MECH (6th Sem) Seminar Topics (MACHINE DESIGN) : SR No. Name of Student Roll No. Topic

Diunggah oleh

Harman S Saini0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

23 tayangan2 halamanRac document ielts punchuatio

Judul Asli

Seminar-1

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniRac document ielts punchuatio

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

23 tayangan2 halamanMECH (6th Sem) Seminar Topics (MACHINE DESIGN) : SR No. Name of Student Roll No. Topic

Diunggah oleh

Harman S SainiRac document ielts punchuatio

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 2

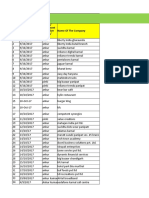

MECH ( 6th Sem ) Seminar Topics (MACHINE DESIGN)

Sr No. Name Of Student Roll No. Topic

1 Abhishek Tripathi 2016/162

2 Akash Kumar 2016/164

Design procedure, Characteristics of a good

3 Akash Pratap Gautam 2016/165

designer,stress concentration

4 Akshay Aneja 2016/166

5 Akul Pawar 2016/167

6 Aman Partap Gautam 2016/168

Properties of engineering materials: elasticity, plasticity,

7 Ankit Kumar 2016/169

malleability, ductility, toughness, hardness and

8 Armanjot Singh 2016/170 resilience. Fatigue,

creep, tenacity, strength

9 Ashok Kumar 2016/171

Selection of materials, criterion of material selection

10 Bharat Mittal 2016/172

11 Chetan Sharma 2016/174

12 Dilpreet Singh 2016/175

Classification of loads Design under

13 Divyansh Kaushik 2016/176

tensile, compressive and torsional loads.

14 Gagandeep Singh 2016/177

15 Gurinderjeet Singh 2016/179

16 Harmandeep Singh 2016/183 Type of shaft, shaft materials, Type of loading on

17 Harmanpreet Singh 2016/184 shaft,Shaft subjected to torsion only, determination of

18 Lalit Kumar 2016/186 shaft diameter (hollow

19 Manmeet Singh Chahal 2016/188 and solid shaft) on the basis of :

20 Manpreet Singh 2016/189 - Strength criterion

21 Mayank Singhal 2016/191

22 Munish Kumar 2016/192

Types of key, materials of key, functions of key Failure

23 Navneet Singh 2016/193

of key (by Shearing and Crushing).

24 Pardeep Kumar 2016/194

25 Pranave Batta 2016/195

26 Rahul Ahuja 2016/196

27 Ripul 2016/197 Knuckle Joints – Different parts of the joint, material

28 Ritik Goyal 2016/198 used for the

29 Sahil Verma 2016/199 joint, type of knuckle Joint, design of the knuckle joint.

30 Sanvir Singh 2016/200

31 Sarbpreet Lal S. Bassan 2016/201

32 Shubham Kumar 2016/203 Cotter Joint – Different parts of the spigot and socket

33 Sourav Kaushal 2016/205 joints,

34 Sourav Kumar Dhiman 2016/206 Design of spigot and socket joint

35 Taran Verma 2016/207

36 Tushar 2016/208

37 Vaibhav 2016/209 Riveted Joints. : Rivet materials, Rivet heads, leak

38 Varun Kumar 2016/210 proofing of

39 Veeren Sharma 2016/211 riveted joint – caulking and fullering.

40 Vijay Kumar 2016/212

41 Yash Chawla 2016/213

42 Yogesh Sharma 2016/214 Necessity of a coupling, advantages of a coupling, types

43 Ajay Singh 2017/226 of couplings, design of

44 Amandeep Singh 2017/227 muff coupling, design of flange coupling.

45 Butta Singh 2017/229

46 Gurdeep Singh 2017/230

47 Gurdeep Singh 2017/231

Introduction, Advantages and Disadvantages of screw

48 Gurpyar Singh 2017/232

joints,Important terms used in screw threads,

49 Karan Dalla 2017/233

50 Krishan Kumar 2017/234

51 Lakhwinder Singh 2017/235

52 Lovepreet Singh 2017/236

Design of key (Determination of key dimension) Effect of

53 Manga ram 2017/237

keyway on shaft strength.

54 Mukesh Kumar 2017/238

55 Narinder Singh 2017/239

56 Nitin Yadav 2017/241

57 Paramjit Singh 2017/242

Comparison of designed and undesigned work Design

58 Parminder Singh 2017/243

– Definition, Type of design, necessity of design

59 Parwinder Singh 2017/244

60 Rashandeep Singh 2017/245

61 Sajmer Chander Gupta 2017/246

62 Simran 2017/249

63 Simranjeet Singh 2017/250 methods to reduce stress concentration,

64 Sourav Singla 2017/251 fatigue, endurance limit. General design consideration

65 Damandeep Singh 2015/179

66 Lovepreet Singh 2015/199

67 Gagandeep Singh 2015/184

68 Sukhdeep Singh 2015/218 Various types of Riveted joints, Types of Welding joints

69 Shubham Sampson 2015/215

Anda mungkin juga menyukai

- SR - No Name Type Registration NumberDokumen10 halamanSR - No Name Type Registration Numberaman3327Belum ada peringkat

- KandaghatDokumen17 halamanKandaghattaniya thakurBelum ada peringkat

- Titans CataDokumen88 halamanTitans CataashielanieBelum ada peringkat

- FarmerList HISARDokumen174 halamanFarmerList HISARDk ZINDWANBelum ada peringkat

- List of Architects in LkoDokumen9 halamanList of Architects in LkoKushal DubeyBelum ada peringkat

- Waiting List of Candidates For AdmissionDokumen4 halamanWaiting List of Candidates For AdmissionNeelotpal TripathiBelum ada peringkat

- Norton WeldingMetalFabCatalog 2011Dokumen182 halamanNorton WeldingMetalFabCatalog 2011RSR_2K5364Belum ada peringkat

- Excel Functions Guide: CONCAT, VLOOKUP, PIVOT Tables & MoreDokumen19 halamanExcel Functions Guide: CONCAT, VLOOKUP, PIVOT Tables & MoreHarshvardhan PatilBelum ada peringkat

- Technolax Trading Employee RecordsDokumen6 halamanTechnolax Trading Employee Recordspraveenraj murugadassBelum ada peringkat

- Date Name of Company Name of Party PurposeDokumen2 halamanDate Name of Company Name of Party PurposelaveshBelum ada peringkat

- Employee Listing with DetailsDokumen110 halamanEmployee Listing with DetailsGanesh VamsharajBelum ada peringkat

- Dandamudi PDF To ExcelDokumen354 halamanDandamudi PDF To ExcelYesBroker InBelum ada peringkat

- Pto Oct22Dokumen6 halamanPto Oct22Saurabh GuptaBelum ada peringkat

- Kabbani Project: Project List W/ ID'sDokumen1 halamanKabbani Project: Project List W/ ID'sAlbyBelum ada peringkat

- POst Match Presentation SpeechDokumen5 halamanPOst Match Presentation SpeechMelissa Murray100% (2)

- Customer List PDFDokumen4 halamanCustomer List PDFN B BabuBelum ada peringkat

- Ug-Mechanical Engineering 2015-19 Batch Placement Record: Maintained By: Shailendra Rai, Ayush KumarDokumen4 halamanUg-Mechanical Engineering 2015-19 Batch Placement Record: Maintained By: Shailendra Rai, Ayush KumarSASWAT MISHRABelum ada peringkat

- NomenclatureDokumen6 halamanNomenclatureSawai PariharBelum ada peringkat

- ACMA Executive Committee 2019-20Dokumen2 halamanACMA Executive Committee 2019-20Vipul KhandelwalBelum ada peringkat

- NNNNNDokumen4 halamanNNNNNsahilBelum ada peringkat

- 5th B MST 1 and 2 Compiled ResultDokumen18 halaman5th B MST 1 and 2 Compiled ResultSukhmander SinghBelum ada peringkat

- A Study and Comparision of Normal Concrete and Admixture Mixed ConcreteDokumen4 halamanA Study and Comparision of Normal Concrete and Admixture Mixed ConcreteCanon chaeBelum ada peringkat

- New Chainless Bicycle Project ReportDokumen30 halamanNew Chainless Bicycle Project Reportshubham gupta58% (12)

- Report ArCacheItemDokumen96 halamanReport ArCacheItemShwetta BajpaiBelum ada peringkat

- Placement Manager RecordsDokumen36 halamanPlacement Manager Recordsmanoj yadav100% (1)

- CashlessGarage Motor MultiBrandDokumen87 halamanCashlessGarage Motor MultiBrandraginisehmbiBelum ada peringkat

- Architects State WiseDokumen674 halamanArchitects State Wiseakash advisorsBelum ada peringkat

- Architects Delhi NCRDokumen10 halamanArchitects Delhi NCRAbhishek MishraBelum ada peringkat

- List of Architect Hyderabad Metro PolitanDokumen70 halamanList of Architect Hyderabad Metro PolitanMalani MarblesBelum ada peringkat

- March 2017 IssueDokumen96 halamanMarch 2017 IssuesurumyBelum ada peringkat

- Institute Name India Rankings 2017 ID DisciplineDokumen1 halamanInstitute Name India Rankings 2017 ID DisciplineManprit SinghBelum ada peringkat

- Blue house T20 cricket Tournament player listDokumen5 halamanBlue house T20 cricket Tournament player listanup kumar paulBelum ada peringkat

- Wa0023Dokumen7 halamanWa0023rahilBelum ada peringkat

- Tires and Wheels GuideDokumen12 halamanTires and Wheels GuideReneChoquetteBelum ada peringkat

- Organization ChartDokumen1 halamanOrganization ChartTARUN PALBelum ada peringkat

- Loop 1Dokumen1 halamanLoop 1anandmuthuraj1950Belum ada peringkat

- Database Mastersheet (AutoRecovered)Dokumen176 halamanDatabase Mastersheet (AutoRecovered)Aastha Singh0% (2)

- Architects and Construction Companies ListDokumen1 halamanArchitects and Construction Companies ListShwetaBelum ada peringkat

- Civil, Mechanical, Electrical Engineering Roll of HonourDokumen5 halamanCivil, Mechanical, Electrical Engineering Roll of HonourishuBelum ada peringkat

- Imba Sem - V CUJ Centre For Business Administration S. No Name Registration NoDokumen10 halamanImba Sem - V CUJ Centre For Business Administration S. No Name Registration NoAkashbaldwinBelum ada peringkat

- Student Registration DatabaseDokumen14 halamanStudent Registration DatabaseSubhashBelum ada peringkat

- ACMA MembersDokumen170 halamanACMA MembersSiddharth Pant100% (4)

- Abrasive Products Catalogue GuideDokumen8 halamanAbrasive Products Catalogue GuideChristopherBelum ada peringkat

- FMG List1Dokumen104 halamanFMG List1Aman DalmiaBelum ada peringkat

- Workers, Staffs & Equip DocsDokumen10 halamanWorkers, Staffs & Equip Docspraveenraj murugadassBelum ada peringkat

- Irc Gov in 116 2014Dokumen20 halamanIrc Gov in 116 2014Debasis Pal100% (1)

- Architech DBDokumen90 halamanArchitech DBTrilok YadavBelum ada peringkat

- K-Series Tire Guide AEXQ0403Dokumen24 halamanK-Series Tire Guide AEXQ0403Jairo PalaciosBelum ada peringkat

- Manro_present - GmbHDokumen11 halamanManro_present - GmbHThillai RajanBelum ada peringkat

- Tracker Geo NorthDokumen358 halamanTracker Geo NorthKumar AbhishekBelum ada peringkat

- Grinding: Name:-Snehal Chauhan and Rucha Date Submitted To: - Mr. Mudit SharmaDokumen15 halamanGrinding: Name:-Snehal Chauhan and Rucha Date Submitted To: - Mr. Mudit SharmaRishikesh DateBelum ada peringkat

- Mitsubishi CatalogDokumen76 halamanMitsubishi CatalogKiran Kumar K TBelum ada peringkat

- List of Seafarers with Ranks and Pass NumbersDokumen7 halamanList of Seafarers with Ranks and Pass NumbersDELTA MARITIMEBelum ada peringkat

- Department of Mechanical Engineering: S. No Year of Pass Out Name of The Student Work DepartmentDokumen1 halamanDepartment of Mechanical Engineering: S. No Year of Pass Out Name of The Student Work Departmentparthasarathi parthuBelum ada peringkat

- CEP Part ManualDokumen179 halamanCEP Part ManualNiten Gupta50% (2)

- Architect List PunjabDokumen11 halamanArchitect List Punjabkapil100% (2)

- Rodamientos Lineales NSKDokumen54 halamanRodamientos Lineales NSKAriel Linder Ureña MontenegroBelum ada peringkat

- 1.3.2. Beams On Elastic Foundation: Shallow FoundationsDokumen54 halaman1.3.2. Beams On Elastic Foundation: Shallow FoundationsENGIDABelum ada peringkat

- Exp. 7 Gas DiffusionDokumen2 halamanExp. 7 Gas DiffusionElaine PuiBelum ada peringkat

- Assig 1Dokumen4 halamanAssig 1atharvaBelum ada peringkat

- Measure Friction Factors in Pipe Flow ExperimentDokumen38 halamanMeasure Friction Factors in Pipe Flow Experimentdivikesh kumarBelum ada peringkat

- Influence Lines: University of San Carlos - Department of Civil EngineeringDokumen31 halamanInfluence Lines: University of San Carlos - Department of Civil EngineeringRex John TapungotBelum ada peringkat

- Magnus Effect ApplicationDokumen16 halamanMagnus Effect ApplicationSyed Imtiaz Ali Shah100% (1)

- Subsonic Wind Tunnel TestingDokumen20 halamanSubsonic Wind Tunnel TestingGovardhan ReddyBelum ada peringkat

- Power Transmission Equipment: Mechanical SystemsDokumen2 halamanPower Transmission Equipment: Mechanical SystemsAnonymous q9eCZHMuSBelum ada peringkat

- 107 ConcreteDokumen44 halaman107 Concretenoadspls2029Belum ada peringkat

- AERO 4630: Structural Dynamics Homework 5: 1 Problem 1: Viscously Damped PendulumDokumen5 halamanAERO 4630: Structural Dynamics Homework 5: 1 Problem 1: Viscously Damped PendulumMD GOLAM SARWARBelum ada peringkat

- Advanced Pattern Cumulative Test-3 (Act-3) : Paper-2Dokumen31 halamanAdvanced Pattern Cumulative Test-3 (Act-3) : Paper-2Tushar Kant0% (1)

- Andrew M Steane Thermodynamics A Complete Undergraduate Course Oxford University Press 2016 66 83Dokumen18 halamanAndrew M Steane Thermodynamics A Complete Undergraduate Course Oxford University Press 2016 66 83Mari SantanaBelum ada peringkat

- Teleportation Is NormalDokumen3 halamanTeleportation Is NormalMokhtar Mohd100% (1)

- (2019) Chemical Bonding and Bonding Models of Main-Group Compounds - Lili ZhaoDokumen65 halaman(2019) Chemical Bonding and Bonding Models of Main-Group Compounds - Lili ZhaoWalter Sperandio SampaioBelum ada peringkat

- 542398flluid in ScramjetDokumen38 halaman542398flluid in ScramjetP KBelum ada peringkat

- CNS 01Dokumen14 halamanCNS 01Manoy BermeoBelum ada peringkat

- Name /or6 Hay Karmal: Important Points For Assignment SubmissionDokumen16 halamanName /or6 Hay Karmal: Important Points For Assignment SubmissionRaj PratyushBelum ada peringkat

- Microwave Engineering PDFDokumen93 halamanMicrowave Engineering PDFbhanumanu0% (1)

- EN380 Naval Materials Science and Engineering Course Notes, U.S. Naval AcademyDokumen16 halamanEN380 Naval Materials Science and Engineering Course Notes, U.S. Naval AcademyGuillaume Hervé POH'SIÉBelum ada peringkat

- Schem SPI Sizing EquationsDokumen62 halamanSchem SPI Sizing EquationsRAJAVIGNESH SBelum ada peringkat

- ExchangersDokumen13 halamanExchangersPeter ArmaosBelum ada peringkat

- Mechanical Au 3-1Dokumen10 halamanMechanical Au 3-1Venkata Sai Kumar NunnaBelum ada peringkat

- (Springer Series in Reliability Engineering) Halil Karadeniz (Auth.) - Stochastic Analysis of Offshore Steel Structures - An Analytical PDFDokumen419 halaman(Springer Series in Reliability Engineering) Halil Karadeniz (Auth.) - Stochastic Analysis of Offshore Steel Structures - An Analytical PDFboboBelum ada peringkat

- Analytic Solution for Torque Between Magnetic DipolesDokumen5 halamanAnalytic Solution for Torque Between Magnetic DipolesLee Kar Huo22% (9)

- Excel CoordinatesDokumen7 halamanExcel CoordinatesjasekanBelum ada peringkat

- COLOUMBDokumen2 halamanCOLOUMBRoldan Ormilla0% (2)

- Unrestrained Beam With End MomentsDokumen9 halamanUnrestrained Beam With End MomentsNikos StathoulopoulosBelum ada peringkat

- THE BOUNDARY CONDITIONS IN DIRECT SIMPLE SHEAR TESTS Developments For Peat Testing at Low Normal StressDokumen92 halamanTHE BOUNDARY CONDITIONS IN DIRECT SIMPLE SHEAR TESTS Developments For Peat Testing at Low Normal StressTiago SchuckBelum ada peringkat

- IJCE v12n4p281 enDokumen11 halamanIJCE v12n4p281 entaw1021966mBelum ada peringkat

- ESVC 2021 Presentation GuidelinesDokumen8 halamanESVC 2021 Presentation GuidelinesRushikesh KaleBelum ada peringkat