JSA Installation of Gearbox

Diunggah oleh

prasong100%(1)100% menganggap dokumen ini bermanfaat (1 suara)

1K tayangan2 halamanaa

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen Iniaa

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

100%(1)100% menganggap dokumen ini bermanfaat (1 suara)

1K tayangan2 halamanJSA Installation of Gearbox

Diunggah oleh

prasongaa

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 2

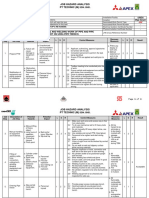

Job Safety Analysis

JSA No: Mec-001

Activity: Installation of Gearbox

(Rev-001)

Project No:

Project Title: ABPR 1&2

Site/Facility: Work Area: Permit No:

P&S Emergency Contact Number: HRSG 21

Date:

0817628414

Personal Protective Equipments: Hard Hat, Safety Shoes, Hand Gloves, Safety Harness, Coverall

RESIDUAL

JOB STEPS POTENTIAL HAZARDS RISK RATING MITIGATION MEASURES RISK RATING

• Permit To Work procedure Amata Begrimm to be

complied

• Ensure all equipments are inspected and certified

as per Amata Begrimm

• All personnel shall undergo Project HSE Induction

• Non-compliance of and EOD Training prior to mobilize 2B

3D

safety procedure • Any findings of EOD, stop the activity, inform (Low)

(Medium)

Company and keep personnel away from the area.

• All Lifting tools and Tackles shall have inspected

prior to mobilize to site.

• All lifting Equipment shall complete the HSE

Inspection and Colour Code.

• Ensure the equipment is certified & visually

inspected and fit for the intended purpose.

Pre - work • Confirm the operators are with both licenses of

construction and driving.

• Ensure all lifting gears and shackles are inspected

with necessary authorized 3rd party inspection

certificates and color coded.

• Poor Task Planning

• Ensure the operator and the rigging crews are

competent, experienced and trained (Awareness

• Non Competent Crew 3D 2B

Training) by III rd Party.

(Medium) • Check the ground condition is safe for operation

(Low)

• Area of activity

and underground services identified and

adequately protected.

• Ensure area of lifting is barricaded and caution

signage placed.

• Clear media of communication shall be

maintained.

• Conduct TBT and discuss about the safe way of

lifting.

• Ensure the ground is stable and properly

compacted.

• Ensure out riggers must have an outrigger pad of

adequate size and thickness.

• Provide steel matting as appropriate if required

• Positioning of the

4D for critical/ heavy lifts. 2B

crane/hiam on unstable

(High) • Maintain safe distance while placing the crane (Low)

ground / Marshy land

Lifting of Gearbox from the excavation/Trench.

• Safe distance shall be maintained from the

overhead power lines.

• Site Safety Analysis for lifting shall be prepared

and approved prior to commence the Lifting

• Over Load • Conduct regular visual inspection of all lifting

4D 2B

gears and mechanism of crane prior to start any

(High) lifting operation by a competent person. (Low)

Page 1 of 2

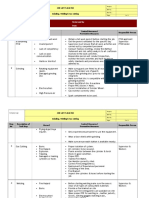

• Mechanical failure • Do not exceed the Safe Working Load of the crane

as per manufacturer standards under any

circumstances.

• Do not override any inbuilt safety devices or take

short cuts during the lifting operations.

• All Lifting tools and tackles shall be visually

inspected and ensured the condition.

• Sharp edges of the load shall be provided with

packing to protect the Lifting tools and tackles

from damage.

• Equipment maintenance shall be done

periodically and records maintained.

• Ensure proper wind up and housekeeping at work

site.

• The accessories and tools shall be clean and store

• Scattered lifting tools and properly.

Job Completion 3C • Vehicle/Equipment shall be parked/ secured in a

1A

other accessories.

House keeping (Medium) (Low)

• House keeping safe place.

• Ensure stored materials will not block the

adjacent Access / Egress.

• Barricade the area placed with Caution Signage

Additional Hazards

(Other than

indicated above)

Permit No: Work Area:

JSA Done Name: Controlling Team:

by Permit

Applicant P&S. No. Signature:

JSA Reviewed Name: Controlling Team:

by Permit

Issuer AMATA BEGRIMM. No. Signature:

Page 2 of 2

Anda mungkin juga menyukai

- M112 Engine PDFDokumen89 halamanM112 Engine PDFprasong80% (5)

- JSA # 3 Column ErectionDokumen6 halamanJSA # 3 Column ErectionRaghava Richhu100% (2)

- JSA For Working at HeightDokumen1 halamanJSA For Working at HeightSafety& Security Supervisor100% (1)

- JSA For Flange AlignmentDokumen5 halamanJSA For Flange AlignmentHưởng Phạm100% (1)

- Job Safety Analysis Sheet: FacilityDokumen1 halamanJob Safety Analysis Sheet: Facilitywahyu nugrohoBelum ada peringkat

- JSA-Manual Lifting of MaterialsDokumen3 halamanJSA-Manual Lifting of Materialsfrancis_e_tan75% (4)

- 7.L015-OHSE Height Work Permit FormatDokumen2 halaman7.L015-OHSE Height Work Permit Formathafis100% (2)

- 08 - Groove - Cutting - Machine ChecklistDokumen1 halaman08 - Groove - Cutting - Machine ChecklistKARTHIK NAIKAR80% (5)

- JSA To Check & Repair Heat Tracing System.Dokumen12 halamanJSA To Check & Repair Heat Tracing System.Chung Trịnh100% (2)

- Petrofac: Job Safety AnalysisDokumen3 halamanPetrofac: Job Safety AnalysisMon Trang Nguyễn100% (5)

- Job Safety Analysis Sheet: Erection & Use of ScaffoldingDokumen1 halamanJob Safety Analysis Sheet: Erection & Use of ScaffoldingAbdullah KamilBelum ada peringkat

- Chapter 3Dokumen5 halamanChapter 3Ngozi OddiriBelum ada peringkat

- Manual Tig Welding (RRC) - Job ProcedureDokumen3 halamanManual Tig Welding (RRC) - Job Proceduretitto84886100% (1)

- JSA For Fabrication WorksDokumen11 halamanJSA For Fabrication Workssurendra behera100% (3)

- JSA Installation of PumpsDokumen6 halamanJSA Installation of Pumpsyc safety100% (2)

- Jsa - Cutting and WeldingDokumen2 halamanJsa - Cutting and WeldingSantos Rex50% (2)

- JSA No. 9 - Safe Use of Pneumatic and Power ToolsDokumen2 halamanJSA No. 9 - Safe Use of Pneumatic and Power ToolsAshok Suresh100% (1)

- Job Safety Analysis: Organization: JSA Number: Work Type: Work Activity: Specific SiteDokumen5 halamanJob Safety Analysis: Organization: JSA Number: Work Type: Work Activity: Specific SiteM M PRADHANBelum ada peringkat

- JSA For Soil ImprovementDokumen4 halamanJSA For Soil ImprovementHilbrecht De Pedro100% (1)

- JSA HandToolsDokumen2 halamanJSA HandToolsCristina Rican100% (3)

- Crane JSADokumen5 halamanCrane JSAKritsada Tiwutanon100% (1)

- JSA For Cutting, Grinding and WeldingDokumen4 halamanJSA For Cutting, Grinding and Weldingyc safety100% (3)

- Hydro Jetting and Sludge RemovalDokumen18 halamanHydro Jetting and Sludge Removalmarvin100% (1)

- JSA Confined Sapce EntryDokumen1 halamanJSA Confined Sapce EntryprasongBelum ada peringkat

- C32 Electronic Unit Injector - Adjust PDFDokumen4 halamanC32 Electronic Unit Injector - Adjust PDFmanu luvunga100% (2)

- SOP Erection TC PDFDokumen3 halamanSOP Erection TC PDFRashidi RahmanBelum ada peringkat

- JSA For Hydro Test Activites (Generic)Dokumen4 halamanJSA For Hydro Test Activites (Generic)Khaled Ismail88% (25)

- Job Safety AnalysisDokumen3 halamanJob Safety AnalysisBhisamS SallehBelum ada peringkat

- JSA PaintingDokumen1 halamanJSA PaintingjonesBelum ada peringkat

- 01 JTSPL WEEKLY CHECK LIST Crane F-15 PDFDokumen5 halaman01 JTSPL WEEKLY CHECK LIST Crane F-15 PDFsanjivan tawdeBelum ada peringkat

- Hot Work: Job Hazard Analysis PT Technic (M)Dokumen4 halamanHot Work: Job Hazard Analysis PT Technic (M)ShahrizatSmailKassim100% (1)

- JSA 08 Gas WeldingDokumen1 halamanJSA 08 Gas Weldingmuthuswamy77Belum ada peringkat

- Form JSA Lifting CraneDokumen6 halamanForm JSA Lifting CraneYeti Srinurhayati100% (1)

- Jsa Pipe Cutting at Fire PumpDokumen5 halamanJsa Pipe Cutting at Fire PumpHow Chin Engineering Sdn BhdBelum ada peringkat

- Lathe Machine Safety OperatingDokumen4 halamanLathe Machine Safety Operatingebad100% (1)

- JSA of Drill Machine UseDokumen1 halamanJSA of Drill Machine UseSumair Khalid100% (1)

- Thyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 7Dokumen4 halamanThyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 7abhijit janaBelum ada peringkat

- JSA Earthpit Construction GeneralDokumen4 halamanJSA Earthpit Construction Generalmukka88Belum ada peringkat

- 4-Safety Violation Report Hemendra Kumar SinghDokumen2 halaman4-Safety Violation Report Hemendra Kumar Singhjithin shankar100% (1)

- Fire Fighting JSADokumen14 halamanFire Fighting JSANikhil Manjrekar83% (6)

- JSA Loading UnloadingDokumen2 halamanJSA Loading UnloadingXtra Babe100% (2)

- Jsa Slip FormDokumen5 halamanJsa Slip Formputrasejahtra50% (2)

- Refueling JSA 4 08 2019 Rev.03 Near WaterDokumen9 halamanRefueling JSA 4 08 2019 Rev.03 Near Waterrisky indra antariBelum ada peringkat

- Jsa forOperatingAForkliftDokumen2 halamanJsa forOperatingAForkliftsupahing supahingBelum ada peringkat

- JSA Unloading & SHIFTING by Manually 10-01-2017Dokumen16 halamanJSA Unloading & SHIFTING by Manually 10-01-2017PAVANKUMAR100% (1)

- NemeDokumen1 halamanNemeTwin Bulls100% (1)

- PTA-JSA-005-Material Handling by Farhana F-15 CraneDokumen6 halamanPTA-JSA-005-Material Handling by Farhana F-15 CraneSaiyad RiyazaliBelum ada peringkat

- Job HAzard Analysis Welding Operations MiftahDokumen3 halamanJob HAzard Analysis Welding Operations MiftahLukmanElekAe100% (2)

- Jsa Grinding Welding Gas CuttingDokumen3 halamanJsa Grinding Welding Gas CuttingQomarudin Comenk100% (2)

- JSA Cable Pulling and Laying WorksDokumen6 halamanJSA Cable Pulling and Laying Workskabir100% (1)

- Jsa For Work at HeightsDokumen4 halamanJsa For Work at Heightsjithin shankar100% (1)

- JSA-Hydraulic Press Testing For PilesDokumen6 halamanJSA-Hydraulic Press Testing For PilesUMUTBelum ada peringkat

- Job Safety AnalysisDokumen4 halamanJob Safety AnalysisDedi Apriadi71% (7)

- Winch MachineDokumen1 halamanWinch MachineJomar Rudolph Cabesas100% (6)

- JSA Excavation PDFDokumen6 halamanJSA Excavation PDFmohamedamine.zemouriBelum ada peringkat

- Job Safety Analysis - Clinker StorageDokumen4 halamanJob Safety Analysis - Clinker StorageMohammed MinhajBelum ada peringkat

- JHA On Erection of Temporary ShedDokumen15 halamanJHA On Erection of Temporary ShedM8Rskn6wcBelum ada peringkat

- JSA UnloadingDokumen4 halamanJSA Unloadinganon_50254931100% (2)

- Jsa Removal Fixing InsulationDokumen2 halamanJsa Removal Fixing InsulationAprilia Rizki Ardila63% (8)

- JSA Loading UnloadingDokumen3 halamanJSA Loading UnloadingRajendra100% (1)

- JSA Installation of GearboxDokumen2 halamanJSA Installation of GearboxDaniel TOMBEBelum ada peringkat

- JSA Tie in ActivitiesDokumen15 halamanJSA Tie in ActivitiesQADEER SHANBelum ada peringkat

- JSA For Scaffolding.Dokumen16 halamanJSA For Scaffolding.jeswinimanualBelum ada peringkat

- Hot Work and Modification PDFDokumen19 halamanHot Work and Modification PDFmyo lwinBelum ada peringkat

- Risk Assessment - Erection of LP Heater 2Dokumen5 halamanRisk Assessment - Erection of LP Heater 2Hanu JemberBelum ada peringkat

- Toyota PDFDokumen54 halamanToyota PDFprasong100% (2)

- 870116a Com Invoice Bar Po 100404Dokumen2 halaman870116a Com Invoice Bar Po 100404prasongBelum ada peringkat

- Intergranular Embrittlement of SS 321 Alloy Due To High Temperature CarburizationDokumen16 halamanIntergranular Embrittlement of SS 321 Alloy Due To High Temperature CarburizationprasongBelum ada peringkat

- Two Way Diverter Technical Specification PDF FreeDokumen94 halamanTwo Way Diverter Technical Specification PDF FreeprasongBelum ada peringkat

- Plate Material SpecificationDokumen24 halamanPlate Material SpecificationprasongBelum ada peringkat

- Pipe Material SpecificationDokumen12 halamanPipe Material SpecificationprasongBelum ada peringkat

- Liner Plate For HRSG Inlet Exp Joint at GT SideDokumen1 halamanLiner Plate For HRSG Inlet Exp Joint at GT SideprasongBelum ada peringkat

- Bms.0100 r1 Bms Manual - Context Scope ResponsibilitiesDokumen1 halamanBms.0100 r1 Bms Manual - Context Scope ResponsibilitiesprasongBelum ada peringkat

- Jsa Removal and Install Expansion JointDokumen1 halamanJsa Removal and Install Expansion JointprasongBelum ada peringkat

- 9053-16-1000 - 01 Stack Threaded BarDokumen4 halaman9053-16-1000 - 01 Stack Threaded BarprasongBelum ada peringkat

- Main Kart Complete Sheet 03 ModelDokumen1 halamanMain Kart Complete Sheet 03 ModelprasongBelum ada peringkat

- Supplier Work Authorization AgreementDokumen1 halamanSupplier Work Authorization AgreementprasongBelum ada peringkat

- W 8benDokumen1 halamanW 8benprasongBelum ada peringkat

- 9009 Anchor Bolt and Nut Mill CertificateDokumen2 halaman9009 Anchor Bolt and Nut Mill CertificateprasongBelum ada peringkat

- 1000-90-0911 - 03 Fabricator Packing and Shipping ProcedureDokumen6 halaman1000-90-0911 - 03 Fabricator Packing and Shipping ProcedureprasongBelum ada peringkat

- GAS Flow: Section Z1-Z1Dokumen1 halamanGAS Flow: Section Z1-Z1prasongBelum ada peringkat

- Note: M12 Screws Not Welded To FlangeDokumen1 halamanNote: M12 Screws Not Welded To FlangeprasongBelum ada peringkat

- Delivery Noted Loading Arm PlatformDokumen1 halamanDelivery Noted Loading Arm PlatformprasongBelum ada peringkat

- Update Notifikasi Depkes FEB 18Dokumen6 halamanUpdate Notifikasi Depkes FEB 18pratistanadia_912023Belum ada peringkat

- Home,: A Solace To Which A Journey Is Never Too Long..Dokumen25 halamanHome,: A Solace To Which A Journey Is Never Too Long..Duvonto RealtyBelum ada peringkat

- OK Flux 231 (F7AZ-EL12) PDFDokumen2 halamanOK Flux 231 (F7AZ-EL12) PDFborovniskiBelum ada peringkat

- Sagar Ovhalkar (Site)Dokumen2 halamanSagar Ovhalkar (Site)Dayanand WasateBelum ada peringkat

- Deaton FE Slab DesignDokumen57 halamanDeaton FE Slab DesignMohamed AliBelum ada peringkat

- Standard Terms & Conditions of Sale Pre-Engineered BuildingsDokumen18 halamanStandard Terms & Conditions of Sale Pre-Engineered BuildingsHongducBuiBelum ada peringkat

- Extended End-Plate Stiffener PDFDokumen2 halamanExtended End-Plate Stiffener PDFaams_sBelum ada peringkat

- HHW 35 m6 GBDokumen6 halamanHHW 35 m6 GBSuper WhippedBelum ada peringkat

- MS275 10 Inch Compound Miter Saw MB4B2ADokumen4 halamanMS275 10 Inch Compound Miter Saw MB4B2ArightoutacontrolBelum ada peringkat

- FM200Dokumen23 halamanFM200Ahmed SherifBelum ada peringkat

- Antena 700 2m - TongyuDokumen2 halamanAntena 700 2m - TongyuLenin Alejandro Ramirez HuaypatinBelum ada peringkat

- Manual Gratis Chery Tig GoDokumen16 halamanManual Gratis Chery Tig GoPaulo Arráiz100% (1)

- Project Management Quick Reference GuideDokumen5 halamanProject Management Quick Reference GuidejcpolicarpiBelum ada peringkat

- Vem BrochureDokumen8 halamanVem BrochureVamshi Krishnam Raju NadimpalliBelum ada peringkat

- Polymers For Transdermal Drug Delivery SystemsDokumen9 halamanPolymers For Transdermal Drug Delivery SystemsAmjadRazaBelum ada peringkat

- No35-Inclined Roof SystemDokumen24 halamanNo35-Inclined Roof SystemKitanovic NenadBelum ada peringkat

- M S 1 1 - M S E 1 1: Hydraulic MotorsDokumen36 halamanM S 1 1 - M S E 1 1: Hydraulic MotorsmehmetBelum ada peringkat

- Maison À BordeauxDokumen5 halamanMaison À BordeauxSpam TestBelum ada peringkat

- KEDDCO BinderDokumen74 halamanKEDDCO BinderWillian FigueroaBelum ada peringkat

- DUNAN Fan Coil UnitDokumen14 halamanDUNAN Fan Coil UnitDjordjeBelum ada peringkat

- UAMDokumen35 halamanUAMVishnu R PuthusseryBelum ada peringkat

- Manual PSW 2600Dokumen18 halamanManual PSW 2600Jc C. GomezBelum ada peringkat

- CFD Analysis of First Stage Nozzle Cooling Optimization in Gas TurbinesDokumen7 halamanCFD Analysis of First Stage Nozzle Cooling Optimization in Gas TurbinesMahmood ElnagarBelum ada peringkat

- Investigate The Natural Time Period, Base Shear, Displacement, Story Drift, Story Stiffness by Etabs and Staad ProDokumen4 halamanInvestigate The Natural Time Period, Base Shear, Displacement, Story Drift, Story Stiffness by Etabs and Staad ProEditor IJTSRDBelum ada peringkat

- 4-3 Deflection Due To Bending: 164 Mechanical Engineering DesignDokumen10 halaman4-3 Deflection Due To Bending: 164 Mechanical Engineering DesignSamawat AhsanBelum ada peringkat

- Lube-Tech: Lubricants For Wind TurbinesDokumen6 halamanLube-Tech: Lubricants For Wind TurbinesMC ABelum ada peringkat

- Grabi Al Jubail ProfileDokumen130 halamanGrabi Al Jubail ProfileSlid ISO100% (1)

- 7695v2.1 (G52 76951X8) (A55 G45 - A55 G55)Dokumen70 halaman7695v2.1 (G52 76951X8) (A55 G45 - A55 G55)Dávid SzabóBelum ada peringkat