Thermal Conductivity and Heat Capacity of Zircaloy 2 4 and Unalloyed Zirconium

Diunggah oleh

anish_npcilHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Thermal Conductivity and Heat Capacity of Zircaloy 2 4 and Unalloyed Zirconium

Diunggah oleh

anish_npcilHak Cipta:

Format Tersedia

Journal of Nuclear Science and Technology

ISSN: 0022-3131 (Print) 1881-1248 (Online) Journal homepage: https://www.tandfonline.com/loi/tnst20

Thermal Conductivity and Heat Capacity of

Zircaloy-2, −4 and Unalloyed Zirconium

Masayuki MURABAYASHI , Shigenori TANAKA & Yoichi TAKAHASHI

To cite this article: Masayuki MURABAYASHI , Shigenori TANAKA & Yoichi TAKAHASHI (1975)

Thermal Conductivity and Heat Capacity of Zircaloy-2, −4 and Unalloyed Zirconium, Journal of

Nuclear Science and Technology, 12:10, 661-662, DOI: 10.1080/18811248.1975.9733170

To link to this article: https://doi.org/10.1080/18811248.1975.9733170

Published online: 15 Mar 2012.

Submit your article to this journal

Article views: 2363

Citing articles: 10 View citing articles

Full Terms & Conditions of access and use can be found at

https://www.tandfonline.com/action/journalInformation?journalCode=tnst20

and TECHNOLOGY,

Journal of NUCLEARSCIENCE 12C103, pp. 661-662 (October 1975). 661

were made 9 mm in diameter and 2 mm thick

SHORT

NOTE for the heat capacity measurements. All the

samples were annealed at 750°C in vacuum

Thermal Conductivity and Heat before each run.

The apparatus and procedures used in the

Capacity of Zircaloy-2, -4 measurement have been described previously

and Unalloyed Zirconium The precision of the measurement was

'*)-(').

within +1.0% for heat capacity and +1.5%

Masayuki MURABAYASHI, Shigenori TANAKA for thermal diffusivity.

and Yoichi TAKAHASHI The measured thermal diffusivities of zir-

caloy-2, -4 and unalloyed zirconium are pre-

Department of Nuclear Engineering, sented in Fig. 1, together with the values for

University of Tokyo* zircaloy-2 measured by Walter et al."), who

reported that for zircaloy-2 no anisotropy of

Received May 22, 1975 heat conduction was observed. They remark-

ed, on the other hand, that the thermal diffu-

KEYWORDS: zircaloy 2, zircaloy 4 , sivity was markedly influenced by differences

zirconium, thermal conductivity, heat in specimen thickness. The present results,

capacity, thermal diffusivity, medium in contrast, reveal only insignificant depend-

temperature, high temperature

ence on the thickness of the specimens. The

values obtained for thermal diff usivity agreed

The thermal diffusivity and the heat capa- reasonably well with those by Walter et al.

city of zircaloy-2, -4 and unalloyed zircanium for specimens of thickness 2 2 mm.

were measured from 300 to 850K by means

of the laser flash method. OVr-----

The specimens of zircaloy-2 and -4 were

prepared from cold-rolled plates, manufactur-

ed by Sumitomo Metal Industries, Ltd., and

the direction of heat flow in the measurement

of thermal diffusivity was arranged to be the

thickness direction. Table 1 gives the stand-

ard composition of the zircaloy-2 and -4 sam-

ples.

Table 1 Standard compositions of zircaloy-2

and -4 (analyzed) (%yo)

Sample Sn Ni Fe Cr Zr 1 0 : Zirconium (Present study). 2 A : Zircaloy-2

(Present study, Specimen: 2mm thick), 3 A : Zir-

Zircaloy-2 1.49 0.06 0.15 0.10 Balance caloy-2 (Present study, Specimen: 0.6mm thick),

4: Zircaloy-2 (Walter et ul.(4), Specimen: 2mm

Zircaloy-4 1.51 - 0.23 0.10 n thick), 5: Zircalou-2 (Walter et ~ l . ( ~Specimen:

),

0.5mm thick), 6 0 :Zircaloy-4 (Present study)

The specimens of unalloyed zirconium were Fig. 1 Thermal diffusivity of zircaloy-2,

sliced from an ingot prepared from reactor -4 and zirconium

grade sponge zirconium by means of electron

beam melting and hence the texture differed The results of heat capacity measurement

somewhat from that of the rolled zircaloy on unalloyed zirconium are shown in Fig. 2,

plates. together with the data reported by other in-

All the specimens were formed into disk- vestigator~'~)(~).

shaped pellets. The size of the specimens The heat capacities of zircaloy-2 and -4 at

for the thermal diff usivity measurements was room temperature were also measured, and

7 mm in diameter and 2 mm thick, while they * Hongo, Bunkyo-ku, Tokyo.

- 61 -

662 SHORTNOTE (M. Murabayashi et al.) J. Nucl. Sci. Technol.,

k=aC,p, (1)

where k is the thermal conductivity (W/cm.K),

a , the thermal diffusivity (cm2/sec), C, the

0.30- specific heat capacity (J/g.K) and p the den-

7

?ccn sity of the sample (g/cmS). In this calcula-

-8

-I tion, correction was made on a to account

for finite pulse time and on both a and p

0.20- for thermal expansion.

T h e resulting data for the thermal con-

ductivity of zircaloy-2 and -4,upon treatment

by least-squares method, can be expressed

by the formulas :

For zircaloy-2 : k=0.138-3.90~ 10-6T

1 0: Present study, 2: Douglascs), 3: ToddcG) +1.184x 10-'T2

Fig. 2 Heat capacity of zirconium (W/cm.K) ( 2 )

were found to be very close to the corre- For zircaloy-4 : k=0.113+2.25x 10-'T

sponding values given in l i t e r a t ~ r e ( ~ ) ";(they

~' +0.725x 1 0 - T '

also agreed well with the present results for (W/cm.K). ( 3 )

unalloyed cast zirconium. T h e heat capaci-

ties of zircaloy-2 and -4 can thus be regarded We wish to thank Prof. T. Mukaibo, Prof.

as being equal to that of zirconium from 300 M. Kanno and Prof. Y. Mishima, of the Uni-

to 850K. versity of Tokyo, for their generous support

T h e determined thermal conductivities of of this work. T h e courtesy of Sumitomo

zircaloy-2, -4 and unalloyed zirconium are Metal Industries, Ltd. for providing us with

shown in Fig. 3, in which they are compared the zircaloy samples is also greatly appreci-

ated. Part of the experimental work was

performed by using the facility of the Re-

search Center for Nuclear Science and Tech-

nology, University of Tokyo.

-

-REFERENCES--

(1) MURABAYASHI, M., TAKAHASHI, Y., NAMBA,

S., MUKAIBO, T. : J. Nucl. Sci. Technol., 6131,

128 (1969).

(2) TAKAHASHI, Y., MURABAYASHI, M. : ibid., 12

(33, 133 (1975).

'O 300 500 700 900 (3) TAKAHASHI, Y. : J. Nucl. Muter., 51, 17 (1974).

71K (4) WALTER,A.J., DELL,R.M., GILCHRIST, K.E.,

1 0 : Zirconium (Present study), 2: Zirconium

et al. : High Temp.-High Pressures, 4,439 (1972).

(Powell et uL(10)). 3 A : Zircaloy-2 (Present (5) DOUGLAS, T.B.: J . Res. Nut. Bur. Stand., A,

study), 4: Zircaloy-2 (Lucks et ul.(11)), 5 0 : 67A, 5, 403 (1963).

Zircaloy-4 (Present study) (6) TODD,S.S. : J . Amer. Chem. SOC.,72,2914 (1950).

Fig. 3 Thermal conductivity of zircaloy-2, (7) BROOKS, C.R., STANSBURY, E.E.: J. Nucl. Muter.,

-4, and zirconium 18, 233 (1966).

(8) DEEM,H.W., ELDRIDGE, E.A.: BMI-1644, (1963).

with the results of other workersclo)cll'.These (9) CASEY, D.N., YATES, B . : High Temp.-High

values of thermal conductivity were calculat- Pressures, 6, 33 (1974).

(lo) POWELL,R.W., TYE,R.P.: J. Less-Common

ed from the present results for thermal dif- Metals, 3, 202 (1961).

fusivity and heat capacity by using the well (11) LUCKS,C.F., DEEM,H.W. : BMI-1273, p. 7-9

established relationship (1958).

- 62 -

Anda mungkin juga menyukai

- Ageing Effect On The Properties of CuCrZr AlloyDokumen5 halamanAgeing Effect On The Properties of CuCrZr AlloyPankaj SahlotBelum ada peringkat

- Study of The Mechanical and Thermal Properties of Sn-5Sb (DR Alla Bahgat)Dokumen15 halamanStudy of The Mechanical and Thermal Properties of Sn-5Sb (DR Alla Bahgat)eidelsayedBelum ada peringkat

- Effect of Applied Stress On Temper Embrittlement of 2Kcr-1Mo SteelDokumen7 halamanEffect of Applied Stress On Temper Embrittlement of 2Kcr-1Mo Steelscg1234Belum ada peringkat

- 1997 - Influence of Ferritic Rolling Temp On Grain Size and Texture in Anneal LowC and IFDokumen9 halaman1997 - Influence of Ferritic Rolling Temp On Grain Size and Texture in Anneal LowC and IFKetnipha SukwannawitBelum ada peringkat

- ZrTiO4 Dielectric StudyDokumen6 halamanZrTiO4 Dielectric Study19Y203 - AMITH B KBelum ada peringkat

- 0283 VangskasenDokumen8 halaman0283 VangskasenAdvantica ServicesBelum ada peringkat

- Heat-Treatment o F UraniumDokumen7 halamanHeat-Treatment o F UraniumOmar VillanuevaBelum ada peringkat

- Electric Field Dependent Specific Heat of Srtio, Batio and Ktao Ferroelectric PerovskitesDokumen7 halamanElectric Field Dependent Specific Heat of Srtio, Batio and Ktao Ferroelectric PerovskitesIJMERBelum ada peringkat

- Haruyama Etal 1993 SolarHeating OrtDokumen12 halamanHaruyama Etal 1993 SolarHeating OrtLuciano del ValleBelum ada peringkat

- 1365 3141 1 PB PDFDokumen5 halaman1365 3141 1 PB PDFIhsan SaputraBelum ada peringkat

- Isothermal Fatigue Properties of Sn-Ag-Cu Alloy EvDokumen8 halamanIsothermal Fatigue Properties of Sn-Ag-Cu Alloy EvLong Nguyen DucBelum ada peringkat

- Thermal Conductivity Titanium Carbide, Zirconium Carbide, and Titanium Nitride at TemperaturesDokumen5 halamanThermal Conductivity Titanium Carbide, Zirconium Carbide, and Titanium Nitride at TemperaturesBasit FebrianBelum ada peringkat

- Development of Johnson Cook Model For Zirconium AlloyFinalDokumen15 halamanDevelopment of Johnson Cook Model For Zirconium AlloyFinalsandeepBelum ada peringkat

- Study of Thermal Annealing Effect On The Properties of Silver Thin Films Prepared by DC Magnetron SputteringDokumen3 halamanStudy of Thermal Annealing Effect On The Properties of Silver Thin Films Prepared by DC Magnetron SputteringKo Mya SanBelum ada peringkat

- Calor Especifico - SerpentineDokumen5 halamanCalor Especifico - SerpentineAna Flávia CamposBelum ada peringkat

- Olivine (Mg2SiO4) Enthalpy Values.Dokumen13 halamanOlivine (Mg2SiO4) Enthalpy Values.Meerab YousufBelum ada peringkat

- Ojay 1ST Publication PDFDokumen16 halamanOjay 1ST Publication PDFvenkatrangan2003Belum ada peringkat

- The Influence of Cooling Rate On The Microstructure and Phase Fraction of Gas Atomized NiAl3 Alloy Powders During Rapid SolidificationDokumen7 halamanThe Influence of Cooling Rate On The Microstructure and Phase Fraction of Gas Atomized NiAl3 Alloy Powders During Rapid SolidificationJotaBelum ada peringkat

- Measurement of Neutron Flux Spectrum by Multi-Foil Activation Method at The Central Graphihte Cavity of UTR-KINKIDokumen14 halamanMeasurement of Neutron Flux Spectrum by Multi-Foil Activation Method at The Central Graphihte Cavity of UTR-KINKI최재원Belum ada peringkat

- Alamos: LA-6928-MSDokumen9 halamanAlamos: LA-6928-MSsultannesru2030Belum ada peringkat

- Nanocrystalline Metals Prepared by High-Energy Ball Milling: II. Experimental DetailsDokumen5 halamanNanocrystalline Metals Prepared by High-Energy Ball Milling: II. Experimental DetailsMohamed KhalifaBelum ada peringkat

- Fuel 79 (1215 1220)Dokumen6 halamanFuel 79 (1215 1220)Melina DVilla Silva LimaBelum ada peringkat

- SIgma Phase in S2205 PDFDokumen5 halamanSIgma Phase in S2205 PDFShoaib Ahmed100% (1)

- Study On The Influence of Carbon On Standardized and Non-Standardized SteelDokumen4 halamanStudy On The Influence of Carbon On Standardized and Non-Standardized SteelAndreea SorleaBelum ada peringkat

- Transport Properties of Silver Selenide Thin Films From 100 To 300 KDokumen5 halamanTransport Properties of Silver Selenide Thin Films From 100 To 300 KSiddhesh Umesh MestryBelum ada peringkat

- Deposition and Characterization of Metalorganic ChemicalDokumen7 halamanDeposition and Characterization of Metalorganic Chemicalunicum78Belum ada peringkat

- 836 Mar2019Dokumen8 halaman836 Mar2019Vivekananda SubramaniBelum ada peringkat

- ML010330422Dokumen249 halamanML010330422EnformableBelum ada peringkat

- Synthesis of Cordierite From y Ash and Its Refractory PropertiesDokumen4 halamanSynthesis of Cordierite From y Ash and Its Refractory PropertiesUmer HayatBelum ada peringkat

- Degradation of Insulating Materials of TransformerDokumen6 halamanDegradation of Insulating Materials of TransformerPaulomario RemuzgoBelum ada peringkat

- 01 - Sol Gel CuZro2Dokumen5 halaman01 - Sol Gel CuZro2myalemusBelum ada peringkat

- 1 s2.0 0029549382901443 MainDokumen14 halaman1 s2.0 0029549382901443 MainJuan IbiapinaBelum ada peringkat

- Formation of Ferroelectric Properties in BaTiO3 Nanoparticles During Heat TreatmentDokumen13 halamanFormation of Ferroelectric Properties in BaTiO3 Nanoparticles During Heat Treatmentisais llanos sisayaBelum ada peringkat

- Theoretical Approach To Investigate Temperature Dependent Ultrasonic and Thermophysical Properties of Ti-Zr-Hf Ternary AlloyDokumen8 halamanTheoretical Approach To Investigate Temperature Dependent Ultrasonic and Thermophysical Properties of Ti-Zr-Hf Ternary AlloyIJRASETPublicationsBelum ada peringkat

- Komolikov2017 - Article - ThermalExpansionOfCompositeCer PDFDokumen4 halamanKomolikov2017 - Article - ThermalExpansionOfCompositeCer PDFkresna murtiBelum ada peringkat

- Thermal Conductivity of Amorphous Sio Thin Film: A Molecular Dynamics StudyDokumen9 halamanThermal Conductivity of Amorphous Sio Thin Film: A Molecular Dynamics StudyAlan de OliveiraBelum ada peringkat

- Investigation On The Creep Behaviour of Friction Stir Processed Al Ni Composite MaterialDokumen4 halamanInvestigation On The Creep Behaviour of Friction Stir Processed Al Ni Composite MaterialEditor IJTSRDBelum ada peringkat

- Crystallization Mechanism and Properties of A Blast Furnace Slag GlassDokumen12 halamanCrystallization Mechanism and Properties of A Blast Furnace Slag GlassAgus Praditya TBelum ada peringkat

- Phase Stability and Thermal Conductivity of YtterbDokumen6 halamanPhase Stability and Thermal Conductivity of Ytterbhiba mhiriBelum ada peringkat

- 1 s2.0 S0921452607003730 MainDokumen6 halaman1 s2.0 S0921452607003730 MainBhabaniBelum ada peringkat

- Preparation and Characterisation of Self-Flowing Refractory Material Containing 971U Type MicrosilicaDokumen6 halamanPreparation and Characterisation of Self-Flowing Refractory Material Containing 971U Type MicrosilicaAhmed Mostafa AL-AboudyBelum ada peringkat

- Volchok 22Dokumen4 halamanVolchok 22amitkkambleBelum ada peringkat

- The Heat Capacities of Titanium Dioxide From The Thermodynamic Properties of Titanium DioxideDokumen3 halamanThe Heat Capacities of Titanium Dioxide From The Thermodynamic Properties of Titanium DioxideNaufal AdityasBelum ada peringkat

- Xiao2013 Article MicrostructureAndPropertiesOfCDokumen6 halamanXiao2013 Article MicrostructureAndPropertiesOfCShivansh MishraBelum ada peringkat

- On Structural, Optical and Dielectric Properties of Zinc Aluminate NanoparticlesDokumen9 halamanOn Structural, Optical and Dielectric Properties of Zinc Aluminate NanoparticlesbudhladaBelum ada peringkat

- Structural and Wear Characterization of Heat Treated En24 SteelDokumen7 halamanStructural and Wear Characterization of Heat Treated En24 Steelsmith willBelum ada peringkat

- Thermal Degradation of Nicalon SiC FibersDokumen13 halamanThermal Degradation of Nicalon SiC FibersbbeeBelum ada peringkat

- Effect of Thermal Exposure On Strength of ZrB2-Based Composites With Nano-SizedDokumen8 halamanEffect of Thermal Exposure On Strength of ZrB2-Based Composites With Nano-Sizedsa_noghabaeeBelum ada peringkat

- Trabajo 5-1Dokumen11 halamanTrabajo 5-1Andres palomino ramosBelum ada peringkat

- Thermal Expansion of SpinelsDokumen6 halamanThermal Expansion of SpinelsRichardBelum ada peringkat

- Grain Boundary Chemistry and Intergranular Corrosion in Alloy 825Dokumen52 halamanGrain Boundary Chemistry and Intergranular Corrosion in Alloy 825Rajkumar MuthumanickamBelum ada peringkat

- 9 MSF 765 130-2013Dokumen7 halaman9 MSF 765 130-2013Marko JukićBelum ada peringkat

- Linear Thermal Expansion CoefficientsDokumen4 halamanLinear Thermal Expansion CoefficientsputriBelum ada peringkat

- Modulation of Thermoelectric Properties of Thermally Evaporated Copper Nitride Thin Films by Optimizing The Growth ParametersDokumen5 halamanModulation of Thermoelectric Properties of Thermally Evaporated Copper Nitride Thin Films by Optimizing The Growth Parameters명길김Belum ada peringkat

- A Study On Zirconium Rich Uranium-Zirconium Alloys PDFDokumen8 halamanA Study On Zirconium Rich Uranium-Zirconium Alloys PDFOmar VillanuevaBelum ada peringkat

- Diffusive and Displacive Transformation in Plagioclase and Ternary Feldspar SerieslDokumen7 halamanDiffusive and Displacive Transformation in Plagioclase and Ternary Feldspar SerieslMartha Elba Moreno MartínezBelum ada peringkat

- 3-D Modelling of Thermal and Sodium Expansion in Soderberg Aluminium Reduction CellsDokumen6 halaman3-D Modelling of Thermal and Sodium Expansion in Soderberg Aluminium Reduction CellsOctaviano MichinelBelum ada peringkat

- Gamma Prime Phase Stability After Long-Term Thermal Exposure in Cast Nickel Based Superalloy, IN-738Dokumen8 halamanGamma Prime Phase Stability After Long-Term Thermal Exposure in Cast Nickel Based Superalloy, IN-738claire_26Belum ada peringkat

- Heat Capacity of Oxide Glasses at High Temperature Region Inaba 2003Dokumen9 halamanHeat Capacity of Oxide Glasses at High Temperature Region Inaba 2003b meryemBelum ada peringkat

- Analytical Chemistry of Zirconium and Hafnium: International Series of Monographs in Analytical ChemistryDari EverandAnalytical Chemistry of Zirconium and Hafnium: International Series of Monographs in Analytical ChemistryBelum ada peringkat

- IntroductionDokumen18 halamanIntroductionanish_npcilBelum ada peringkat

- Grid Generation Tgrid: Me469B/2B/Gi 1Dokumen15 halamanGrid Generation Tgrid: Me469B/2B/Gi 1anish_npcilBelum ada peringkat

- Candu Fundamentals20040700Dokumen314 halamanCandu Fundamentals20040700giampierovalenti100% (1)

- CANDU & PWRDokumen20 halamanCANDU & PWRanish_npcilBelum ada peringkat

- Heat Loss From A Pipe Calculator - Engineers EdgeDokumen2 halamanHeat Loss From A Pipe Calculator - Engineers EdgeJA KBelum ada peringkat

- Nsport Phenomena in Materials Engineering PDF Book - Mediafile Free File SharingDokumen3 halamanNsport Phenomena in Materials Engineering PDF Book - Mediafile Free File SharingSanjeev Sahu0% (1)

- 16 - Blending and AgitationDokumen20 halaman16 - Blending and AgitationRafael ReyesBelum ada peringkat

- Price List Moshiur 06 05 17Dokumen96 halamanPrice List Moshiur 06 05 17Shah Newaz Kabir75% (8)

- Practical Uses Kinetic Seperation in Sample System DesignDokumen14 halamanPractical Uses Kinetic Seperation in Sample System DesignSamit ShaikhBelum ada peringkat

- Unit - 1-Rayleigh and Fanno FlowDokumen86 halamanUnit - 1-Rayleigh and Fanno Flowmebrahtu100% (4)

- YCAB ManDokumen44 halamanYCAB Manttt44967% (3)

- Two Phase FlowDokumen11 halamanTwo Phase FlowVikrant DeshmukhBelum ada peringkat

- Designing Systems For Oxygen ServiceDokumen27 halamanDesigning Systems For Oxygen Servicejuan nina100% (1)

- Uow009694 Hydraulic Services Design StandardsDokumen37 halamanUow009694 Hydraulic Services Design StandardsstarykltBelum ada peringkat

- The Integral Forms of The Fundamental Laws - 2Dokumen24 halamanThe Integral Forms of The Fundamental Laws - 2Jenille C. VillanuevaBelum ada peringkat

- Chapter C3: Ventilation of Non-Domestic BuildingsDokumen15 halamanChapter C3: Ventilation of Non-Domestic BuildingsAli AimranBelum ada peringkat

- Cadabadi - T1 - Taller ConduccionDokumen5 halamanCadabadi - T1 - Taller ConduccionAndres FigueroaBelum ada peringkat

- T-021 - Site Survey Report TAGS - MOC 1405 - IFCDokumen22 halamanT-021 - Site Survey Report TAGS - MOC 1405 - IFCTarkeshwar SharmaBelum ada peringkat

- The MABR TechnologyDokumen10 halamanThe MABR TechnologyJam OdonelBelum ada peringkat

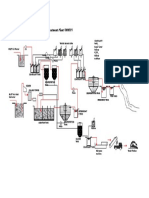

- Flow Chart WWTPDokumen1 halamanFlow Chart WWTPRahmi AsyariBelum ada peringkat

- PVG 32 Sauer DanfossDokumen44 halamanPVG 32 Sauer DanfossRafaelBelum ada peringkat

- Stim-03.006 - en Control FluidDokumen17 halamanStim-03.006 - en Control Fluidbikendiaguirre100% (1)

- Talk 6-3-2 CST EUC 2012Dokumen43 halamanTalk 6-3-2 CST EUC 2012Sanjay_Tadepal_9503Belum ada peringkat

- Clorius enDokumen3 halamanClorius enRiski SuhardinataBelum ada peringkat

- DS WasteWaterTreatment SGR 0318 ENGDokumen2 halamanDS WasteWaterTreatment SGR 0318 ENGvictor diazBelum ada peringkat

- Pipesim User Guide PDFDokumen809 halamanPipesim User Guide PDFGuilherme MonteiroBelum ada peringkat

- FX 400-2000Dokumen8 halamanFX 400-2000francisco jose arruda de sousaBelum ada peringkat

- Colfax Americas / Imo PumpDokumen8 halamanColfax Americas / Imo PumprajeegargBelum ada peringkat

- Assignment Plus Question Bank-1Dokumen1 halamanAssignment Plus Question Bank-1jeyovi4685Belum ada peringkat

- Sewage Treatment Plant (Project)Dokumen16 halamanSewage Treatment Plant (Project)Juhi YadavBelum ada peringkat

- CST14 Compressor Oil Flow Case StudyDokumen12 halamanCST14 Compressor Oil Flow Case StudyGustavoBelum ada peringkat

- Tuberia PVC Ced40Dokumen64 halamanTuberia PVC Ced40KoOkz GarciaBelum ada peringkat

- 794 - Metso HH 200 C5 Curve RELDokumen1 halaman794 - Metso HH 200 C5 Curve RELHumberto GoncalvesBelum ada peringkat

- Index: 1. Check Point of P&ID 2. Check Point of ISO DrawingDokumen26 halamanIndex: 1. Check Point of P&ID 2. Check Point of ISO DrawingandrenugrahaBelum ada peringkat