Greco2010 Discussion - Active Earth Pressure On Retaining Wall For C-Phi Soil Backfill Under Seismic Loading Condition

Diunggah oleh

jorge.jimenezJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Greco2010 Discussion - Active Earth Pressure On Retaining Wall For C-Phi Soil Backfill Under Seismic Loading Condition

Diunggah oleh

jorge.jimenezHak Cipta:

Format Tersedia

DISCUSSIONS AND CLOSURES

a2 = p cos  cos共⬘ − 兲 + q 共5a兲

Discussion of “Active Earth Pressure on

Retaining Wall for c- Soil Backfill under

a1 = p sin共 + ⬘ − 兲 共5b兲

Seismic Loading Condition” by S. K.

Shukla, S. K. Gupta, and N. Sivakugan

a0 = p sin  sin共⬘ − 兲 + q 共5c兲

Downloaded from ascelibrary.org by British Columbia Institute of Technology on 01/05/15. Copyright ASCE. For personal use only; all rights reserved.

May 2009, Vol. 135, No. 5, pp. 690–696.

DOI: 10.1061/共ASCE兲GT.1943-5606.0000003

d2 = cos共 + ␦ + ⬘兲cos 共6a兲

1

Venanzio R. Greco

1

Dept. of Structural Engineering, Univ. of Calabria, 87036 Rende 共Cs兲, d1 = sin共 + ␦ + ⬘ + 兲 共6b兲

Italy. E-mail: venanziogreco@strutture.unical.it

d0 = sin共 + ␦ + ⬘兲sin 共6c兲

The authors’ paper is welcome because it makes up for a lack in with

the original method of Coulomb and renders it applicable to c⬘-⬘

soil backfills. Such a backfill type could be studied with the 1 ⫾ kv sin共 − 兲

method of Rankine but this does not have the versatility of Cou- p= 共7a兲

cos sin2

lomb’s method for analyzing thrust wedges with various geo-

metrical shapes and subject to surcharges. Therefore, the paper is

very important for geotechnical engineering practice. 2c⬘ sin共 − 兲

q= cos ⬘ 共7b兲

However, the formulation is limited to backfills with a hori- ␥h sin

zontal profile 共 = 0兲, walls with a vertical backface 共 = / 2兲, and

no friction between backfill and wall backface 共␦ = 0兲. Moreover, and, using Eq. 共22兲 of the original paper, we can write

it does not take the presence of tension cracks, which are prob-

q c⬘ cos

ably present in a cohesive soil subjected to a reduction in the =2 cos ⬘ sin  = 2m cos ⬘ sin  共7c兲

lateral stress, into account. This discussion aims to contribute to p ␥h 1 ⫾ kv

the approach followed by the authors by extending the field of Because Eq. 共9兲 of the original paper is equivalent to the condi-

applicability of the method to: tion

1. Backfills with an inclined profile 共 ⫽ 0兲, walls with an in-

clined backface 共 ⫽ / 2兲, and a friction angle ␦ between dPae

wall and backfill soil; and =0 共8兲

d tan ␣

2. Backfills with tension cracks up to a depth of zc.

the thrust Pae is maximized for that value of ␣ solving the qua-

dratic equation

Formulation for Inclined Backfill and Wall Backface

共a1d2 − a2d1兲tan2 ␣ − 2共a0d2 − a2d0兲tan ␣ + 共a0d1 − a1d0兲 = 0

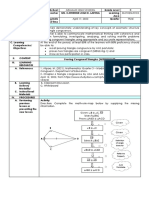

With reference to Fig. 1, where the geometry of the thrust wedge 共9兲

ABC and the forces acting on it are shown, the equilibrium con-

ditions of forces lead to the following relation for the thrust Pae which gives the critical value of the inclination angle ␣ maximiz-

ing the thrust Pae in general geometrical conditions.

1 ⫾ kv sin共␣ − + 兲 C cos ⬘

Pae = W − 共1兲

cos sin共 + ␦ + ⬘ − ␣兲 sin共 + ␦ + ⬘ − ␣兲 A ε

where W = weight of the thrust wedge ABC B

1 sin共 − 兲sin共 − ␣兲 k vW

W = ␥h2 共2兲 k hW

2 sin2  sin共␣ − 兲

C

and C = force on AC due to cohesion W

h

h sin共 − 兲 β−π/2 π/2−α

C = c⬘ 共3兲 φ'

sin  sin共␣ − 兲 δ Pa

Introducing Eqs. 共2兲 and 共3兲 in Eq. 共1兲, we have α R

β

1 a2 tan2 ␣ − a1 tan ␣ + a0 C

Pae = ␥h2 共4兲

2 d2 tan2 ␣ − d1 tan ␣ + d0 Fig. 1. Cross section of a wall and the thrust wedge ABC without

where tension cracks

JOURNAL OF GEOTECHNICAL AND GEOENVIRONMENTAL ENGINEERING © ASCE / NOVEMBER 2010 / 1583

J. Geotech. Geoenviron. Eng. 2010.136:1583-1584.

A' sin  cos

ε 共12兲

B' B" hc = h − zc .

cracke

d soil zc sin共 − 兲

sin β cos ε

zc zc k W

sin(β − ε) v A

B In the second member of Eq. 共11兲, the first term represents the

k hW C weight of the triangle B⬘BB⬙, the second that of the parallelogram

h W B⬙BAA⬘ 共B⬙ is on the vertical crossing point B兲, and the third that

hc of the triangle BCA.

β−π/2 π/2−α The force C acting on CA is given by

δ Pa φ'

α R

β hc sin共 − 兲

Downloaded from ascelibrary.org by British Columbia Institute of Technology on 01/05/15. Copyright ASCE. For personal use only; all rights reserved.

C

C = c⬘ 共13兲

sin  sin共␣ − 兲

Fig. 2. Cross section of a wall and the thrust wedge B⬘CAA⬘ with

tension cracks Introducing Eqs. 共11兲–共13兲 in Eq. 共1兲, we have

1 b2 tan2 ␣ − b1 tan ␣ + b0

Pae = ␥h2c 共14兲

Obviously, if  = / 2, = 0, and ␦ = 0 as in the original paper, 2 d2 tan2 ␣ − d1 tan ␣ + d0

the value of ␣c given by Eq. 共9兲 is equal to that given by Eq. 共11兲

of the original paper. In this case, in fact, the coefficients of Eq. where

共9兲 becomes

b2 = 共p0 cos + p1 cos 兲cos共⬘ − 兲 + q 共15a兲

a1d2 − a2d1 = − p关sin ⬘ cos共⬘ − 兲 + 2m cos2 ⬘兴 共10a兲

b1 = p0 sin共 + ⬘ − 兲 + p1 sin共 + ⬘ − 兲 共15b兲

a0d2 − a2d0 = − p关cos ⬘ sin共⬘ − 兲 + m sin 2⬘兴 共10b兲

b0 = 共p0 sin + p1 sin 兲sin共⬘ − 兲 + q 共15c兲

a0d1 − a1d0 = p关cos ⬘ sin共⬘ − 兲 + 2m cos2 ⬘兴 共10c兲

with

冉冊

and the solution of Eq. 共9兲 is given by Eq. 共11兲 of the original

paper. 1 ⫾ kv zc 2

cos  cos

p0 = 共16a兲

The influence of the angles , , and ␦ on the values of ␣c and cos hc sin共 − 兲

Pae is relevant. For example, in the specific case of ⬘ = 24°, c⬘

= 5 kPa, H = 5 m, ␥ = 20 kN/ m3,  = 80°, = 15°, ␦ = 12°, kh = 0.2

and kv = 0.1, Eq. 共9兲 gives ␣c = 32.5° and Pae = 137.4 kN/ m 关Eq.

共4兲兴, while the inappropriate use of Eqs. 共11兲 and 共14兲 of the

original paper leads to ␣c = 48.0° and Pae = 121.6 kN/ m.

p1 =

cos

冋

1 ⫾ kv zc cos sin共 − 兲

2

hc sin

+

sin2

册 共16b兲

2c⬘ cos ⬘

Soils with Tension Cracks q= sin共 − 兲 共17兲

␥hc sin

If we suppose that tension cracks are vertical 共as shown by the

application of Rankine’s method to materials not resistant to trac- Eq. 共8兲 leads to the quadratic equation

tion兲 and extended up to depth zc, the thrust wedge is limited by

the slip surface CA 共inclined at ␣兲 and by the tension crack AA⬘. 共b1d2 − b2d1兲tan2 ␣ − 2共b0d2 − b2d0兲tan ␣ + 共b0d1 − b1d0兲 = 0

Therefore the thrust wedge is the quadrilateral B⬘CAA⬘ and its

weight is given by 共18兲

which gives the critical value of the inclination angle ␣c in the

1 cos  cos cos sin共 − ␣兲 presence of tension cracks up to depth zc. In absence of tension

W = − ␥z2c + ␥zchc

2 sin共 − 兲 sin  sin共␣ − 兲 cracks, p0 = 0, p1 = p and Eq. 共18兲 reduces to Eq. 共9兲.

With the previous numerical data, if we calculate the depth zc

1 sin共 − 兲sin共 − ␣兲 of the tension cracks with the equation zc = 共2c⬘ / ␥兲cos ⬘ /

+ ␥h2c 共11兲

2 sin2  sin共␣ − 兲 共1-sin⬘兲, we have zc = 0.77, hc = 4.19 m, ␣c = 30.8°, and Pae

= 143.4 kN/ m. In this case, the tension crack presence leads to an

increase of 4% in the value of Pae, but if c⬘ = 10 kPa, this increase

where 共Fig. 2兲 becomes 17%.

1584 / JOURNAL OF GEOTECHNICAL AND GEOENVIRONMENTAL ENGINEERING © ASCE / NOVEMBER 2010

J. Geotech. Geoenviron. Eng. 2010.136:1583-1584.

2008兲. Alternatively, one can use its value obtained from the

Closure to “Active Earth Pressure on field observations.

Retaining Wall for c- Soil Backfill under

Seismic Loading Condition” by S. K. Shukla,

S. K. Gupta, and N. Sivakugan References

May 2009, Vol. 135, No. 5, pp. 690–696.

Das, B. M. 共2008兲. Fundamentals of geotechnical engineering, 3rd Ed.,

DOI: 10.1061/共ASCE兲GT.1943-5606.0000003

Thomson, Mason, Ohio.

Lambe, T. W., and Whitman, R. V. 共1979兲. Soil mechanics, SI Version,

Sanjay Kumar Shukla1 Wiley, New York.

1

Assoc. Prof. and Program Leader, Discipline of Civil Engineering,

Downloaded from ascelibrary.org by British Columbia Institute of Technology on 01/05/15. Copyright ASCE. For personal use only; all rights reserved.

School of Engineering, Edith Cowan Univ., 270 Joondalup Dr., Joon-

dalup, WA 6027, Australia. E-mail: s.shukla@ecu.edu.au

Discussion of “Use of SPT Blow Counts to

The writer thanks the discusser for finding our paper very impor-

Estimate Shear Strength Properties of

tant for geotechnical engineering practice. The discusser has ex-

tended our expression for the total active earth pressure for its Soils: Energy Balance Approach” by

applicability to backfills with inclined profile, walls with inclined H. Hettiarachchi and T. Brown

backface, friction angle between wall and backfill soil, and back- June 2009, Vol. 135, No. 6, pp. 830–834.

fills with tension crack. The discusser is greatly appreciated for DOI: 10.1061/共ASCE兲GT.1943-5606.0000016

this highly valuable contribution. Derivation of Eqs. 共1兲 to 共18兲

presented by the discusser has been checked carefully, and they Fernando Schnaid1; Edgar Odebrecht2; and

have been found to be correct. However, readers should note the Bianca O. Lobo3

corrections as mentioned below: 1

Assoc. Prof., Dept. of Civil Engineering, Federal Univ. of Rio Grande do

1. Eq. 共1兲 contains and ⬘, which refer to the effective angle Sul, Av. Osvaldo Aranha, 99–3° andar-90035-190 Porto Alegre, Rio

of shearing resistance; it should contain only ⬘. Grande do Sul, Brazil. E-mail: farnando@ufrgs.br

2. In Eq. 共10b兲, cos ⬘ should be replaced by sin ⬘. 2

Asst. Prof., Dept. of Civil Engineering, State Univ. of Santa Catarina,

3. In Eqs. 共15a-c兲, q should be replaced by another symbol, say Rua Machado de Assis, 277-Ap. 602-89204-390-Joinville, Santa

q0, because q refers to a different expression in Eq. 共7b兲. 3

Catarina, Brazil. E-mail: edgar@geoforma.com.br

It should be noted that we have explained through Eq. 共24兲 in Asst. Prof., Dept. of Civil Engineering, Federal Univ. of Santa Catarina,

Servidão Corintians, 97-Ap. 704-88040-100-Florianópolis, Santa

the original paper how one can use our analytical expression for

Catarina, Brazil. E-mail: lobo_bianca@yahoo.com.br

estimating active earth pressure on a retaining wall from the c-

soil backfill under seismic loading condition, considering tension

crack. It appears that the discusser has not noticed this fact; how- The authors proposed approach for interpretation of SPT test re-

ever, the approach adopted in the discussion is appreciated. sults appears to have the right framework given the fact that en-

One of the interesting observations is that Eq. 共9兲 and Eq. 共18兲 ergy concepts have been incorporated to the prediction of soil

can be expressed in the determinant form, respectively, as follows properties. However, the approach relies on a number of assump-

tions that the writers find difficult to accept. In particular it has

冨 冨

tan2 ␣ 2 tan ␣ 1 been argued that possible loss of wave energy in a long rod could

a0 a1 a2 = 0 共1兲 be partially compensated by the extra weight added by the long

d0 d1 d2 rods, leading to the assumption that energy losses are negligible.

This hypothesis emerges from a recent ASCE paper published

and by Odebrecht et al. 共2005兲 that states that “the sampler energy can

be conveniently expressed as a function of nominal potential en-

冨 冨

tan2 ␣ 2 tan ␣ 1 ergy E*, sampler final penetration, and weight of both hammer

b0 b1 b2 = 0 共2兲 and rods. The influence of rod length produces two opposite ef-

d0 d1 d2 fects: wave energy losses increase with increasing rod length and

in a long composition of rods the gain in potential energy from

The above determinant form of equations can easily be re- rod weight is significant and may partially compensate measured

membered by the readers for their use while making the calcula- energy losses.” This conclusion is directly derived from the sys-

tion for the total active force. The readers should also note the tem energy delivered to the sampler Esampler by considering the

following: combined effects of the hammer potential energy 共Eh兲 and rod

1. The symbol used in the equations of the discussion is given potential energy 共Er兲

by Eq. 共21兲 of our paper.

2. The discusser has suggested to use the expression for the ESampler = 3关1Eh + 2Er兴 = 3关1共H + ⌬兲M hg + 2⌬M rg兴

depth of tension crack 共1兲

zc = 冉 冊冉

2c⬘

␥

cos ⬘

1 − sin ⬘

冊 共3兲

where M h = hammer weight; M r = rod weight; g = gravity accelera-

tion; ⌬ = sampler penetration; H = height of fall; and 1, 2, and

3 = efficiency coefficients. In this proposed equation, both ham-

without any reference. This value is based on Rankine’s mer and rod potential energies are a function of ⌬ and the length

analysis of active earth pressure from the c- soil backfill of the rod in addition to the M h and H, whereas efficiency is not

under static condition 共Lambe and Whitman 1979; Das affected by ⌬. These principles have been extensively evaluated

JOURNAL OF GEOTECHNICAL AND GEOENVIRONMENTAL ENGINEERING © ASCE / NOVEMBER 2010 / 1585

J. Geotech. Geoenviron. Eng. 2010.136:1583-1584.

&''(' *+, &''(' *+,

" # $ % ! " # $ % !

! !

"# "#

"$

"$

" " %& "

" %&

Downloaded from ascelibrary.org by British Columbia Institute of Technology on 01/05/15. Copyright ASCE. For personal use only; all rights reserved.

" '&

" '&

"! "!

-./01 *2,

-./01 *2,

# #

#! #!

$ $

$! $!

Fig. 1. 共a兲 Rod energy losses error 共American standard兲; 共b兲 rod energy losses error 共Brazilian standard兲

by numerical analysis to demonstrate that energy losses from yields an error of about 40% 共i.e., the contribution of the rod

wave propagation cannot be entirely compensated by the rod po- energy is larger than losses produced by wave propagation兲. Only

tential energy 共Odebrecht et al. 2005兲, which is illustrated in Fig. in dense sand 共Nspt = 40兲 the error is negligible.

18 of the original paper. The authors could argue that despite simplified considerations,

This effect is demonstrated in Fig. 1, in which errors intro- the angle of internal friction ⬘ is derived with reasonable accu-

duced by the misinterpretation of energy balance are related to racy. The database adopted to validate the method might partially

rod length. The error is defined as explain this apparently successful application. Friction angles

from Tables 1 and 3 共of the original paper兲 fall in a very narrow

共Esampler

rod

− 0.6E*兲 band 共from 28° to 35°兲, despite the wide range of associated SPT

Error = 100 共2兲

0.6E* blow counts 共7 ⬍ N60 ⬍ 97兲. These adopted values are signifi-

cantly lower than reported data published by the U.S. Bureau of

rod

where Esampler = 3关2⌬M rg兴 is the contribution of the rod energy

ⴱ Reclamation 共De Mello 1971兲 and by Hatanaka and Uschida

and E the nominal potential energy corrected to the reference

共1996兲, as illustrated in Fig. 2 共after Schnaid et al. 2009兲. To

value of 60%. Note that Fig. 1共a兲 relates to American standards

enable a direct comparison to published data, the blow count N60

whereas Fig. 1共b兲 refers to Brazilian standards. From these figures

used by the authors had to be corrected to 共N1兲60 adopting the

it is observed that a 30-m-long rod in loose sand 共Nspt = 3兲

value of CN 共 = 共100/ ⬘v兲0.5兲 proposed by Liao and Whitmann

""

共1986兲.

C02: CD 02: CD.CE Since the database shows some discrepancy with preceding

"! C02: F9GG *CD 1= CE,

experience, there appears to be enough evidence to question the

CE D9<:H=21

$" proposed approach and to suggest caution in using the method for

/0102030 4 56789:0 *%))&,

;<7=>?1 *%)(),

engineering works until proven by practical experience.

$!

φB /<1190?078789 4 @?=A2 * !!),

#"

References

#!

" De Mello, V. F. B. 共1971兲 “The standard penetration test.” Proc., 4th Pan

!

American Conference on Soil Mechanics and Foundation Engineer-

! %! ! #! $! "! &! '! (! )! %!! %%! % ! %#! ing, Vol. 1, Puerto rico, 1–87.

*+%,&! . /0102030 4 56789:0 *%))&, Hatanaka, M., and Uchida, A. 共1996兲. “Empirical correlation between

*+%,&! . ;<7=>?1 *%)(), penetration resistance and effective friction of sand soil.” Soil Found.,

*+%,&! . /<1190?078789 4 @?=A2 * !!),

36共4兲, 1–9.

Liao, S. S. C., and Whitman, R. V. 共1986兲. “Overburden correction fac-

Fig. 2. Peak friction angle of sands from SPT resistance tors for SPT in sand.” J. Geotech. Engrg., 112共3兲, 373–377.

1586 / JOURNAL OF GEOTECHNICAL AND GEOENVIRONMENTAL ENGINEERING © ASCE / NOVEMBER 2010

J. Geotech. Geoenviron. Eng. 2010.136:1583-1584.

Odebrecht, E., Schnaid, F., Rocha, M. M., and Bernardes, G. P. 共2005兲. the discussers compare the results produced by the proposed

“Energy efficiency for standard penetration test.” J. Geotech. Geoen- model with data from published literature and two other models.

viron. Eng., 131共10兲, 1252–1263. For blow counts in the range of 20–40 the proposed model pro-

Schnaid, F., Odebrecht, E., Rocha, M. M., and Bernardes, G. P. 共2009兲. duces friction angles from 28°–32°. For the same range of blow

“Prediction of soil proprieties from the concepts of energy transfer in

counts, other data/methods provide friction angles as high as 46°.

dynamic penetration tests.” J. Geotech. Geoenviron. Eng., 135共8兲,

The authors are in agreement with the discussers about using

1092–1100.

caution in using the proposed equations until they are proven by

experience. In addition the writers also believe that the proposed

model parameters may have to be fine-tuned for different types of

material.

Closure to “Use of SPT Blow Counts to

Downloaded from ascelibrary.org by British Columbia Institute of Technology on 01/05/15. Copyright ASCE. For personal use only; all rights reserved.

Estimate Shear Strength Properties of

Soils: Energy Balance Approach” by

H. Hettiarachchi and T. Brown Discussion of “Reliability-Based

June 2009, Vol. 135, No. 6, pp. 830–834. Economic Design Optimization of Spread

DOI: 10.1061/共ASCE兲GT.1943-5606.0000016 Foundations” by Y. Wang

Vol. 135, No. 7, July 1, 2009, pp. 954–959.

Hiroshan Hettiarachchi1 DOI: 10.1061/共ASCE兲GT.1943-5606.0000013

1

Asst. Prof., Dept. of Civil Engineering, Lawrence Technological Univ.,

21000 West Ten Mile Rd., Southfield, MI 48075. E-mail:

hiroshan@ltu.edu

Sarat Kumar Das1 and Manas Ranjan Das2

1

Assoc. Prof., Civil Engineering Dept., National Institute of Technology

Rourkela, Orissa-769008, India. E-mail: saratdas@rediffmail.com;

sarat@nitrkl.ac.in

The writers wish to thank discussers for their interest in this paper 2

Asst. Prof., Dept. of Civil Engineering, ITER, SOA Univ., Orissa-

and also for the constructive criticism. The discussers’ comments 769008, India. E-mail: manasdas.iter@gmail.com

opened up a discussion on the importance of incorporating SPT

rod weight into the formulation of energy balance equations.

It may be true that the proposed equations could have been The author has proposed reliability-based economic design opti-

improved by incorporating SPT rod weight. However, the writers mization framework of spread foundation comprising of reliabil-

are skeptical about the degree of improvement it can make. The ity based design methodology, construction cost estimate and cost

discussers suggest that the proposed equations may cause 40% optimization. The author has discussed the economically opti-

error for 30-m-long rod in loose sand 共with N = 3兲, but agree that mized design in the line proposed in available literature 共Wang

for the same depth, the error may be negligible in dense sand. If and Kulhawy 2008兲. Both in this paper and in Wang and Kulhawy

a 30-m-long rod is used during an SPT, obviously the test must 共2008兲, the approach is expressed as a constrained optimization

have been conducted at least at a depth greater than 25 m. At process, in which the objective is to minimize the total construc-

deeper depths 共such as 25 m兲, it is rare to find sand that can give tion cost. Design parameters, such as the dimensions of the foun-

blow counts as low as 3. According to the error analysis presented dations have been treated as variables, which vary in the ranges

by the discussers 共Fig. 1兲, shallower depths produce relatively low constrained by design requirement including ultimate limit state

error for a wide range of N values. Fig. 1 also suggests that at 共ULS兲 and serviceability limit state 共SLS兲 requirements. The op-

deeper depths the proposed equations produce considerable error timization model has been set up in a Microsoft Excel spreadsheet

only for very low N values. Therefore, Fig. 1 indirectly supports and has been solved using the Excel function solver. As the above

the practical level of accuracy produced of the proposed equations problems are nonlinear it is solved using generalized reduced gra-

even in their current forms. dient 共GRG兲 algorithm in solver. The GRG method is a direct

The writers also have a concern about the way the discussers method of solving a constrained optimization problem, unlike the

define error. If they are attempting to quantify the error due to the Lagrange multiplier method that is solved as a sequential uncon-

omission of rod weight, it is more meaningful to define the error strained optimization problem. The GRG method is based on the

as the energy difference between the two methods 共with rod en- principles of elimination of variables using equality constraint

ergy and without rod energy兲 compared to the energy given by the 共Deb 2005兲. The optimization method is a numerical method and

more detailed method 共with rod energy兲. It is not clear why the

discussers would define the error as the difference between the Table 1. Comparison of Spread Footing Designs

rod energy and hammer energy. Optimized

The discussers’ argument on predicting a narrow 28°–35° fric- Design variable value Constraints

tion angles from 7 to 97 wide range of SPT blow counts is also

misleading. It is true that the writers used a 7–92 wide range of Factor of

SPT blow counts to estimate the model parameters. However, the Width Length Depth safety

Design 共B兲 共L兲 共D兲 Cost against Settlement

blow count data used in the verification was only limited to 11–69

option 共m兲 共m兲 共m兲 共USD兲 bearing 共mm兲

and it produced a reasonable range of 28°–35° friction angles. As

discussed in the paper, one of the attractive features of the pro- Optimized 1.86 2.30 1.38 1086.00 2.97 25.01

posed model is its ability to slightly underpredict. While few 共Wang and

other widely used models are overpredicting friction angles, the Kulhawy

2008兲

proposed model provided more conservative answers. This is also

Present study 2.06 2.12 0.50 959.10 3.00 25.00

clearly indicated in Fig. 2 provided by the discussers. In Fig, 2,

JOURNAL OF GEOTECHNICAL AND GEOENVIRONMENTAL ENGINEERING © ASCE / NOVEMBER 2010 / 1587

J. Geotech. Geoenviron. Eng. 2010.136:1583-1584.

depends upon the initial value 共guess兲 of the design variable. value. The discussers have also faced similar difficulties while

As it is very much difficult to predict global optimum of such optimizing the problems using MS Excel solver.

points it is required that the problems should be checked with As discussed above both the constraints are the inequality type

different initial point. Another important aspect of the constrained and the GRG method is based on the principle of elimination of

optimization problem is constraint violation, which needs to be variable using equality constraint. Hence the discusser would re-

checked for the optimized value. However, such a study is neither quests the author to verify the constraint violation of the results

discussed in Wang and Kulhawy 共2008兲 nor in this paper. The for their problem and also should be checked with different initial

discussers have made such a study based on the results of Wang point before drawing their conclusions.

and Kulhawy 共2008兲 and observed different trends in the obtained

results in terms of optimized values and the design parameters.

The results are shown in Table 1 and it can be seen that the References

Downloaded from ascelibrary.org by British Columbia Institute of Technology on 01/05/15. Copyright ASCE. For personal use only; all rights reserved.

obtained optimized value is less than that given in Wang and

Kulhawy 共2008兲. The constraint violations are also better and the Deb, K. 共2005兲. Optimization for engineering design algorithms and ex-

depth of the foundation is more practical considering it as a rein- amples, PHI Pvt. Ltd., New Delhi, India.

forced concrete foundation. This also shows that it is very much Wang, Y., and Kulhawy, F. H. 共2008兲. “Economic design optimization of

important to consider different initial point to arrive at optimized foundations.” J. Geotech. Geoenviron. Eng., 134共8兲, 1097–1105.

1588 / JOURNAL OF GEOTECHNICAL AND GEOENVIRONMENTAL ENGINEERING © ASCE / NOVEMBER 2010

J. Geotech. Geoenviron. Eng. 2010.136:1583-1584.

Anda mungkin juga menyukai

- SoilDokumen4 halamanSoilRenalyn Grace ResueloBelum ada peringkat

- Ghosh 2012 MO Extension For AEPDokumen11 halamanGhosh 2012 MO Extension For AEPsiddalingeshwarahBelum ada peringkat

- Yang Influence Zone JGGEDokumen9 halamanYang Influence Zone JGGEMekonen MagogaBelum ada peringkat

- Culvert Hydraulics: Comparison of Current Computer Models and Recommended ImprovementsDokumen7 halamanCulvert Hydraulics: Comparison of Current Computer Models and Recommended ImprovementsAndres AguirreBelum ada peringkat

- Analytical Solution of Passive Earth Pressure: P 2 2 2 Ł Tan 9Dokumen3 halamanAnalytical Solution of Passive Earth Pressure: P 2 2 2 Ł Tan 9JairoBelum ada peringkat

- Construction Load Evaluation of Flat Plate SlabsDokumen6 halamanConstruction Load Evaluation of Flat Plate SlabsAbstruse ConsultnatsBelum ada peringkat

- Evaluation of Tension Capacity of Pile Case Study in Sandy SoilDokumen8 halamanEvaluation of Tension Capacity of Pile Case Study in Sandy SoilMULLAIBelum ada peringkat

- On Involute and Evolute of The Curve and Curve-SurDokumen5 halamanOn Involute and Evolute of The Curve and Curve-SurMera khataBelum ada peringkat

- CEG 801 - Consolidation TestDokumen28 halamanCEG 801 - Consolidation TestbeqsBelum ada peringkat

- Lecture 3 (Consolidation Settlement)Dokumen24 halamanLecture 3 (Consolidation Settlement)Muhammad Soban Chaudhry Shabbir Hussain ChaudhryBelum ada peringkat

- April 17Dokumen4 halamanApril 17Catherine LapeñaBelum ada peringkat

- 02-03-Calculo de Asent en Arenas Agustin-DemeneghiDokumen11 halaman02-03-Calculo de Asent en Arenas Agustin-DemeneghiJOSE LUIS GONZALEZBelum ada peringkat

- Pile Foundation (Part II-Group Piles)Dokumen8 halamanPile Foundation (Part II-Group Piles)Francis Philippe Cruzana CariñoBelum ada peringkat

- Parallel Plate Capacitor GuideDokumen4 halamanParallel Plate Capacitor Guide97390005460% (1)

- Extension of Mononobe-Okabe Theory to Evaluate Seismic Active Earth Pressure Supporting c-φ BackfillDokumen10 halamanExtension of Mononobe-Okabe Theory to Evaluate Seismic Active Earth Pressure Supporting c-φ BackfillAnin Kuwi UpinBelum ada peringkat

- Consolidation Around Stone Columns. Influence of Column DeformationDokumen27 halamanConsolidation Around Stone Columns. Influence of Column DeformationSeif EddineBelum ada peringkat

- Uicklook Visual AnalysisDokumen8 halamanUicklook Visual AnalysisKaiysse YoukéBelum ada peringkat

- Geotechnical Engineering 1 July 2016 (2010 Scheme)Dokumen2 halamanGeotechnical Engineering 1 July 2016 (2010 Scheme)Tony JosephBelum ada peringkat

- S Kempton 1955Dokumen18 halamanS Kempton 1955Paulo Vinícius MartinsBelum ada peringkat

- Persentasi Bearing Capacity of Deep Foundation in SandDokumen39 halamanPersentasi Bearing Capacity of Deep Foundation in SandAwal AwalmansurBelum ada peringkat

- Tociej 9 763Dokumen5 halamanTociej 9 763Har AhmadBelum ada peringkat

- Various Methods of Tunnel Lining Design in Elastically Embedded Soil PDFDokumen5 halamanVarious Methods of Tunnel Lining Design in Elastically Embedded Soil PDFNaveen RBelum ada peringkat

- Challenge Problems PDFDokumen16 halamanChallenge Problems PDFBeiman Rodriguez MozoBelum ada peringkat

- 7-1-The Design of Embankments On Soft Clays, JakobsonDokumen11 halaman7-1-The Design of Embankments On Soft Clays, Jakobsonد.م. محمد الطاهرBelum ada peringkat

- CE6601 NotesDokumen115 halamanCE6601 NotesAlam Mohammad Parvez SaifiBelum ada peringkat

- s4 Physics Paper 3 Exam 5Dokumen4 halamans4 Physics Paper 3 Exam 5MUSOKE GERALDBelum ada peringkat

- CE Board Nov 2020 - Hydraulics - Set 17Dokumen2 halamanCE Board Nov 2020 - Hydraulics - Set 17Justine Ejay MoscosaBelum ada peringkat

- Evaluation of Tension Capacity of Pile Case Study in Sandy SoilDokumen8 halamanEvaluation of Tension Capacity of Pile Case Study in Sandy SoilRyan Achmad FadhillahBelum ada peringkat

- Ee-Module 2 PDFDokumen38 halamanEe-Module 2 PDFravitej71% (7)

- Flood Simulation Using A Well-Balanced Shallow Flow Model: Qiuhua LiangDokumen7 halamanFlood Simulation Using A Well-Balanced Shallow Flow Model: Qiuhua Liangjmiheso2012Belum ada peringkat

- WONG 2005 TC Varios Overland Flow YEN CHOW 1983Dokumen6 halamanWONG 2005 TC Varios Overland Flow YEN CHOW 1983Valter AlbinoBelum ada peringkat

- Day 21 - 2Dokumen14 halamanDay 21 - 2Minato NamikazeBelum ada peringkat

- 1.4electrical CapacityDokumen5 halaman1.4electrical CapacityashaBelum ada peringkat

- Plasticity and Critical State Soil Mechanics SummaryDokumen31 halamanPlasticity and Critical State Soil Mechanics SummaryZar MaghustBelum ada peringkat

- Open Channel Flow FundamentalsDokumen24 halamanOpen Channel Flow FundamentalsKristelleBelum ada peringkat

- Las in Pre Calculus ForDokumen104 halamanLas in Pre Calculus ForRommel CorcueraBelum ada peringkat

- Mpodule 2 EmwDokumen41 halamanMpodule 2 Emws8102003Belum ada peringkat

- Seismic Bearing Capacity of Strip Footing Resting On Reinforced E (Swami Saran)Dokumen8 halamanSeismic Bearing Capacity of Strip Footing Resting On Reinforced E (Swami Saran)budhnabamBelum ada peringkat

- Guia PDFDokumen3 halamanGuia PDFCristian Rodrigo Ubal NúñezBelum ada peringkat

- CE Board May 2021 - Hydraulics - Set 12Dokumen2 halamanCE Board May 2021 - Hydraulics - Set 12Rain Wynette LeyvaBelum ada peringkat

- Design of Piles in Sand: Case Study of Lekki Pennisula, Lagos NigeriaDokumen10 halamanDesign of Piles in Sand: Case Study of Lekki Pennisula, Lagos NigeriaLavanyan SatchithananthanBelum ada peringkat

- SSC JE Mains Civil Engineering Practice QuestionsDokumen23 halamanSSC JE Mains Civil Engineering Practice QuestionsPiriyangan BBelum ada peringkat

- Triangle CongruenceDokumen6 halamanTriangle CongruenceYeoj ParasBelum ada peringkat

- Note On Relation Between Enhanced Ind-Sheaves and Enhanced Subanalytic SheavesDokumen77 halamanNote On Relation Between Enhanced Ind-Sheaves and Enhanced Subanalytic Sheavesscri.veBelum ada peringkat

- Improved Formulation of the Hardening Soil Model for Undrained BehaviorDokumen8 halamanImproved Formulation of the Hardening Soil Model for Undrained BehaviorBrandon Nova AndlerBelum ada peringkat

- Application of Surface-Renewal-Stretch Model For Interface Mass TransferDokumen13 halamanApplication of Surface-Renewal-Stretch Model For Interface Mass Transfer季理Belum ada peringkat

- Computing The Trajectory of Free Jets: Technical NotesDokumen5 halamanComputing The Trajectory of Free Jets: Technical NotesguildkeyBelum ada peringkat

- Soil Compressibility As Measured in The OedometerDokumen4 halamanSoil Compressibility As Measured in The OedometerNhân NguyễnBelum ada peringkat

- MIT2 25F13 Solution6.21Dokumen5 halamanMIT2 25F13 Solution6.21MariaBelum ada peringkat

- 1062 1 PDFDokumen1 halaman1062 1 PDFArcangelo Di TanoBelum ada peringkat

- Diff. & Inte. - MergedDokumen11 halamanDiff. & Inte. - MergedNITIN KUMARBelum ada peringkat

- Theories of Earth Pressures: CE 407 Foundation EngineeringDokumen4 halamanTheories of Earth Pressures: CE 407 Foundation EngineeringDnyanesh BorseBelum ada peringkat

- Discussion Muir Wood Circular Tunnel in Elastic GroundDokumen7 halamanDiscussion Muir Wood Circular Tunnel in Elastic GroundAmmar SohailBelum ada peringkat

- GAUGE INVARIANCE AND QFT-GR BLEND at Rahmi Hocam Talk by Prof. Dr. Durmus DemirDokumen37 halamanGAUGE INVARIANCE AND QFT-GR BLEND at Rahmi Hocam Talk by Prof. Dr. Durmus DemirAli ÖvgünBelum ada peringkat

- Stone Column DesignDokumen11 halamanStone Column DesignKha nguyenBelum ada peringkat

- 5.0 ConsolidationDokumen35 halaman5.0 Consolidationchurchill ochiengBelum ada peringkat

- Fundamental Considerations' On Ti$E Shear Strength Of' SoilDokumen10 halamanFundamental Considerations' On Ti$E Shear Strength Of' Soiljorge.jimenezBelum ada peringkat

- Briaud 1999Dokumen10 halamanBriaud 1999jorge.jimenezBelum ada peringkat

- Engelhardt 1975Dokumen9 halamanEngelhardt 1975jorge.jimenezBelum ada peringkat

- Ahmed & Fayed, 2015Dokumen19 halamanAhmed & Fayed, 2015José Quiroz OlmosBelum ada peringkat

- General Theory of Stability of Slopes-BishopDokumen11 halamanGeneral Theory of Stability of Slopes-Bishopفردوس سليمانBelum ada peringkat

- Settlement of Buildings and Associated Damage: January 1975Dokumen47 halamanSettlement of Buildings and Associated Damage: January 1975jorge.jimenezBelum ada peringkat

- General Theory of Stability of Slopes-BishopDokumen11 halamanGeneral Theory of Stability of Slopes-Bishopفردوس سليمانBelum ada peringkat

- DELMAG Maeklerprospekt enDokumen8 halamanDELMAG Maeklerprospekt enKenan ButurovicBelum ada peringkat

- SEEPAGE LENGTH ANALYSISDokumen6 halamanSEEPAGE LENGTH ANALYSISjorge.jimenezBelum ada peringkat

- 63 - Undrained Stability of Braced Excavations in Clay PDFDokumen18 halaman63 - Undrained Stability of Braced Excavations in Clay PDFMohamad El KheirBelum ada peringkat

- 2012 BhandariDokumen18 halaman2012 Bhandarijorge.jimenezBelum ada peringkat

- English Comparing With AdjectivesDokumen12 halamanEnglish Comparing With Adjectivesjorge.jimenezBelum ada peringkat

- Mohr-Coulomb Model PDFDokumen12 halamanMohr-Coulomb Model PDFRamesh100% (1)

- NAVFAC-DM-7.2 Foundation & Earth Structure PDFDokumen280 halamanNAVFAC-DM-7.2 Foundation & Earth Structure PDFFauzankalibata100% (1)

- Bjerrum1956 - Stability Os Strutted Excavations in ClayDokumen153 halamanBjerrum1956 - Stability Os Strutted Excavations in Clayjorge.jimenezBelum ada peringkat

- 1 IDokumen35 halaman1 Ikunalji_jainBelum ada peringkat

- Plaxis Common MistakeDokumen22 halamanPlaxis Common MistakeBenjamin HasecicBelum ada peringkat

- 2D Numerical Simulations of Soil Nail Walls - Babu-Vikas - Original PaperDokumen11 halaman2D Numerical Simulations of Soil Nail Walls - Babu-Vikas - Original Paperjorge.jimenezBelum ada peringkat

- Chan and LueDokumen15 halamanChan and LueHari RamBelum ada peringkat

- The Design of Vibro Replacement (Priebe Teory)Dokumen17 halamanThe Design of Vibro Replacement (Priebe Teory)paduco100% (3)

- Cyclic Threshold Strains in Clays Versus Sands and The Change of Secant Shear Modulus and Pore Water Pressure at Small Cyclic StrainsDokumen243 halamanCyclic Threshold Strains in Clays Versus Sands and The Change of Secant Shear Modulus and Pore Water Pressure at Small Cyclic Strainsjorge.jimenezBelum ada peringkat

- 2014 - Cabas Et Al - Site ResponseDokumen12 halaman2014 - Cabas Et Al - Site Responsejorge.jimenezBelum ada peringkat

- Fundamentals of Continuum Mechanics of Soils (1991)Dokumen637 halamanFundamentals of Continuum Mechanics of Soils (1991)jorge.jimenezBelum ada peringkat

- Soil Nailed Slope Analysis Using Strength Reduction and Limit Equilibrium MethodsDokumen17 halamanSoil Nailed Slope Analysis Using Strength Reduction and Limit Equilibrium Methodsjorge.jimenezBelum ada peringkat

- NCH 433 of 1966 Mod 2012Dokumen77 halamanNCH 433 of 1966 Mod 2012Andrea Muirhead Garcia100% (1)

- CE 240 Soil Mechanics & Foundations: Stresses in A Soil Mass I (Das, Ch. 9)Dokumen27 halamanCE 240 Soil Mechanics & Foundations: Stresses in A Soil Mass I (Das, Ch. 9)jorge.jimenezBelum ada peringkat

- 17 ICE - A Practical Design Approach For Piles With Negative FrictionDokumen11 halaman17 ICE - A Practical Design Approach For Piles With Negative Frictionjorge.jimenezBelum ada peringkat

- Benchmarking Geotechnical Numerical AnalysisDokumen26 halamanBenchmarking Geotechnical Numerical Analysisjorge.jimenezBelum ada peringkat

- Never Fear Velocity ReversalsDokumen6 halamanNever Fear Velocity Reversalsjorge.jimenezBelum ada peringkat

- Inspirational Quotes ThesisDokumen6 halamanInspirational Quotes Thesisanngarciamanchester100% (2)

- Anthropology Paper 1 Pyq AnalysisDokumen6 halamanAnthropology Paper 1 Pyq AnalysisRimita Saha100% (1)

- Jffii - Google SearchDokumen2 halamanJffii - Google SearchHAMMAD SHAHBelum ada peringkat

- MS 1806 Inventory ModelDokumen5 halamanMS 1806 Inventory ModelMariane MananganBelum ada peringkat

- Simic 2015 BR 2 PDFDokumen23 halamanSimic 2015 BR 2 PDFkarimesmailBelum ada peringkat

- Jesu, Joy of Mans DesiringDokumen6 halamanJesu, Joy of Mans DesiringAleksandar TamindžićBelum ada peringkat

- BUSINESS ETHICS - Q4 - Mod1 Responsibilities and Accountabilities of EntrepreneursDokumen20 halamanBUSINESS ETHICS - Q4 - Mod1 Responsibilities and Accountabilities of EntrepreneursAvos Nn83% (6)

- Dismantling My Career-Alec Soth PDFDokumen21 halamanDismantling My Career-Alec Soth PDFArturo MGBelum ada peringkat

- Your Guide To Starting A Small EnterpriseDokumen248 halamanYour Guide To Starting A Small Enterprisekleomarlo94% (18)

- Valve SheetDokumen23 halamanValve SheetAris KancilBelum ada peringkat

- 50Dokumen3 halaman50sv03Belum ada peringkat

- Risk Management in Banking SectorDokumen7 halamanRisk Management in Banking SectorrohitBelum ada peringkat

- Land Land Patent - Declaration (19291)Dokumen2 halamanLand Land Patent - Declaration (19291)Seasoned_Sol100% (2)

- Division of WorkDokumen19 halamanDivision of WorkBharadwaj KwcBelum ada peringkat

- Contractor Support of USCENTCOM AOR, 3rd Quarter FY 2013Dokumen9 halamanContractor Support of USCENTCOM AOR, 3rd Quarter FY 2013Feral JundiBelum ada peringkat

- KYC FAQsDokumen5 halamanKYC FAQsmicorreBelum ada peringkat

- Phone, PTCs, Pots, and Delay LinesDokumen1 halamanPhone, PTCs, Pots, and Delay LinesamjadalisyedBelum ada peringkat

- CoveredCA EnrollmentDokumen4 halamanCoveredCA EnrollmentdandiamondBelum ada peringkat

- Unit 2 Management of EthicsDokumen19 halamanUnit 2 Management of Ethics088jay Isamaliya0% (1)

- Allotment Order 2022-23 - FIRST Round Arts - 52212302 - KARUNRAJ MDokumen2 halamanAllotment Order 2022-23 - FIRST Round Arts - 52212302 - KARUNRAJ MKarun RajBelum ada peringkat

- ASEAN-Maybank Scholarship - Parents Income Declaration Form v1Dokumen1 halamanASEAN-Maybank Scholarship - Parents Income Declaration Form v1hidayanti.ridzuanBelum ada peringkat

- Project Management in Practice 6th Edition Meredith Solutions ManualDokumen25 halamanProject Management in Practice 6th Edition Meredith Solutions ManualMatthewFosteroeqyp98% (48)

- When Technology and Humanity CrossDokumen26 halamanWhen Technology and Humanity CrossJenelyn EnjambreBelum ada peringkat

- Immersion-Reviewer - Docx 20240322 162919 0000Dokumen5 halamanImmersion-Reviewer - Docx 20240322 162919 0000mersiarawarawnasahealingstageBelum ada peringkat

- 1 Herzfeld, Michael - 2001 Sufferings and Disciplines - Parte A 1-7Dokumen7 halaman1 Herzfeld, Michael - 2001 Sufferings and Disciplines - Parte A 1-7Jhoan Almonte MateoBelum ada peringkat

- Module 6 ObliCon Form Reformation and Interpretation of ContractsDokumen6 halamanModule 6 ObliCon Form Reformation and Interpretation of ContractsAngelica BesinioBelum ada peringkat

- Man and Cannabis in Africa: A Study of Diffusion - Journal of African Economic History (1976)Dokumen20 halamanMan and Cannabis in Africa: A Study of Diffusion - Journal of African Economic History (1976)AbuAbdur-RazzaqAl-MisriBelum ada peringkat

- The Value of EquityDokumen42 halamanThe Value of EquitySYAHIER AZFAR BIN HAIRUL AZDI / UPMBelum ada peringkat

- Edit 610 Lesson Plan RedesignDokumen3 halamanEdit 610 Lesson Plan Redesignapi-644204248Belum ada peringkat