A Coal Mine Dump Stability Analysis PDF

Diunggah oleh

Min HtweJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

A Coal Mine Dump Stability Analysis PDF

Diunggah oleh

Min HtweHak Cipta:

Format Tersedia

Geomaterials, 2011, 1, 1-13

doi:10.4236/gm.2011.11001 Published Online April 2011 (http://www.SciRP.org/journal/gm)

A Coal Mine Dump Stability Analysis

—A Case Study

Ashutosh Kainthola*, Dhananjai Verma, S. S. Gupte, T. N.Singh

Department of Earth Sciences, Indian Institute of Technology Bombay, Mumbai, India

E-mail: ashuddn@live.com

Received April 12, 2011; revised April 14, 2011; accepted April 18, 2011

Abstract

The present paper mainly deals with a case study of failed dump slope in western coalfield limited, Nagpur,

India. A huge mass of debris flow had happened during the routine the activity of mining. The failed dump

had a height of 75 m with 43˚ slope angle which had slipped forward by 18m. Representative loose dump

material samples were collected from the site and tested to determine the physico-mechanical properties of

dump material. The dump material consisted of loose fragments and lumps of friable sandstone, shale, clay

and carbonaceous shale. To evaluate the condition of failure, a well known, shear strength reduction tech-

nique has been applied to achieve the desired factor of safety using two dimensional finite element code. Fi-

nally, a economical, sustainable and stable dump angle and height has been suggested for smooth and safe

disposal of the dump.

Keywords: Dump Stability, Factor of Safety, Shear Strength Reduction, Wardha Valley

1. Introduction utilized by various local producing countries like Austra-

lia, Canada and USA, then there is no fear to adopt this

With the increasing size of opencast mines and the large technique to avoid further requirement of land for

stripping ratio associated with these mines, the amount of dumping and aggravate various associated problems.

overburden removal will also increase substantially. However, the combination of external dumps and inter-

Only Coal India Limited (CIL) has removed overburden nal dumps shall substantially reduce the required land.

21, 160, 462 and 695 million cubic metres during 1976, As a result, it shall reduce the surface land requirement

1986 - 87, 1999 - 2000 and 2009 - 2010 respectively. significantly which is very difficult task to arrange in any

Considering the major opencast projects XII Five Year area due to growth of population forest cover and associ-

plan, the amount of overburden to be handled in near ated problem. In this decade few destabilization of inter-

future will be more than 20 000 million cubic metres for nal dumps have taken place in coal mines. It is necessary

these projects alone. The maximum overburden disposal to study such cases and find out the cause of destabiliza-

from an individual mine in the coal sector is likely to be tion.

50 million cubic metres per year (WCL).

Overburden dumps can be external dumps created at a 2. Destabilization of Internal Dumps

site away from the coal bearing area or it can be internal-

dumps created by in-pit dumping (IPD) concurrent to the Failure of internal dumps is a complex problem. In addi-

creation of voids by extraction of coal. Practice of tion to environmental considerations, it directly affects

dumping overburden in the external dumps have some the resource recovery, mine safety and mining cost.

serious problems [1] foremost amongst them are re- Overburden has been traditionally disposed off in the

quirement of additional land, involves very high trans- most economical way throughout the world. However,

port and rehandling cost which will increase the cost of some massive spoil pile failures around the world attract

coal production substantially, stability and reclamation at the attention of geo-scientists and engineers to this prob-

the site. It is not possible to eliminate the option of the lem [2-4]. The stability of dump is now recognized to be

external dumps concept completely, even if we adopt an important aspect of designing large open pit mines.

IPD practice. The internal dump concept is very well The majority of slope stability analyses performed in

Copyright © 2011 SciRes. GM

2 A. KAINTHOLA ET AL.

practice still use traditional limit equilibrium approaches the slope failure, the arc of rupture surface meets the

involving methods of slices that have remained essen- slope above the toe. This is possible only when slope

tially unchanged for decades. The finite element method angle steep and the soil close to the toe possess high

represents a powerful alternative approach for slope sta- strength. Toe failure occurs when the soil mass of the

bility analysis which is use to accurate, versatile and re- slope above the base and below the base is mainly ho-

quires fewer a priori assumptions, especially, regarding mogeneous.

the failure mechanism. Slope failure in the finite element There are a number of factors, which affect the dump

model occurs ‘naturally’ through the zones in which the stability [6-8]. These factors are broadly classified as:

shear strength of the dump material is insufficient to re- ● Geometry and strength of the dump material,

sist the shear stresses. It is argued that the finite element ● Hydro geological and rain water condition of

method of slope stability analysis is a more powerful dumping area,

alternative to traditional limit equilibrium methods and ● Load bearing capacity of dumping ground, and

its wide-spread use should be standard in geotechnical ● External loading conditions

practice [5]. The slope geometry and the geo-mechanical strength

Elasto-plastic analysis of geotechnical problems using of the dump material always control the stability of the

the finite element method (FEM) has been widely ac- dump [2,9,10]. Dump material is anisotropic in their be-

cepted in the research area for many years; however, its havior and its stress-strain behavior is quite erratic, ow-

routine use in geotechnical practice for slope stability ing to the presence of clay mineral. The visco-elastic

analysis still remains limited. The challenge for an ex- behavior due to the presence of water poses serious

perienced engineer is to know which kind of problem threat during the rainy season. The shear strength reduc-

would benefit from a FEM treatment and which would tion due to rise in pore water pressure leads to the failure.

not. In general, linear problems such as the predictions of Consolidation and compaction is another key factor be-

settlements and deformations, the calculation of flow cause of the uneven size distribution of the dump mate-

quantities due to steady seepage or the study of transient rial.

effects due to consolidation are all highly amenable to Bearing capacity of the ground has a direct influence

solution by finite element.

on the stability of the dump slope. A sloping ground with

low bearing capacity lead destabilizing of the dump

3. Factors Affecting Dump Failure

slope stability due to foundation failures [11].

In dump materials, failure is likely to form as a shallow, High variation in temperature can cause dump material

large radius surface extending from a tension crack close to spall due to the accompanying dilation. Water freezing

behind the crest to the toe of the slope (Figure 1). It fails in voids may causes damage by further loosening the

in a circular manner as the slope dimensions are substan- slope material. Repeated freeze/thaw cycles may result in

tially greater than the dimensions of the rock fragments. gradual loss of strength. Except for periodic maintenance

The actual shape of the “circular” slide surface is influ- requirements, temperature effects are a surface phe-

enced by the geological conditions in the slope mass. nomenon and are most likely of little concern for final

The slopes with loose, weak and soft rock masses can waste dump slopes. However, in a few cases, surface

basically have three different failure geometries viz. weakening could activate dump slope instability in large

slope failure, toe failure and base failure (Figure 2). In scale [12].

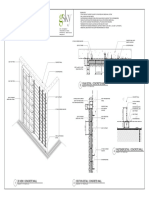

Figure 1. View of the failed dump slope.

Copyright © 2011 SciRes. GM

A. KAINTHOLA ET AL. 3

Figure 2. Different types of failure in waste dump slopes.

Ground water and surface water flow condition plays a bly reduces the rock mass shear strength. The decrease in

critical role on the stability of dump slope. Frictional shear strength may allow movement in dump slope along

strength is reduced as the height of the dump is raised, weak plane. In addition, localized erosion may also result

due to the presence of water. The pore water pressure in increased permeability and ground-water flow either

reduces the normal stress acting on the material. The the slope. This may lead to failure due to formation of

cohesive strength of weak geo-material will be further gully and deep flow channels in dump.

reduced due to presence of pore water pressure. Waste

dump placed in a loose state, shear failure is often fol- 4. Failure Criterion and Geo- Mechanical

lowed by static liquefaction which is complete loss of Strength Parameters of the Dump

strength [13]. The flow of water may enhance the seep- Material

age force, leading to the formation and migration of ten-

sion cracks. Mohr- Coulomb’s failure criterion was used for the nu-

Erosion also plays an important role in affecting the merical analysis of the dump material. The soft and loose

stability by surface weathering [14], groundwater or sur- mine dumps are mostly fine grained material. The shear

face-water seepage [15,16], toe erosion and slope modi- failure in dumps is by slippage of particles shear failure.

fication [17], primary is massive scale erosion, such as The failure is caused by a critical combination of normal

river erosion at the toe of the river bed. The other one is and shear stresses. The dump material fails when the

comparatively localized erosion caused due to ground- shear stress on the failure plane at failure is an exclusive

water or surface runoff. Erosion changes the waste dump function of the normal stress acting on that plane.

slope geometry and morphological characters. The This failure criterion is concerned with the shear stress

weathering and attrition of material at the toe of a poten- at failure plane at failure. The curve defined by this is

tial slide reduces the restraining force that may destabi- known as the failure envelope. The shear strength of a

lize the slope. Erosion of void filling material, or zones material at a point on a particular plane was expressed by

of percolation, can efficiently decrease cohesion among Coulomb as a linear function of the normal stress on that

grain boundaries. The decease of cohesive strength nota- plane, τ = c + tan(φ), where τ is the shear strength, σ is

Copyright © 2011 SciRes. GM

4 A. KAINTHOLA ET AL.

normal stress, φ is angle of internal friction and C is the tinuum model which can be used for analysis of complex

cohesive strength of the material [18]. geometries, stress modelling and material behaviour. In

Shear potency of the waste dump material is the criti- the FEM, the continuum structural system is modelled by

cally important parameter in stability analysis. The loose a set of appropriate finite elements interconnected at

broken material usually has low shear strength but its points called nodes. Elements may have physical as well

strength increases with time as it becomes more and as elastic properties such as thickness, density, Young’s

more compact. Therefore, the evaluation of shear strength modulus, shear modulus and Poisson's ratio. The ele-

with rational exactness is a condition for the stability ments are interconnected only at the exterior nodes, and

analysis of the dump slopes [19]. The various laboratory altogether they cover the entire domain as accurately as

techniques have been used by different researchers to possible. Nodes have nodal (vector) displacements or

determine the shear strength of rock and soil [20-22]. degrees of freedom which may include translations, rota-

The strength of the material depends on the grain size, as tions, and for special applications, higher order deriva-

well as the interlocking of the material. The deform- tives of displacements. When the nodes displace, they

ability has been found to be associated with arrangement drag the elements along in a certain manner dictated by

of the granular material as well its compaction [23]. the element formulation. In other words, displacements

In the studied dump slope the material consists of of any points in the element will be interpolated from the

fragments of friable sandstone, clay, shale, carbonaceous nodal displacements, and this is the main reason for the

shale. The fragment dump samples from five different approximate nature of the solution. A uniform mesh with

zones from the slope were collected for determination of 6 noded trianglular elements was used for the analysis

the geo-mechanical parameters of the failure criterion. mine dump. A major advantage of the finite element-

The fragments range in size from 1 / 256 mm to 1m. The SSR method is that it does not demand any earlier as-

tests were carried out as per the specification of stan- sumptions on the nature of failure mechanisms. The

dards [20,21]. The samples were tested for the measure- Shear Strength Reduction (SSR) technique in the finite

ment of their cohesive strength, angle of internal friction, element method involves successive reduction (by some

elastic modulus and poissons ratio. factors) in the shear strengths of the slope forming mate-

The average annual rainfall in the studied area is 1200 rial until it fails, which is indicated by the non conver-

mm, to take into account the effect of water on the dump gence to a solution of the finite element model [25-27].

material so test were conducted under 30% saturation For Mohr-Coulomb material shear strength reduction

level. The mean value of the five tested sample were factor (factor of safety) F can be determined from the

taken for the numerical solution of the dump stability equation:

problem (Table 1). τ c tanφ

= + (1)

F F F

5. Simulation of the Dump

where τ is the shear strength of the material and F is the

The dump slope was numerically analyzed using a finite strength reduction factor (SRF)or the factor of safety

element code. The finite element code (FEM) is a con- (FOS).

Table 1. Strength parameters for the dump material.

Peak angle of Residual angle

Unit weight Elastic modulus Poissons’s Peak cohesion Residual

Dump material Sr. no. internal friction of internal

(MN/m3) (MPa) ratio (KPa) cohesion (KPa)

(˚) friction (˚)

1 0.0240 68 0.31 95 23.5 39 19.5

2 0.0245 73 0.33 88 24 37 20.4

3 0.0243 70 0.31 93 25.5 38.4 22.3

Compacted fragments

of friable sandstone,

4 0.0248 77 0.34 83 24.6 34 21.9

shale, clay and

carbonaceous shale

5 0.0245 75 0.33 88 25 35 22

6 0.0247 71 0.34 85 25.2 35.7 23

Mean

0.0244 72.3 0.326 88.6 24.6 36.5 21.5

Value

Copyright © 2011 SciRes. GM

A. KAINTHOLA ET AL. 5

6. Numerical Analysis of the Dump Slope rest of the input parameters constant, till the safety factor

reduced to 1.2. An effective shear stress of 0.29 MPa had

The failed dump slope having an initial height of 75 m developed inside the dump above the critical SRF of 0.8

and 43˚ slope angle was simulated with the determined which lead to the failure, when at an angle of 43˚ (Figure

strength parameters in the laboratory to optimize the 3 & 4). With the dump slope angle of 41˚ and slope height

slope. The back analysis of the failed slope was done for of 75 m, the SRF achieved was 0.82 generating a maxi-

validation of the simulation which gave a SRF of 0.8 mum shear stress 0.075 MPa at the toe dump (Figure 13).

(Figure 3). The simulation provides a displacement of The safety factor increased to 0.87 when the mine

1.3 m for the critical SRF of 0.8, which will increase to dump angle was reduced to 39˚, the maximum effective

68 m for the critical SRF value of 1. The slope angles stress at this critical SRF was 0.094 MPa. The plot shows

were reduced successively at an interval of 2˚, keeping the maximum shear strain concentration for the SRF

rest of the parameters constant. When the safety factor of above the critical value to get a better picture of the shear

1.3 was achieved, the slope height was raised keeping the strain focus (Figure 5).

Figure 3. Back analysis of the failed dump slope at 43˚ inclination showing maximum strain concentration and the deformed

mesh.

Figure 4. Effective stress variation along the distance A-B, for the failed dump slope.

Copyright © 2011 SciRes. GM

6 A. KAINTHOLA ET AL.

A safety factor of 0.92 was yielded by the model at a With additional reduction in dump angle by 2˚, keep-

slope angle of 37˚, the maximum shear stress developed ing the dump angle at 31˚, the FOS achieved was 1.07

was 0.14MPa at the toe of the dump slope. Most of the (Figure 7). For the dump angle of 29˚ the analysis gave a

mining companies go for the dump angle ranging be- critical SRF of 1.13 with maximum shear stress of 0.26

tween 37˚ - 39˚, but the FOS yielded for these dump an- MPa.

gles are less than 1 and at very critical state. Dump angle Diminution of dump angle to 27˚ yielded the safety

was further reduced to reach the optimum FOS. factor of 1.2 and further lessening of the dump angle to

The safety factor further increased to 0.94 when the 25˚ gave the desired safety factor of 1.3 (Figures 8 and 9).

dump angle was reduced by 2˚ to 35˚ (Figure 6). The Once the FOS reached up to 1.3, the slope height was

critical SRF of 1 was achieved with the dump angle of raised from 75 m to 95 m at an interval of 5m to see the

33˚. The aim was to reach the safety factor of 1.3 for the effect of increase in height on the FOS as well as to op-

mine dump as with FOS value of 1, the dump is only timize the dump for safe and stable accommodation of

theoretically stable as the driving and resisting forces for the mine waste. The material properties were kept con-

the failure are in equilibrium with each other [28]. stant as like in their earlier case.

Figure 5. Maximum shear strain plot for the dump with a slope angle of 39˚.

Figure 6. Maximum shear strain plot for the dump with a slope angle of 35˚.

Copyright © 2011 SciRes. GM

A. KAINTHOLA ET AL. 7

Figure 7. Total displacement plot with displacement vectors with for 31˚ slope angle.

Figure 8. Total displacement plot with displacement vectors with for 27˚ slope angle.

Figure 9. Maximum shear strain plot shear and tension points for dump slope angle of 25˚.

Copyright © 2011 SciRes. GM

8 A. KAINTHOLA ET AL.

The FOS reduced by 3% when the dump height was priate.

raised by 5 m (Figure 10). Effective shear stress of 0.045

MPa was developed at the toe of the dump with a height 7. Discussion

of 80 m.

A critical safety factor of 1.22 was attained when the A 75 m high failed dump slope consisting of low

dump height was raised to 85m (Figure 11). It is it in- strength material was numerically solved and analyzed

teresting to observe that, even changing the height from for slope angle optimization. The investigated mine

85 m to 90 m does not affect FOS. dump having weak material strength gave a FOS value of

When the height of the dump was raised further more 1 when it was at angle of 33˚ i.e. 10˚ less the original

with slope angle of 25˚, the FOS reduced up to 1.2 (Fig- value at which it has already failed. Keeping the Dump

ure 12). The simulation was stopped at 95 m slope height constant at 75 m the FOS varied logarithmically

height as raising more height would have given a much with the dump slope angle (Figure 13). FOS can be cor-

lesser value of FOS, which is undesired and not appro- related with dump angle for the 75 m high studied dump

Figure 10. Maximum shear strain plot with tension and shear points for slope angle 25˚ and dump height of 80 m.

Figure 11. Maximum shear strain plot with tension and shear points for slope angle 25˚ and dump height of 85 m.

Copyright © 2011 SciRes. GM

A. KAINTHOLA ET AL. 9

Figure 12. Stress trajectories for dump slope angle 25˚ and dump height of 95 m.

Figure 13. Correlation between dump slope angle Vs. FOS with constant slope height of 75 m.

by the equation strength of the material will reduce significantly above

FOS= –0.91 ln (slope angle) + 4.215 (2) the critical SRF value (Figure 14).

The effective shear stresses have a similar trend for the

The aim was to reach a FOS of 1.3 for the optimum different dump angles and FOS or SRF values along the

stability of the dump which was attained at an angle of dump slope length (Figure 15).

25˚ (Table 2). The effective shear stress along the dump The effective shear stress variation for different

slope length has been calculated to increase with FOS of FOS/SRF values has been depicted against slope length

the dump. This increase in stress can be attributed to the which has been divided into 200 equal divisions for each

fact that, with higher SRF value for the model, the shear slope length (Figures 14 and 15).

Copyright © 2011 SciRes. GM

10 A. KAINTHOLA ET AL.

Table 2. Variation of FOS with respect to slope angle with constant height of 75 m.

Slope angle FOS or SRF Percentage Increase in FOS

430 0.8 0

0

41 0.82 2.5

0

39 0.87 6.09

370 0.92 5.7

0

35 0.94 2.1

330 1.0 6.3

310 1.07 7

290 1.13 5.6

270 1.2 6.2

0

25 1.3 8.3

Figure 14. Effective shear strain plot along the slope length for different dump angles.

Figure 15. Effective shear strain plot along the slope length for different dump height.

Copyright © 2011 SciRes. GM

A. KAINTHOLA ET AL. 11

For better efficiency of the dump, managements the 15).

height was raised to keeping the dump angle constant at The generation of tension and shear zones on the

25˚, till the FOS was reduced to 1.2 (Table 3). The FOS dump slope model when in the critical state gives us a

again reduced logarithmically with respect to the raise in great deal of information about the critical zones which

dump height, Similar observation was expressed previ- can be used for the stabilization. The rear vicinity and the

ously by an author [30] (Figure 16). For the investigated slope surface of the dump are undergoing tension avoid

dump with slope angle of 25˚ the FOS can be estimated of failure while the maximum shear strain concentration

with respect to the dump height using the empirical equa- is at depth of 14 m from the dump surface (Figure 9).

tion, Generally, waste dumps are designed for factor of

FOS= –0.41 ln (dump height) + 3.059 (3) safety of 1.10 to 1.15 have only a minor risk of failure

Effective shear stress has increased with rise in dump under saturated conditions. Waste dumps with a FOS less

height reaching a maximum value of 0.16 MPa for the 95 than 1.1 are subject to always used great risk, even with

m dump (Figure 15). The results have only minor incon- accurate data, it is due to the anomalous conditions re-

sistencies, as there was no significant reduction in FOS lating to height and strength of dump material or the un-

when the dump height was raised from 85 m to 90 m. derlay which are likely to be present with the dump.

But the maximum effective shear stress along the slope Such anomalous conditions may result in local fluctua-

length was raised from 0.08 MPa to 0.1 MPa (Figure tion in the FOS by 10%.

Table 3. Variation of FOS w.r.t slope height with constant 25˚ slope angle.

Dump Height (m) FOS or SRF Percentage Reduction in FOS

75 1.3

80 1.26 3.07

85 1.22 3.17

90 1.22 0

95 1.2 1.63

Figure 16. Variation of FOS with respect to the dump height (constant dump angle 25˚) .

Copyright © 2011 SciRes. GM

12 A. KAINTHOLA ET AL.

8. Conclusion [9] Morgenstern, N. R. and Price, V. E., “The analysis of the

stability of general slip surface,” Geotechnique, Vol. 15,

No. 4, 1965, pp. 289-290.

In pit dumping , particularly in Wes tern coal field Ltd.,

is very crucial due to the none availability of land as well [10] Dawson, E. M., Roth W.H. and Drescher, A., “Slope

as weak rock condition as well as heavy rain. In the pre- Stability Analysis by Strength Reduction”, Geotechnique,

Vol. 49, No. 6, 1999, pp. 835-840.

sent study a failed dump slope problem from India was

numerically examined and based on back analysis, an [11] Khandelwal M. and Singh, T. N., “Prediction of Blast

induced ground vibration using intelligent approach - A

optimum dump angle and height have been suggested for Case Study,” I33rd Mine Safety Workshop, Rajasthan,

safe and stable dumping. The factor of safety was found 2009, pp. 45-48.

to increase logarithmically with reduction in dump angle [12] Steiakakis, E., Kavouridis K. and Monopolis, D., “Large

while keeping the dump height constant at 75 m. The scale failure of the external waste dump at the South

dump slope gave an FOS of 1.3 when at an angle of 25˚ Field lignite mine,” Northern Greece, Engineering Geol-

and height of 85 m and hence owing to the weak geo- ogy Vol. 104, 2009, pp. 269-279.

mechanical strength of the dump it was suggested to [13] Chowdhury, R., “Geotechnical Slope Analysis,” Pub-

keep the flatter slope of 25˚ with a height of 75 m. The lished by CRC Press, New York, 2009,

FOS also reduced logarithmically when the dump height [14] Matsukura, Y. and Mizuno, K., “The influence of weath-

was raised up till 25 m. The numerical study provides a ering on the geotechnical properties and slope angles of

comprehensive understanding about the slope mecha- mudstone in the Mineoka earth-slide area,” Japan. Vol.

nism failure in weak material. 11, No. 3, 2006, pp. 263-273.

[15] Norris, R. M. and Back, W., “Erosion of seacliffs by

9. Acknowledgements groundwater. Groundwater Geomorphology: The role of

subsurface water in Earth-surface processes and land

forms,” C. G. Higgins and D. R. Coates, eds., Geological

The authors would like to thank the management of Society of America, Boulder, Colo., 1990, pp. 283-290.

WCL, India, for their cooperation and support during the

[16] Hampton, M., “Gravitational failure of sea cliffs in

field work. The views expressed in the article are those weakly lithified sediment,” Environmental Engineering

of the author and are not necessarily any organization or Geosciences, Vol. 83, 2002, pp. 175-191.

institution.

[17] Barton, M. E. and Cresswell, A., “Slope stability in a

sand/ sandstone borderline material,” Proc., 2nd Int.

10. References Symp., The Geotechnics of Hard Soils—Soft Rocks, Vol.

3, A. Evangelista and L. Picarelli, eds., Balkema, Rotter-

[1] Upadhyay, O. P., Sharma, D. K. and Singh, D. P., “Fac- dam, The Netherlands, 1998, pp. 1051-1055.

tors affecting stability of waste dumps in mines,” Interna- [18] Mohr, O., “Ueber die Darstellung des Spannungszustan-

tional Journal of Surface Mining and Reclamation, Vol. 4, des und des Deformationszustandes eines Körperele-

1990, PP. 95-99. mentes und über die Anwendung derselben in der Festig-

[2] Bishop A. W, “The use of the slip circle in the stability keitslehre,” Civilengenieur, Vol. 28, 1882, pp.113-56.

analysis of slopes,” Geotechnique, Vol. 5, 1955, pp. 7-17. [19] Chaulya, S. K., Singh, R. S., Chakraborty, M. K. and

[3] Calder, P. N. and Workman, J. L., “The design of stable Dhar, B.B, “Numerical modelling of biostabilisation for a

highwalls and spoil piles in strip mining,” SME-AIME coal mine overburden dump slope,” Ecological Modelling,

Meeting, Minneapolis, Minn., Preprint, 1980, pp. 80-368. Vol. 14, 1999, pp. 275-286.

[4] Richards, B. G., Coulthard, M. A., and Toh, C. T., [20] American Society for Testing and Materials, Standard

“Analysis of slope stability at Goonyella mine,” Cana- test method for direct shear test of soils under consoli-

dian Geotechnical Journal, Vol. 18, 1981, pp. 179-194. dated drained conditions. ASTM D3080-98. Annual book

of ASTM Standards. ASTM, 1998, West Conshohocken,

[5] Griffiths, D. V. and Lane, P. A., “Slope stability analysis

PA.

by finite elements,” Geotechnique, Vol. 49, No. 3, 1999,

pp. 387-403. [21] Chakravorty, M. K., Chaulya, S. K. and Singh T. N.,

“Method of waste dump stability analysis—an overview,”

[6] Singh, T. N. and Chaulya, S. K.,” External Dumping of

In: Proceeding national symposium. Engineering, mining

Overburden in Opencast Mine,” Indian Journal of Engi-

and ground control, technology, Varanasi, 1996, pp.

neers, Vol. 22 (1 & 2), 1992, pp. 65-73.

287-2.

[7] Singh, T. N., Singh, A. P. and Goyal, M., “Stability of

[22] Gue S. S. and Tan, Y. C., “The Determination of shear

Waste Dump and its Relation to Environment,” Indian

strength in residual soils for slope stability analysis,”

Journal of Cement Review, Vol. 9(2), 1994, pp. 15-21.

Seminar Cerun Kebangsaan, 2001, Cameron Highlands.

[8] Singh, A. P. and Singh, T. N., “Assessing instability of

[23] Singh T. N. and Naidu S., “Influence of strain Rate and

Coal Mine waste dump,” The Indian mineral industry

cyclic compression on physicmechanical behavior of

journal, 2006, pp. 113-118.

rocks,” Indian. Journal. of Engineering. and material sci-

Copyright © 2011 SciRes. GM

A. KAINTHOLA ET AL. 13

ences, Vol. 59, 2000, pp. 482-486. [26] Ann, T., SCheang,. W. Hai O. P and D. Ta, “Finite Ele-

[24] ISRM, “Suggested method for the determining the ment Analysis of A Soil Nailed Slope-Some Recent Ex-

strength of the rock materials in triaxial compression: re- perience,” GeoAsia, 2004.

vised version,” International Journal Rock Mining Sci- [27] Rocscience, “A new area in slope stability analysis: Shear

ence Geo-mechanics Abstract, Vol. 20,1983, PP.283-290 strength reduction finite element technique.” RocNews.

[25] Zhou, W. Y., Xue L. J., Yang Q., and Y. R. Liu, “Rock 2004.

slope stability analysis with nonlinear finite element [28] Jha, G. K. and Lal, K. M., “Slope stability of external OB

method,” Taylor & Francis, 1994, pp. 503-507. dumps”, Opencast, 1998, pp.119-125.

Copyright © 2011 SciRes. GM

Anda mungkin juga menyukai

- Rock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesDari EverandRock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesBelum ada peringkat

- Mine Overburden Dump Failure Mechanism AnalysisDokumen13 halamanMine Overburden Dump Failure Mechanism AnalysisnishantBelum ada peringkat

- Application of The Q-System To Australian Underground Metal MinesDokumen12 halamanApplication of The Q-System To Australian Underground Metal MinesCraig ThomasBelum ada peringkat

- Jurnal Teknologi: Discrete Element Modelling of Complex Failure Mechanism at Quarry SlopeDokumen9 halamanJurnal Teknologi: Discrete Element Modelling of Complex Failure Mechanism at Quarry SlopeFebry Aulia TonangBelum ada peringkat

- Strata Behaviors in Extra-Thick Coal SeamsDokumen10 halamanStrata Behaviors in Extra-Thick Coal Seamskatta_sridharBelum ada peringkat

- Ansell - 2004 - in Situ Testing of Young Shotcrete Subjected To Vibrations From Blasting PDFDokumen10 halamanAnsell - 2004 - in Situ Testing of Young Shotcrete Subjected To Vibrations From Blasting PDFUnurbayar EnkhbaatarBelum ada peringkat

- Journal of Rock Mechanics and Geotechnical Engineering: Manchao HeDokumen15 halamanJournal of Rock Mechanics and Geotechnical Engineering: Manchao HeMilton TeranBelum ada peringkat

- Journal of Rock Mechanics and Geotechnical Engineering: Amin Manouchehrian, Ming CaiDokumen10 halamanJournal of Rock Mechanics and Geotechnical Engineering: Amin Manouchehrian, Ming CaiPaul MatshonaBelum ada peringkat

- Ubicacion Optima de La BandaDokumen9 halamanUbicacion Optima de La BandaCarlos Pretell RodriguezBelum ada peringkat

- Practical Manual on Block Cave MiningDokumen525 halamanPractical Manual on Block Cave MiningJorge Ariel Osorio GuzmanBelum ada peringkat

- Rock Mechanics Challenges in Underground Construction and MiningDokumen16 halamanRock Mechanics Challenges in Underground Construction and MiningyashwanthBelum ada peringkat

- Planning and Execution of Soil InvestigaDokumen9 halamanPlanning and Execution of Soil InvestigaLinusBelum ada peringkat

- Development of A Multiple Level Underground Limestone MineDokumen5 halamanDevelopment of A Multiple Level Underground Limestone MineMuhammad ReyhandBelum ada peringkat

- 0.1 BawdenDokumen18 halaman0.1 BawdenedwinsBelum ada peringkat

- A Laboratory Study of Rock Properties Affecting The Penetration Rate of Pneumatic Top Hammer DrillsDokumen10 halamanA Laboratory Study of Rock Properties Affecting The Penetration Rate of Pneumatic Top Hammer DrillsFelipe MilhomemBelum ada peringkat

- Bulletin 10 ADEQ (1978)Dokumen332 halamanBulletin 10 ADEQ (1978)markurban100% (2)

- Mining Mate SyllabusDokumen7 halamanMining Mate SyllabusRahul Thakurta100% (1)

- 12EE IJRMMS-PalaboraInSARDokumen13 halaman12EE IJRMMS-PalaboraInSARJuniorMendoza97Belum ada peringkat

- Carter PaperDokumen13 halamanCarter Paperronan2000Belum ada peringkat

- An operational approach to ground control in deep minesDokumen15 halamanAn operational approach to ground control in deep minesRsmoothBelum ada peringkat

- Fookes Et Al 1985 QJEG Dubai Etc EvaporitesDokumen27 halamanFookes Et Al 1985 QJEG Dubai Etc EvaporitesJohan Van Staveren100% (1)

- CLSAU Mining0615Dokumen40 halamanCLSAU Mining0615pokygangBelum ada peringkat

- Rock Characterization at El Teniente Mine PDFDokumen15 halamanRock Characterization at El Teniente Mine PDFEmanuel NicolásBelum ada peringkat

- Managing Risks for Grouting in Karst FormationsDokumen12 halamanManaging Risks for Grouting in Karst Formationsmjbyle100% (1)

- Three-Dimensional Simulation of Cave Initiation, Propagation and Surface Subsidence Using A Coupled Finite Difference-Cellular Automata SolutionDokumen16 halamanThree-Dimensional Simulation of Cave Initiation, Propagation and Surface Subsidence Using A Coupled Finite Difference-Cellular Automata SolutionMatías Ignacio Fuentes BustamanteBelum ada peringkat

- Establishing A Site Specific Mining Geotechnical Logging AtlasDokumen9 halamanEstablishing A Site Specific Mining Geotechnical Logging AtlasVinodh Kumar YallaBelum ada peringkat

- Mine PlanningDokumen14 halamanMine PlanningFebri Ruswandi Anggara PutraBelum ada peringkat

- Measurement-While-Drilling Technique PDFDokumen9 halamanMeasurement-While-Drilling Technique PDFWilkhen ChuraBelum ada peringkat

- 14EE MiningTechnology-CavingSlopeInteractionModellingDokumen9 halaman14EE MiningTechnology-CavingSlopeInteractionModellingMezamMohammedCherifBelum ada peringkat

- Underhand Cut and Fill Mining As Practiced in Therr Deeo Hard Rock Mines in The Unired States PDFDokumen11 halamanUnderhand Cut and Fill Mining As Practiced in Therr Deeo Hard Rock Mines in The Unired States PDFwcamilo015Belum ada peringkat

- Karst Eng Classn QJ2003Dokumen19 halamanKarst Eng Classn QJ2003Rachel OpiyoBelum ada peringkat

- IADC/SPE 59121 When Rock Mechanics Met Drilling: Effective Implementation of Real-Time Wellbore Stability ControlDokumen13 halamanIADC/SPE 59121 When Rock Mechanics Met Drilling: Effective Implementation of Real-Time Wellbore Stability ControlCAMILO ANDRES BOHORQUEZ ESPARZABelum ada peringkat

- Economic Valuation of Wetlands - BLRDokumen14 halamanEconomic Valuation of Wetlands - BLRManish NairBelum ada peringkat

- f094 PDFDokumen4 halamanf094 PDFAnshuman SinghBelum ada peringkat

- Decline Design in Underground Mines Using Constrained Path OptimisationDokumen8 halamanDecline Design in Underground Mines Using Constrained Path OptimisationJhan HuayraBelum ada peringkat

- Introduction To Karst and CavesDokumen22 halamanIntroduction To Karst and CavesJuan Cruz HarasimiukBelum ada peringkat

- TP 141 PDFDokumen24 halamanTP 141 PDFWilliam ProvidoBelum ada peringkat

- US Army Corps of Engineers HEC-1 Flood Hydrograph Package User's ManualDokumen120 halamanUS Army Corps of Engineers HEC-1 Flood Hydrograph Package User's ManualAndrea CalderónBelum ada peringkat

- Basic Ground-Water Hydrology: by Ralph C. HeathDokumen88 halamanBasic Ground-Water Hydrology: by Ralph C. HeathJerome MosquedaBelum ada peringkat

- Australian GW School - Melbourne ProgramDokumen4 halamanAustralian GW School - Melbourne ProgramGilangBelum ada peringkat

- Risk Assessment and Prediction of Rock Fragmentation Produced by Blasting Operation A Rock Engineering SystemDokumen13 halamanRisk Assessment and Prediction of Rock Fragmentation Produced by Blasting Operation A Rock Engineering SystemW N Nan FajarBelum ada peringkat

- Long-term production scheduling model using ILPDokumen6 halamanLong-term production scheduling model using ILPjeha kunramadiBelum ada peringkat

- Chapter 2: Literature ReviewDokumen14 halamanChapter 2: Literature ReviewShahadat HossainBelum ada peringkat

- Engineering Characterisation of The Glaciofluvial Gravels of Cork CityDokumen13 halamanEngineering Characterisation of The Glaciofluvial Gravels of Cork CityAnonymous VcSQvILHmEBelum ada peringkat

- Mine ManagementDokumen7 halamanMine ManagementBranden OxfordBelum ada peringkat

- MSC Thesis e AlderliesteDokumen120 halamanMSC Thesis e Alderliestejmwalker90Belum ada peringkat

- IJEMS 5 (4) 223-235 WTPDokumen13 halamanIJEMS 5 (4) 223-235 WTPratneshkumar2004Belum ada peringkat

- Guidelines For Use of The Scaled Span Method PDFDokumen34 halamanGuidelines For Use of The Scaled Span Method PDFpedroBelum ada peringkat

- Mathematical Programming Application in Sublevel Caving Production SchedulingDokumen12 halamanMathematical Programming Application in Sublevel Caving Production SchedulingCamila Ordenez OlivaresBelum ada peringkat

- Rock Mechanics Review: The Monitoring of Structures in RockDokumen30 halamanRock Mechanics Review: The Monitoring of Structures in RocktilimBelum ada peringkat

- Practical Application of Ground Support & Reinforcement To Address Weak Rock Mass in Underground MinesDokumen16 halamanPractical Application of Ground Support & Reinforcement To Address Weak Rock Mass in Underground MinesAlain CubaBelum ada peringkat

- Managing Buried Treasure Across Frontiers: The International Law of Transboundary AquifersDokumen11 halamanManaging Buried Treasure Across Frontiers: The International Law of Transboundary AquifersKevin Ken Sison GancheroBelum ada peringkat

- Hunt 2014 Tunneling in Cobbles and Boulders, FDokumen38 halamanHunt 2014 Tunneling in Cobbles and Boulders, FswhuntBelum ada peringkat

- Enterprise OptimisationDokumen13 halamanEnterprise OptimisationMarcos BuenoBelum ada peringkat

- Causes of Mine CollapseDokumen5 halamanCauses of Mine CollapseMuhammad SultanBelum ada peringkat

- Techn of WaterResourc Invest. Met Determ Inorg Subst in Water & Fluv Sedim USGS PDFDokumen560 halamanTechn of WaterResourc Invest. Met Determ Inorg Subst in Water & Fluv Sedim USGS PDFMárcio Antônio Mendonça de SousaBelum ada peringkat

- Use of Pre-Splitting Technique As An Alternative Approach ToDokumen4 halamanUse of Pre-Splitting Technique As An Alternative Approach Toalvaroaac4Belum ada peringkat

- Establishing A Site Specific Mining Geotechnical Logging Atlas PDFDokumen9 halamanEstablishing A Site Specific Mining Geotechnical Logging Atlas PDFJnthan Prado AlvarezBelum ada peringkat

- NATM Tunneling in Soft Rock in San Diego: Integrating Design and ConstructionDokumen12 halamanNATM Tunneling in Soft Rock in San Diego: Integrating Design and Constructionرياض عصادBelum ada peringkat

- Rancang Bangun Sistem Irigasi Tetes Otomatis Berbasis Perubahan Kadar Air Tanah Dengan Menggunakan Mikrokontroler Arduino NanoDokumen8 halamanRancang Bangun Sistem Irigasi Tetes Otomatis Berbasis Perubahan Kadar Air Tanah Dengan Menggunakan Mikrokontroler Arduino NanoAnde IsnendaBelum ada peringkat

- WaterfloodingDokumen4 halamanWaterfloodingjayeshepBelum ada peringkat

- Metar HelpDokumen5 halamanMetar HelpNelson GonzàlezBelum ada peringkat

- Innovative Offerings for Desalination PlantsDokumen24 halamanInnovative Offerings for Desalination Plantscvolkan1Belum ada peringkat

- Phytoremediation 150123100305 Conversion Gate02Dokumen49 halamanPhytoremediation 150123100305 Conversion Gate02Kumar MadhuBelum ada peringkat

- ANDRITZ Company Presentation eDokumen6 halamanANDRITZ Company Presentation eAnonymous OuY6oAMggxBelum ada peringkat

- PhotosynthesisDokumen5 halamanPhotosynthesisbluemonkeymei4921100% (1)

- Cumene MSDS: Section 1: Chemical Product and Company IdentificationDokumen5 halamanCumene MSDS: Section 1: Chemical Product and Company Identificationburhanettin_erdemBelum ada peringkat

- Thermal and Refregeration Based Projects PDFDokumen3 halamanThermal and Refregeration Based Projects PDFShankar GBelum ada peringkat

- Biogeochemical Cycles Webquest ActivityDokumen5 halamanBiogeochemical Cycles Webquest Activitykate nicole labandriaBelum ada peringkat

- Improve concrete quality with Pozz-SandDokumen1 halamanImprove concrete quality with Pozz-Sandvijay kBelum ada peringkat

- Quiz 1Dokumen11 halamanQuiz 1jomalilo23Belum ada peringkat

- Sedimentary RockDokumen65 halamanSedimentary RockAbdul Moeed KalsonBelum ada peringkat

- CambodiaDokumen16 halamanCambodiaThach BunroeunBelum ada peringkat

- PERFORMANCE CHECKLIST With Oral Questioning ToolDokumen3 halamanPERFORMANCE CHECKLIST With Oral Questioning ToolChonaMarieEstellinaBelum ada peringkat

- Revolutionary Package Sewage TreatmentDokumen31 halamanRevolutionary Package Sewage TreatmentM.Sreeram SanjayBelum ada peringkat

- Rye1976 Temper PotteryDokumen34 halamanRye1976 Temper PotteryROGBelum ada peringkat

- Silt Control at Head WorksDokumen37 halamanSilt Control at Head WorksSridhar Reddy0% (1)

- 06 GestionambientalDokumen346 halaman06 GestionambientalÁngela RamosBelum ada peringkat

- Bwa Belgard Ev2050 Gpi - WFDokumen2 halamanBwa Belgard Ev2050 Gpi - WFdalton2004Belum ada peringkat

- GSKY Green Wall Panel Installation on Concrete WallDokumen1 halamanGSKY Green Wall Panel Installation on Concrete WallAbbasi HussainBelum ada peringkat

- FISPQ - Lauril Eter Sulfato S Dio 70 Rev 01 2019 GHS enDokumen7 halamanFISPQ - Lauril Eter Sulfato S Dio 70 Rev 01 2019 GHS enMarko NenkBelum ada peringkat

- BR363-Embankment Dam SafetyDokumen112 halamanBR363-Embankment Dam SafetyBart kaczynskiBelum ada peringkat

- Specification For Pipe Culvert Construction: 1. ScopeDokumen8 halamanSpecification For Pipe Culvert Construction: 1. Scope061 David RajuBelum ada peringkat

- Decoduct UPVC Conduits & Fittings Manufactured To BS 6099 & BS 4607 and BS EN 50086 / BS EN 61386 Price ListDokumen3 halamanDecoduct UPVC Conduits & Fittings Manufactured To BS 6099 & BS 4607 and BS EN 50086 / BS EN 61386 Price ListAly SamirBelum ada peringkat

- Level of Organisation of Protein StructureDokumen18 halamanLevel of Organisation of Protein Structureyinghui94Belum ada peringkat

- Geoarchaeology - Using Earth Sciences To Understand The Archaeological RecordDokumen32 halamanGeoarchaeology - Using Earth Sciences To Understand The Archaeological RecordLaly QuintanaBelum ada peringkat

- Science 10 Quarter ExamDokumen5 halamanScience 10 Quarter ExamlorenzfloresBelum ada peringkat

- How leaves and roots help plants make their own foodDokumen11 halamanHow leaves and roots help plants make their own foodLeocarl Fabunan Simon RABelum ada peringkat

- Third. Summative Test in Industrial Arts 6Dokumen2 halamanThird. Summative Test in Industrial Arts 6Joecel A Polinag100% (1)