Sabater-Fundimol Catalog p32-33 PDF

Diunggah oleh

Sağlam RasimDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Sabater-Fundimol Catalog p32-33 PDF

Diunggah oleh

Sağlam RasimHak Cipta:

Format Tersedia

ALUMINIUMS Alloys Aluminium - Magnesium 5754

Chemical composition

% Si Fe Cu Mn Mg Cr Zn Ti Others

Minimum 2,6

Maximum 0,40 0,40 0,10 0,50 3,6 0,30 0,20 0,15 0,15

International Equivalences

Europe USA Spain France Germany G.B. Italy Sweden Switzerland Japan

E.N. 573 A.A. U.N.E. AFNOR D.I.N. B.S. U.N.I. S.I.S. V.S.M. J.I.S.

EN AW 38.339 AL Mg 3 3059/9005-

5754 A-G3M (N51) 4130 AL Mg 3

5754 L-3390 33535 P3

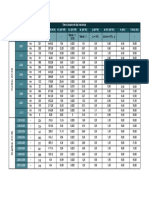

Mechanical properties of sheets Standard: EN 485-2 Aluminium EN AW-55754 [Al Mg3]

Nominal

Rm MPa Rp0,2 MPa Min. elongation % Bending radius

Treatment thickness mm Hardness

state HBS

Greater

up to min. max. min. max. A50mm A 180º 90º

than

F 2,5 100,0 190

O/H111 0,2 0,5 190 240 80 12 0,5 t 0t 52

0,5 1,5 190 240 80 14 0,5 t 0,5 t 52

1,5 3,0 190 240 80 16 1,0 t 1,0 t 52

3,0 6,0 190 240 80 18 1,0 t 1,0 t 52

6,0 12,5 190 240 80 18 2,0 t 52

12,5 100,0 190 240 80 17 52

H12 0,2 0,5 220 270 170 4 66

0,5 1,5 220 270 170 5 66

1,5 3,0 220 270 170 6 66

3,0 6,0 220 270 170 7 66

6,0 12,5 220 270 170 9 66

H14 0,2 0,5 240 280 190 3 72

0,5 1,5 240 280 190 3 72

1,5 3,0 240 280 190 4 72

3,0 6,0 240 280 190 4 72

6,0 12,5 240 280 190 5 72

H22/H32 0,2 0,5 220 270 130 7 1,5 t 0,5 t 63

0,5 1,5 220 270 130 8 1,5 t 1,0 t 63

1,5 3,0 220 270 130 10 2,0 t 1,5 t 63

3,0 6,0 220 270 130 11 1,5 t 63

6,0 12,5 220 270 130 10 2,5 t 63

H24/H34 0,2 0,5 240 280 160 6 2,5 t 1,0 t 70

0,5 1,5 240 280 160 6 2,5 t 1,5 t 70

1,5 3,0 240 280 160 7 2,5 t 2,0 t 70

3,0 6,0 240 280 160 8 2,5 t 70

6,0 12,5 240 280 160 10 3,0 t 70

page (32) SABATER FUNDIMOL

ALUMINIUMS Alloys Aluminium - Magnesium 5754

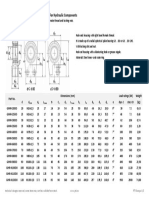

Mechanical properties Standard: EN 755-2 Alloy: EN AW-5754 [Al Mg3]

Extruded bar

Measurements mm Rm MPa Rp0,2 MPa A% A50 mm %

Treatment state

1) 2)

D S min. max. min. max. min min.

150 150 180 – 80 – 14 12

F4), H112

150 < D 250 150 < S 250 180 – 70 – 13 –

O, H111 150 150 180 250 80 – 17 15

Extruded tube

Measurements Rm MPa Rp0,2 MPa A% A50 mm %

Treatment state 3)

mm e

min. max. min. max. min min.

4),

F H112 25 180 – 80 – 14 12

O, H111 25 180 250 80 – 17 15

Extruded profile

Measurements Rm MPa Rp0,2 MPa A% A50 mm %

Treatment state 3)

mm e

min. max. min. max. min min.

4)

F , H112 25 180 – 80 – 14 12

1) D = Diameter of circular section bars.

2) S = Distance between faces for square-section and hexagonal bars, thickness for rectangular section bars.

3) e = Wall thickness.

4) Treatment state "F": the values of the characteristics are indicated merely for the sake of information.

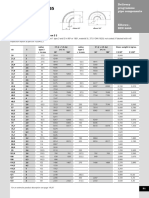

Physical properties

Modulus of Specific Melting Linear expansion Thermal Electrical

Electrical Dissolution

elasticity weight temperature coefficient conductivity resistivity at

conductivity% IACS potential V

N/mm2 g/cm3 ºC 1/106K W/mK 20ºC - cm

70.500 2,68 590-640 23,8 133 5,2 32,5 -0,85

Technological suitabilities

Welding Natural behaviour Anodized Mechanization State: 0 H24

For

Under flame MB In a rural environment MB MB Chip fragmentation R R

protection

At the arc under argon In an industrial

MB MB Decorative B Surface gloss MB MB

gas environment

Owing to electrical In a marine Hard

MB MB MB

resistance environment anodized

Brazed R In sea water B

Thermal treatments Products Observations and applications

Forging temperature interval: 350º - Bars, wires, extruded Alloy endowed with high mechanical resistance,

500ºC. profiles, tubes, very easy to weld using conventional methods with

Total annealing: 340ºC. sheets, strips and an excellent capacity to receive protection

Partial annealing: 240ºC. plates. anodizing treatments and hard.

Its corrosion-proofing is good, comparable to that

of pure aluminium as a whole and even better in a

marine environment which is why it is highly suited

to; shipbuilding as well as fridges, fish trays, proton

floats etc.

It is also used in boiler-making, recipients for

petrol, chemical industry, tanks for transport, the

automobile industry, railway and underground

wagons, buses etc.

SABATER FUNDIMOL page (33)

Anda mungkin juga menyukai

- Aluminium 1050Dokumen2 halamanAluminium 1050Sephiwe MafilikaBelum ada peringkat

- DIN 2093 UNI 8737 Molle A TazzaDokumen6 halamanDIN 2093 UNI 8737 Molle A TazzaRoby MastreBelum ada peringkat

- Hidrología - Ing. Ricardo Adrián Márquez DuranDokumen7 halamanHidrología - Ing. Ricardo Adrián Márquez DuranDaniel Vidal CamachoBelum ada peringkat

- Worksheet in RC Retaining WallDokumen1 halamanWorksheet in RC Retaining WallteweldeBelum ada peringkat

- Sabater Fundimol Catalog p22 23Dokumen2 halamanSabater Fundimol Catalog p22 23Pep VasilevaBelum ada peringkat

- Cantoni - Induction MotorsDokumen28 halamanCantoni - Induction MotorsAlim KhalimbetovBelum ada peringkat

- Plastic Welding Machine Mini Maxi Workshop PVDF Up To OD 315 MMDokumen2 halamanPlastic Welding Machine Mini Maxi Workshop PVDF Up To OD 315 MMtinzarmoeBelum ada peringkat

- Tabel SondirDokumen3 halamanTabel SondirNishaaadd 21Belum ada peringkat

- Ejemplo EsalDokumen22 halamanEjemplo Esalanyelo crakBelum ada peringkat

- Ejercicio ConsumidorDokumen6 halamanEjercicio ConsumidorAngelica BarbaranBelum ada peringkat

- Dataaa Kurva Yg Mau DiprintDokumen3 halamanDataaa Kurva Yg Mau DiprintThesalonika PanjaitanBelum ada peringkat

- Kurva Kesetimbangan Uap Cair RDokumen6 halamanKurva Kesetimbangan Uap Cair RWanda YunitaBelum ada peringkat

- DNI Test - 1 Test - 2 Test - 3 Test - 4 Test - 5 Test - 6 Act - IglesiasDokumen2 halamanDNI Test - 1 Test - 2 Test - 3 Test - 4 Test - 5 Test - 6 Act - IglesiasLUCÍABelum ada peringkat

- K91.31 Fig T302-M3 B302-S13 en FinalDokumen1 halamanK91.31 Fig T302-M3 B302-S13 en FinaladrianioantomaBelum ada peringkat

- Operation Bulletin Style: BCG 7 STYLE Name Foam Padded Des: Molded Parameters IED 600 100% 79% 17 Est Time SAMDokumen10 halamanOperation Bulletin Style: BCG 7 STYLE Name Foam Padded Des: Molded Parameters IED 600 100% 79% 17 Est Time SAMgouthamShetty DBelum ada peringkat

- Welding Studs Capacitor Discharge CD: Threaded Stud PTDokumen1 halamanWelding Studs Capacitor Discharge CD: Threaded Stud PTAli KhalafBelum ada peringkat

- Slab Design Oneway R2Dokumen3 halamanSlab Design Oneway R2Kumy engineeringBelum ada peringkat

- Oxy Fuel Cut Chart Koike All 1Dokumen12 halamanOxy Fuel Cut Chart Koike All 1Norden ConradBelum ada peringkat

- Donahue Abrahamson 2014 EQS Appendix ADokumen3 halamanDonahue Abrahamson 2014 EQS Appendix AÖzkan KaleBelum ada peringkat

- Cable THW 90 CeperDokumen2 halamanCable THW 90 CeperManuel PelaesBelum ada peringkat

- Laboratorul1 PS Bivol Tudor - XLSBDokumen7 halamanLaboratorul1 PS Bivol Tudor - XLSBTudor BivolBelum ada peringkat

- Planilha de Cálculo Das Lajes - Concreto I - Tabela de Dimensionamento Das ArmadurasDokumen1 halamanPlanilha de Cálculo Das Lajes - Concreto I - Tabela de Dimensionamento Das ArmadurasEduarda tamyBelum ada peringkat

- ALLPUMP Catalogue For G Type Screw Pump-1Dokumen7 halamanALLPUMP Catalogue For G Type Screw Pump-1dirumah AjaBelum ada peringkat

- ExactApply Nozzles Auto ModeDokumen11 halamanExactApply Nozzles Auto ModequekaBelum ada peringkat

- Electricity TariffDokumen2 halamanElectricity Tariffbrajeshchandra28Belum ada peringkat

- Parametros Generales de Corte LaserDokumen43 halamanParametros Generales de Corte LaserAgustin Daker100% (1)

- Cam AnalysisDokumen7 halamanCam Analysisk4k4zimBelum ada peringkat

- 3 Dados Motores Assíncronos Trifásicos Com Rotor em Curto-Circuito Tab 6.4Dokumen4 halaman3 Dados Motores Assíncronos Trifásicos Com Rotor em Curto-Circuito Tab 6.4andreBelum ada peringkat

- Corrosion Raccords Proform 2018 PDFDokumen34 halamanCorrosion Raccords Proform 2018 PDFDiegoBelum ada peringkat

- Spring Lock Washer Dimensions-DIN-128-A-ENDokumen1 halamanSpring Lock Washer Dimensions-DIN-128-A-ENivanBelum ada peringkat

- Fortune Update 1Dokumen5 halamanFortune Update 1Durga SBelum ada peringkat

- Slider Crank Mechanism (AutoRecovered)Dokumen6 halamanSlider Crank Mechanism (AutoRecovered)Jàwád QûreShïBelum ada peringkat

- Viscosity Converting ChartDokumen3 halamanViscosity Converting ChartMaria Victoria Morales GalindezBelum ada peringkat

- Reduced Load: M MA AR RY YL LA AN ND D M ME ET TR Riic CS SDokumen1 halamanReduced Load: M MA AR RY YL LA AN ND D M ME ET TR Riic CS SRenny DevassyBelum ada peringkat

- Diaphragm Air Compressors & Vacuum Pumps: OEM CatalogDokumen8 halamanDiaphragm Air Compressors & Vacuum Pumps: OEM CatalogBong Kek ChiewBelum ada peringkat

- 1.4 Sondir Jembatan S. Desa Burau PantaiDokumen16 halaman1.4 Sondir Jembatan S. Desa Burau PantaiNursusanti SyafruddinBelum ada peringkat

- GIHR-K..DO - Rod Ends For Hydraulic ComponentsDokumen1 halamanGIHR-K..DO - Rod Ends For Hydraulic ComponentsQuintrae DelfinBelum ada peringkat

- Cadenas de Acero RedondoDokumen145 halamanCadenas de Acero RedondoRandolph LoayzaBelum ada peringkat

- Elbows - DIN 2605: VL Code 711Dokumen3 halamanElbows - DIN 2605: VL Code 711pedroserusBelum ada peringkat

- Elbows - DIN 2605: VL Code 711Dokumen3 halamanElbows - DIN 2605: VL Code 711ZAQWBelum ada peringkat

- Elbows - DIN 2605: VL Code 711Dokumen3 halamanElbows - DIN 2605: VL Code 711Omil RastogiBelum ada peringkat

- Elbows - DIN 2605: VL Code 711Dokumen3 halamanElbows - DIN 2605: VL Code 711Guillermo ZaragozaBelum ada peringkat

- 127 Od ElbowDokumen3 halaman127 Od ElbowMrityunjoy BarBelum ada peringkat

- Din 2605 PDFDokumen3 halamanDin 2605 PDFZAQWBelum ada peringkat

- Elbows - DIN 2605: VL Code 711Dokumen3 halamanElbows - DIN 2605: VL Code 711zafarbadalBelum ada peringkat

- Din 2605 PDFDokumen3 halamanDin 2605 PDFPedro Montes MarinBelum ada peringkat

- Elbows - DIN 2605: VL Code 711Dokumen3 halamanElbows - DIN 2605: VL Code 711ramonaghergheBelum ada peringkat

- Elbows - DIN 2605: VL Code 711Dokumen3 halamanElbows - DIN 2605: VL Code 711Marijan TurkBelum ada peringkat

- Din 2605 PDFDokumen3 halamanDin 2605 PDFAdolf-Norbert KosBelum ada peringkat

- DIN 2605 (Elbows) PDFDokumen3 halamanDIN 2605 (Elbows) PDFAleksandarSashaStankovichBelum ada peringkat

- Notas Finales - Conv - 2Dokumen6 halamanNotas Finales - Conv - 2Raúl Cisternes MedinaBelum ada peringkat

- EconometricsDokumen30 halamanEconometricsNini TkemaladzeBelum ada peringkat

- SOAL A Penentuan Illuminasi - HARDI IBNU ZUKAI 20191330033Dokumen8 halamanSOAL A Penentuan Illuminasi - HARDI IBNU ZUKAI 20191330033ZzzzBelum ada peringkat

- ExtrasArmaturiPlanseu (-0 12)Dokumen2 halamanExtrasArmaturiPlanseu (-0 12)Dan CalugarBelum ada peringkat

- Bab 5 Kurva-Kurva Prestasi Dan Kavitasi PompaDokumen9 halamanBab 5 Kurva-Kurva Prestasi Dan Kavitasi PompaMuhammad Khoirul AnwarBelum ada peringkat

- Soundir 1 PJDokumen2 halamanSoundir 1 PJHeri BudiantoBelum ada peringkat

- Reducer Eccentric Din 86089 Cuni10fe1.6mnDokumen1 halamanReducer Eccentric Din 86089 Cuni10fe1.6mnrijalharunBelum ada peringkat

- LAMPIRAN PerhitunganDokumen7 halamanLAMPIRAN Perhitunganjenni sisika ria purbaBelum ada peringkat

- U-Sections: General Product DescriptionDokumen3 halamanU-Sections: General Product Descriptionharold1aguirre-1Belum ada peringkat

- Msds Diapolisher PasteDokumen10 halamanMsds Diapolisher PasteIka KusumawatiBelum ada peringkat

- 1 Rhenogran S-80Dokumen2 halaman1 Rhenogran S-80KeremBelum ada peringkat

- Greenhouse ManagementDokumen49 halamanGreenhouse ManagementAnouer Belkadi43% (14)

- Montreal ProtocolDokumen17 halamanMontreal ProtocolJan Aldrin AfosBelum ada peringkat

- Provisional RestorationsDokumen10 halamanProvisional Restorationsapi-3775747100% (1)

- Isooctyl Mercaptan PDFDokumen9 halamanIsooctyl Mercaptan PDFGilar GumelarBelum ada peringkat

- Oxalic AcidDokumen70 halamanOxalic Acidraihona100% (2)

- One-Dimensional Swell or Collapse of Soils: Standard Test Methods ForDokumen10 halamanOne-Dimensional Swell or Collapse of Soils: Standard Test Methods ForYarisel Shosha MuñozBelum ada peringkat

- Flame Test & Spectroscopy Virtual LabDokumen4 halamanFlame Test & Spectroscopy Virtual LabFilip Salek50% (2)

- Physics Project 1Dokumen19 halamanPhysics Project 1Amarjeet Singh33% (3)

- Magnasoft JSSDokumen5 halamanMagnasoft JSSLe LocBelum ada peringkat

- Enardo Catalog 2010-04Dokumen318 halamanEnardo Catalog 2010-04Suara84Belum ada peringkat

- MSA Global EU UK RoHS Declaration 09072022Dokumen15 halamanMSA Global EU UK RoHS Declaration 09072022Felipe CarmonaBelum ada peringkat

- Divine Child High School Ghod Dod Road, Surat Sub: Science Class: 8 STD Fa-1 NotesDokumen12 halamanDivine Child High School Ghod Dod Road, Surat Sub: Science Class: 8 STD Fa-1 Notesshivam thakurBelum ada peringkat

- Cassava Flour Processing StagesDokumen8 halamanCassava Flour Processing StagesAhmed BinBelum ada peringkat

- Selection of The Disc Brake Material Using Pin On Disc ApparatusDokumen7 halamanSelection of The Disc Brake Material Using Pin On Disc ApparatusIJIERT-International Journal of Innovations in Engineering Research and TechnologyBelum ada peringkat

- 3 - Way Valve ManualDokumen8 halaman3 - Way Valve ManualSrikar Reddy GummadiBelum ada peringkat

- Opio Faith K 201301 PHD PDFDokumen266 halamanOpio Faith K 201301 PHD PDFMiguel FrezBelum ada peringkat

- Gas Liquid Chromatography (GLC)Dokumen10 halamanGas Liquid Chromatography (GLC)Gopinathan MBelum ada peringkat

- CO2 Liquefaction PlantDokumen32 halamanCO2 Liquefaction Plantmuzammal100% (1)

- Albumin BLT00001 & 02Dokumen2 halamanAlbumin BLT00001 & 02Aniket dubeyBelum ada peringkat

- Antiwashout Admixtures For Underwater ConcreteDokumen2 halamanAntiwashout Admixtures For Underwater Concretemanil_5Belum ada peringkat

- Denn Vco Proposal 8Dokumen1 halamanDenn Vco Proposal 8Lyking Caliste TulodBelum ada peringkat

- Polymer Blends and AlloysDokumen15 halamanPolymer Blends and AlloysSurenderMalanBelum ada peringkat

- TTQC L-4Dokumen3 halamanTTQC L-4api-3710756100% (2)

- Maharastra PWD 2012-13Dokumen278 halamanMaharastra PWD 2012-13chiranjeeviyarla0% (1)

- Coating TechnologyDokumen38 halamanCoating TechnologyReal Anmol Arora100% (5)

- Galacid Food 80 (GB)Dokumen5 halamanGalacid Food 80 (GB)Abc AbcdBelum ada peringkat

- 8 Easy Care FinishingDokumen53 halaman8 Easy Care FinishingBeyene DumechaBelum ada peringkat

- Dermatitis Eksematosa - Dr. Kristo A. Nababan, Sp. KKDokumen91 halamanDermatitis Eksematosa - Dr. Kristo A. Nababan, Sp. KKJhost Clinton PurbaBelum ada peringkat