Fine Print of Metallurgy

Diunggah oleh

dhruvHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Fine Print of Metallurgy

Diunggah oleh

dhruvHak Cipta:

Format Tersedia

HT-Be Aware 5/24/05 11:09 AM Page 41

Heat Treating

Be Aware of the ‘Fine Print’ In the

Science of Metallurgy of Induction

Hardening: Part 2

Valery Rudnev, Inductoheat Group, Madison Heights, Mich.

Certain metallurgical phenomena and principles of heat treatment

frequently are incorrectly assumed or improperly used in the appli-

cation of induction hardening.

e are reminded in many martensite crystalline structure [1-3]. Figure 1 shows that Ms-Mf temperature

aspects of our lives today Martensite formation is governed by a range is directly related to the steel's car-

to read the "fine print" shear-type (diffusionless) transformation of bon content. The carbon content and

contained in manuals, austenite; that is, the transformation actual amount of martensite formed exclu-

warrantees, instructions, etc., so that we occurs almost instantaneously upon reach- sively determine the maximum hardness of

don't miss important information. ing a certain temperature. given steel. In the range of 0.2 to 0.65%

Important information also is often over- If the continuous cooling transforma- carbon, the hardness of the steel is propor-

looked in the science of metallurgy. While tion (CCT) diagram of steel is shifted far to tional to the carbon content.

there is no fine print, there are metallurgi- the left, the cooling curve will enter the Mf temperatures for plain carbon steels

cal "fine points" and subtleties, which upper transformation start region regard- with high carbon content, cast irons and

require paying close attention. In many less of quench severity, preventing the some alloy steels are well below room tem-

cases, certain metallurgical phenomena capability to obtain an entirely martensitic

and principles of heat treatment are incor- microstructure. In such cases, the final Shape of martensite

Lath +

rectly assumed or improperly used in induc- microstructure of the hardened layer will Lath plate Plate

600

tion hardening. It is important to look consist of a combination of martensite and

500

closer at the “fine points” of metallurgical upper transformation products (e.g.,

Temperature, ˚C

400

theory to ensure optimal results. To illus- pearlite and banite) regardless of the sever-

300 Ms

trate this, following are additional exam- ity of the quench from austenitic tempera-

ples to those discussed in Part 1 of this arti- ture down to ambient temperature. 200

cle (March 2005 IH). Although a fully martensitic structure 100 Mf

might not be obtained, the amount of 0

0 0.4 0.8 1.2 1.6

Is it always possible to obtain a fully upper transformation products can be Carbon content, wt %

martensitic structure of noneutectoid appreciably small and might not noticeably

600

plain carbon steels using severe affect component mechanical properties in

500

water spray quench? certain applications.

400

In hardening applications, the ability to Martensitic transformation occurs over a

Temperature, ˚C

obtain a certain degree of martensitic temperature range between the Ms 300

Ms

structure is often the measure of how suc- (martensite start) to Mf (finish), which 200

cessful the heat treating process was. depends on the particular steel chemical 100

Martensite is a supersaturated solid solu- composition, and from practical perspec- 0

tion of carbon in ferrite with a body-cen- tive, cannot be changed by varying quench Mf

-100

tered tetragonal crystalline (BCT) struc- severity. If cooling upon quenching is inter- -200

ture. Upon rapid cooling, carbon is trapped rupted at a certain temperature within the 0 0.4 0.8 1.2 1.6 2

in the crystal structure. The high hardness martensite transformation range, no further Carbon content, wt %

developed when steel is transformed to transformation to martensite will occur.

Fig. 1. Influence of carbon content on Ms

martensite is due to distortion in the trans- Martensite transformation resumes upon and Mf temperatures. Source: top (Ref. 4,5);

formation from FCC (austenite) to BCT further cooling to a lower temperature. bottom (Ref. 6).

IndustrialHeating.com – May 2005 41

HT-Be Aware 5/24/05 11:09 AM Page 42

Heat Treating

perature. Thus, even if quench severity is When discussing hardenability, it is impor- At larger diameters or thicknesses, the

sufficient to miss the upper transformation tant to recognize factors that influence depth of the hardened layer (hardened

region of the CCT diagram, a fully marten- hardness distribution in through hardening depth) also increases. In addition, because

sitic structure will not be obtained within compared with surface hardening. the core is at a greater distance from the

the hardened layer. The existence of a Through hardening (hardening a work- quenched surface, thermal conductivity

noticeable amount of untransformed, or piece through its entire cross section) typi- provides less intense cooling of the core dur-

retained, austenite will be unavoidable cally requires heating the part uniformly to ing surface quenching. At a certain point,

(Fig. 2). Cryogenic treatment can be used the austenitizing temperature range and the CCT curve representing core cooling

to transform the retained austenite into quenching to ambient temperature. During conditions during surface quenching shifts

martensite. Note that a full untempered quenching, the cooling rate at the surface farther to the right (Fig. 3), eventually pass-

martensitic structure has low ductility [1]. always is more intense compared with the ing through an area where transformation

The inability to obtain a fully martensitic rate at internal locations; particularly com- starts at a temperature higher than the Ms

structure is directly related to not having pared with the rate at its core. For a thin temperature. Thus, depending on the cool-

homogeneous austenite. As mentioned in part, the cooling intensity at the core

Part 1 of this article, rapid induction heat- might be severe enough to miss the upper 60

ing can result in inhomogeneous austenite transformation region of the continuous 50

Retained autenite, vol%

with a ferritic/pearlitic network (dependent cooling diagram and to form a sufficient Ref. 6

on chemical composition, prior microstruc- amount of martensite in core, resulting in a 40

ture and process specifics), which remains relatively uniform through-hardened pat- 3

in the as-quenched structure, preventing a tern. Also, because the cooling rate at the Ref. 3

fully martensitic structure. surface is always more intense than that at 20

Nonuniform distribution of carbon is the core, more martensite forms at the sur- 10

another characteristic of inhomogeneous face and subsurface than in the core, result-

0

austenite. After fast heating, a ing in a higher hardness at the surface 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6

ferrite/pearlite network might not exist, (assuming that surface has not been over- Carbon content, wt %

but the austenite phase could consist of heated and severe oxidation and/or decar- Fig. 2. Influence of carbon content on volume

localized regions of enriched carbon and burization did not occur). of retained austenite

reduced carbon. Since both Ms and Mf

temperatures depend on carbon content,

austenite areas of high and low carbon con- Core Surface Core Surface

centration will have different critical cool-

ing rates (CCT curves) resulting in differ-

ent transformations to martensite. This

may lead to the appearance of alternative

Hardness

Hardness

products within the martensitic structure.

Carbon content not only influences

50%

achievable surface hardness and case depth, Martensite

but also the transition zone. For example,

eutectoid steel always has a shorter transi-

Diameter Diameter

tion zone compared with a hypoeutectoid

steel (assuming temperature distribution

Surface Core Surface Core

and quenching conditions are the same).

Can results of Grossmann's harden- A1 A1

ability tests and Jominy end-quench

Temperature

Temperature

tests be directly applied to selective F F

hardening? P P

Hardenability is an important property of

steel and cast iron, defining the ability of

B B

the metal to be hardened to a certain depth. Ms Ms

It is measured as the distance from the sur-

face where certain hardness can be obtained

Time Time

or a specific percentage of martensite can be

formed (e.g., 50 HRC or 50% martensite). Fig. 3. Influence of test specimen diameter on hardness profile and core cooling rate [1]

42 May 2005 – IndustrialHeating.com

HT-Be Aware 5/24/05 11:09 AM Page 43

ing rate, a certain amount of upper-transfor- (particularly induction surface hardening)

mation products (i.e., bainite, pearlite, fer- due to the assumptions in measurements

rite) form within the core leading to a soft- that have been done.

er core compared with the surface. The standard Jominy end-quench test is

Surface hardening (case hardening) suitable for moderate cooling rates.

involves a relatively short heat up time and Therefore, it can provide misleading results

a pronounced skin effect, and core tempera- at cooling rates 150˚C/sec (270˚F/sec) or

ture does not rise significantly during the higher experienced with a majority of

heating stage [1]. Upon quenching, the cold induction hardening applications. Quench

core provides an additional cooling effect severity exceeds 1000˚C/sec (1830˚F/sec)

on the case hardening area compared with in some induction hardening applications.

through-heated parts. A more intensive In standard hardenability tests, a speci-

quench increases hardness and steel harden- men is heated to the austenitic tempera-

ability, and dramatically increases the forma- ture and held long enough to ensure form-

tion and distribution of residual stresses [1]. ing homogeneous austenite. By compari-

son, induction hardening involves intense

Hardenability tests heating with a relatively short or no hold-

Techniques used to determine steel and ing time, which can produce inhomoge-

cast-iron hardenability include neous austenite with corresponding differ-

Grossmann's hardenability test and the ences in the hardenability curves. Intense

Jominy end-quench test–the most widely heating during induction hardening shifts

used tests [1-3]. Grossmann's test involves the A1 and A3 critical curves toward high-

the concept of critical diameter. er temperatures [1,7]. Quenching from

Cylindrical bars having different diameters temperatures that are often 100 to 180˚C

are cooled from a specific austenitizing (180 to 325˚F) higher than the tempera-

temperature down to ambient temperature ture used during hardenability tests can

using a given quench medium. For a par- result in appreciable errors.

ticular quenchant, a bar having 50% Conventional hardenability curves also

martensite at its core would correspond to are modified by the cold core serving as a

the critical diameter Dcr. The critical heat sink and by higher surface and subsur-

diameter is influenced by chemical compo- face quenching severity. The cold core can

sition, grain size and homogeneous austen- have a self-quenching (mass quenching)

ite, which can be relatively easily defined. effect, which allows the elimination of liq-

However, quenching condition often is the uid spray quenching in some hardening Fig. 4. Compact system for hardening cast

iron camshafts. Courtesy of Inductoheat Inc.

least defined factor, particularly in the case applications with a small case depth.

of induction hardening. Cooling severity Hardenability tests are primarily orient-

during spray quenching depends on a com- ed toward cylindrical shape specimens ver- induction hardening of carbon steels, but

bination of factors including quenchant sus other shapes, which make it difficult to there are some significant differences [1].

type and purity; concentration; quenching apply test results to parts having complex Cast irons comprise a family of materials

temperature, pressure and flow rate; shape. Data obtained from a standard represented on the right side of the Fe-

quench block design; number and distribu- Jominy or Grossman test should be used for FeC3 phase diagram having a high carbon

tion of quench holes, orifice size and densi- reference purposes only. content (2+%) and a wide range of proper-

ty; spray impingement and part rotation. ties [1,7]. Gray, ductile (nodular) and mal-

The Jominy end-quench was developed Are the procedures for choosing leable and compacted-graphite iron (to a

to overcome the complexity of the process parameters for induction lesser extent) are induction hardened.

Grossmann's hardenability test. In the test, hardening of steels and cast irons Gray iron contains carbon as graphite in

a 25 mm OD by 100 mm long (~1 in. by 4 identical? flake form (Fig. 5), which combined with

in.) cylindrical specimen is uniformly heat- One of the most common applications of the high carbon content makes gray iron

ed to achieve homogeneous austenite and induction heat treatment is hardening cast castings brittle and hard, with low tensile

spray quenched on one end, producing a iron parts such as camshafts, crankshafts, strength and a poor ability to withstand

longitudinal hardness distribution as a liners, gears, rollers, etc. Figure 4 shows an appreciable thermal shock and shock load.

function of the distance from the quenched induction system used to heat treat cast Due to their relatively high silicon con-

end. Both test methods require some iron camshafts. Induction surface harden- tents, commercial cast irons should be con-

degree of caution for induction hardening ing of cast irons has many similarities to sidered as at least ternary Fe-C-Si alloys.

IndustrialHeating.com – May 2005 43

HT-Be Aware 5/24/05 11:09 AM Page 44

Heat Treating

As a result, all critical temperatures of cast elements and residual impurities that could

irons differ from those shown in the right affect critical temperatures.

side of the Fe-Fe3C diagram [1]. A key metallurgical difference between

The ability of gray irons to be hardened steels and cast irons that causes many prob-

depends on the type of matrix (i.e., ferritic, lems in selective hardening is matrix carbon

ferritic-pearlitic or pearlitic) and the content versus total carbon content (CE)

amount, size, shape, and distribution of [8]. In steels, carbon content is fixed by

graphite flakes. A pearlitic matrix provides chemical composition and cannot exceed

a better response to induction hardening of this value in a fully austenitic condition. In

gray irons. Being brittle, gray iron may contrast, cast irons have a carbon “reserve”

present certain challenges to induction in the primary graphite particles, which can

Fig. 5. Representative gray cast iron micro-

hardening due to a tendency toward crack- cause localized increasing amounts of car-

structure containing graphite flakes [9]

ing from fast heating and intense cooling bon to dissolve into the austenite matrix at

[1,9,10]. Preheating and soft quenching are higher austenitizing temperatures. This high

often used. However, some gray iron parts (and variable depending on temperature)

have been successfully hardened using matrix carbon content is the most critical

short heat time (less than 2 seconds) and metallurgical factor in the selective harden-

quenching using plant water (Fig. 6). ing of cast irons, and lies at the root of prob-

In contrast to gray irons, ductile irons lems such as excessive retained austenite,

have carbon particles in the form of coarse martensite and unusual hardness pat-

graphite nodules, which serve as crack terns. Alloying elements can affect harden-

arresters. This gives ductile irons some ability and retained austenite (by decreasing

advantages over gray irons including duc- Ms temperature) in steels, but matrix car- Fig. 6. Unitized machine with two independ-

tility, relatively high tensile and bending bon content in cast irons have an over- ently operated heat stations and high-

strength and moderate elongation. An whelming effect. speed, servo-driven scanning assemblies for

induction hardening the ID of gray iron

induction hardened ductile (nodular) cast Ferritic ductile iron typically is not a

cylinder liners. Production rate is 50 liners/h

iron crankshaft with case hardness pattern good candidate for induction hardening with a 0.8 mm (0.03 in.) case having 47-49

and microstructure, transition zone and due to the inability to transform low car- HRC as-quenched hardness. Courtesy of

green core is shown in Fig. 7. bon containing ferrite into martensite. Inductoheat Banyard Ltd., Dorset, UK.

Ductile (nodular) irons offer a wide

range of properties. Five subgroups of duc-

tile iron are ferritic, pearlitic-ferritic,

“Green”

pearlitic, martensitic and austempered core

ductile irons. Induction hardening is usu-

ally applied to martensitic, pearlitic and,

to a lesser extent, pearlitic-ferritic ductile

irons. Martensitic ductile iron requires the

lowest hardening temperatures, shortest

Transition

heat-up time and provides well-defined, zone

crisp hardness patterns with a relatively

shallow transition zone [1].

Being inherently strong, ductile irons

can handle much greater stresses than gray

irons upon heating and quenching without Hardened

cracking. However, the presence of case

graphite nodules as crack-arresters does not

guarantee ductile iron castings will not

crack during intensive heating or/and

severe quenching.

A temperature range of 860 to 960°C Fig. 7. Induction hardened ductile cast iron

(1580 to 1760°F) is typical for induction crankshaft with corresponding microstruc-

tures of the hardened case, transition zone

hardening of iron castings. Besides carbon and green core. Required case depth: 1.8

and silicon, all commercial cast irons also Surface

mm (0.07 in.). Courtesy of Inductoheat Inc.

have other intentionally added alloying

44 May 2005 – IndustrialHeating.com

HT-Be Aware 5/24/05 11:09 AM Page 46

Heat Treating

However, intense induction heating and a gray iron hardening operation, it is the ability of a material to conduct the

quenching can be used to improve the important to conduct a run-off using rela- magnetic flux better than vacuum or air. It

fatigue strength of ferritic ductile cast irons tively “fresh” castings. Using castings that has a marked effect on all basic induction

[12] from the ability to create localized have been on the shop floor for some time phenomena including the skin effect, end

martensitic areas and compressive stresses for process development or run-off could effect and proximity effect, and also has a

near the boundaries of graphite nodules result in hardening age-strengthened parts. major effect on coil electrical parameters

due to carbon diffusion from graphite nod- Such results could be overly optimistic, [1]. The magnetic permeability of a partic-

ules into ferrite matrix. and cracking might suddenly occur during ular metal is a function of both tempera-

Sections of varying thickness in complex a production run [1]. ture and magnetic field intensity.

shaped iron castings heat up at different rates, The response of cast irons to electro- Electrical resistivity and magnetic per-

promoting thermal gradients and thermal magnetic heating is different than that of meability are strongly dependent on the

stresses, which can result in distortion and steels. It is important to remember that in chemical composition (Figs. 9, 10 and 11).

crack development, particularly in locations contrast to alternative heating processes,

having a drastic change of mass. the intensity of induction heating is more

resistivity

Electrical

Complications can arise when transitional sensitive to a chemical composition, and is

thermal stresses combine with residual stress- directly related to the electromagnetic

es from previous operations (e.g., casting, properties of the heated metal.

machining, honing, surface peening, etc.). Electromagnetic properties of materials

Complex-shaped steel parts have less tenden- in a broad sense include magnetic perme-

cy to crack than complex cast iron parts. ability, electrical resistivity (electrical con-

permeability

Magnetic

Stress relieving iron castings prior to induc- ductivity), saturation flux density, coercive

tion hardening is often recommended to force, hysteresis loss, permittivity, magnet-

reduce the probability of cracking. Formation ic susceptibility and others. While all elec-

of stresses during induction hardening and tromagnetic properties are important, this 0% Carbon content 4%

tempering is discussed in [1]. Reasons for discussion is limited to the effect of electri-

crack development during hardening cast cal resistivity and relative magnetic perme- Fig. 9. Influence of carbon content on elec-

trical resistivity and magnetic permeability

irons and plain carbon or alloy steels are dif- ability on the ability of metal to be heated

of carbon steels and cast irons at ambient

ferent [1,9,10]. For example, age strengthen- by induction. Electrical resistivity and temperature

ing can occur in gray iron castings but not in magnetic permeability have the most pro-

steel parts. If age strengthening occurs, some nounced effect on performance of the 22,000

Magnetic flux density (B), gauss

castings may harden relatively easily, while induction heating system (Fig. 8). 20,000

18,000 Cast steel

others may crack, even though heating and Electrical resistivity, the reciprocal of 16,000

quenching conditions were identical. electrical conductivity, affects nearly all 14,000

12,000 Cast iron

A study of the age strengthening phe- induction heating system parameters 10,000

nomenon [11] reported that aging at room including depth of heating (current pene- 8,000

temperature for about 60 days can tration depth), heat uniformity, coil elec- 6,000

4,000

strengthen gray iron castings by as much as trical efficiency, coil impedance (load 2,000

12%. The tensile strength-to-hardness matching capability) and others. Electrical 0

0 200 400 600 800 1,000 1,200

ratio also increases because the hardness resistivity varies with temperature, chemi- Magnetic field intensity (H), oersted

does not change with time. In a production cal composition, metal microstructure and

Fig. 10. Magnetization B-H curves for cast

environment, the time between casting grain size. It increases nonlinearly with steel and cast iron [13]

and heat treating can be relatively short, temperature for steels and cast irons.

and age strengthening will not occur. Thus, Relative magnetic permeability (µr) is a 22

Electrical resistivity, µΩ-cm

to ensure the reliability and repeatability of nondimensional parameter that indicates 20 Si

Al

18

Mn

Property Change Influence on induction heat treatment process 16 Cu

Mo

Less soaking action from the high temperature areas towards low temperature regions. 14

Thermal Ni

Decrease Greater temperature gradients and stresses during heating and quenching. Slower cool- 12 W

conductivity

ing of workpiece internal areas and core during quenching. Shorter transition area. Co

10

Electrical Greater depth of heating and larger current penetration depth. Increase of the coil elec- 0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6

Increase Alloying element in iron, %

resistivity trical efficiency produces higher temperatures while utilizing the same energy/power.

Magnetic Greater depth of heating, larger current penetration depth and lower coil electrical efficien-

Decrease Fig. 11. Influence of small amounts of alloy-

permeability cy. Coil power factor reduction. Smaller thermal gradients and stresses during heating.

ing elements on the electrical resistivity of

Fig. 8 Effects of material physical properties on induction heating behavior iron [14]

46 May 2005 – IndustrialHeating.com

HT-Be Aware 5/24/05 11:09 AM Page 47

Cast irons have higher electrical resistivi- native heat treating methods to prevent

ty but lower magnetic properties com- unanticipated surprises. IH

pared with carbon steels. Thus, a coil

using the same power supply and frequen- References

cy has a different heating effect on carbon 1. Rudnev, V., Loveless,D., et al., Handbook of

steel, alloy steel or cast iron parts of the Induction Heating, Marcel Dekker, 2003

2. Brooks, C., Principles of the Heat Treatment

same geometry [1].

of Plain Carbon and Low Alloy Steels, ASM

A material's thermal properties also are a Intl., 1996

function of chemical composition. Since 3. Krauss, G., Steels: Heat Treatment and

the cycle time of induction heating is much Processing Principles, ASM Intl., 1999

shorter than those of alternative heating 4. Semiatin, S.L. and Stutz, D.E., Induction Heat

processes, the variation in thermal conduc- Treatment of Steel, ASM Intl., 1986

tivity of the heated material has a greater 5. Troiano, A. and Greninger, A., Metal

Progress, 1946

effect on transient and final thermal condi-

6. Gulyaev, A. Metallurgy, Metallurgia,

tions of the inductively heated parts.

Moscow, 1977

Thermal conductivity of cast irons is 7. Rudnev, V., Be aware of the 'fine print' in

typically lower than that of carbon steels the science of metallurgy of induction

resulting in much weaker “soaking” action hardening, Part 1, Ind. Htg., Mar., 2005

during surface hardening or selective hard- 8. Private communication with Norman

ening. Therefore, in contrast to surface Carter, May, 2003

9. Rudnev, V., Induction Hardening Cast Iron,

hardening of steels, self-quenching is prac-

Ht. Trtg. Prog., ASM Intl., Mar., 2003

tically never used in hardening cast irons.

10. Rudnev, V., Troubleshooting Cracking in

For example, in the case hardening of gray Induction Hardening, Ht. Trtg. Prog., Aug.,

iron cyclinder liners in Fig. 6, self-quench- 2003

ing was not applied even for the required 11. Nicola, W. and Richards, V., Age Strength-

shallow case depth of 0.8 mm (0.03 in.). It ening of Gray Iron, AFS Trans., 2000

is important to remember that the size, 12. Misaka, Y., et. al., Fatigue strength of ferritic

ductile cast iron, Japan IOM, 2004

shape, dispersion and amount of graphite

13. Attwood, S., Electrric and Magnetic Fields,

flakes affect not only the mechanical prop-

John Wiley, 1941

erties, but also the electrical, magnetic and 14. Bozorth, R., Ferromagnetism, IEEE Press,

thermal properties of gray cast irons [1]. N.Y., 1993

When discussing induction surface

hardening of steel, the phenonmenon of For more information: Valery Rudnev is Group

super hardening is often mentioned [1,4], Director, Science & Technology, Inductoheat

wherein the surface hardness of an induc- Group, Inductoheat Inc., 32251 N. Avis Dr.,

tion hardened steel could be 2-3 HRC Madison Heights, MI 48071; tel: 248-585-5055; fax:

higher than that for through-heated, fur- 248-589-1062; e-mail: rudnev@indctoheat.com;

nace-hardened steel [1,4]. This phenome- Web: www.inductoheat.com

non is particularly noticeable in induc-

tion hardened steels having a 0.35-0.6%

carbon content. Super hardening has Additional related information may be

found by searching for these (and other)

never been observed in induction harden-

key words/terms via BNP Media LINX at

ing iron castings.

www.industrialheating.com: induction

hardening, surface hardening, selective

Conclusion

hardening, induction heating, CCT diagram,

The material discussed in Part 1 and Part 2

self quench, mass quench, martensite

of this article is representative of metallurgi-

transformation, retained austenite, cryo-

cal “fine points” and subtleties that some- genic treatment, homogeneous austenite,

times are incorrectly assumed or improperly hardenability, Jominy-end quench,

used in the application of induction harden- Grossmann's test, cast iron, carbon equiva-

ing.. However, there many other principles lent (CE), electromagnetic properties, elec-

of heat treatment that must be carefully trical resistivity, magnetic permeability,

thought out when applying them to the super hardening.

induction hardening compared with alter-

IndustrialHeating.com – May 2005 47

Anda mungkin juga menyukai

- Understanding The Microstructure of Overheated Carbon Steel: ConstituentsDokumen6 halamanUnderstanding The Microstructure of Overheated Carbon Steel: ConstituentsHOSSIENBelum ada peringkat

- 2004-11-18-Effect of Martensite Volume Fraction and Its Morphology On The Tensile Properties of Ferritic Ductile Iron With Dual Matrix StructuresDokumen8 halaman2004-11-18-Effect of Martensite Volume Fraction and Its Morphology On The Tensile Properties of Ferritic Ductile Iron With Dual Matrix StructuresSelauco Vurobi JrBelum ada peringkat

- Influence of martensite volume fraction and tempering time on tensile properties of partially austenitized in the (α + γ) temperature range and quenched + tempered ferritic ductile ironDokumen8 halamanInfluence of martensite volume fraction and tempering time on tensile properties of partially austenitized in the (α + γ) temperature range and quenched + tempered ferritic ductile ironSelauco Vurobi JrBelum ada peringkat

- Heattreatment English 99Dokumen13 halamanHeattreatment English 99shreemugBelum ada peringkat

- Tempering MartensiteDokumen21 halamanTempering Martensitejardel de matosBelum ada peringkat

- Spain 2005Dokumen6 halamanSpain 2005jorrgeeBelum ada peringkat

- Vibgyor: Annealing and Normalizing of AISI 1045 Steel: A Lamellae AnalysisDokumen6 halamanVibgyor: Annealing and Normalizing of AISI 1045 Steel: A Lamellae AnalysisEdna Odette Melo UscangaBelum ada peringkat

- Failures Related To Heat Treating Operations PDFDokumen32 halamanFailures Related To Heat Treating Operations PDFChin-Min YangBelum ada peringkat

- Embitterment of SteelDokumen2 halamanEmbitterment of SteelAshfaq AliBelum ada peringkat

- Lec 10 Thermal ProcessingDokumen17 halamanLec 10 Thermal ProcessingHdjdBelum ada peringkat

- Tempering of BainiteDokumen26 halamanTempering of BainiteEfvan Adhe Putra PradanaBelum ada peringkat

- Failures Related To HT Operations PDFDokumen33 halamanFailures Related To HT Operations PDFSivaraman VisvanathanBelum ada peringkat

- O HC HCDokumen101 halamanO HC HCIndustrial Infra Jobs100% (1)

- Lec 9 Thermal ProcessingDokumen16 halamanLec 9 Thermal ProcessingHdjdBelum ada peringkat

- A Case Study of Heat Treatment On Mechanical Properties and Microstructure of C1040 SteelDokumen5 halamanA Case Study of Heat Treatment On Mechanical Properties and Microstructure of C1040 SteelShafayat HossainBelum ada peringkat

- Phase Transformations Across High Strength Dissimilar Steel Inertia Friction WeldDokumen11 halamanPhase Transformations Across High Strength Dissimilar Steel Inertia Friction WeldNipun AhujaBelum ada peringkat

- Ductile Cast Iron Microstructure Adjustment by Means of Heat TreatmentDokumen4 halamanDuctile Cast Iron Microstructure Adjustment by Means of Heat Treatment2022353017Belum ada peringkat

- The Jominy End-Quench Test Hardenability CurvesDokumen18 halamanThe Jominy End-Quench Test Hardenability CurvesMohammed AlryaniBelum ada peringkat

- High-Strength Stainless Steels With "Microduplex" Structure For Cryogenic ApplicationsDokumen3 halamanHigh-Strength Stainless Steels With "Microduplex" Structure For Cryogenic ApplicationsakhileshBelum ada peringkat

- SS304 Hardening BehaviourDokumen4 halamanSS304 Hardening BehaviourrbagriBelum ada peringkat

- Engineering Metallurgy Chapter-8 Ref: Introduction To Physical MetallurgyDokumen34 halamanEngineering Metallurgy Chapter-8 Ref: Introduction To Physical MetallurgyMD Al-AminBelum ada peringkat

- Engineering Design QuestionsDokumen10 halamanEngineering Design QuestionsBasavaraja GBelum ada peringkat

- Hafeez 2020 Mater. Res. Express 7 016553 PDFDokumen13 halamanHafeez 2020 Mater. Res. Express 7 016553 PDFArturo CervantesBelum ada peringkat

- 2009 - Steel Res Int - Influence of Martensite Distribution On The Mechanical Properties of Dual Phase Steels Experiments and SimulationDokumen6 halaman2009 - Steel Res Int - Influence of Martensite Distribution On The Mechanical Properties of Dual Phase Steels Experiments and SimulationOmar S Al-AbriBelum ada peringkat

- 1997-Free Ferrite in Pearlitic Ductile Iron - Morphology and Its Influence On Mechanical PropertiesDokumen7 halaman1997-Free Ferrite in Pearlitic Ductile Iron - Morphology and Its Influence On Mechanical PropertiesSelauco Vurobi JrBelum ada peringkat

- Microstructure-Property Relationships in High Chromium White Iron Alloys PDFDokumen24 halamanMicrostructure-Property Relationships in High Chromium White Iron Alloys PDFLuis AcevedoBelum ada peringkat

- Effect of Heat Treatment On The Damping Capacity of Austempered Ductile Cast IronDokumen6 halamanEffect of Heat Treatment On The Damping Capacity of Austempered Ductile Cast IronShilpin BhadaniaBelum ada peringkat

- Effects of Cryogenic Treatment On Mechanical Properties and Microstructure of Fe-Cr-Mo-Ni-C-Co AlloyDokumen5 halamanEffects of Cryogenic Treatment On Mechanical Properties and Microstructure of Fe-Cr-Mo-Ni-C-Co Alloyermes_il_fisicoBelum ada peringkat

- wj0507 125 PDFDokumen10 halamanwj0507 125 PDFtazzorroBelum ada peringkat

- Prcat WeldingDokumen6 halamanPrcat WeldingFrancoisBelum ada peringkat

- 1994 Bhadeshia - Austenite Films in Bainitic MicrostructuresDokumen10 halaman1994 Bhadeshia - Austenite Films in Bainitic MicrostructuresEugenia AmundarrayBelum ada peringkat

- Questão 01Dokumen17 halamanQuestão 01eduardoBelum ada peringkat

- The Influence of Lamellar Graphite Cast Iron Annealing On Hardness and StructureDokumen11 halamanThe Influence of Lamellar Graphite Cast Iron Annealing On Hardness and StructureJaromír Roučka100% (1)

- Precipitation Hardening Stainless SteelsDokumen2 halamanPrecipitation Hardening Stainless SteelsRongbaaz BongBelum ada peringkat

- 6-Phase Transformation 4 - Fe-CDokumen8 halaman6-Phase Transformation 4 - Fe-ChamalBelum ada peringkat

- Insight Into The Induction Hardening of A New 0,4 C Microalloyed SteelDokumen19 halamanInsight Into The Induction Hardening of A New 0,4 C Microalloyed SteelGscoelhoBelum ada peringkat

- Microstructure and Mechanical Properties of A Microalloyed Steel After Thermal TreatmentsDokumen5 halamanMicrostructure and Mechanical Properties of A Microalloyed Steel After Thermal Treatmentsputra sriBelum ada peringkat

- TJ 11 2017 4 166 170 PDFDokumen5 halamanTJ 11 2017 4 166 170 PDFInisial DIBelum ada peringkat

- Microstructural Changes in HSLA-100 Steel Thermally To Simulate The Heat-Affected Zone During Welding CycledDokumen17 halamanMicrostructural Changes in HSLA-100 Steel Thermally To Simulate The Heat-Affected Zone During Welding CycledKay WhiteBelum ada peringkat

- ADI Crankshafts: Melt Preparation & Casting Machining Heat Treatment GrindingDokumen10 halamanADI Crankshafts: Melt Preparation & Casting Machining Heat Treatment GrindingShashwatamBelum ada peringkat

- ME 216 - Engineering Materials II: Heat Treatment (Part I)Dokumen15 halamanME 216 - Engineering Materials II: Heat Treatment (Part I)ozanBelum ada peringkat

- TTT Diagram & Heat TreatmentDokumen65 halamanTTT Diagram & Heat TreatmentSudheer ChauhanBelum ada peringkat

- 2003, Mehmet Erdogan, New Dual Phase SteelDokumen6 halaman2003, Mehmet Erdogan, New Dual Phase Steelahmed ezwaiBelum ada peringkat

- Gupta 2008Dokumen5 halamanGupta 2008MadeBelum ada peringkat

- 1 s2.0 S0925838810031683 MainDokumen6 halaman1 s2.0 S0925838810031683 MainMehtap KuzuBelum ada peringkat

- High Temperature & Low Temperature Thermo-Mechanical ProcessesDokumen24 halamanHigh Temperature & Low Temperature Thermo-Mechanical Processesnaseema shaikBelum ada peringkat

- Nanoausferritic Matrix of Ductile IronDokumen7 halamanNanoausferritic Matrix of Ductile IronMostafa OthmanBelum ada peringkat

- Journal of Materials Processing Technology: M. Soliman, H. Ibrahim, A. Nofal, H. PalkowskiDokumen10 halamanJournal of Materials Processing Technology: M. Soliman, H. Ibrahim, A. Nofal, H. PalkowskiDouglas VidalBelum ada peringkat

- Unit 21: Materials Engineering: Unit Code: F/601/1626 QCF Level: 4 Credit Value: 15Dokumen18 halamanUnit 21: Materials Engineering: Unit Code: F/601/1626 QCF Level: 4 Credit Value: 15Jo okBelum ada peringkat

- Powder Metallurgical Nanostructured Medium Carbon Bainitic Steel - Kinetics, Structure, and in Situ Thermal Stability StudiesDokumen9 halamanPowder Metallurgical Nanostructured Medium Carbon Bainitic Steel - Kinetics, Structure, and in Situ Thermal Stability StudiesJotaBelum ada peringkat

- Quenching and Partitioning Heat Treatment in Ductile Cast IronsDokumen9 halamanQuenching and Partitioning Heat Treatment in Ductile Cast Irons2022353017Belum ada peringkat

- Comparison of Microstructure and Mechanical Behavior of Lower Bainite and Tempered Martensite in JIS SK5 SteelDokumen8 halamanComparison of Microstructure and Mechanical Behavior of Lower Bainite and Tempered Martensite in JIS SK5 SteelekopujiantoeBelum ada peringkat

- Souza-Amateau1999 Article DeformationOfMetastableAusteniDokumen12 halamanSouza-Amateau1999 Article DeformationOfMetastableAustenimoonstarBelum ada peringkat

- Microstructural Characteristics and Mechanical Properties of Heat Treated High-Cr White Cast Iron AlloysDokumen12 halamanMicrostructural Characteristics and Mechanical Properties of Heat Treated High-Cr White Cast Iron AlloysjoeljBelum ada peringkat

- Make Sure Your Specified Heat Treatment Is AchievableDokumen6 halamanMake Sure Your Specified Heat Treatment Is AchievableFebri SSBelum ada peringkat

- הרצאה 6Dokumen8 halamanהרצאה 6api-26922789Belum ada peringkat

- Optics & Laser Technology: M.M.A. Khan, L. Romoli, R. Ishak, M. Fiaschi, G. Dini, M. de SanctisDokumen9 halamanOptics & Laser Technology: M.M.A. Khan, L. Romoli, R. Ishak, M. Fiaschi, G. Dini, M. de SanctisLuan CaetanoBelum ada peringkat

- AFS Thermal Analysis of CupsDokumen10 halamanAFS Thermal Analysis of Cupsyash_ganatraBelum ada peringkat

- Thermomechanical Processing of High-Strength Low-Alloy SteelsDari EverandThermomechanical Processing of High-Strength Low-Alloy SteelsBelum ada peringkat

- Changing IGBTDokumen7 halamanChanging IGBTdhruvBelum ada peringkat

- Annex A Step by Step Guide For ISO 9001 2015 NG FG AGDokumen39 halamanAnnex A Step by Step Guide For ISO 9001 2015 NG FG AGRt Saragih100% (1)

- Diffrent CapacitorDokumen4 halamanDiffrent CapacitordhruvBelum ada peringkat

- AH Series CatalogDokumen2 halamanAH Series CatalogdhruvBelum ada peringkat

- Compact NS630b To 1600 (Fixed Version) : ConnectionDokumen1 halamanCompact NS630b To 1600 (Fixed Version) : ConnectiondhruvBelum ada peringkat

- DC To DC Converters and Its Application For Railway System-A ReviewDokumen9 halamanDC To DC Converters and Its Application For Railway System-A ReviewdhruvBelum ada peringkat

- Annex A Step by Step Guide For ISO 9001 2015 NG FG AGDokumen39 halamanAnnex A Step by Step Guide For ISO 9001 2015 NG FG AGRt Saragih100% (1)

- Polytechnic Hub: Electrical Slip RingsDokumen3 halamanPolytechnic Hub: Electrical Slip RingsdhruvBelum ada peringkat

- Origin of Harmonics - Electrical Installation Guide PDFDokumen3 halamanOrigin of Harmonics - Electrical Installation Guide PDFdhruvBelum ada peringkat

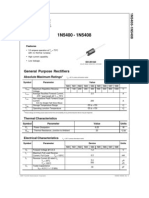

- General Purpose Rectifiers: Absolute Maximum RatingsDokumen3 halamanGeneral Purpose Rectifiers: Absolute Maximum Ratingsapi-3749263Belum ada peringkat

- Calculate Cable Size and Voltage DropDokumen4 halamanCalculate Cable Size and Voltage DropdhruvBelum ada peringkat

- Earthing CalculationDokumen4 halamanEarthing Calculationanandpurush100% (1)

- EMC Design of IGBT Model PDFDokumen20 halamanEMC Design of IGBT Model PDFKen OhBelum ada peringkat

- Earthing Resistance Value: Size of Capacitor For Power Factor CorrectionDokumen17 halamanEarthing Resistance Value: Size of Capacitor For Power Factor Correctiondhruv100% (2)

- Calculate Size of ContactorDokumen3 halamanCalculate Size of ContactordhruvBelum ada peringkat

- A Space Vector Modulation Based Three-Level PWM Rectifier Under Simple Sliding Mode Control StrategyDokumen8 halamanA Space Vector Modulation Based Three-Level PWM Rectifier Under Simple Sliding Mode Control StrategydhruvBelum ada peringkat

- 5 - AC Motor Starter PDFDokumen10 halaman5 - AC Motor Starter PDFPrem KumarBelum ada peringkat

- Harmonic Filtering - Electrical Installation GuideDokumen4 halamanHarmonic Filtering - Electrical Installation GuidedhruvBelum ada peringkat

- R.M.S. Values - Electrical Installation Guide PDFDokumen1 halamanR.M.S. Values - Electrical Installation Guide PDFdhruvBelum ada peringkat

- Design of Igbt Based LLC Resonant InverterDokumen7 halamanDesign of Igbt Based LLC Resonant InverterdhruvBelum ada peringkat

- Basic Solutions To Mitigate Harmonics - Electrical Installation GuideDokumen3 halamanBasic Solutions To Mitigate Harmonics - Electrical Installation GuidedhruvBelum ada peringkat

- Usefulness of The Various Indicators of Harmonic Distortion: From Electrical Installation GuideDokumen2 halamanUsefulness of The Various Indicators of Harmonic Distortion: From Electrical Installation GuidedhruvBelum ada peringkat

- Origin of Harmonics - Electrical Installation Guide PDFDokumen3 halamanOrigin of Harmonics - Electrical Installation Guide PDFdhruvBelum ada peringkat

- Selection of A Circuit-Breaker - Electrical Installation GuideDokumen11 halamanSelection of A Circuit-Breaker - Electrical Installation GuidedhruvBelum ada peringkat

- Isc at The Receiving End of A Feeder As A Function of The Isc at Its Sending End - Electrical Installation GuideDokumen3 halamanIsc at The Receiving End of A Feeder As A Function of The Isc at Its Sending End - Electrical Installation GuidedhruvBelum ada peringkat

- Experimental Investigation On The Behaviour of IGBT at Short Circuit During On StateDokumen6 halamanExperimental Investigation On The Behaviour of IGBT at Short Circuit During On StatedhruvBelum ada peringkat

- HV Igbt Includes Active ClampingDokumen2 halamanHV Igbt Includes Active ClampingdhruvBelum ada peringkat

- Hard Switching Behaviour of MOSFETs and IGBTsDokumen6 halamanHard Switching Behaviour of MOSFETs and IGBTsdhruvBelum ada peringkat

- Current Source LLC InverterDokumen6 halamanCurrent Source LLC InverterdhruvBelum ada peringkat

- Standards and Description of Circuit-Breakers: From Electrical Installation GuideDokumen3 halamanStandards and Description of Circuit-Breakers: From Electrical Installation GuidedhruvBelum ada peringkat

- WEICON CatalogueDokumen284 halamanWEICON CataloguefranekzapaBelum ada peringkat

- Basic Piping PrintDokumen22 halamanBasic Piping PrintDeepak KumarBelum ada peringkat

- Grand SummaryDokumen4 halamanGrand SummaryBishnu Thapa MagarBelum ada peringkat

- Cavity Wall-Method StatementDokumen4 halamanCavity Wall-Method StatementTAHER AMMAR100% (1)

- Pipe Inspection, Testing & MarkingDokumen12 halamanPipe Inspection, Testing & MarkingRamalingam PrabhakaranBelum ada peringkat

- Sheet Metal DesignDokumen13 halamanSheet Metal Designsivakumar subramanianBelum ada peringkat

- Exam 1 On API 510 Code .Close BookDokumen24 halamanExam 1 On API 510 Code .Close Bookdjaber abadlia100% (1)

- Architectural Structural Holabird Bid Set DrawingsDokumen96 halamanArchitectural Structural Holabird Bid Set DrawingsM IQbal100% (1)

- Chemical AdmixtureDokumen3 halamanChemical AdmixtureFayeTaylorBelum ada peringkat

- Kobang - Nisa Alkarni - 1810923027 (Kel.19)Dokumen15 halamanKobang - Nisa Alkarni - 1810923027 (Kel.19)Fathir HidayahBelum ada peringkat

- Rupture DiscDokumen2 halamanRupture Discbigs1303Belum ada peringkat

- Stress CorrosionDokumen13 halamanStress CorrosionAbhinav GuptaBelum ada peringkat

- Structural Design of A Reinforced Concrete Balcony Slab To BS 8110Dokumen3 halamanStructural Design of A Reinforced Concrete Balcony Slab To BS 8110Saabir GariireBelum ada peringkat

- FREYSSINET Prestress ManualDokumen53 halamanFREYSSINET Prestress Manualras_deep100% (2)

- Builders in Chennai - Construction - Chennai Builders - Construction CompanyDokumen4 halamanBuilders in Chennai - Construction - Chennai Builders - Construction CompanyvgroshanBelum ada peringkat

- Soil NailingDokumen1 halamanSoil NailingPartha Pratim Sasmal0% (1)

- Strengths of Aluminum BoltsDokumen1 halamanStrengths of Aluminum BoltsAbdullah NajjarBelum ada peringkat

- ACI318-08 RC Beam - XLS: Material PropertiesDokumen3 halamanACI318-08 RC Beam - XLS: Material PropertiesEdgardo ArriesgadoBelum ada peringkat

- Masterseal 595: Technical Data GuideDokumen4 halamanMasterseal 595: Technical Data GuideKannan MurugesanBelum ada peringkat

- Fluorinated Polymer Processing Aids: How A Laboratory Cleanout Mistake Created A Family of Polymers That Is Still Growing Even After 50 YearsDokumen8 halamanFluorinated Polymer Processing Aids: How A Laboratory Cleanout Mistake Created A Family of Polymers That Is Still Growing Even After 50 YearsAmirhosein FazilatiBelum ada peringkat

- Masonry: Building Weather-Resistant Masonry WallsDokumen4 halamanMasonry: Building Weather-Resistant Masonry WallsghchgBelum ada peringkat

- Astm D-3840 - 01Dokumen9 halamanAstm D-3840 - 01Bipin SasikumarBelum ada peringkat

- Design of Superpassage (Ch. 75.377)Dokumen6 halamanDesign of Superpassage (Ch. 75.377)Sumit Kumar100% (1)

- PVC CatalogDokumen40 halamanPVC CatalogKhalil EbrahimBelum ada peringkat

- BricklayingDokumen11 halamanBricklayingPecandu KopiBelum ada peringkat

- Cable Construction & Cable Selection-Part:1Dokumen4 halamanCable Construction & Cable Selection-Part:1A. HassanBelum ada peringkat

- DSR 2007 ExcelDokumen277 halamanDSR 2007 ExcelProjjal GhoshBelum ada peringkat

- Boq of Swimming PoolDokumen2 halamanBoq of Swimming PoolSENG Phearak88% (24)

- Standards and Specifications For GRCDokumen2 halamanStandards and Specifications For GRCHani NemrawiBelum ada peringkat

- A Review On Use of FRP Mesh and Bamboo Fiber Composite Material For AAC Block Masonry Wall Strengthening and WaterDokumen5 halamanA Review On Use of FRP Mesh and Bamboo Fiber Composite Material For AAC Block Masonry Wall Strengthening and WaterIJRASETPublicationsBelum ada peringkat