Track Rope Calculations For Reversible Ropeways: L U I N L V L

Diunggah oleh

Dheeraj ThakurJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Track Rope Calculations For Reversible Ropeways: L U I N L V L

Diunggah oleh

Dheeraj ThakurHak Cipta:

Format Tersedia

ENGLISH SPECIALI

A. - OS'L42 2.3. 11 1.. , ~.AI\

5.4-. C)\)

Track rope calculations for

reversible ropeways

Prof Gabor Oplatka discusses the question of a possible reduction in track rope design

factors for reversible ropeways

I. The problem tOdifferences nOt only in legal requiremcnts The 101lowi ng co mmenrs I'ebre ro fh e

'fhe subjecr of fmrher possible rcduc~ but also in defin itions of rhe key p:1ramerers, causes of damage listed in Tablc 4:

cions to ehe track cape design f.1cror is not i,e, breaking strengrh of the rope and l1l axi~ • Roller chains: In the etlrly yetirs the rad ii

new. Thc rhinking behind rhe proposal is mum tensile force under operating condi- selected 101' some I'oll er chains were cxces·

based on thc finding arrribured ro the I'Ope~ rions. Whar is considered acceprable will sivel y oprimisric and rhe need for additio nal

way pionc<:r Luis Zucgg co ehe effeet [hat depend on thc individual case. Fatiguc lub rication to thc ropes On th e chains waS

hi gher te lision i l~ ehe (r<lek tOp<: rechlces strength is not always a factor, c,g. in du: nOt recogni:r..ed in lim e. Neverrheless, of rhe

I'CVC I'se bendi ng stress from passage of rhe case of I'opeways builr for re mpO I'ary use 172 [!'ack I'Opes located on roller chains,

ca rriagc whcds of the carriers on ehe linc. and /o r a limited numbe r of rides, and ca n ~ only rhose listed in the mble h;\d tO be dis-

That Gnding is still valid today, ami to that not always be a fana r, c.g, in the case of carded due to permanenr damage.

exrem the pl'Oposal fOl' reduced design fac- rellirbishmenc pl'ojects wh el'e I'igluer radii • Corrosion: Ga lva nizcd wire is rarcly t1Sed

(Q[S is arrracrivc at first sigh r. luve [0 be se!ected because of lim ired space for rrack rapes because of rhe tight tole r-

Rcduci ng ehe track fOpe design factor, in the terminals, T hanks to the improvc- anccs involved . Loca l cO I'I'osion occurs

however, has a !lumbe!' of ol'her, bot'h posi- ments mad e 111 cenns oF rope consrwction bene:l l'il rhe ou rel' wires as rhe resulr ofinrcr·

tive and negative effccrs, wh ich would cLlr~ and lubl'ical'ion, and I'Opeway design raking rupred lubricant flow during the stranding

rcndy sccm tu be of grcarcr import and mo re account of the limits of rope perfo r~ process,

therefore need 1'0 be considered ca reful1y mance. tatiglle st rength req ll lremellts Ctin be • Farigue brea ks fl'om repeated stress

he fore adecision is taken. A num hel' of rhese mer even where rhe ropes :l1'e subjecl'ed [0 I'eversals wirh transverse forccs tend to be

dlccts are listed al1<.! assessed bclow, paying considerable loads, thc exception,

due ,utention {'o {'he operato(s' und erstand- lt can be seen by comparing Tables 1 and

able inrel'e,u in I'Opeway insrallarions I'hal' are 2 I'ha r I'he GEN standard is based on I'he 3. Scope for design factor reductions

simpler, safer a11(! more economica! in terms lower of rhe nat ional design facro rs. To rhar Track rope design 0 1' safety factors Can be

orboth initi,ll and follow-up tosts. extent rhc call for rcduced design factors h"s reduced in tlHee ways:

already bee n met in palt. a. by reducing rhe breaking strength of the

2. State of the art wirrs for the same rope geol11ctry am! at

2.1. Design facto r 2.2. Service life for track ropes constant puH a10ng the I'ope,

'The design facrol' (0 1' safe')' r."cor) of ,he ']"rack wpe pertormance in terms or se r- b. by in c,'easin g pulling force along the

rape is an expression of rhe rario berween vice life in $wirzedand is summal'ized in I'Ope using rhe same rope,

the breaking strcngth or the rope a11(!maxi ~ Tablcs 3 and 4. Ir should be noted that not c, by reducing rope diameter ar cOlismnr

mum tensi le lorce in {,he rope under operat- On\; of the ropes had to bc replaced due to

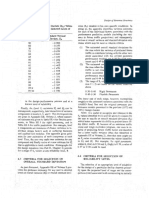

yeafs of number of %

ing condiriol1s. Umi l we are ahle [Q dere i'· pCl'manenr damage dlHing rhe fit's r re n yeal's service copcs di.scarded

mine the safety h'Ctor for the actllal wires of service, and rhat track rapes that have 1 to 10 94 0

with rheir reduced levels of tensiO l1 (which is completed fo rty yta rs of service are consid- J t 10 20 102 11.8

nor ro be expccted in the fOI'eseeab!e ftHlII'e el'ed Guigue- l'esiSl'ing. ( Ti'ack I'OpeS I'el'il'ed 211030 146 8.9

in spite of the cfforcs made), we have ro duc (Q manufacrUl'ing faults, accidcnr· 3 11040 133 9.8

4 1 [0 50 41 0

milke do wirh {'h is design filCtor, although it im!uced damagc or dcmolition/refurbish- SI [0 GO 0 0

is merely arario based on experience :lS a key menc of rhe insml bl'ion :ll'e nor dassifled as

1'0 reasonable rope life. discards. Thc multilayel' srl'anded ropes of Toble 3: Number arid age of track ropes In

The "ctual figure for the design factor eqllal round strands thaI' were discarded Swltzerlarld and percentage discarded due

val'ies from COlllHt'Y ro COllIHl'Y in acco l'- decades ago Me riOt rel evant to rhi s disCliS- to permanent da mage up to 1999 (source:

dance wirh national regulations. Th is is duc sion and have rhe refOl'e been exd uded) (00.) A. Ha ller)

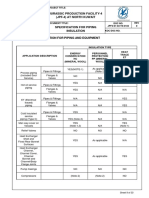

Operali Olia l $Ial e: C,tku lll.led MIll1mU11l Opcrational s[at e

brea lcillg $Ire'l glll breakiu g stre ngeh Without al:tu alcd tral:k ro pe brakc 3.1 5

Without ac[u3[cd track ropc brakc 3. 15 10 3.50 3.05 IQ 3.25 With at.tuatt d track rOp C bn.lte 2.70

Willl aclua[ed tral:k rope brake 2 .80 [0 3.50 2.70 to 3. 15 E):ceptiOI' (lIla:ll: im IllU wjnd aud/Qr ki ng I ropcway closcd) 2.25

Table I: Standard design factors for track ropes In European countries Tab le 2: Design factors fa r minimum brt!oklng strcngth pursuant to the

in 1993 (source: J. P. Larq uetout) CEN sta ndard ....

4 IN i HNAT ION .... l f\OP@ w,\Y "'~VIEW )/2001

• ROPES ENGLISH SPECIAL I

•

il.L e e e e

,."

no· YCIl U R IWU IWO IWB IWB EWB EWß EWß EWß note

Re

2 12 ,., Re

I

term

0

tower

2

line

'.7 0

term.

0

towe r

0

li n e

0

ftC term . lower line

yd

3. 4 17 y" 81 0 0 0 0

•0 0 0

<6 2 17 17 3.

• 0 0 0 0 y" y"

.,

Y'"

2.

3.

4

4

2.

2.

.0

n•

'0

I

0

•

0

•0 •I yu

y"

0

y"

y"

y" 2

2 2. no 0 0 0 0 yd

"

H.S 2

"2. 2

,.,

yt.s 20 A 23 I y" y"

,.,...

42

37 " 30

15 0

0

2

0

2.

10

0

0

I

0

15

I

y"

y"

60 2 33 3 0 30 0 0 0 0 4

3. I 35 2 .0 Y'"

4I 2 35 n. 12 y" y"

26 2 37 .0 0

• 5 YC} 2

'"3. , 2 3.

3.

n.

no

0

0

0

0

0

0

0

0

0

•

0

0

y"

,.. 3

Toble 4: Data (or track ropot dltcarded due to permanent damage in Switzerland (source:A, Haller), Legend: d ~ rope diameter, no, ~ number of

= =

ropes, years =years of service, RL relocatlon, RC roller choln, IWB = internal wire breaks. EWB = external wire breaks. C = corrosion, term. ~

terminal area, tower ~ tower sectlon,lIne = on the IIne, I ;;;; diagram no longer m@onlng(ul after 9th year of service, 2 ;;;; pronounced corrosion da-

mage to who/e rop e. 3 .= pronounced local corroslon on all ropes

puH along the rope (for practical purposes 4. Impacts of lower design factor. ß, The I'csu lrs of an increase in pull along

presllmably rhe most impo rranr case). 4.1. Eff«1S on ,he li ne t hc track ropc:

A combina tio n of rhc t1ucc is also feasi- A. A I'educt" ion in I'he breaking stre ngth of • H,educed sag in l'he indi vidU:l1 rope spn l\s

ble. Ir goes without saying dmt nOne of rhese the wircs has no direct effecr on fhe li ne as • Flarrer fOI'ce disp lace mcnr cUI'ves on rhe

meas ures m:l.Y be applied ro excess. rope lTI<lSS and thus linc geo l1lcrry rel11ain downh ilI sieles of du: towers and thcrcforc

unchan ged . reduced forces iti the haul ropes (wh ich

mea ns sma ll el'~djamerel' haut I'Opes, Sill aller

shcavcs and Icss powcrful prima ry l11overs)

• Shorter hu ngers thnnks to thc reduced

risk of caniage lir[~off I'csulring f,'om rhe

flatter fo rce d isplaccm cnr curvcs and

incrcascd de<irance for carrier swing (which

rneans lower rel'lninal sr['ucrtll'es and rowel's)

• Bigher surface pressures on the mwer

saddles and roller chains (requ iring biggcr

f{ldii, wh ic h me:l.ns f.,1Ste l' passage over the

towers but reduced transverse srabilicy in the

track ropcs on thc towers)

• Reduced lo,ernl deAeccion of the trock

ropes in strong winds

• Highcr forces in thc anchors ami more

powerful rensiOliing ge{l r

• Increased towel' forces ar positive chord

displacement and reduccd tower forces at

neg{l tive chord displ{lcement (wlth rhe pos-

sibili ry of om itting such towers)

C, T he results of rcd ucing rape diameter ar

COnsrallr pull along the rope:

• Lighrer Hack ropes

• Cost savings in terms of track rope pu r-

chtlse, shippillg and install atiol)

• Reduced sag {wirh ["h e sa me effeclS :1S in

secrion ß excepr for the last (Wo)

• Highcr surface press ures On the carriage

., France Plant · 25, avenue de Lyon · BP. 38

wheels

01002 BOURG EN BRESSE Codox FrMC~ • Reduced impact of wavincss in the rapes

Phone +33 4 74 32 82 82 - Telefa x +33 4 74 32 81 05 on the smoorhness of the ride

~~ 'Y"~I, ~r!;IIII!el/~fjfturqPf,(\>In

• R.ed uced !ateral deFl ecdon of ['he track

rapes in strang winds

4.2. Effects On the tr:\ck rope

A. Wi l'es wirh a lower brea ki ng strength

6 !NTERNAT!ONAL ROPEWAY REV!EW 312002

ROPES .

have superior deformacioll properti es ;l.nd therr.:forc grcatcr capaciry co

absorb loeal peak stresses (whieh Illeans rh:u wil'c brea ks should take

longe r tO develop ur such points).

ß. 'I'he resu!rs of an increase in pull along ehe track rape:

• Incrcascd [cmilc stresses in {he fOp eS

• Ir'lcreased alternat'illg tensilc stresses in rapes pcrm anel1l'ly anchored

at hoch cnds

• Nominally unchangcd forced bending (o n rhe tOwer saddles and

roller chains) hut reduced fatiguc strcngth duc [0 higher rensile srress-

es and sUI'face pl'CSSUI'CS (wh ich mCanS bending radii muse be increased

{Q achicvc ehe same rope life)

• Reduced pulsating bending lInder rhe caniage wheels ;\1 co" St::lIl t

wheelloads (whieh means wheelloads can bc increased in [he frame·

work of whecllincr perfol'lnance)

or

C. The results redudng rope diameter ar co nsr:m r pu1l alollg the (Üpe:

• Increased tcnsile suesses in rh e ropes

• Jncreased alrcrnating rensile snesses in ropes permancndy anchorcd

ar both ends

• Highct· surrace pressures in addition ro higher tensi le s{l"esses whet·e

forccd bending occurs, i.e. on rower sadd les and roller chains (which

meallS the radii should not bc reduccd in li ne wi!"h the red ucti on in

rope diamel'er)

• No change in fhe [ensio n ~t'o-she;lr ratio at constant wheclloads bm

or

an incrcasc in pu Isaring bcnding loads by t·he squ,lre rOO t tensile strcss

• Higher su rr;l ce pressures for rrack rape brak ing (which can be co m-

pensarcd by incrcasing the length of the brake shoes)

• I-ligher surfacc pressurcs on rhe cat·ringe wheels (Wllich means sofr lin-

erSshould be used so that only rhe service life of (he lilters is ;lfTected)

5. Open questions

• Are there orher aspccts to be considered?

The above list' cann ot claim to be cam piere, and I'isk analysis is

No matter which machine type or make

-

ealled for to check out orhe r f."ICto rs.

• How wi ll thc ropcs react?

Any red llclion in track rope design facrors bclow rhei r presen~ lev-

• you use. HALL Tracks are 100 percent compatible

and impress with innovative technology,

els will rake us inro unch:lrted te rri to ry, which makes ir impossible to prime quality and a convincing cost-benefit ratio.

cxtra polarc for a11 the consequenccs wi rh I'he necessa ry degree of rclia~ All component s and spare parts earn an "excellent"

bility. Invesrigatiol1s are needcd [0 srlldy Ihe effecrs on rope perro r- rating and have proved th ei r worth under tough

mance of any changes t'o {"he indiv idual componelHs of rope loading, everyday slope conditions at many

namdy tens ion, bcnding and st.ll'face pl'essure, and also rhe behavior of ski resorts around the world.

ropes subj ected to such loads in cases of mechanical damage, lightllillg

discha"ge, erc.

• Rope inspccrion inrervals?

At hi gher operating loads, any rope danuge ca n be ex pected to

develop mO I'e quiekly. This wi ll reduce (he ea rly waming I1lal'gin ;lnd

ca n lead [0 apremature discard cOI,dition. For that reason it will be

necessary to shonen the inspccrion and rest iIHerv:l Is.

• Ti me and reSO\l rces needcd to clarify these ope n quesrions?

Thc rime reqll ired fOI' :l positive result from tests on sc!ccred insra l·

lations (i n situ) will bc not less chan lWenty yeacs. (So why did we not

swrr twenty yeafs :.lgo~ Prcs umably rhe same question will be asked in

[wenry years' rime). 1_1boratO ry tests, roo, rake time and mOlley. They

also requirc conrinui ry and cal'e, Aparr from th;lt, thc res ulrs of labo- HALL tracks

raco ry rest'Sdo not always fully match (he situation in th e (leid.

full power!

6. Acknowledgements HANS HALL Inc. HANS HALL Gm~H

I wis h to thallk Mr. August HalIei' fol' I'he track rope sratistics for 71 17 S. 400 West, Suite 5 Pistenfahrzeugketten & Teile

revers ible ropeways in Switzerland and Mr. Gody H ofm ~lIl1\ for sug- Midvale. UT 84047 Krügerstraße 11

ges ring rhe subject cf this paper and reading thc manuscripr wirh such USA 0.88250 Weingarten

a cri tical eye, GABOR OPLATKA Office: (801) 561-9990 Tel. +49(0)751 / 561430

Fax: (801) 561·9992 Fax +49(0)751 / 52736

bil' ,moss@hans·hall.com info@hans-hall.com

Anda mungkin juga menyukai

- How To Make Disposable Silencers Vol IDokumen86 halamanHow To Make Disposable Silencers Vol IChris Breezley78% (9)

- AirportEngineering-Ashford 1992Dokumen528 halamanAirportEngineering-Ashford 1992Tynmec100% (1)

- Theory of Elasticity Timoshenko J N GoodierDokumen519 halamanTheory of Elasticity Timoshenko J N GoodierThotho Kennedy100% (2)

- Disamatic GatingDokumen7 halamanDisamatic Gatingtanto_deep_15Belum ada peringkat

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDari EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsPenilaian: 4.5 dari 5 bintang4.5/5 (10)

- WRC470 2002 PDFDokumen34 halamanWRC470 2002 PDFs100% (1)

- Ship Fittings by A NyghDokumen12 halamanShip Fittings by A NyghTyasno PrasetyoBelum ada peringkat

- Marine and Offshore Pumping and Piping SystemsDari EverandMarine and Offshore Pumping and Piping SystemsPenilaian: 4.5 dari 5 bintang4.5/5 (2)

- Making Paper From Nettles Organic PaperDokumen16 halamanMaking Paper From Nettles Organic PaperDheeraj ThakurBelum ada peringkat

- Pipes On DeckDokumen34 halamanPipes On DeckNataly Janataly100% (1)

- Anchor Bolts - Concrete Capacity Design PDFDokumen22 halamanAnchor Bolts - Concrete Capacity Design PDFGraham RobertsBelum ada peringkat

- Piping and Instrument Diagram SymbolsDokumen15 halamanPiping and Instrument Diagram Symbolsaviz gumayaBelum ada peringkat

- Bonney Forge SIFs VariousFittingsDokumen45 halamanBonney Forge SIFs VariousFittingscamellias2010100% (2)

- L-S16 (Specification For Telephone Installation)Dokumen20 halamanL-S16 (Specification For Telephone Installation)MUHAMMAD KHUDRI BIN HALIM BASHAH, IR. (JKR)100% (1)

- Machinery S Reference Series (No 001)Dokumen52 halamanMachinery S Reference Series (No 001)Ronin2008100% (2)

- Liquid Line SizingDokumen12 halamanLiquid Line Sizinglolofm25Belum ada peringkat

- The Sugar Mill Roller: BV R. I,. Geokge MDokumen9 halamanThe Sugar Mill Roller: BV R. I,. Geokge MuksrajBelum ada peringkat

- Hoist CapacityDokumen10 halamanHoist CapacityDheeraj ThakurBelum ada peringkat

- Design Calculations of Trash RackDokumen3 halamanDesign Calculations of Trash RackDheeraj Thakur100% (4)

- Sheave Design Versus Wire Rope LifeDokumen2 halamanSheave Design Versus Wire Rope LifeSandeep GuptaBelum ada peringkat

- 1 - Aircraft Electrical Cables PDFDokumen26 halaman1 - Aircraft Electrical Cables PDFSallak IdrisBelum ada peringkat

- Chapter 8. Analyses of The Lateral Load Tests at The Route 351 BridgeDokumen24 halamanChapter 8. Analyses of The Lateral Load Tests at The Route 351 BridgeMaheswara VarmaBelum ada peringkat

- Linear IC Applications: A Designer's HandbookDari EverandLinear IC Applications: A Designer's HandbookPenilaian: 4 dari 5 bintang4/5 (1)

- Design and Analysis of Industrial Ball Valve Using Computational Fluid DynamicsDokumen7 halamanDesign and Analysis of Industrial Ball Valve Using Computational Fluid DynamicsPradeep AdsareBelum ada peringkat

- 1995 Transmission Line Design ProcessDokumen10 halaman1995 Transmission Line Design Processjoydeep_d3232Belum ada peringkat

- Catalogo 13 Eng - Nuovo Needle ValvesDokumen8 halamanCatalogo 13 Eng - Nuovo Needle ValvesDheeraj ThakurBelum ada peringkat

- ECCS - 125 - Buckling of Steel Shells, European Design Recommendations, Eurocode 3, Part 1-6, 5th Edition - OCR PDFDokumen374 halamanECCS - 125 - Buckling of Steel Shells, European Design Recommendations, Eurocode 3, Part 1-6, 5th Edition - OCR PDFmihaidelian67% (3)

- Svrcek S 3 Phase Separator ArticleDokumen12 halamanSvrcek S 3 Phase Separator ArticleRobert MontoyaBelum ada peringkat

- Depressuring & BDVDokumen9 halamanDepressuring & BDVAmir Ali Haddadi100% (1)

- Pile Cap For 4 PilesDokumen4 halamanPile Cap For 4 Pileshemantkle2u100% (2)

- General Types of Cooling Tower IllustrationsDokumen10 halamanGeneral Types of Cooling Tower IllustrationsanisalyaaBelum ada peringkat

- Interturn Short-Circuit Detector For Turbine-Generator Rotor WindingsDokumen6 halamanInterturn Short-Circuit Detector For Turbine-Generator Rotor WindingsEng Bagaragaza Romuald100% (1)

- Preview PDFDokumen56 halamanPreview PDFDheeraj Thakur100% (1)

- Determination of Tramway Wheel and Rail Profiles To Minimise DerailmentDokumen122 halamanDetermination of Tramway Wheel and Rail Profiles To Minimise Derailmentnandoreis123Belum ada peringkat

- GE Thrust BearingsDokumen17 halamanGE Thrust BearingsBill Murray100% (2)

- Dimensions and Design 01 Rope Reeving Components: Ly N NT U H T I Jun I NDokumen4 halamanDimensions and Design 01 Rope Reeving Components: Ly N NT U H T I Jun I NEmiddio PelosiBelum ada peringkat

- Drying of PaperDokumen38 halamanDrying of PaperLingga MediatamaBelum ada peringkat

- Wire Calculations in Helical Undergoing: Stress Strands BendingDokumen8 halamanWire Calculations in Helical Undergoing: Stress Strands BendingHoàng LongBelum ada peringkat

- Scaffolding & Form Works For SlabsDokumen27 halamanScaffolding & Form Works For Slabssaleh ehmouda99Belum ada peringkat

- Tech TipDokumen5 halamanTech TipCaro LeijaBelum ada peringkat

- And That Task But: in The HaveDokumen3 halamanAnd That Task But: in The HaveTayssa MarquesBelum ada peringkat

- Rethinking The Allowable Pipe Load On Rotating Equipment NozzlesDokumen12 halamanRethinking The Allowable Pipe Load On Rotating Equipment Nozzlessateesh chandBelum ada peringkat

- Technology Twi 1.Dokumen15 halamanTechnology Twi 1.Alex KullehBelum ada peringkat

- Kim Lighting CCL Curvilinear Cutoff Luminaires Brochure 1983Dokumen18 halamanKim Lighting CCL Curvilinear Cutoff Luminaires Brochure 1983Alan MastersBelum ada peringkat

- Hojas Método AASHTODokumen5 halamanHojas Método AASHTORoberto bryan vergara valenzuelaBelum ada peringkat

- Kim Lighting Concept 5000 Series Brochure 1995Dokumen24 halamanKim Lighting Concept 5000 Series Brochure 1995Alan MastersBelum ada peringkat

- Test 3Dokumen38 halamanTest 3123Belum ada peringkat

- Llo!rs) MSRK !qud Mrrki,: LltrrincDokumen17 halamanLlo!rs) MSRK !qud Mrrki,: Lltrrincbhaswath2000Belum ada peringkat

- Brugg HalatDokumen8 halamanBrugg HalatsyalmanBelum ada peringkat

- How Do Beams in RC Buildings Resist EarthquakesDokumen2 halamanHow Do Beams in RC Buildings Resist Earthquakessamir_ssh7151Belum ada peringkat

- Kim Lighting Concept 5000 Series Brochure 1993Dokumen24 halamanKim Lighting Concept 5000 Series Brochure 1993Alan MastersBelum ada peringkat

- Kim Lighting AFL2 Series Architectural Floodlights Brochure 1993Dokumen32 halamanKim Lighting AFL2 Series Architectural Floodlights Brochure 1993Alan MastersBelum ada peringkat

- Segun GLDokumen1 halamanSegun GLfina ginoBelum ada peringkat

- Iso 9226 1992 PDFDokumen8 halamanIso 9226 1992 PDFMario AguillonBelum ada peringkat

- Kim Lighting Concept 5000 Series Brochure 1991Dokumen24 halamanKim Lighting Concept 5000 Series Brochure 1991Alan MastersBelum ada peringkat

- Basic Principles of Control Valves and Actuators: ObjectivesDokumen14 halamanBasic Principles of Control Valves and Actuators: ObjectivesNur Irfansyah SBelum ada peringkat

- Tes GR VB Electrical 2013 Paper 0Dokumen16 halamanTes GR VB Electrical 2013 Paper 0RaaBelum ada peringkat

- Kim Lighting LLF Low Level Floodlight Brochure 1994Dokumen38 halamanKim Lighting LLF Low Level Floodlight Brochure 1994Alan MastersBelum ada peringkat

- Copuyepairs: Tolerant AircraftDokumen53 halamanCopuyepairs: Tolerant AircraftAli TBelum ada peringkat

- Non-Destructive Testing of High-Pressure Gas PipelinesDokumen10 halamanNon-Destructive Testing of High-Pressure Gas PipelinesAnonymous qGtdQZcuBelum ada peringkat

- Philpott 1996Dokumen9 halamanPhilpott 1996Lopes ChavezBelum ada peringkat

- Kim Lighting Concept 5000 Series Brochure 1986Dokumen24 halamanKim Lighting Concept 5000 Series Brochure 1986Alan MastersBelum ada peringkat

- Section 11Dokumen13 halamanSection 11Jacky TiongBelum ada peringkat

- Storm Drain PrintableDokumen10 halamanStorm Drain PrintableAnder AndersBelum ada peringkat

- ANSI/AWS A5.1-91 E6013 Rutile Electrodes: The Effect of WollastoniteDokumen10 halamanANSI/AWS A5.1-91 E6013 Rutile Electrodes: The Effect of WollastoniteSushil KumarBelum ada peringkat

- Envision Adams Morgan Land Use, Zoning, and Historic Preservation Baseline ReportDokumen9 halamanEnvision Adams Morgan Land Use, Zoning, and Historic Preservation Baseline ReportEnvision Adams MorganBelum ada peringkat

- NSCP 2015 (Sec 204, Sec 205)Dokumen8 halamanNSCP 2015 (Sec 204, Sec 205)Krizia Marie Morandarte VillosBelum ada peringkat

- Catalogo Cadenas PDFDokumen20 halamanCatalogo Cadenas PDFJulio VargasBelum ada peringkat

- Chaplin 1995Dokumen13 halamanChaplin 1995Rodrigo Alejandro Flores ZuñigaBelum ada peringkat

- IV 3 - Brochure MezDokumen12 halamanIV 3 - Brochure MezAsep DarojatBelum ada peringkat

- Kim Lighting LLF Low Level Floodlight Brochure 1990Dokumen38 halamanKim Lighting LLF Low Level Floodlight Brochure 1990Alan MastersBelum ada peringkat

- A Machine For Interactive Fatigue TestinDokumen11 halamanA Machine For Interactive Fatigue Testinshah nauman100% (1)

- Joining of Lead-Antimony and Lead-Calcium Alloy LugsDokumen16 halamanJoining of Lead-Antimony and Lead-Calcium Alloy Lugsehsan453Belum ada peringkat

- Design Philosophy For de Icing of The Gates: IntroductionDokumen1 halamanDesign Philosophy For de Icing of The Gates: IntroductionDheeraj ThakurBelum ada peringkat

- Cross PlotDokumen1 halamanCross PlotDheeraj ThakurBelum ada peringkat

- Tagetesminuta Cultivationphytochemistry PDFDokumen24 halamanTagetesminuta Cultivationphytochemistry PDFDheeraj ThakurBelum ada peringkat

- Hydrology: QuantitativeDokumen4 halamanHydrology: QuantitativeDheeraj ThakurBelum ada peringkat

- Tagetesminuta-Cultivation Phyto ChemistryDokumen24 halamanTagetesminuta-Cultivation Phyto ChemistryDheeraj ThakurBelum ada peringkat

- Abdelhaleem2017 PDFDokumen11 halamanAbdelhaleem2017 PDFDheeraj ThakurBelum ada peringkat

- Ishii 1992Dokumen24 halamanIshii 1992Dheeraj ThakurBelum ada peringkat

- The Perils of Bungee Jultiww4GDokumen3 halamanThe Perils of Bungee Jultiww4GDheeraj ThakurBelum ada peringkat

- WVI - My Green Bin - V5Dokumen9 halamanWVI - My Green Bin - V5Dheeraj ThakurBelum ada peringkat

- Impact Erosion Prediction Using The Finite Volume Particle Method With Improved Constitutive ModelsDokumen11 halamanImpact Erosion Prediction Using The Finite Volume Particle Method With Improved Constitutive ModelsDheeraj ThakurBelum ada peringkat

- Accoustic EmmissionDokumen7 halamanAccoustic EmmissionDheeraj ThakurBelum ada peringkat

- Pum Storage NorwayDokumen113 halamanPum Storage NorwayDheeraj ThakurBelum ada peringkat

- Saha2015 PDFDokumen6 halamanSaha2015 PDFDheeraj ThakurBelum ada peringkat

- Automatic Aeroponic Irrigation System Based On Arduino's PlatformDokumen13 halamanAutomatic Aeroponic Irrigation System Based On Arduino's PlatformDheeraj ThakurBelum ada peringkat

- Estimation of Silt Erosion in Hydro TurbineDokumen4 halamanEstimation of Silt Erosion in Hydro TurbineDheeraj ThakurBelum ada peringkat

- Is 3973 1984Dokumen33 halamanIs 3973 1984Dheeraj Thakur100% (1)

- 1.1.2 Storyboard LaunchDokumen15 halaman1.1.2 Storyboard Launchshoaib1985Belum ada peringkat

- 3Dokumen4 halaman3Anonymous oUoJ4A8xBelum ada peringkat

- 220F14 Homework-13 PDFDokumen2 halaman220F14 Homework-13 PDFseabreezeBelum ada peringkat

- Phung Duc Long (2011) Deep ExcavationsDokumen7 halamanPhung Duc Long (2011) Deep ExcavationsVanDuongNguyenBelum ada peringkat

- PDFDokumen88 halamanPDFrafieeBelum ada peringkat

- Improving The Durability of The Optical Fiber Sensor Based On Strain Transfer AnalysisDokumen8 halamanImproving The Durability of The Optical Fiber Sensor Based On Strain Transfer Analysisrqpkwcvh9gBelum ada peringkat

- Transition State TheoryDokumen10 halamanTransition State TheoryNurshuhada NordinBelum ada peringkat

- 2000 Modelling Particulate FlowsDokumen63 halaman2000 Modelling Particulate FlowsRana UzairBelum ada peringkat

- USS Physics-Pages-491-493Dokumen3 halamanUSS Physics-Pages-491-493Arnav PatilBelum ada peringkat

- Pressure Vessel Plan: General NotesDokumen1 halamanPressure Vessel Plan: General NotesErwin Bernard NionesBelum ada peringkat

- Experiment 3 - Bend Test of Reinforcing Steel BarsDokumen7 halamanExperiment 3 - Bend Test of Reinforcing Steel BarsJaya Mae Mañago0% (1)

- Complete GT Investigation Report Dt. 22.05.2013Dokumen26 halamanComplete GT Investigation Report Dt. 22.05.2013parvez100% (1)

- Tie Beam (7pg)Dokumen7 halamanTie Beam (7pg)dheeraj SureshBelum ada peringkat

- InsulationDokumen5 halamanInsulationjaleelBelum ada peringkat

- Oedometer Test: ConceptDokumen3 halamanOedometer Test: ConceptMiguel BenítezBelum ada peringkat

- Vdocuments - MX - Proportionate and Nonproportionate Shear Walls PDFDokumen5 halamanVdocuments - MX - Proportionate and Nonproportionate Shear Walls PDFMalavika G BabuBelum ada peringkat

- Hostel SECOND TERM EXAMINATIONDokumen6 halamanHostel SECOND TERM EXAMINATIONAlvan MmaduwubaBelum ada peringkat

- Article Review: "Density Estimation For Ionic Liquids"Dokumen26 halamanArticle Review: "Density Estimation For Ionic Liquids"Gie AndalBelum ada peringkat

- PHD Thesis VGribniak 2009Dokumen216 halamanPHD Thesis VGribniak 2009aecom2009Belum ada peringkat

- Ce 6306 Som Part A AnswersDokumen21 halamanCe 6306 Som Part A Answersommech2020Belum ada peringkat