Elevated Storege Tanks

Diunggah oleh

Sanjay RaoDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Elevated Storege Tanks

Diunggah oleh

Sanjay RaoHak Cipta:

Format Tersedia

Concrete

Q&A

Minimum Reinforcement in

Elevated Water Storage Tanks

Q.

Table 5.2 in “Guide for the concrete columns per Chapter 10 of

Analysis, Design, and ACI 318-05.4

Construction of Elevated Because of tank geometry, an

Concrete and Composite Steel-Concrete all-concrete tank typically has a much

Water Storage Tanks (ACI 371R-08),”1 smaller pedestal diameter than a

includes recommendations for minimum composite tank. The “wall” provisions

wall reinforcement. Under the heading, can lead to thick concrete sections in

“Seismic coefficient SD1 < 0.20,” the table regions of high seismicity, so it’s

has two minimum reinforcement ratios customary to design the pedestal as a

for vertically oriented bars, depending on “reinforced concrete column” in

the “maximum compressive fiber stress these situations. Section 5.2.2.3.3 of

based on actual axial plus flexure stress ACI 371R-08 states: “When the effects

resulting on gross concrete section” fc. The of vertical load and bending caused by

ratio is 0.0015 when fc is below 1 ksi the presence of slabs, diaphragms, or

(7 MPa), but it’s 0.005 when fc is 1 ksi or domes and other discontinuities are

more. Why is there such a jump when fc determined by rational analysis, the

exceeds 1000 psi? Also, could you provide pedestal wall should be designed as a

more details on the calculation of fc? column of unit circumferential width

according to ACI 318-05, Section 14.4,

A.

In brief, the 1000 psi limit is and the applicable sections of

Fig. 1: Common configuration of elevated

a convenient demarcation ACI 318-05, Chapter 10. The vertical

composite steel-concrete tanks (Fig. 1.2

between lightly loaded, wall reinforcement should be equal to

in ACI 371R-081)

large-diameter pedestals used for or greater than 0.005Ag and need not

composite tanks (tanks comprising a be enclosed by lateral ties when

reinforced concrete pedestal and steel the conditions of ACI 318-05,

tank as shown in Fig. 1) and more Section 14.3.6, are satisfied.”1

highly loaded, small-diameter pedestals Therefore, the minimum

used for all-concrete tanks (Fig. 2). reinforcement ratio of 0.005 in

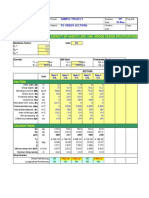

Table 5.2 of ACI 371R-081 (Fig. 3) Table 5.2 of ACI 371R-08 comes

includes recommendations for both from limits for reinforcement

composite and all-concrete tanks and of compression members in

is effectively an expanded version of ACI 318-05:

Table 4.8.2 in ACI 371R-982 (Fig. 4), •• “…it shall be permitted to

which dealt only with composite tanks. base the minimum reinforce-

The pedestal design recommendations ment and strength on a

for composite tanks are based on reduced effective area Ag not

provisions for reinforced concrete less than one-half the total

walls per Chapter 14 of ACI 318-95,3 area” (Section 10.8.4); and

which don’t include the vertical •• “Area of longitudinal

reinforcing in compressive strength reinforcement, Ast, for

calculations. For all-concrete tanks, the noncomposite compression

pedestal design recommendations are members shall be not less than Fig. 2: Common configuration of elevated all-

based on provisions for reinforced 0.01Ag…” (Section 10.9.1). concrete tanks (Fig. 1.1 in ACI 371R-081)

82 april 2013 Concrete international

Questions in this column were asked by users of ACI documents and have been answered

by ACI staff or by a member or members of ACI technical committees. The answers do not

represent the official position of an ACI committee. Only a published committee document

represents the formal consensus of the committee and the Institute.

We invite comment on any of the questions and answers published in this column. Write to the

Concrete Q&A Editor, Concrete International, 38800 Country Club Drive, Farmington Hills, MI 48331; contact

us by fax at (248) 848-3701; or e-mail Rex.Donahey@concrete.org.

Fig. 3: Minimum wall reinforcement (Table 5.2 in ACI 371R-081)

Guidance regarding the calculation

of fc can be found in ANSI/AWWA

D107-10,5 a standard for the design,

construction, inspection, and testing of

composite elevated tanks that was

developed somewhat concurrently

with ACI 371R-08 and uses the ACI

guide as one of its source documents.

The ANSI/AWWA standard includes a

provision for determining minimum

wall thickness: “Compression stress

shall not exceed 0.25 fc´ nor 1000 psi

(7 MPa) for load combination S1.1 in

Sec. 4.3.3.1,” where load combination

S1.1 is a nominal service load

Fig. 4: Minimum wall reinforcement (Table 4.8.2 in ACI 371R-982)

combination of dead load and stored

water load. The intent of the 1000 psi

limit (which is 25% of fc´ for 4000 psi Elevated Concrete and Composite Steel- 4. ACI Committee 318, “Building Code

[28 MPa] concrete) is to apportion the Concrete Water Storage Tanks (ACI 371R-08),” Requirements for Structural Concrete

permissible service load stress (roughly American Concrete Institute, Farmington (ACI 318-05) and Commentary,” American

0.55 fc´) nearly equally between gravity Hills, MI, 2008, 41 pp. Concrete Institute, Farmington Hills, MI,

loads and environmental loads. So the 2. ACI Committee 371, “Guide for the 2005, 430 pp.

AWWA standard effectively limits fc to Analysis, Design, and Construction of 5. AWWA Standards Committee on

1000 psi under the action of gravity Concrete-Pedestal Water Towers Composite Elevated Tanks, “Composite

loads, and this can be considered the (ACI 371R-98),” American Concrete Institute, Elevated Tanks for Water Storage (ANSI/

basis for the 1000 psi limit on fc found in Farmington Hills, MI, 1998, 36 pp. AWWA D107-10),” American Water Works

Table 5.2 of ACI 371R-08. 3. ACI Committee 318, “Building Code Association, Denver, CO, Dec. 2010, 164 pp.

Requirements for Structural Concrete

References (ACI 318-95) and Commentary,” American Thanks to Rolf Pawski, Landmark

1. ACI Committee 371, “Guide for the Concrete Institute, Farmington Hills, MI, Structures, for providing the answer to

Analysis, Design, and Construction of 1995, 369 pp. this question.

Concrete international april 2013 83

Concrete Q&A

Corrections to “Dowel Bars in Slabs-on-Ground”

The answer to the March 2013 Q&A (p. 79) cited

information from ACI 360R-06. Instead, it should have

referred to ACI 360R-10,1 so:

•• Section 5.2 of ACI 360R-06 should be replaced with

Section 6.2 of ACI 360R-10 as a go-to reference on

load-transfer mechanisms for slabs-on-ground;

•• References to Fig. 3.9 and 3.6 from ACI 302.1R-04 (Fig. 1

and 2 in the March 2013 Q&A, respectively) should be

replaced with references to Fig. 6.5 in ACI 360R-10, as

that figure contains updated information; and

•• Table 5.1 from Section 5.2 of ACI 360R-06 (Fig. 3 in

March 2013 Q&A) should be replaced with Table 6.1

from Section 6.2 of ACI 360R-10, as that table also

contains updated information.

In addition, the answer should refer readers to Section 2.2.10

of ACI 117-10,2 which provides tolerances for placement of

dowels in slabs-on-ground. See ACI 360R-10 for the latest

information on design of slabs-on-ground.

References

1. ACI Committee 360, “Guide to Design of Slabs-on-Ground (ACI

360R-10),” American Concrete Institute, Farmington Hills, MI, 2010,

74 pp.

2. ACI Committee 117, “Specification for Tolerances for Concrete

Construction and Materials (ACI 117-10) and Commentary,” American

Concrete Institute, Farmington Hills, MI, 2010, 78 pp.

Editor’s note: We regret that the latest ACI documents were not

cited, and we thank Wayne Walker, Norcross, GA, for notifying us. Fig. 6.5: Typical doweled joints

84 april 2013 Concrete international

Anda mungkin juga menyukai

- Simplified Seismic Analysis Procedures For Elevated TanksDokumen19 halamanSimplified Seismic Analysis Procedures For Elevated TanksCesar Yoshio Sanchez HuchiyamaBelum ada peringkat

- Malhotra, P., Wenk, T., Wieland, A. "Simple Procedure For Seismic Analysis of Liquid-Storage Tanks"Dokumen5 halamanMalhotra, P., Wenk, T., Wieland, A. "Simple Procedure For Seismic Analysis of Liquid-Storage Tanks"Alejandro JoseBelum ada peringkat

- A Programmable Solution For Stepped Crane ColumnsDokumen4 halamanA Programmable Solution For Stepped Crane ColumnsMohamed Mostafa IbrahimBelum ada peringkat

- Tanques ReforzadosDokumen11 halamanTanques ReforzadosJulio Humberto Díaz RondánBelum ada peringkat

- Driven Steel Piling - BBGEDokumen2 halamanDriven Steel Piling - BBGEmasterumBelum ada peringkat

- Shear Lug DesignDokumen19 halamanShear Lug DesignariyaBelum ada peringkat

- WRC 297 RWE NODE 6340 25febDokumen4 halamanWRC 297 RWE NODE 6340 25febnamasralBelum ada peringkat

- Dow Insulatio For Geotechnical ApplicationsDokumen16 halamanDow Insulatio For Geotechnical Applicationshahaer77Belum ada peringkat

- Elevated Water TankDokumen16 halamanElevated Water TankRANJITH PULIKESHIBelum ada peringkat

- Shear Key or Shear Lug Design - US AISC SectionDokumen4 halamanShear Key or Shear Lug Design - US AISC SectionJun AtienzaBelum ada peringkat

- Stainless Steel Laser Fused Universal Beams and ColumnsDokumen8 halamanStainless Steel Laser Fused Universal Beams and ColumnsDushyantha JayawardenaBelum ada peringkat

- Architecture Design Handbook - Flashings and Copings - Coping CoversDokumen5 halamanArchitecture Design Handbook - Flashings and Copings - Coping CoversDukeBelum ada peringkat

- Concrete Section Shear Capacity by Aashto LRFD 1998 Bridge Design Specifications (2000 Interim)Dokumen5 halamanConcrete Section Shear Capacity by Aashto LRFD 1998 Bridge Design Specifications (2000 Interim)AlfonsoHdzBelum ada peringkat

- Behavior of Concrete Liquid Containing Structures Subjected To Seismic LoadingDokumen16 halamanBehavior of Concrete Liquid Containing Structures Subjected To Seismic LoadingEric WilkinsBelum ada peringkat

- Checklist For Concrete Shear Wall (ACI 318-14)Dokumen5 halamanChecklist For Concrete Shear Wall (ACI 318-14)renzo1221Belum ada peringkat

- Seismic Analysis and Design of Steel Liquid Storage Tanks PDFDokumen7 halamanSeismic Analysis and Design of Steel Liquid Storage Tanks PDFBala SutharshanBelum ada peringkat

- Welded Steel Water Tanks: Steel Plated Structures (Lecture Notes) Fourth Year Civil 2006-2007Dokumen20 halamanWelded Steel Water Tanks: Steel Plated Structures (Lecture Notes) Fourth Year Civil 2006-2007MazenMowafyBelum ada peringkat

- Roof TrussDokumen4 halamanRoof TrussShamie Dela Cruz CaldeaBelum ada peringkat

- WTanksDokumen26 halamanWTanksestebanosorionovaBelum ada peringkat

- Basics of Tank Seismic OCRDokumen35 halamanBasics of Tank Seismic OCRmario_gBelum ada peringkat

- WeldDokumen7 halamanWeldMuhammad Akbar Faereza NugrahaBelum ada peringkat

- Practical Design Stepped ColumnsDokumen12 halamanPractical Design Stepped ColumnstaosyeBelum ada peringkat

- Pipe Concrete AnchorDokumen6 halamanPipe Concrete AnchorRahmat RiskiBelum ada peringkat

- Steel DeckDokumen13 halamanSteel Deckrini100% (1)

- IBC 2006 Seismic CalculationDokumen1 halamanIBC 2006 Seismic CalculationMonotobo X MakinaBelum ada peringkat

- Indian Standard Radial GateDokumen8 halamanIndian Standard Radial GateMirza FadlulahBelum ada peringkat

- Checks For CompactnessDokumen15 halamanChecks For CompactnessjologscresenciaBelum ada peringkat

- Seismic Behaviour of Elevated Water TankDokumen5 halamanSeismic Behaviour of Elevated Water TankFrederick TanBelum ada peringkat

- Anchor Design HILTIDokumen14 halamanAnchor Design HILTIRohit GadekarBelum ada peringkat

- Spreadsheets To BS 8110Dokumen11 halamanSpreadsheets To BS 8110NitinShepurBelum ada peringkat

- Chapter 7 Snow LoadsDokumen14 halamanChapter 7 Snow LoadsGhaedan HameedBelum ada peringkat

- Design of JointsDokumen41 halamanDesign of JointsVivek LevinBelum ada peringkat

- Pressure Pipe Design-Moser CH 4 ExrptDokumen8 halamanPressure Pipe Design-Moser CH 4 ExrptAnjan SigdelBelum ada peringkat

- ShoringDokumen7 halamanShoringARUN RAWATBelum ada peringkat

- Research Report On Single Plate Shear Connections: North Carolina State UniversityDokumen51 halamanResearch Report On Single Plate Shear Connections: North Carolina State UniversityHarshaVeeragandhamBelum ada peringkat

- 2400 Tema DCDokumen7 halaman2400 Tema DCMasoodMiyanBelum ada peringkat

- 2000 IBC Handbook Seismic Wind PDFDokumen9 halaman2000 IBC Handbook Seismic Wind PDFAnonymous xC6bM4x6U6Belum ada peringkat

- Water Tank 2Dokumen19 halamanWater Tank 2Paul KarijaBelum ada peringkat

- Limit State of ServiceabilityDokumen17 halamanLimit State of ServiceabilityRadhikaBelum ada peringkat

- 21-3971-CLA - DisenŞo Preliminar Cimentacion - Normal SoilDokumen4 halaman21-3971-CLA - DisenŞo Preliminar Cimentacion - Normal SoilJose ManzanarezBelum ada peringkat

- STAADPro V8i Verification ManualDokumen176 halamanSTAADPro V8i Verification ManualjasimabdBelum ada peringkat

- Changes in ACI 318 Code Provisions For Earthquake Resistant StructuresDokumen5 halamanChanges in ACI 318 Code Provisions For Earthquake Resistant StructuresTrầmLãngBelum ada peringkat

- Simpson Strong-Tie CFS Designer ManualDokumen26 halamanSimpson Strong-Tie CFS Designer Manualdnl_vicarsBelum ada peringkat

- Seimic Response of Liquid Storage TankDokumen4 halamanSeimic Response of Liquid Storage TanklucianduBelum ada peringkat

- Mitek 12kN Pile FixingDokumen2 halamanMitek 12kN Pile FixingTuroyBelum ada peringkat

- All Type Pile Cap DesignDokumen2 halamanAll Type Pile Cap DesignJohn BandaBelum ada peringkat

- General Design of Rectangular Tanks: The Walls Are Designed Both For Direct Tension and Bending MomentDokumen17 halamanGeneral Design of Rectangular Tanks: The Walls Are Designed Both For Direct Tension and Bending MomentAlvin AsinguaBelum ada peringkat

- 01 Plate Analysis Result Staad ProDokumen1 halaman01 Plate Analysis Result Staad ProSunil NepalBelum ada peringkat

- Aisc Member Dimensions and Properties ViewerDokumen23 halamanAisc Member Dimensions and Properties ViewerMadara Uchija100% (1)

- 300 Lab Manual (Pspice and Mathcad)Dokumen107 halaman300 Lab Manual (Pspice and Mathcad)jogaryBelum ada peringkat

- SAP Basics - Modelling, Analysis, Design (Autosaved) PDFDokumen97 halamanSAP Basics - Modelling, Analysis, Design (Autosaved) PDFinam ullahBelum ada peringkat

- How To Apply Horizontal Moving LoadsDokumen2 halamanHow To Apply Horizontal Moving LoadsRojan MathewBelum ada peringkat

- Significant Changes in ACI 318-11Dokumen4 halamanSignificant Changes in ACI 318-11cabpcabpBelum ada peringkat

- PDFsam TMPbuffer HRHPR1Dokumen58 halamanPDFsam TMPbuffer HRHPR1ryan rakhmat setiadiBelum ada peringkat

- Differences ACI-318-08 To 11Dokumen13 halamanDifferences ACI-318-08 To 11Dangutu KhanbraBelum ada peringkat

- ACI 108-S43 SpanThickness Limits For Deflection ControlDokumen8 halamanACI 108-S43 SpanThickness Limits For Deflection ControlconcretemadBelum ada peringkat

- Steel Interchange: Drift LimitsDokumen2 halamanSteel Interchange: Drift Limitsmaxeytm_839061685Belum ada peringkat

- Https WWW - Sefindia.org Q System Files Confinement+Reinforcement+for+Columns-ICJ Aug+11Dokumen9 halamanHttps WWW - Sefindia.org Q System Files Confinement+Reinforcement+for+Columns-ICJ Aug+11Igor GjorgjievBelum ada peringkat

- For Official Use Only DOC: WRD 14 (546) P: Preliminary Draft Indian StandardDokumen8 halamanFor Official Use Only DOC: WRD 14 (546) P: Preliminary Draft Indian StandardSouvik DasBelum ada peringkat

- Chapter18 Beam Subjected To Torsion & Bending IIDokumen29 halamanChapter18 Beam Subjected To Torsion & Bending IIVincent TengBelum ada peringkat

- Folded PlatesDokumen49 halamanFolded PlatesSivaAgathamudiBelum ada peringkat

- Brochure 1467801522Dokumen6 halamanBrochure 1467801522Sanjay RaoBelum ada peringkat

- 1 Historical Development and Characteristics of Structural SteelsDokumen30 halaman1 Historical Development and Characteristics of Structural Steelsron_dany100% (1)

- Filler SlabDokumen3 halamanFiller SlabSanjay RaoBelum ada peringkat

- Sika Spalling RepairDokumen3 halamanSika Spalling RepairSanjay RaoBelum ada peringkat

- DPRDokumen132 halamanDPRSanjay RaoBelum ada peringkat

- Over Head TankDokumen44 halamanOver Head TankSyed Mohd MehdiBelum ada peringkat

- Highway AlignmentDokumen35 halamanHighway AlignmentSanjay RaoBelum ada peringkat

- V 35119123Dokumen5 halamanV 35119123akash nairBelum ada peringkat

- Bs-105 Guidelines On Pipeline Crossings Under Railway TrackDokumen16 halamanBs-105 Guidelines On Pipeline Crossings Under Railway TrackMohammad Munazir Ali0% (1)

- IS-875-Part1 - Dead Loads For DesignDokumen39 halamanIS-875-Part1 - Dead Loads For Designlokesh2325100% (7)

- Compression MembersDokumen22 halamanCompression MembersAnonymous dlSmlsymHBelum ada peringkat

- Building A Semi-Anechoic ChamberDokumen28 halamanBuilding A Semi-Anechoic ChamberSanjay Rao100% (1)

- Is 383 Specification For Coarse and Fine Aggregates From Nat.180180049Dokumen21 halamanIs 383 Specification For Coarse and Fine Aggregates From Nat.180180049love9Belum ada peringkat

- Forensic Ballistics Reviewer - ScribdDokumen589 halamanForensic Ballistics Reviewer - ScribdMelcon S. Lapina96% (25)

- Emhart Inspection Defect GuideDokumen1 halamanEmhart Inspection Defect GuideBryan Nadimpally75% (4)

- EM - I-Assignment - II (NA) - 1Dokumen2 halamanEM - I-Assignment - II (NA) - 1deepakBelum ada peringkat

- Tuguegarao Certificate of Non-Availability of Stocks: Product Code Product Description UOM PriceDokumen7 halamanTuguegarao Certificate of Non-Availability of Stocks: Product Code Product Description UOM PriceNenbon NatividadBelum ada peringkat

- ISO 16923-2016 Text - Natural Gas Fuelling Stations - CNGDokumen50 halamanISO 16923-2016 Text - Natural Gas Fuelling Stations - CNGمحمد مجدي100% (2)

- M2 Pre-Task: Application Software - System Software Driver Software Programming SoftwareDokumen2 halamanM2 Pre-Task: Application Software - System Software Driver Software Programming SoftwareBee Anne BiñasBelum ada peringkat

- General Information NC Detector: SignatureDokumen2 halamanGeneral Information NC Detector: SignatureEvelin FriasBelum ada peringkat

- Compressor House Unit-3Dokumen199 halamanCompressor House Unit-3Priyanka BasuBelum ada peringkat

- Discrete Mathematics - Propositional LogicDokumen8 halamanDiscrete Mathematics - Propositional LogicAldrich PanioBelum ada peringkat

- Math 9 Q1 Summative Test 1Dokumen4 halamanMath 9 Q1 Summative Test 1John Paul GaoatBelum ada peringkat

- Embase - Other - EmbaseScopusOverview Base de DatosDokumen5 halamanEmbase - Other - EmbaseScopusOverview Base de DatosAditya GhoshBelum ada peringkat

- New 2010 York PerfectDokumen9 halamanNew 2010 York Perfectbasl haymourBelum ada peringkat

- Neeraj BitcellDokumen2 halamanNeeraj BitcellPRANJAL RAJANBelum ada peringkat

- Firmware Update of Protection and Control Relays DescriptionDokumen3 halamanFirmware Update of Protection and Control Relays DescriptionHutch WoBelum ada peringkat

- E Commerce A Solution To Pakistans Economic WoesDokumen27 halamanE Commerce A Solution To Pakistans Economic WoesInciaBelum ada peringkat

- Rodavigo Acoplamientos 02 Acoplamientos de BielasDokumen20 halamanRodavigo Acoplamientos 02 Acoplamientos de BielasArturo J. Londono MBelum ada peringkat

- JKIT - Dialog SAP Revamp Phase II As-Is Proposal V2.0Dokumen10 halamanJKIT - Dialog SAP Revamp Phase II As-Is Proposal V2.0Hathim MalickBelum ada peringkat

- Series Al5000 Light Tower: Operation/Service & Parts ManualDokumen64 halamanSeries Al5000 Light Tower: Operation/Service & Parts ManualJovanBelum ada peringkat

- Lecture-3 (Design Methods)Dokumen26 halamanLecture-3 (Design Methods)Mohsin IqbalBelum ada peringkat

- Psychology of Color2Dokumen33 halamanPsychology of Color2abdikani abdilaahiBelum ada peringkat

- Ab 521 Requirements For Engineered Pressure EnclosuresDokumen39 halamanAb 521 Requirements For Engineered Pressure EnclosuresCarlos Maldonado SalazarBelum ada peringkat

- Update Penjualan 2019 1Dokumen941 halamanUpdate Penjualan 2019 1Viar TimikaBelum ada peringkat

- VerilatorDokumen224 halamanVerilatorGolnaz KorkianBelum ada peringkat

- Keras - TF2 - BookDokumen364 halamanKeras - TF2 - BookDuy LinhBelum ada peringkat

- Master Trip Relay PDFDokumen2 halamanMaster Trip Relay PDFEr Suraj KumarBelum ada peringkat

- As 3850-2003 Tilt-Up Concrete ConstructionDokumen8 halamanAs 3850-2003 Tilt-Up Concrete ConstructionSAI Global - APACBelum ada peringkat

- Business Statistics Communicating With Numbers 4E 4Th Edition Sanjiv Jaggia Full ChapterDokumen67 halamanBusiness Statistics Communicating With Numbers 4E 4Th Edition Sanjiv Jaggia Full Chapterdoris.heck867100% (3)

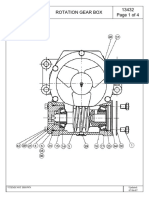

- Caja de Engranes para Pluma DunbarRotationGearBoxDokumen4 halamanCaja de Engranes para Pluma DunbarRotationGearBoxMartin CalderonBelum ada peringkat

- GE TVSS Specification Data Sheet (TME 65ka - 100ka - Wall Monut)Dokumen3 halamanGE TVSS Specification Data Sheet (TME 65ka - 100ka - Wall Monut)Angela TienBelum ada peringkat

- Module 2 Global Youth: A Estrutura Do Teste Sintetiza-Se No Quadro SeguinteDokumen11 halamanModule 2 Global Youth: A Estrutura Do Teste Sintetiza-Se No Quadro SeguinteLaura HenriquesBelum ada peringkat