Itp Electrical Chewee

Diunggah oleh

Ronnel Dean LimHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Itp Electrical Chewee

Diunggah oleh

Ronnel Dean LimHak Cipta:

Format Tersedia

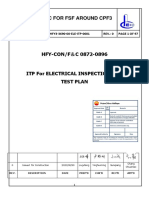

PARK TRIANGLE MALL

AND CORPORATE CENTER (CHEWEE)

Inspection and Test Plan

GENERAL ELECTRICAL WORKS

(Roughing-ins & Wiring Installation, Equipment Installation,

Termination, Testing and Commissioning)

Ronnel D. Lim Danica Jane A. De Leon Electrical Works

A 22 August 2017 QA/QC Engineer -VECC MDC – Field Engineer (Installation and Testing)

Rev. Date Prepared Checked Description

Document Review

Activity Company Name Title Signature Date

Reviewed by MDC Eiren Cris D. Santos OPCEN TSD Supervisor

Reviewed by MDC Kattleen V. Olivar QA Area Supervisor / QA On-site

Reviewed by MDC Rodrigo Umayam MEPFS Supervisor

Approved by MDC Ferdinand R. Cancino Project Manager / PIC

Makati Development Corporation ITP Number Rev

GENERAL ELECTRICAL WORKS

(Roughing-ins & Wiring Installation, Equipment Installation, Page 5 of 5 W P - I T P - 1 3 2 - 1 3 3 A

Termination, Testing and Commissioning)

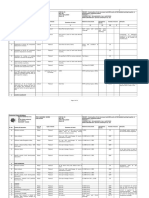

By Whom Frequencies Test

Item Description Inspection or Testing Acceptance Criteria QA Records

(QC) (QC) Methods

WORK-IN-PROGRESS

Construction –General-First Fixed (Roughing-ins Works)

PARK TRIANGLE MALL QA

Inspect and Review 3 set of shop drawings prior

AND

1

CORPORATE

Shop Drawing

CENTER (CHEWEE)

Approved Shop Drawing

/MEPFS Operation

to fabrication and installation

Approved by consultant Visual Check Shop Drawing

2 Box Setting and

QA-MDC

QC-Subcontractor

Inspection andApproved

TestMethod

Plan

Statement Inspect/Check Inspection and

Roughing-Ins Inspect Before Installation Visual

MEPFS Operation (Section 4 – 4.1) (Witness) acceptance report

(Embedded/Exposed)

Construction – General – 2nd Fixed(Wiring-Ins)

Item Description Inspection or Testing By Whom Frequencies Acceptance Criteria Comply

Test with the

Methods QA Records

Installation of Wires and

QA-MDC Approved

1

Cable (Conductor and (QC)

QC-Subcontractor

(QC) Method Inspection and

Cable/ High-Voltage Inspect During Installation Approved Submittal Inspect/Check

Work Activity

Cable/Low-Voltage Submittal MEPFS Operation Statement acceptance report

(Section 4 –

Cables/ Fire-rated Cables)

Pre-Construction 4.2)

Pre-Construction – Shop Drawings

Comply with the

1 Shop Drawings Review shop drawings TSD, Contractor N/A Accept by Electrical Approved

N/A Check if shop Shop Drawings

QA-MDC

2 Supervisor, QC Consultantto SPECS Method drawings are Inspection and

Megger Testing of Wires Inspect QC-Subcontractor During Installation Conformance Inspect/Check

Statement approved acceptance report

MEPFS Operation

(Section 4 –

2 Electrical Specification Review Electrical Installation and Contractor N/A Accept by Electrical N/A

4.3) Check if shop Execution Plan and

Test requirement as per Supervisor, QC Consultant drawings are Project Specification

procedure specifications and QA-MDC approved

Installation of Grounding other contract QC-Subcontractor Inspection and

3 Inspect During Installation Non-conformance to SPECs Visual Witness

Pre-Construction

Wire – Method Statement MEPFS Operation acceptance report

1 Method Statement Prepare Method Statement Field Per type of work Approved by Electrical N/A Review Method Statement

Construction – General – 3rd Fixed (Device Installation)

(Methodology) Engineer/QC Consultant

Contractor

Item Description

Pre-Construction Inspection or Testing

– Materials By Whom Frequencies Acceptance Criteria Test Method QA Records

(QC)

1. Installation of Lighting Inspect QA-MDC After installation Approved Method Statement Comply with the Witness Inspection and

1 Flexible, IMC & EMT Pipe & Inspect and verify delivered QC/QA-MDC Upon Delivery MC-HSS-14-002 N/A Check/Inspect Delivery Report

Fixture and Power QC-Subcontractor Approved acceptance report

fittings material submittal and sample /Field Engr. /Approved Material

MEPFS Operation Method

Submittal

Statement

2 PVC & FITTINGS Inspect and verify delivered QC/QA-MDC Upon Delivery MC-HSS-14-002 N/A Check/Inspect Delivery Report

material submittal and sample /Approved Material

Comply with the Submittal

QA-MDC

Approved Inspection and

2

3 SwitchboardPROTECTION

LIGHTNING and Panel Inspect

Inspect and verify deliveredQC-Subcontractor

QC/QA-MDC After Installation

Upon Delivery Approved Method Statement

MC-HSS-14-002 N/A Witness

Check/Inspect Delivery Report

Method acceptance report

material submittal and sampleMEPFS Operation /Approved Material

Statement

Submittal

4 GROUND ROD Inspect and verify delivered QC/QA-MDC Upon Delivery MC-HSS-14-002 N/A Check/Inspect Delivery Report

Post-Construction (Finalmaterial

Inspection/Testing)

submittal and sample /Approved Material

Submittal

Item Description Inspection or Testing By Whom Frequencies Acceptance Criteria Test Method QA Records

5 SUPPORT SYSTEM Inspect and verify delivered QC/QA-MDC Upon Delivery

(QC) MC-HSS-14-002 N/A Check/Inspect Delivery Report

material submittal and sample /Approved Material

Submittal

Work Inspection Request

QA-MDC >Approved Method Comply with the

Form

1 Work Inspection Request Inspect QC-Subcontractor Statement Approved

After installation/work is done Hold (FORM NO.: F-QM-GF-

per activity MEPFS Operation >Approved Submittals for Construction

001)

Construction Specification Specification

Makati Development Corporation ITP Number Rev

QA-MDC >Approved Method Comply with

Electrical Checklist Form

After installation/work isW

2 ElectricalGENERAL

ELECTRICAL

Checklist Inspect WORKS

QC-Subcontractor Page 5 of 5 done P - I T

Statement P - 1

Approved 3 2 -

Hold 1 3(FORM 3 NO.: F-QM-EE-

A

MEPFS Operation >Approved Submittals for Construction

(Roughing-ins & Wiring Installation, Equipment Installation, Construction Specification Specification

005)

Termination, Testing and Commissioning)

QA-MDC A voltage of 1000VDC Continuity and insulation

Continuity and

Continuity and Insulation QC-Subcontractor (100Mohms) for low voltage test Form

Testing After installation Insulation Hold

3 resistance test MEPFS Operation cable be applied for one (FORM NO. : F-QM-EET-

testing

minute or 60 seconds. 020)

Anda mungkin juga menyukai

- VERVE RESIDENCES PLUMBING INSPECTION TEST PLANDokumen3 halamanVERVE RESIDENCES PLUMBING INSPECTION TEST PLANEdBelum ada peringkat

- NSC-400-CE-3220-ITP-02-A-Transmission Line Conductor - Stringing & InstallationDokumen2 halamanNSC-400-CE-3220-ITP-02-A-Transmission Line Conductor - Stringing & InstallationElisco Pher SalmasanBelum ada peringkat

- LV Panel ChecklistDokumen1 halamanLV Panel ChecklistvaradharajanBelum ada peringkat

- Inspection and Tests Plan: OPGW 60mm, 24coresDokumen3 halamanInspection and Tests Plan: OPGW 60mm, 24coresErika Rafani WibowoBelum ada peringkat

- Client Material Verification and Installation Inspection SNPL NepalDokumen22 halamanClient Material Verification and Installation Inspection SNPL Nepalirfan vpBelum ada peringkat

- ITP & Checklist For Installtion of Conduits, Boxes Ans Switches Rev.0Dokumen3 halamanITP & Checklist For Installtion of Conduits, Boxes Ans Switches Rev.0shameer khanBelum ada peringkat

- Installation of Electrical EquipmentDokumen7 halamanInstallation of Electrical Equipmentadeniyi abiolaBelum ada peringkat

- 00-GE-EQA-001 (Rev.a) Site Inspection and Test Plan For Electrical and I&C WorkDokumen12 halaman00-GE-EQA-001 (Rev.a) Site Inspection and Test Plan For Electrical and I&C WorkAbdul Mohid SheikhBelum ada peringkat

- Method Statement For Electrical ServicesDokumen6 halamanMethod Statement For Electrical ServicesUmaira ZainalBelum ada peringkat

- CHECKLIST For Installation of Electrical UPVC DuctsDokumen1 halamanCHECKLIST For Installation of Electrical UPVC DuctskevinBelum ada peringkat

- Electrical Inspection and Test PlanDokumen1 halamanElectrical Inspection and Test PlanJames Pol JumarangBelum ada peringkat

- Checklist For UPS & Accessories InstallationDokumen1 halamanChecklist For UPS & Accessories InstallationguspriyBelum ada peringkat

- Itr Ew 01a - EngDokumen2 halamanItr Ew 01a - Engwassim nasriBelum ada peringkat

- E&I Quality PlanDokumen9 halamanE&I Quality PlanJithuRajBelum ada peringkat

- Method of Statement For Conduit InstallationDokumen15 halamanMethod of Statement For Conduit InstallationMohd MuksinBelum ada peringkat

- ITP For Electrical WorksDokumen22 halamanITP For Electrical WorksDebesh Chaudhary100% (6)

- HFY3-3690-00-ELE-ITP-0001 - 0 ITP For Electrical Inspection and Test PlanDokumen97 halamanHFY3-3690-00-ELE-ITP-0001 - 0 ITP For Electrical Inspection and Test PlanAmmar AlkindyBelum ada peringkat

- ITP For Testing and Commissioning of ACSDokumen1 halamanITP For Testing and Commissioning of ACSRommel Espinosa ParasBelum ada peringkat

- Quality Assurance PlanDokumen2 halamanQuality Assurance PlanSAGARBelum ada peringkat

- QC-143 R2 Distribution Panel ChecklistDokumen1 halamanQC-143 R2 Distribution Panel ChecklistCamilo Jorquera100% (1)

- ITP For Cable Tray - Rev BDokumen6 halamanITP For Cable Tray - Rev BDonny Subarja100% (1)

- Grounding Installation Inspection and Test Plan ITPDokumen2 halamanGrounding Installation Inspection and Test Plan ITPtristan guarinoBelum ada peringkat

- Project: Samsun CCPP: Title: ITP of SwitchgearsDokumen4 halamanProject: Samsun CCPP: Title: ITP of SwitchgearsUtku Can Kılıç100% (1)

- Inspection and Test Plan (Itp) For ElectricalDokumen38 halamanInspection and Test Plan (Itp) For ElectricalJames Pol JumarangBelum ada peringkat

- ITP For EarthingDokumen18 halamanITP For EarthingBilibili weekly TOP 10 videos0% (1)

- Larsen & Toubro underground piping inspection planDokumen4 halamanLarsen & Toubro underground piping inspection planBhavani PrasadBelum ada peringkat

- Inspection & Test Check ListDokumen1 halamanInspection & Test Check ListPRAKTISIBelum ada peringkat

- Checklist For Cable Try Fabrication and EractionDokumen2 halamanChecklist For Cable Try Fabrication and Eractionnayum100% (1)

- Itp UpsDokumen4 halamanItp UpsAshraf MohammedBelum ada peringkat

- Visual and Technical Checking of I&C SystemsDokumen13 halamanVisual and Technical Checking of I&C SystemszhangyiliBelum ada peringkat

- Installation Check Sheet For Ahu FahuDokumen2 halamanInstallation Check Sheet For Ahu FahuSamer AliBelum ada peringkat

- C - Electrical Quality Control Plan - March 2013Dokumen36 halamanC - Electrical Quality Control Plan - March 2013mkrasanBelum ada peringkat

- 5 Formwork ChecklistDokumen81 halaman5 Formwork ChecklistAlphaBelum ada peringkat

- Project: Instrument Junction Box InstallationDokumen2 halamanProject: Instrument Junction Box InstallationAhmad DagamsehBelum ada peringkat

- SSE-QC-ELE-510 - CT & PT Installation ChecklistDokumen2 halamanSSE-QC-ELE-510 - CT & PT Installation ChecklistBhalsingh JangraBelum ada peringkat

- ITP &checklist For Installation and Testing of LV CablesDokumen6 halamanITP &checklist For Installation and Testing of LV Cablesshameer khanBelum ada peringkat

- Method Statement For Audio Visual System InstallationDokumen8 halamanMethod Statement For Audio Visual System InstallationArshad PcBelum ada peringkat

- E&I QAP's - Submitted To Contractor HZADokumen33 halamanE&I QAP's - Submitted To Contractor HZASuraj ShettyBelum ada peringkat

- Appendix H: Design and Construction Manual Design RequirementsDokumen17 halamanAppendix H: Design and Construction Manual Design RequirementsPageduesca RouelBelum ada peringkat

- p103-Stts-gec-Asi-ms-ele-003 - Method Statement For Installation of LV Distribution Panels (MDB, Capacitor Bank, VFD, SMDB, DB)Dokumen6 halamanp103-Stts-gec-Asi-ms-ele-003 - Method Statement For Installation of LV Distribution Panels (MDB, Capacitor Bank, VFD, SMDB, DB)Anandu AshokanBelum ada peringkat

- MS-E019 Installation of 11KV SwitchgearDokumen8 halamanMS-E019 Installation of 11KV Switchgeara wasayBelum ada peringkat

- ITP For Batteries, Chargers and UPSDokumen7 halamanITP For Batteries, Chargers and UPSUtku Can Kılıç100% (1)

- Global Power Test Sdn. Bhd. Site Acceptance Test Report: Testing of 415V LV Switchgear PanelDokumen10 halamanGlobal Power Test Sdn. Bhd. Site Acceptance Test Report: Testing of 415V LV Switchgear PanelTHULASI RAMBelum ada peringkat

- Epic For Upgradation of Ac Ups Units in Ngl3, Mesaieed: Item Checklist Description Result RemarksDokumen1 halamanEpic For Upgradation of Ac Ups Units in Ngl3, Mesaieed: Item Checklist Description Result RemarksmeeBelum ada peringkat

- Inspection & Test Plan for Chilled Water Expansion TanksDokumen1 halamanInspection & Test Plan for Chilled Water Expansion TanksvictorBelum ada peringkat

- Method Statement For MV Power Cables & Accessories InstallationDokumen9 halamanMethod Statement For MV Power Cables & Accessories InstallationAdil HasanovBelum ada peringkat

- FQP GeneralDokumen21 halamanFQP GeneralgaladrialBelum ada peringkat

- Procedure Installation of Grounding & Lightning System - LABUAN BAJO PDFDokumen9 halamanProcedure Installation of Grounding & Lightning System - LABUAN BAJO PDFWika Djoko OBelum ada peringkat

- Itp Package UnitDokumen2 halamanItp Package UnitWasim AhmedBelum ada peringkat

- Checklist Cable Drum CardDokumen7 halamanChecklist Cable Drum CardSanket JainBelum ada peringkat

- QAP Plan Elect.Dokumen2 halamanQAP Plan Elect.insap_dineshBelum ada peringkat

- Bus Duct Installation - Method of StatementDokumen13 halamanBus Duct Installation - Method of StatementTalha Altaf100% (1)

- Qatar Petroleum Construction Co. Ltd Inspection & Test PlanDokumen1 halamanQatar Petroleum Construction Co. Ltd Inspection & Test PlanmeeBelum ada peringkat

- Checklist (Underground Pipe Laying Report) : Mr. Aden LiuDokumen36 halamanChecklist (Underground Pipe Laying Report) : Mr. Aden LiuADEN LIU100% (1)

- Method Statement FOR Testing and Commissioning: Grounding SystemDokumen3 halamanMethod Statement FOR Testing and Commissioning: Grounding SystemNon Etabas Gadnatam100% (1)

- Mandrelling Test / Checklist: Pmqs Construction Solutions, IncDokumen1 halamanMandrelling Test / Checklist: Pmqs Construction Solutions, IncAbnar KumplishaBelum ada peringkat

- Inspection and Test Plan For Electrical Lighting Systems Installation With Checklists - Inspection and Test Plan TemplatesDokumen5 halamanInspection and Test Plan For Electrical Lighting Systems Installation With Checklists - Inspection and Test Plan TemplatesMouayed Zeadan100% (1)

- ITP For CCTV System Testing & CommissioningDokumen1 halamanITP For CCTV System Testing & CommissioningTamer EidBelum ada peringkat

- Statement For CCTV System Testing & CommissioningDokumen9 halamanStatement For CCTV System Testing & CommissioningAnonymousBelum ada peringkat

- ITP Box Setting On CHB or Macro WallDokumen3 halamanITP Box Setting On CHB or Macro WallRitchie OcampoBelum ada peringkat

- Grid-tied System Design NY: Calculating Module and Inverter NeedsDokumen52 halamanGrid-tied System Design NY: Calculating Module and Inverter Needsbedilu77Belum ada peringkat

- Veriflex Intercon 1.8-3kV Cable - 1Dokumen2 halamanVeriflex Intercon 1.8-3kV Cable - 1anastasia abengoaBelum ada peringkat

- Digital Earth Resistance Tester: AC V DC VDokumen2 halamanDigital Earth Resistance Tester: AC V DC VVincent LinzieBelum ada peringkat

- Yamamoto A08-S Amplifier Kit: Horber Steige 25 72172 Sulz Germany Tel: ++49-1755382641Dokumen6 halamanYamamoto A08-S Amplifier Kit: Horber Steige 25 72172 Sulz Germany Tel: ++49-1755382641Kris RasBelum ada peringkat

- Plant MOR - Hydro.template - Annex A.3Dokumen4 halamanPlant MOR - Hydro.template - Annex A.3Clint Bryan VirayBelum ada peringkat

- 400A 4-Pole Transfer SwitchDokumen3 halaman400A 4-Pole Transfer Switchbachir oussamaBelum ada peringkat

- Penetration of EV in IndiaDokumen24 halamanPenetration of EV in IndiaVishal ThakurBelum ada peringkat

- Ul 1283 BulletinDokumen4 halamanUl 1283 BulletinMboriko MwashaBelum ada peringkat

- Curtis PDFDokumen3 halamanCurtis PDFmax_6744Belum ada peringkat

- X-Ray Generators: Resident Physics LecturesDokumen54 halamanX-Ray Generators: Resident Physics LecturesAhmed TorkyBelum ada peringkat

- ModelsDokumen716 halamanModelsshyamda100% (2)

- Presentation To CEO TESCO April 2019Dokumen18 halamanPresentation To CEO TESCO April 2019sirajBelum ada peringkat

- EPE Courses Bolona - 1st, 2nd & 3rd StageDokumen6 halamanEPE Courses Bolona - 1st, 2nd & 3rd StageMohamed A. HusseinBelum ada peringkat

- Standard Ac Eng PDFDokumen324 halamanStandard Ac Eng PDFPranav KrishnaBelum ada peringkat

- Electrician Practice Test: A. Knife Blade Switch B. Fuse Block C. Circuit Breakers D. Bus BarDokumen6 halamanElectrician Practice Test: A. Knife Blade Switch B. Fuse Block C. Circuit Breakers D. Bus BarRudi FajardoBelum ada peringkat

- ETI Green Protect 2019Dokumen100 halamanETI Green Protect 2019123Belum ada peringkat

- Eep Practical File: IndexDokumen17 halamanEep Practical File: IndexAkash GandharBelum ada peringkat

- S1-5-Reducing Transformer Mass and Dimensions - S Ryder-DobleDokumen9 halamanS1-5-Reducing Transformer Mass and Dimensions - S Ryder-DobleMallikarjunBelum ada peringkat

- Electricity Generation MethodsDokumen5 halamanElectricity Generation MethodsCecil Dayoan100% (1)

- Humidity and terminal connection specifications for PIC101A process indicatorDokumen2 halamanHumidity and terminal connection specifications for PIC101A process indicatorசசி குமார்Belum ada peringkat

- Hydropower Engineering IIDokumen141 halamanHydropower Engineering IIashe zinab100% (7)

- Electronics Devices and Circuit: Engr. Vanessa Marie GabonDokumen87 halamanElectronics Devices and Circuit: Engr. Vanessa Marie GabonVanessa Marie GabonBelum ada peringkat

- Electrical Malfunctions MID 128 Check Injector CircuitsDokumen1 halamanElectrical Malfunctions MID 128 Check Injector Circuitsuser1Belum ada peringkat

- SECTION 26 3213 Engine Generators Part 1 General 1.01 Section IncludesDokumen31 halamanSECTION 26 3213 Engine Generators Part 1 General 1.01 Section IncludesMarcos FernandezBelum ada peringkat

- Solenoid Operated Valves Continuous Duty Coils-ED 100%: EC-04W-X-Y-ZDokumen1 halamanSolenoid Operated Valves Continuous Duty Coils-ED 100%: EC-04W-X-Y-ZAnton HidayatBelum ada peringkat

- Data Schedule EXLIM P420-GV550MDokumen2 halamanData Schedule EXLIM P420-GV550MabdulBelum ada peringkat

- A New Multi-Input DC-DC Converter Integrated MPPT System For Hybrid Renewable Energy and Battery StorageDokumen6 halamanA New Multi-Input DC-DC Converter Integrated MPPT System For Hybrid Renewable Energy and Battery StoragesankarBelum ada peringkat

- Powerit MV Air Insulated Motor Control: Featuring Advance and Safegear TechnologyDokumen72 halamanPowerit MV Air Insulated Motor Control: Featuring Advance and Safegear TechnologyRaja Bharath DonthiBelum ada peringkat

- 7805T Ecg-960Dokumen2 halaman7805T Ecg-960bellscbBelum ada peringkat

- X Ray GeneratorDokumen70 halamanX Ray Generatorub17075% (4)