09200-En-30 Process Facility Site Change Management

Diunggah oleh

fernandoHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

09200-En-30 Process Facility Site Change Management

Diunggah oleh

fernandoHak Cipta:

Format Tersedia

9.

2 Process/ Facility Site Change Management

Purpose:

To manage the introduction of the process/facility site changes in order to ensure that there is no negative impact on supplier products.

(The scope of the Process / Facility Site Change Management covers all changes made by the Tier 1 supplier or in their supply chain.)

Note(s):

The supplier shall have a change management system which includes, schedule for the changes, risk analysis & management, product

verification & validation activities.

Once the adoption of the change is confirmed as successful, mass production part approval from Renault-Nissan is necessary before shipment

of any change affected product.

The supplier shall ensure that all requests for Process/Facility site changes are authorized by Renault-Nissan prior to any change takes place.

The Process / Facility Site Change Request document shall be submitted 3 months before implementation of any change.

The Tier 1 supplier or its sub-supplier shall not carry out any Process / Facility site changes during Phase 4 and Phase 5 Ramp-Up.

(The facility site provided for the "off-process" condition shall be in line with that agreed at the supplier sourcing confirmation.)

If the Tier 1 supplier or their sub-suppliers will make a Process / Facility site change, the Tier 1 supplier shall submit a Process/ Facility Site

Change Request document to the relevant Renault-Nissan department. Example of changes that require Renault-Nissan authorization are

described below (Routine planned maintenance activities such as Total Preventative Maintenance (TPM) do not require Renault-Nissan

authorization but require the Process/ Facility Site Change management activity under Tier 1 supplier responsibility.)

The Process / Facility Site Change Request document shall be submitted to the first customer in Renault-Nissan, if it has effect on several

plants in Renault-Nissan.

The supplier shall provide information of all planned changes including case of not necessary submission Process / Facility Site Change

Request on Renault-Nissan requirement (categories of changes should be clearly defined as major and minor changes for example ).

Alliance New Product Quality Procedure (ANPQP)

Printed versions of this document are not controlled by the version management system.

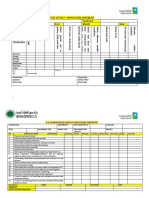

Example of Process Change Activity level (required) Remark

Supplier self-review

1st layer under Tier 1 resp.

2nd layer Review with

Renault-NISSAN

4M

3rd layer (Submit Doc.*1).

Production site change

Relocation/Move to a different site X X

To another site owned by the parent company

To a different company ( out sourced)

Relocation/Move within the current site X X

Layout Change

Relocate production line (inc inspection process)

Newly developed or Expansion to the current production line (inc

inspection process)

Process sequence (inc adding or eliminating process steps) X X

Machine/Equipment on the production line change (inc inspection machine)

Installing new equipment X X

Addition or replacement of machine/equipment X X

Machine/Equipment parameters (except calibration in daily checking) X X

Modification of existent machine/equipment X X

Repairs (Unplanned maintenance and repairs) X No effect to

Machine

Planned maintenance and repairs X process/product

characteristics by

PM*2).

Alliance New Product Quality Procedure (ANPQP)

Printed versions of this document are not controlled by the version management system.

Dies/ Molds change

Addition or replacement of new dies/molds X X

Modification of existent dies/molds X X

Repairs (Unplanned maintenance and repairs) X No effect to

Planned maintenance and repairs X process/product

characteristics by

PM*2).

Tools change

Addition or replacement of new tools X X

Modification of existent tools X X

Repairs (Unplanned maintenance and repairs) X No effect to

Planned maintenance and repairs X process/product

characteristics by

PM*2).

Inspection/ measurement tools change X X

Addition or replacement of dedicated inspection / measurement tool (specific

gauge etc)

Modification of special inspection/measurement tool X X

Addition or replacement of general inspection/measurement tool (vernier X

caliper,micrometer etc)

Modification of general inspection / measurement tool (vernier X

caliper,micrometer etc)

Repairs (Unplanned maintenance and repairs) X No effect to

Planned maintenance and repair X process/product

characteristics by

PM*2).

Working method change Contact Renault-

X X NISSAN

Method

Assembling/Processing method (welding, surface finishing, heat treating, etc )

Inspection method X X responsible dept if

logistics and/or

Change/Eliminate inspection process (inc specification change)

Alliance New Product Quality Procedure (ANPQP)

Printed versions of this document are not controlled by the version management system.

Transporting method between process and process X packaging method

Storing method X will change.

Product, Work-in-process, Component, Raw material, Indirect

material

Indirect material change (excluding the material which Renault-NISSAN approved in its Submit "Design

specification) X X Change Request" if

Material

Component of indirect material (cleaning agent, degreasing agent, etc) Renault-NISSAN

Supplier of indirect material (inc relocation) X X approved material

will change.

Assignment of new worker X

Worker's shift change X

Qualified worker change

Man

Assigned workers working on special characteristic features (ANPQP X

requirement)

(But are not limited to) *1) Doc.; Process / Facility Site Change Request, *2) PM; Preventive Maintenance

Alliance New Product Quality Procedure (ANPQP)

Printed versions of this document are not controlled by the version management system.

Timeline Supplier Renault-Nissan

Study process/facility site change To the first customer in

Renault/ Nissan

Process/Facility Site

-3 months Change Request

(Major or minor

change)

Review

Y

N es N

o Feasible? o Approve?

Y

End (Cancel es

request) Designate item for Part Submission Warrant

(PSW)

Review the action item & update the plan

Beginning Implement activity along with the plan

of change

Production traial

Part Submission

Warrant (PSW)

Review

Audit (if necessary)

N

o Approve?

Y

es

Start mass production & deliver product

End (Receive the product)

Alliance New Product Quality Procedure (ANPQP)

Printed versions of this document are not controlled by the version management system.

Phase 1 2 3 4 5

-Plan the change and perform risk analysis.

-Complete and submit the Process / Facility Site Change Request document to Renault / Nissan for approval.

-Implement the planned change.

Activity -Confirm the quality before and after change to ensure there is no deterioration

Content -Update all documents and re-apply for PSW approval before the delivery of post-change parts, unless

otherwise agreed with Renault / Nissan.

-Notify Renault / Nissan of successful completion of the Process / Facility Site change by submission

of the final ‘Notification of Completion' section of the authorized Process / Facility Site Change Request

document.

Output

-Process /Facility Site Change Request

Document

ISO/TS 16949 Reference Number

7.1 Planning of product realization (for example; 7.1.4 Change control)

7.2 Customer-related processes (for example; 7.2.2 Review of requirements related to the product)

7.3 Design and development (for example; 7.3.5 Design and development review)

7.4 Purchasing (for example; 7.4.1.1 Regulatory conformity)

8.5 Improvement (for example; 8.5.1.2 Manufacturing process improvement)

Alliance New Product Quality Procedure (ANPQP)

Printed versions of this document are not controlled by the version management system.

Anda mungkin juga menyukai

- Conducting Drop Object Inspection - RA-R9-01-017-01Dokumen1 halamanConducting Drop Object Inspection - RA-R9-01-017-01cmrig74Belum ada peringkat

- Health, Safety, Environment (HSE) Training Matrix - Houston: Today's DateDokumen4 halamanHealth, Safety, Environment (HSE) Training Matrix - Houston: Today's Datemonica dwimandhaBelum ada peringkat

- Safety Training For VisitorsDokumen13 halamanSafety Training For VisitorsHugo MarquesBelum ada peringkat

- MS KPI Trend - Management System Compliance - November 2023Dokumen1 halamanMS KPI Trend - Management System Compliance - November 2023DUSTIN AYEN KERBY DEALOLABelum ada peringkat

- Chapter 9. Failure Root Cause PreventionDokumen23 halamanChapter 9. Failure Root Cause PreventionAbdirahman Ali mohamudBelum ada peringkat

- Inspection ReportDokumen6 halamanInspection ReportRyn RcioBelum ada peringkat

- Hazardous Material Weekly InspectionDokumen1 halamanHazardous Material Weekly InspectionYexiong YIALENGBelum ada peringkat

- NEBBinar ASHRAE 202 PDFDokumen42 halamanNEBBinar ASHRAE 202 PDFrasheedillikkal100% (2)

- Validation of Processes Is Similar To The Requirements of 4.9 Process Control of The 1994 Standard. There Are No Significant ChangesDokumen2 halamanValidation of Processes Is Similar To The Requirements of 4.9 Process Control of The 1994 Standard. There Are No Significant ChangesManivannanMudhaliarBelum ada peringkat

- Mudon Ahlia Real Estate Co.W.L.L. Annual Training Plan 2014: Prepared byDokumen2 halamanMudon Ahlia Real Estate Co.W.L.L. Annual Training Plan 2014: Prepared byHebatallah FahmyBelum ada peringkat

- 4M Change ManagementDokumen2 halaman4M Change ManagementManoj KumarBelum ada peringkat

- Condition SurveyDokumen24 halamanCondition Surveypankajsingh fosrocBelum ada peringkat

- Kerui XJ650 Rig WorkoverDokumen29 halamanKerui XJ650 Rig WorkoverElieser MirandaBelum ada peringkat

- Electrical Safety AuditDokumen27 halamanElectrical Safety AuditprempaltyagiBelum ada peringkat

- OP-09 - H5 Noise MonitoringDokumen1 halamanOP-09 - H5 Noise Monitoringsalman farisBelum ada peringkat

- SysAdmin Ebook Final Feb2010Dokumen525 halamanSysAdmin Ebook Final Feb2010JohnJ.Bateman100% (1)

- Safety Alert Incident-Left Eye Injury Dated 02042010Dokumen1 halamanSafety Alert Incident-Left Eye Injury Dated 02042010NethiyaaRajendran100% (1)

- Plan de Trabajos: Cash FlowDokumen3 halamanPlan de Trabajos: Cash FlowAriel IsaackBelum ada peringkat

- Safety Moment - PPEDokumen1 halamanSafety Moment - PPEtimbulBelum ada peringkat

- Kaizen 5W 1H PDFDokumen20 halamanKaizen 5W 1H PDFSUBA NANTINI A/P M.SUBRAMANIAMBelum ada peringkat

- Employee HandbookDokumen12 halamanEmployee HandbookEvert W. VanderBerg100% (2)

- QEHS ManualDokumen100 halamanQEHS ManualRob WillestoneBelum ada peringkat

- QSP 7.1-03 Control of Organizational Knowledge (Preview)Dokumen4 halamanQSP 7.1-03 Control of Organizational Knowledge (Preview)Centauri Business Group Inc.100% (1)

- JOB Description: Position Title Department Position Reports To Job Class Job SummaryDokumen2 halamanJOB Description: Position Title Department Position Reports To Job Class Job SummaryVijay RajaindranBelum ada peringkat

- Management Walk-Through Check List: What We See What We Want To See SalesDokumen6 halamanManagement Walk-Through Check List: What We See What We Want To See SalesDhananjay PatilBelum ada peringkat

- Visual - Workplace.improvingbusinessperformance - Slideshare.pp1 SafetyDokumen49 halamanVisual - Workplace.improvingbusinessperformance - Slideshare.pp1 SafetytrangnhBelum ada peringkat

- HSE Design Reviews and Action Close-OutDokumen6 halamanHSE Design Reviews and Action Close-OutAhmed AnsariBelum ada peringkat

- Crane and Hoist Safety ProgramDokumen22 halamanCrane and Hoist Safety Programshahrilmr6934Belum ada peringkat

- HSE Plan 2015 - Original PDFDokumen43 halamanHSE Plan 2015 - Original PDFAnkit DudejaBelum ada peringkat

- "Red" High (1) "Yellow" Medium (2) "Green" Low (3) : IllnessDokumen2 halaman"Red" High (1) "Yellow" Medium (2) "Green" Low (3) : IllnessBarb O'NeillBelum ada peringkat

- Eil Permit For Energy Isolation & De-IsolationDokumen1 halamanEil Permit For Energy Isolation & De-IsolationAvesh ChauahanBelum ada peringkat

- Office 5S ChecklistDokumen15 halamanOffice 5S ChecklistRohit NegiBelum ada peringkat

- Step 9 Recommend Specific Strategies and LongDokumen2 halamanStep 9 Recommend Specific Strategies and LongIzna Saboor100% (1)

- HRSG Inspection Services - 2 PDFDokumen4 halamanHRSG Inspection Services - 2 PDFNuraini LusiBelum ada peringkat

- Weekly Hazardous Waste Inspection Checklist PDFDokumen1 halamanWeekly Hazardous Waste Inspection Checklist PDFOM SUTARBelum ada peringkat

- Red Tag Red Tag Red Tag: Log No. Log No. Log NoDokumen1 halamanRed Tag Red Tag Red Tag: Log No. Log No. Log NovishvendanBelum ada peringkat

- 6-S Audit Score CardDokumen1 halaman6-S Audit Score CardJawad HarisBelum ada peringkat

- SLA For App ServiceDokumen6 halamanSLA For App Servicebkb45724Belum ada peringkat

- Telecom AcronymsDokumen286 halamanTelecom Acronymssrm057Belum ada peringkat

- Maruti Suzuki Project ReportDokumen79 halamanMaruti Suzuki Project ReportSiddharth Joon82% (60)

- JCPS Corrective Action PlanDokumen23 halamanJCPS Corrective Action PlanInsider LouisvilleBelum ada peringkat

- FY05-FY08 Performance Audit-Maintenance FINAL (3!20!09)Dokumen112 halamanFY05-FY08 Performance Audit-Maintenance FINAL (3!20!09)Kevin WhitedBelum ada peringkat

- Q1 PDFDokumen8 halamanQ1 PDFSandra SandersBelum ada peringkat

- All Certificates - WordDokumen6 halamanAll Certificates - WordHimanhsu ParmarBelum ada peringkat

- Rajiv Gandhi Proudyogiki Vishwavidyalaya, Bhopal: (University of Technology of Madhya Pradesh)Dokumen1 halamanRajiv Gandhi Proudyogiki Vishwavidyalaya, Bhopal: (University of Technology of Madhya Pradesh)Jay RajputBelum ada peringkat

- Fire Extinguisher BrochureDokumen2 halamanFire Extinguisher BrochureJenaro UrquietaBelum ada peringkat

- DSL API Cat I II Training PDFDokumen2 halamanDSL API Cat I II Training PDFnjava1978Belum ada peringkat

- Template Request Clarification Gunanusa-HDKDokumen1 halamanTemplate Request Clarification Gunanusa-HDKTrias KuswardhanaBelum ada peringkat

- EGA SETP TT-CSM 13 Prequal Questionnaire v2.00Dokumen6 halamanEGA SETP TT-CSM 13 Prequal Questionnaire v2.00shijadBelum ada peringkat

- Account and Finance Departmental ObjectiveDokumen7 halamanAccount and Finance Departmental ObjectiveVICTORBelum ada peringkat

- DNV BrochureDokumen4 halamanDNV Brochureanoopm101Belum ada peringkat

- World Cup 2022Dokumen3 halamanWorld Cup 2022Ahmad DodolBelum ada peringkat

- Venkateswaraa Insulation Achieve 100Ppm / SQ Mark - Check ListDokumen14 halamanVenkateswaraa Insulation Achieve 100Ppm / SQ Mark - Check ListdysonBelum ada peringkat

- HSE PRO 02 F01b Contractor Pre-Qual Questionnaire - 2016-08Dokumen4 halamanHSE PRO 02 F01b Contractor Pre-Qual Questionnaire - 2016-08DKY EDPAPBelum ada peringkat

- Luxathane 5160Dokumen2 halamanLuxathane 5160shameelBelum ada peringkat

- Incident Reporting Form Pages 1&2Dokumen2 halamanIncident Reporting Form Pages 1&2Abraham MathewBelum ada peringkat

- Daily Observation ReportDokumen1 halamanDaily Observation ReportJunard Lu HapBelum ada peringkat

- Consequence Management Framework: The QuestionDokumen7 halamanConsequence Management Framework: The QuestionAnilBelum ada peringkat

- Maintenance Report Alcad BatteriesDokumen8 halamanMaintenance Report Alcad BatteriesAlejandro SastreBelum ada peringkat

- REGDOC2 1 2 Safety Culture Final EngDokumen31 halamanREGDOC2 1 2 Safety Culture Final Engnagatopein6Belum ada peringkat

- Waste Monitoring Flow Chart PicDokumen1 halamanWaste Monitoring Flow Chart PicDilip Kumar KBelum ada peringkat

- Rep-10-152-Report Infrared Inspection For Sabah Gas ASAGADokumen14 halamanRep-10-152-Report Infrared Inspection For Sabah Gas ASAGAAlfi SanBelum ada peringkat

- Form 105, Internal Quality Audit RecordDokumen2 halamanForm 105, Internal Quality Audit RecordadiqualityconsultBelum ada peringkat

- Safety Daily Site Checklist Mastoura co-SA-1-12Dokumen12 halamanSafety Daily Site Checklist Mastoura co-SA-1-12LawrenceBelum ada peringkat

- Jotun Hardtop XPL TDSDokumen4 halamanJotun Hardtop XPL TDSRajan SteeveBelum ada peringkat

- Part Submission WarrantDokumen4 halamanPart Submission WarrantSam AnuBelum ada peringkat

- 1S2S Audit ChecklisDokumen6 halaman1S2S Audit ChecklisArun Biswal100% (1)

- Change Control Report: X Pharmaceutical Manufacturing Company Quality Assurance Department Ref. SOP No.: Sop-XxxDokumen7 halamanChange Control Report: X Pharmaceutical Manufacturing Company Quality Assurance Department Ref. SOP No.: Sop-Xxxrouss1906Belum ada peringkat

- ANPQP - 3.0 - Category 9Dokumen10 halamanANPQP - 3.0 - Category 9jefry sitorusBelum ada peringkat

- Iseb SWT2Dokumen56 halamanIseb SWT2bmcurranBelum ada peringkat

- DP Transmitter Debris Filter PDFDokumen12 halamanDP Transmitter Debris Filter PDFSyaf HudaBelum ada peringkat

- Warehouse and StorageDokumen3 halamanWarehouse and StorageAnonymous mO72yqNcBelum ada peringkat

- Najmi Osconf2009Dokumen30 halamanNajmi Osconf2009Harisfazillah JamelBelum ada peringkat

- 10 - Principles of Sustainable Transport SystemDokumen1 halaman10 - Principles of Sustainable Transport SystemJawadRanaBelum ada peringkat

- As9100 Quality Management SystemDokumen9 halamanAs9100 Quality Management Systemselinasimpson3001Belum ada peringkat

- Tri WheelDokumen6 halamanTri WheelAminul HoqueBelum ada peringkat

- Dbms NotesDokumen59 halamanDbms NotesRehan SabirBelum ada peringkat

- Customer-Defined Service Standards: Presented by IsmailayazruknuddinDokumen18 halamanCustomer-Defined Service Standards: Presented by IsmailayazruknuddinZahid HassanBelum ada peringkat

- Is Now Part ofDokumen9 halamanIs Now Part ofAgung SetyonoBelum ada peringkat

- 23-29 July 2011Dokumen16 halaman23-29 July 2011pratidinBelum ada peringkat

- Feasibility Study-Laundry ServicesDokumen63 halamanFeasibility Study-Laundry ServicesHannah Rea VasquezBelum ada peringkat

- Agile TermsDokumen36 halamanAgile Termskerlos ZakryBelum ada peringkat

- Compressor Oil SDokumen2 halamanCompressor Oil SQuy CocanhBelum ada peringkat

- Precision Design For ManufacturabilityDokumen8 halamanPrecision Design For ManufacturabilityFuadBelum ada peringkat

- Chapters 8 - 13 - 14 - 15 QuestionsDokumen5 halamanChapters 8 - 13 - 14 - 15 QuestionsJamie N Clint BrendleBelum ada peringkat

- Torsional Vibration Model Based Optimization of Gearbox Geometric Design Parameters To Reduce Rattle Noise in An Automotive TransmissionDokumen16 halamanTorsional Vibration Model Based Optimization of Gearbox Geometric Design Parameters To Reduce Rattle Noise in An Automotive TransmissionLivrosScrBelum ada peringkat

- Apple Supplier List 2014Dokumen29 halamanApple Supplier List 2014Wizard LeoBelum ada peringkat

- Abhishek Gupta JBM AutoDokumen26 halamanAbhishek Gupta JBM AutoRashmi SinghBelum ada peringkat

- Your Interactive Guide To The Digital WorldDokumen67 halamanYour Interactive Guide To The Digital Worldrana khubaibBelum ada peringkat