Pressure Drop Calculation for Item No. 2432 at Varying Clog Conditions

Diunggah oleh

Kailas NimbalkarJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Pressure Drop Calculation for Item No. 2432 at Varying Clog Conditions

Diunggah oleh

Kailas NimbalkarHak Cipta:

Format Tersedia

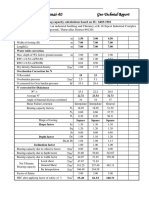

Pressure Drop Calculations for Item No:.

2432

Density :.992.85 Kg/m3

Viscocity:. 1 Cp

Process At 100% Clean At 50% Clogged

Strainer Pipe Screen Condition Condition

Parameters

Outside

Size(mm) 50(2)" 6.03 Diameter of Screen(cm) 6.00 p - Density of Liquid in gm/cm3 0.993 0.993

Diameter(cm)

Type Y STRAINER Pipe Schedule(Sch) STD Length of Screen(cm) 13.00 μ - viscosity of Liquid in gm/cm-s 0.010 0.010

Surface Area

Class Rating 150 Thickness (cm) 0.391 245.08 Flow in Cm3/sec 3111.024 3111.024

of Screen(SAS) (cm2) at Clean Condition

V - Superficial Velocity of fluid

Surface Area of Screen 1t 50%

Inside Diameter 5.2 122.54 based upon the gross area of the 50.153 100.306

Clogged

screen cm/sec

Net Area of Screen used for filtering (cm2)

Area of Pipe 21.6 62.03 V/α = 198.147 396.295

at Clean Condition

Net Area of Screen used for filtering @ 50%

31.02 (p/μ) = 99.285 99.285

Clogged (cm2)

Ratio at Clean Condition 2.87 Re - Reynolds No=D*(V/α)*(p/μ) 739.510 1479.020

C - Coefficient of discharge

Ratio at 50% Clogged 1.43 1.000 1.300

(From Perry page no. 5-40)

Q - % opening in 20 Wire Mesh for 28 SWG 49.60 g - Gravitational force cm/sec2 981.000 981.000

K - Velocity Head Loss =

P- Perforation (6mm Hole,8mm pitch) 51.03 14.609 8.645

(1/(C*C) * (1-(α*α)/(α*α)))

Pressure Drop (ΔP) =

D - Opening Width (cm) 0.04 18.595 44.013

(K*p*V*V)/2*g

Pressure Drop (ΔP) Inches of

α - Effective opening area mmSq 0.25 7.321 17.328

Water

Pressure Drop (ΔP) Kg/cm2(g) 0.018 0.043

Pressure Drop (ΔP) mBar 17.877 42.312

Anda mungkin juga menyukai

- Pressure drop calculations for item no. 8402 A/BDokumen1 halamanPressure drop calculations for item no. 8402 A/BKailas Nimbalkar0% (1)

- Pressure drop calculation for item no. 2412A/BDokumen1 halamanPressure drop calculation for item no. 2412A/BKailas NimbalkarBelum ada peringkat

- Pressure Drop Calculations - BST-001 Flow:.25m3/hr Density:.904 Kg/m3 Viscocity:. 457 CPDokumen1 halamanPressure Drop Calculations - BST-001 Flow:.25m3/hr Density:.904 Kg/m3 Viscocity:. 457 CPAssure TurbinesBelum ada peringkat

- Pressure Drop Calculations - BST-005 Flow:.15m3/hr Density:.860 Kg/m3 Viscocity:. 3186 CPDokumen1 halamanPressure Drop Calculations - BST-005 Flow:.15m3/hr Density:.860 Kg/m3 Viscocity:. 3186 CPAssure TurbinesBelum ada peringkat

- Conical Strainer PDC 40NBDokumen1 halamanConical Strainer PDC 40NBKailas Nimbalkar0% (1)

- DESIGN OF RC RETAINING WALLDokumen1 halamanDESIGN OF RC RETAINING WALLAHSANBelum ada peringkat

- FRNT ColDokumen96 halamanFRNT ColARUN RAWATBelum ada peringkat

- Jpf5-E-0022 - 17 08 22Dokumen10 halamanJpf5-E-0022 - 17 08 22pradeep yadavBelum ada peringkat

- Grade Slab ACI 150thkDokumen7 halamanGrade Slab ACI 150thkraahul_nBelum ada peringkat

- Retaining Wall ExcelDokumen82 halamanRetaining Wall ExcelOuseppachan AmbookenBelum ada peringkat

- Basic Weights Calc - ACHEDokumen6 halamanBasic Weights Calc - ACHESiva ShankarBelum ada peringkat

- 23-HA-103 - Rating Case - 1Dokumen11 halaman23-HA-103 - Rating Case - 1yadav yadavBelum ada peringkat

- DESIGN OF FLOOR SLAB (0.15m Thick)Dokumen9 halamanDESIGN OF FLOOR SLAB (0.15m Thick)Living Life100% (1)

- Weight CalculationDokumen13 halamanWeight CalculationPankaj BijweBelum ada peringkat

- Wind Girder Calculations: Appendix 'M' Is Applicable?Dokumen8 halamanWind Girder Calculations: Appendix 'M' Is Applicable?Anonymous LKi1w1uBelum ada peringkat

- ALDECK3Dokumen5 halamanALDECK3Mustafa ÇakırBelum ada peringkat

- Output Summary: SI UnitsDokumen1 halamanOutput Summary: SI Unitsdaboo sanatBelum ada peringkat

- Purlin - Check - Hat SectionDokumen2 halamanPurlin - Check - Hat SectionPrince MittalBelum ada peringkat

- Laboratory Test ResultDokumen1 halamanLaboratory Test ResultAwan KintonBelum ada peringkat

- Slab design summary and reinforcement checksDokumen5 halamanSlab design summary and reinforcement checksShingirai JoeBelum ada peringkat

- Tugas Take Home UTSDokumen18 halamanTugas Take Home UTSdodikBelum ada peringkat

- One Way SlabDokumen23 halamanOne Way SlabmeerahBelum ada peringkat

- Progen: Pipe Thickness Calculation As Per IBR 350 Eqn.Dokumen4 halamanProgen: Pipe Thickness Calculation As Per IBR 350 Eqn.P s JagatheesanBelum ada peringkat

- Butterfly Valve Hydrodynamic Calculation Sheet: S D Max 3Dokumen6 halamanButterfly Valve Hydrodynamic Calculation Sheet: S D Max 3Ly Thanh HaBelum ada peringkat

- Slab DesignDokumen9 halamanSlab Designsuleiman.ahBelum ada peringkat

- Crack Width CheckDokumen2 halamanCrack Width CheckJitendra SinghBelum ada peringkat

- Chocolatos 2Dokumen1 halamanChocolatos 2Hariyono Rudi NovantoBelum ada peringkat

- HTRI Heat Exchanger Rating SummaryDokumen6 halamanHTRI Heat Exchanger Rating SummaryCami Vander MeyBelum ada peringkat

- Idris Kris Shandy - 203303048Dokumen1 halamanIdris Kris Shandy - 203303048Idris KrisBelum ada peringkat

- Design of SlabsDokumen42 halamanDesign of SlabsMuralidargouda BhagavantagoudarBelum ada peringkat

- Geo-Tech Report for Industrial BuildingDokumen1 halamanGeo-Tech Report for Industrial BuildingAbhijeet OundhakarBelum ada peringkat

- Item Date Checker Contact Email Crack Width 10-May-07 Tayeb KazemiDokumen8 halamanItem Date Checker Contact Email Crack Width 10-May-07 Tayeb KazemipradeeshBelum ada peringkat

- Crack Width Check BS5400 4Dokumen4 halamanCrack Width Check BS5400 4fontec.info2023Belum ada peringkat

- Eccentic Footing (One Side)Dokumen25 halamanEccentic Footing (One Side)Raaj NagpalBelum ada peringkat

- STUP Consultants P. LTD.: 2.6.1 Analysis of Pile Section Under Bending and ThrustDokumen9 halamanSTUP Consultants P. LTD.: 2.6.1 Analysis of Pile Section Under Bending and Thrustraja mistryBelum ada peringkat

- B41OA Data Sheet 2015-2016Dokumen10 halamanB41OA Data Sheet 2015-2016Leanne ChewBelum ada peringkat

- See Runtime Message Report For Warning MessagesDokumen1 halamanSee Runtime Message Report For Warning MessagesAnonymous Q2hxfbghBelum ada peringkat

- Floating RC Slab Design (EN1992)Dokumen5 halamanFloating RC Slab Design (EN1992)Shingirai JoeBelum ada peringkat

- ChocolatosDokumen1 halamanChocolatosHariyono Rudi NovantoBelum ada peringkat

- Depth of Neutral Axis For Long Term Ec - (X) : Directly Under The Bar LocationDokumen2 halamanDepth of Neutral Axis For Long Term Ec - (X) : Directly Under The Bar LocationUsama ChauguleBelum ada peringkat

- Seal Gas - 1Dokumen1 halamanSeal Gas - 1bondsivamaniBelum ada peringkat

- PramonnoDokumen1 halamanPramonnoHariyono Rudi NovantoBelum ada peringkat

- RicisDokumen1 halamanRicisHariyono Rudi NovantoBelum ada peringkat

- Appendix 10: Base Slab Crack Width Calculation (As Per IS 456: ANNEX: F)Dokumen2 halamanAppendix 10: Base Slab Crack Width Calculation (As Per IS 456: ANNEX: F)Md Nadeem Akhtar100% (1)

- FS22-002-Process Calculation For Chiller - Rev.A-Bundle OptionDokumen3 halamanFS22-002-Process Calculation For Chiller - Rev.A-Bundle OptionJason DoBelum ada peringkat

- Lowering in Calculation: Calculation of Deflection CheckDokumen5 halamanLowering in Calculation: Calculation of Deflection CheckVinodParameswaran NairBelum ada peringkat

- Energy Cables Catalogue 150Dokumen1 halamanEnergy Cables Catalogue 150Thiago BarcelosBelum ada peringkat

- Reliance: Mangalore ST 12-May-2020 1 - 4068Dokumen4 halamanReliance: Mangalore ST 12-May-2020 1 - 4068Anilkumar VidelaBelum ada peringkat

- Design of two-way reinforced concrete slabDokumen15 halamanDesign of two-way reinforced concrete slabMohammed Saleem Syed KhaderBelum ada peringkat

- NSW Pump Calculation 26-05-2017-r4Dokumen28 halamanNSW Pump Calculation 26-05-2017-r4Ardian200% (1)

- Mohammad Al Mazroui Villa (Plot#8) : Storm Water Calculation SummaryDokumen1 halamanMohammad Al Mazroui Villa (Plot#8) : Storm Water Calculation Summaryroula abi rachedBelum ada peringkat

- RCC92 Ribbed Slabs (Tables)Dokumen7 halamanRCC92 Ribbed Slabs (Tables)Cioabla BogdanBelum ada peringkat

- API 650 RF Pad Calculation PDFDokumen1 halamanAPI 650 RF Pad Calculation PDFBimal DeyBelum ada peringkat

- API 650 RF Pad Calculation PDFDokumen1 halamanAPI 650 RF Pad Calculation PDFRakeshBelum ada peringkat

- 1-WAY SOLID CONCRETE SLAB DESIGN To BS 81101997 Table 3.12Dokumen7 halaman1-WAY SOLID CONCRETE SLAB DESIGN To BS 81101997 Table 3.12Tamer. ThekingBelum ada peringkat

- Calculation MOLDokumen2 halamanCalculation MOLIrsyad RosyidiBelum ada peringkat

- Materials Science and Technology of Optical FabricationDari EverandMaterials Science and Technology of Optical FabricationBelum ada peringkat

- Pressuremeter Testing: Methods and InterpretationDari EverandPressuremeter Testing: Methods and InterpretationPenilaian: 5 dari 5 bintang5/5 (2)

- Analytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportDari EverandAnalytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportBelum ada peringkat

- Aerothermodynamics of Turbomachinery: Analysis and DesignDari EverandAerothermodynamics of Turbomachinery: Analysis and DesignBelum ada peringkat

- Radhika Waste ManagementDokumen28 halamanRadhika Waste ManagementKailas NimbalkarBelum ada peringkat

- Authorization LetterDokumen1 halamanAuthorization LetterKailas NimbalkarBelum ada peringkat

- Abhijit Lagare 2018 - 3Dokumen3 halamanAbhijit Lagare 2018 - 3Kailas NimbalkarBelum ada peringkat

- Performance LogDokumen1 halamanPerformance LogKailas NimbalkarBelum ada peringkat

- MouDokumen4 halamanMouadishBelum ada peringkat

- Nabl 400Dokumen481 halamanNabl 400parveshnain19Belum ada peringkat

- PROPOSAL OF GREEN HC - MSW - Eng - Ver.1Dokumen77 halamanPROPOSAL OF GREEN HC - MSW - Eng - Ver.1Kailas NimbalkarBelum ada peringkat

- THERMODYNAMIC PROPERTIESDokumen15 halamanTHERMODYNAMIC PROPERTIESKailas NimbalkarBelum ada peringkat

- Specification SheetDokumen1 halamanSpecification SheetKailas NimbalkarBelum ada peringkat

- 2 Mass Production ProductsDokumen12 halaman2 Mass Production ProductsKailas NimbalkarBelum ada peringkat

- Kailas Nimbalkar expense report listing various items purchased from Aug-Oct 2020Dokumen6 halamanKailas Nimbalkar expense report listing various items purchased from Aug-Oct 2020Kailas NimbalkarBelum ada peringkat

- Service Customer DetailsDokumen12 halamanService Customer DetailsKailas NimbalkarBelum ada peringkat

- Problem Solving in Solid Waste Engineering: January 2012Dokumen66 halamanProblem Solving in Solid Waste Engineering: January 2012Kailas Nimbalkar100% (1)

- Contact Details of RTAsDokumen487 halamanContact Details of RTAsnir0% (1)

- MKT 078 04 AG ST Bioactive Surface TreatmentDokumen2 halamanMKT 078 04 AG ST Bioactive Surface TreatmentKailas NimbalkarBelum ada peringkat

- OPERATIONS-Hyderabad CompressedDokumen16 halamanOPERATIONS-Hyderabad CompressedKailas NimbalkarBelum ada peringkat

- Pune Cs CX Mar12Dokumen42 halamanPune Cs CX Mar12Kailas NimbalkarBelum ada peringkat

- Fungal Remediation and Protective Antimicrobial Treatment of A Grossly Contaminated Ten Story HospitalDokumen7 halamanFungal Remediation and Protective Antimicrobial Treatment of A Grossly Contaminated Ten Story HospitalKailas NimbalkarBelum ada peringkat

- ACAC Council-Certified Indoor Environmental ConsultantDokumen1 halamanACAC Council-Certified Indoor Environmental ConsultantKailas NimbalkarBelum ada peringkat

- StepsDokumen1 halamanStepsKailas NimbalkarBelum ada peringkat

- GoalsDokumen8 halamanGoalsKailas NimbalkarBelum ada peringkat

- Method Statement Titania VS 1 2 and Titania FAir (INDIA)Dokumen12 halamanMethod Statement Titania VS 1 2 and Titania FAir (INDIA)Kailas NimbalkarBelum ada peringkat

- GOALSDokumen4 halamanGOALSKailas NimbalkarBelum ada peringkat

- Bharti Tools Payment 12980Dokumen1 halamanBharti Tools Payment 12980Kailas NimbalkarBelum ada peringkat

- BSF CatalogDokumen2 halamanBSF CatalogKailas NimbalkarBelum ada peringkat

- Pressure Vessel & Air Receiver CatalogDokumen16 halamanPressure Vessel & Air Receiver CatalogrenebbBelum ada peringkat

- E-Way Bill System-DELIVERY CHALLAN-1Dokumen1 halamanE-Way Bill System-DELIVERY CHALLAN-1Kailas NimbalkarBelum ada peringkat

- Eaton Self Cleaning StrainerDokumen40 halamanEaton Self Cleaning StrainerKailas NimbalkarBelum ada peringkat

- Smart OrbitersDokumen2 halamanSmart OrbitersKailas NimbalkarBelum ada peringkat

- Air Receivers: Technology You Can TrustDokumen6 halamanAir Receivers: Technology You Can TrustNorman FerdianBelum ada peringkat

- Date: 11 April 2023 Project: Contract-N111-Design and Construction of North South Corridor (NSC) Between Ang Mo Kio Ave 9 and SG SeletarDokumen18 halamanDate: 11 April 2023 Project: Contract-N111-Design and Construction of North South Corridor (NSC) Between Ang Mo Kio Ave 9 and SG SeletarYing CeBelum ada peringkat

- EPOM F OBE ASSIGNMENT Shuvro Sankar Sen 18-37524-1Dokumen7 halamanEPOM F OBE ASSIGNMENT Shuvro Sankar Sen 18-37524-1Shuvro Sankar SenBelum ada peringkat

- NFPA Codes & Standards - 4Dokumen1 halamanNFPA Codes & Standards - 4karpanaiBelum ada peringkat

- 1 1-QPDokumen8 halaman1 1-QPQasim BilalBelum ada peringkat

- Subject: Hydraulics: Faiz Ul Hassan Roll No - Ct-2K18-16Dokumen13 halamanSubject: Hydraulics: Faiz Ul Hassan Roll No - Ct-2K18-16Eng Zeeshan TariqBelum ada peringkat

- Wax vs Oil: Key DifferencesDokumen26 halamanWax vs Oil: Key DifferencesJessa Mae Malinao100% (2)

- Synthesis of Potassium Tris (Oxalato) Ferrate (III)Dokumen7 halamanSynthesis of Potassium Tris (Oxalato) Ferrate (III)Timothy Tan83% (36)

- Engineering Dynamics Problem Set 9Dokumen4 halamanEngineering Dynamics Problem Set 9700tyBelum ada peringkat

- Darshan Ranganathan - A Tribute: Personal NewsDokumen3 halamanDarshan Ranganathan - A Tribute: Personal NewsDeepak House Videos collectionBelum ada peringkat

- Selectivity in BioleachingDokumen8 halamanSelectivity in BioleachingemiaBelum ada peringkat

- Phreeqc 3 2013 ManualDokumen519 halamanPhreeqc 3 2013 ManualpauloalpeBelum ada peringkat

- TEMPOS - Manual - WebDokumen51 halamanTEMPOS - Manual - WebFelipe RosasBelum ada peringkat

- Bio VentingDokumen16 halamanBio VentingMARIA KARREY CABICO. SUNGAHIDBelum ada peringkat

- The Elements of the Periodic TableDokumen1 halamanThe Elements of the Periodic TableDragos AndrianaBelum ada peringkat

- 5a3b861fe4b08acd45659ace 5ba3e3dae4b0639d7c27ddc3 1554554852182 PDFDokumen48 halaman5a3b861fe4b08acd45659ace 5ba3e3dae4b0639d7c27ddc3 1554554852182 PDFÑikhil Ķumar100% (1)

- Lesson 3 - Atomos, Aristotle and Alchemy (Chemistry Before Modern History)Dokumen18 halamanLesson 3 - Atomos, Aristotle and Alchemy (Chemistry Before Modern History)Eji Alcoreza100% (1)

- Redox Reaction NotesDokumen5 halamanRedox Reaction Notesapi-316351882Belum ada peringkat

- High Nitrogen Nickel-Free Austenitic Stainless Steel: A Promising Coronary Stent MaterialDokumen13 halamanHigh Nitrogen Nickel-Free Austenitic Stainless Steel: A Promising Coronary Stent Materialayman aliBelum ada peringkat

- NON-DESTRUCTIVE TESTING MCQ BANKDokumen6 halamanNON-DESTRUCTIVE TESTING MCQ BANKMegha DixitBelum ada peringkat

- Machine Design & CAD - Lecture 2Dokumen18 halamanMachine Design & CAD - Lecture 2Adil KhawajaBelum ada peringkat

- Nitration of Methyl Benzoate to Methyl-3-nitrobenzoateDokumen6 halamanNitration of Methyl Benzoate to Methyl-3-nitrobenzoateRun Xiang Ang100% (2)

- PoteniometryDokumen85 halamanPoteniometrymalyaaBelum ada peringkat

- Chapter 6 Aromatic CompoundsDokumen41 halamanChapter 6 Aromatic Compoundsnur izzaidahBelum ada peringkat

- Bonderite M-Fe 1070 (Known As Bonderite 1070)Dokumen6 halamanBonderite M-Fe 1070 (Known As Bonderite 1070)Jean GuerraBelum ada peringkat

- Erdenet Concentrate Desliming - Alternate gMAX4 Simulation PDFDokumen1 halamanErdenet Concentrate Desliming - Alternate gMAX4 Simulation PDFolziitulga batboldBelum ada peringkat

- Multistep Synthesis of PhenytoinDokumen8 halamanMultistep Synthesis of PhenytoinHussain RazaBelum ada peringkat

- Properties of Crude Oil and Petroleum ProductsDokumen54 halamanProperties of Crude Oil and Petroleum ProductsMihaelaPaval0% (1)

- 4 FlotationDokumen27 halaman4 FlotationAnonymous c8tyA5XlBelum ada peringkat

- Absorption SpectrometerDokumen8 halamanAbsorption SpectrometerAshley Lumbreras0% (1)

- Refractories OverviewDokumen54 halamanRefractories OverviewArun Kumar S.L.Belum ada peringkat