

- Mechatronics Exp 2Dokumen4 halamanMechatronics Exp 2Prachi patilBelum ada peringkat

- D TECT 1 Manual GJD110Dokumen6 halamanD TECT 1 Manual GJD110Arnoldo AguilarBelum ada peringkat

- Patrol - 101: Weatherproof Curtain Pir & MW Detector For Outdoor UseDokumen2 halamanPatrol - 101: Weatherproof Curtain Pir & MW Detector For Outdoor UseClairefrance McbrookBelum ada peringkat

- Outdoor Detector SpecificationsDokumen4 halamanOutdoor Detector SpecificationsFrancis Narváez PacahualaBelum ada peringkat

- F10-AR User ManualDokumen110 halamanF10-AR User ManualRendraBelum ada peringkat

- Equipo Sirena Contra Incendio Exx ProofDokumen2 halamanEquipo Sirena Contra Incendio Exx Proofluisrruiz_123Belum ada peringkat

- WatchOUT EXtreme Brochure en-LRDokumen4 halamanWatchOUT EXtreme Brochure en-LRluisrruiz_123Belum ada peringkat

- DOC-02-072 - C - HS-NCM Sales DatasheetDokumen4 halamanDOC-02-072 - C - HS-NCM Sales Datasheetluisrruiz_123Belum ada peringkat

- DN 6720 PDF PDFDokumen4 halamanDN 6720 PDF PDFClaudia Patricia Carazas SarmientoBelum ada peringkat

- Noti - Fire - Net™: Release 5.0Dokumen4 halamanNoti - Fire - Net™: Release 5.0luisrruiz_123Belum ada peringkat

- 08 VESDA Cold Stores App Brochure A4 LoresDokumen4 halaman08 VESDA Cold Stores App Brochure A4 LoresPepe ZapataBelum ada peringkat

- LT-894 FleXNet Installation Manual-LONG CABLEADODokumen148 halamanLT-894 FleXNet Installation Manual-LONG CABLEADOluisrruiz_123Belum ada peringkat

- BEAM200, BEAM200S Single-Ended Reflected Type Projected Beam Smoke DetectorDokumen14 halamanBEAM200, BEAM200S Single-Ended Reflected Type Projected Beam Smoke Detectorluisrruiz_123Belum ada peringkat

- APC DIN Rail UPS Protects Control PanelsDokumen3 halamanAPC DIN Rail UPS Protects Control Panelsluisrruiz_123Belum ada peringkat

- FIER RESISTANT 2-Hour Fire Rated Cables PDFDokumen4 halamanFIER RESISTANT 2-Hour Fire Rated Cables PDFJairo WilchesBelum ada peringkat

- airMAX Ti Sector DS PDFDokumen11 halamanairMAX Ti Sector DS PDFluisrruiz_123Belum ada peringkat

- Tugas No. 1: Pengurutan AngkaDokumen11 halamanTugas No. 1: Pengurutan AngkaLia NamikazeBelum ada peringkat

- OAF TrainiingDokumen23 halamanOAF TrainiingCoral Shiny0% (1)

- SGSN ArchitectureDokumen17 halamanSGSN ArchitectureTejBelum ada peringkat

- Jabra Android SDK Developers GuideDokumen12 halamanJabra Android SDK Developers GuideEmilio AlejandroBelum ada peringkat

- Types of Prose Lesson PlanDokumen2 halamanTypes of Prose Lesson PlanChun Sa ParkBelum ada peringkat

- The World's First All in One $25 Digital Business Is The NEW, Smarter, Faster Way To, So You Can See Results in As Little As 24 Hours!!Dokumen20 halamanThe World's First All in One $25 Digital Business Is The NEW, Smarter, Faster Way To, So You Can See Results in As Little As 24 Hours!!zthubeBelum ada peringkat

- BOP Replacement Parts CatalogDokumen60 halamanBOP Replacement Parts Catalogdesavinicius100% (1)

- KPT ShapeShifterDokumen28 halamanKPT ShapeShifterLuis TovarBelum ada peringkat

- Đề Chuyên (Chính Thức) 2017Dokumen10 halamanĐề Chuyên (Chính Thức) 2017Nguyễn Minh ThưBelum ada peringkat

- C5G - R1C - Roboshop Program 2.0.0Dokumen82 halamanC5G - R1C - Roboshop Program 2.0.0kukaBelum ada peringkat

- Raspberry Pi Projects Book PDFDokumen204 halamanRaspberry Pi Projects Book PDFstanchan82100% (1)

- Sunnxt AppDokumen8 halamanSunnxt ApppsiphoniphoneBelum ada peringkat

- Final Survey SRM 4th Year ProjectDokumen3 halamanFinal Survey SRM 4th Year ProjectJayita KarBelum ada peringkat

- SQL Introduction and Practical ExamplesDokumen97 halamanSQL Introduction and Practical ExamplesRajiv Kumar100% (1)

- Analysis of Algorithm FinalDokumen11 halamanAnalysis of Algorithm FinalJohnny WangBelum ada peringkat

- Oed 2,0 2022Dokumen139 halamanOed 2,0 2022Ellish ErisBelum ada peringkat

- Incentive Week 23-24Dokumen12 halamanIncentive Week 23-24Pratiksha KumariBelum ada peringkat

- Compact NSX - SchneiderDokumen296 halamanCompact NSX - SchneiderNicolás Santiago UgarteBelum ada peringkat

- ABB Price Book 714Dokumen1 halamanABB Price Book 714EliasBelum ada peringkat

- Withdrawal Withdrawal Withdrawal WithdrawalDokumen15 halamanWithdrawal Withdrawal Withdrawal WithdrawalAradhya 19-1807Belum ada peringkat

- Conectividad para Sistemas Industriales Jun 2018Dokumen49 halamanConectividad para Sistemas Industriales Jun 2018Cristian TorresBelum ada peringkat

- Apollo247 247201631 Labinvoice CompleteDokumen1 halamanApollo247 247201631 Labinvoice CompleteAjay VanaparthiBelum ada peringkat

- SPDIF WhitepaperDokumen14 halamanSPDIF Whitepaperapi-3760834100% (1)

- TS80 Soldering Iron User Manual V1.1Dokumen23 halamanTS80 Soldering Iron User Manual V1.1nigger naggerBelum ada peringkat

- Implementation Guide C2MDokumen127 halamanImplementation Guide C2MLafi AbdellatifBelum ada peringkat

- BN20 e PreDokumen59 halamanBN20 e PreTuan DinhBelum ada peringkat

- C Pointers Questions PDFDokumen30 halamanC Pointers Questions PDFRoshni Khurana0% (2)

- Submit Report As JobDokumen2 halamanSubmit Report As JobFrederico MorgadoBelum ada peringkat

- Ds-7104Ni-Sl/W: Embedded Mini Wifi NVRDokumen1 halamanDs-7104Ni-Sl/W: Embedded Mini Wifi NVRLuis GutierrezBelum ada peringkat