Incoming Inspection

Diunggah oleh

GAURAV SHARMADeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Incoming Inspection

Diunggah oleh

GAURAV SHARMAHak Cipta:

Format Tersedia

Document Part No.

Rev Page

100-0044 007 1 of 11

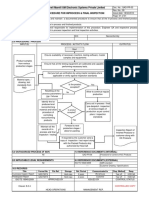

INCOMING INSPECTION PROCEDURE

1.0 PURPOSE

To establish instructions for incoming inspection of specified materials.

2.0 SCOPE & RESPONSIBILITY

The scope of this work instruction is to list, document, and Reference the required procedure for Incoming Inspection of mate rial LOTS. The

Engineering Manager is responsible for the maintenance of this procedure.

3.0 REFERENCES

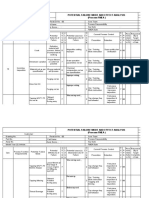

ISO_2859: Acceptable Quality Limit (AQL) Incoming Inspection

N CM R P r o c e d u r e Q A -1 0 6 9

4.0 DEFINITIONS

4.1 Items exempt from incoming inspection shall be those that are not associated with the development, production, and/ or

quality of manufactured finished good assemblies. Such items include:

Office Supplies, Consumable, Janitorial Supplies, Educational Materials

4.2 If sample size cannot be determined via the AQL II (2.5), the ENTIRE LOT shall be inspected.

4.3 Unless otherwise specified via explicit inspection requirements for a particular item, items flagged for incoming inspection

shall be inspected to the following SAMPLING PLAN based on ISO 2859 AQL Incoming Inspection

4.4 All Non-conforming Material must be tagged and processed per NCMR process QA-1069

5.0 PROCEDURES

Note: ERP Locations and markings of physical locations are subject to change, shown only for reference.

5.1 Inspect items for shelf life criteria (if applicable) -Receiving

5.2 Flag items for Incoming Inspection - Engineering

Materials purchased that have parameters and/ or requirements explicitly outlined in Purchase Specifications,

Engineering Specifications, and/ or drawings shall be flagged at the ITEM MASTER level by engine ering for incoming

inspection prior to placing in inventory.

5.3 Quality Control notified

If flagged, QC incoming personnel are notified via email notification that items have been received and are ready

for inspection.

5.4 Items to be inspected & Location

Items are located near the warehouse receiving area on a shelf marked as QC INCOMING" material.

ERP location: is QC-INCOMING_COP/ QC_INCOMING_FIB.

5.5 Adhesive materials

Located in the EPOXY PENDING APPROVAL" cabinet located in the indoor fiber production area.

ER P Loc a tion: QC -IN COMI NG_E PX .

All printed copies of this document are uncontrolled - Document Control System contains the most current revision.

Anda mungkin juga menyukai

- Sample Minutes of MeetingDokumen3 halamanSample Minutes of MeetingMohamad AzmeerBelum ada peringkat

- Incoming Inspection CriteriaDokumen1 halamanIncoming Inspection CriteriaRavikant Pandey100% (1)

- QP Nonconforming Product Sample 2014Dokumen2 halamanQP Nonconforming Product Sample 2014Anna Maree100% (1)

- QSP-010 Product Iden.&TraceabilityDokumen5 halamanQSP-010 Product Iden.&TraceabilityJamal Mohamed Rahamathullah100% (1)

- Supplier Audit ProcedureDokumen4 halamanSupplier Audit Proceduresakshi patil100% (2)

- Control of Measuring Equipment ProcedureDokumen3 halamanControl of Measuring Equipment Proceduretony s100% (2)

- Rework & Repair ProcedureDokumen1 halamanRework & Repair ProcedureManu Sharma100% (4)

- Attention: 6R60/6R75/6R80 Installation GuideDokumen4 halamanAttention: 6R60/6R75/6R80 Installation GuideEdwinferBelum ada peringkat

- Sta-P08-02 Non Conforming ProductDokumen6 halamanSta-P08-02 Non Conforming ProductAnonymous B7pghhBelum ada peringkat

- APQP Flow Chart Sample 2 Rev ADokumen9 halamanAPQP Flow Chart Sample 2 Rev ALuis AlejandroBelum ada peringkat

- QAD Procedure - Inspection & Testing (Inprocess & Final Inspection)Dokumen1 halamanQAD Procedure - Inspection & Testing (Inprocess & Final Inspection)suman100% (2)

- Supplier Quality Manual PDFDokumen13 halamanSupplier Quality Manual PDFSAMPATHU100% (1)

- QMP 15 Identification and TraceabilityDokumen6 halamanQMP 15 Identification and Traceabilityom cncBelum ada peringkat

- QMP-18 Initial Production ControlDokumen5 halamanQMP-18 Initial Production Controlom cncBelum ada peringkat

- Ac7120 Rev e 2 - FinalDokumen32 halamanAc7120 Rev e 2 - FinalOswaldo Rivera100% (1)

- AS9102 EFormDokumen4 halamanAS9102 EFormkmalysiakBelum ada peringkat

- A Standard Procedure For DeviationDokumen2 halamanA Standard Procedure For DeviationGAURAV SHARMA100% (1)

- Current Area Item Assembly Process Production Qa CheckingDokumen32 halamanCurrent Area Item Assembly Process Production Qa Checkingteresa100% (1)

- SOP For Calibration of InstrumentDokumen2 halamanSOP For Calibration of InstrumentRAVI KUMAR Carpenter100% (1)

- Temporary Deviation RequestDokumen3 halamanTemporary Deviation RequestSead ZejnilovicBelum ada peringkat

- Lesson Plan 2 BasketballDokumen3 halamanLesson Plan 2 Basketballapi-313716520100% (1)

- TA35 & TA40 Articulated Dumptruck Maintenance Manual: Click Here For Table ofDokumen488 halamanTA35 & TA40 Articulated Dumptruck Maintenance Manual: Click Here For Table ofKot878100% (2)

- SMT Generic Control PlanDokumen3 halamanSMT Generic Control PlanPedro Lopez Rodriguez100% (1)

- Control Plan TrainingDokumen20 halamanControl Plan TrainingGAURAV SHARMABelum ada peringkat

- Control Plan TrainingDokumen20 halamanControl Plan TrainingGAURAV SHARMABelum ada peringkat

- Process Validation RecordDokumen11 halamanProcess Validation Recordthindmanmohan50% (2)

- Control of Calibrated Equipment ProcedureDokumen8 halamanControl of Calibrated Equipment ProcedureFaisalBelum ada peringkat

- Ppap Review ChecklistDokumen4 halamanPpap Review Checklistpchakkrapani100% (1)

- Flab International Pvt. LTD.: Supplier Performance Rating Score CardDokumen3 halamanFlab International Pvt. LTD.: Supplier Performance Rating Score CardGAURAV SHARMABelum ada peringkat

- Chapter 15. Monitoring and Measurement Resources Related: (Clause Description-Paraphrase)Dokumen12 halamanChapter 15. Monitoring and Measurement Resources Related: (Clause Description-Paraphrase)Vikram BillalBelum ada peringkat

- AIAG PPAP Cover SheetDokumen1 halamanAIAG PPAP Cover SheetSCHOPENHAUERBelum ada peringkat

- Product Audit FormatDokumen2 halamanProduct Audit FormatSUBODHH50% (2)

- First Article Inspection FAI AS9102 PresentationDokumen28 halamanFirst Article Inspection FAI AS9102 PresentationaldiBelum ada peringkat

- WI-824-003 First Article InspectionDokumen2 halamanWI-824-003 First Article InspectionAndreas Schlager100% (1)

- QMP-13 Production ControlDokumen9 halamanQMP-13 Production Controlom cncBelum ada peringkat

- PPAP Process Checklist / Sign Off Sheet InstructionsDokumen7 halamanPPAP Process Checklist / Sign Off Sheet InstructionsSantosh TiwariBelum ada peringkat

- 06.supplier QMS Development Audit ChecklistDokumen5 halaman06.supplier QMS Development Audit ChecklistvishvendanBelum ada peringkat

- Kova Fasteners (P) LTD: Sampling PlanDokumen1 halamanKova Fasteners (P) LTD: Sampling PlanAmandeep SinghBelum ada peringkat

- PPAP - 4th Edition - Course MaterialDokumen18 halamanPPAP - 4th Edition - Course MaterialMy Dad My WorldBelum ada peringkat

- Inspection Report FormDokumen1 halamanInspection Report Forminterconnect_scottBelum ada peringkat

- Chirimuuta, Mazviita - Outside Color - Perceptual Science and The Puzzle of Color in Philosophy-The MIT Press (2017)Dokumen263 halamanChirimuuta, Mazviita - Outside Color - Perceptual Science and The Puzzle of Color in Philosophy-The MIT Press (2017)Karishma borgohainBelum ada peringkat

- Quality Control Process Chart (Machining)Dokumen7 halamanQuality Control Process Chart (Machining)mani317Belum ada peringkat

- Procedure: Measurement System Analysis ExecutionDokumen1 halamanProcedure: Measurement System Analysis Executionaslam100% (1)

- Customer:: Potential Failure Mode and Effect Analysis (Process FMEA)Dokumen8 halamanCustomer:: Potential Failure Mode and Effect Analysis (Process FMEA)Rajnish PotdarBelum ada peringkat

- Wi SPCDokumen4 halamanWi SPCSujeet Kumar100% (1)

- Incoming Inspection Procedure: Document Part No. Rev 100-0044 007 1 of 11Dokumen11 halamanIncoming Inspection Procedure: Document Part No. Rev 100-0044 007 1 of 11Sandip Jawalkar100% (1)

- Rework Record For Heat Treated Parts: Original Production DetailsDokumen1 halamanRework Record For Heat Treated Parts: Original Production DetailsBalram Ji100% (2)

- Quality Control PlanDokumen10 halamanQuality Control PlanGAURAV SHARMABelum ada peringkat

- SOP-10 Final Inspection ProcedureDokumen3 halamanSOP-10 Final Inspection ProceduretriveshBelum ada peringkat

- Lesson 5 Flight of Projectile, Air Resistance Neglected: OverviewDokumen7 halamanLesson 5 Flight of Projectile, Air Resistance Neglected: OverviewNadjer C. AdamBelum ada peringkat

- Purpose:: Procedure Manual FifoDokumen3 halamanPurpose:: Procedure Manual FifoartiBelum ada peringkat

- Route Card Implementation (In In-House and Supplier)Dokumen10 halamanRoute Card Implementation (In In-House and Supplier)Manoharar RBelum ada peringkat

- Manual de Caja Eaton Fuller ET20113Dokumen22 halamanManual de Caja Eaton Fuller ET20113Juan Gomez100% (3)

- Supplier Audit Check Sheet.Dokumen1 halamanSupplier Audit Check Sheet.ALI ASGHARBelum ada peringkat

- Supplier Production Part Approval Process (PPAP) Training Please Mute Your Phone For This TrainingDokumen17 halamanSupplier Production Part Approval Process (PPAP) Training Please Mute Your Phone For This TrainingRicky MarkBelum ada peringkat

- IQC ChartDokumen1 halamanIQC Chartrishi gautamBelum ada peringkat

- Materials Receivig Work Instruction in A Manufacturing UnitDokumen2 halamanMaterials Receivig Work Instruction in A Manufacturing Unitdeiveeganv411591% (11)

- KQP 16 Inspection & Testing Rev 04Dokumen11 halamanKQP 16 Inspection & Testing Rev 04Mohd Isa HarunBelum ada peringkat

- Complete Quality Manual of Garments Factory PDFDokumen11 halamanComplete Quality Manual of Garments Factory PDFGAURAV SHARMABelum ada peringkat

- Outsourced Processes 9001 2015Dokumen2 halamanOutsourced Processes 9001 2015Navnath Tamhane0% (1)

- Verefaction ProcessDokumen7 halamanVerefaction ProcessSaid ElsamnaBelum ada peringkat

- SA-QA-SOP-01 Rev 3 SOP For Quality Assurance 01 Oct 20 NewDokumen6 halamanSA-QA-SOP-01 Rev 3 SOP For Quality Assurance 01 Oct 20 NewdwarakababuBelum ada peringkat

- Inventory Report Finishing TrimsDokumen786 halamanInventory Report Finishing TrimsGAURAV SHARMABelum ada peringkat

- Fit/Function KPC:: Special Characteristics 11.1 Key Product Characteristic (KPC) DefinitionsDokumen3 halamanFit/Function KPC:: Special Characteristics 11.1 Key Product Characteristic (KPC) Definitions57641Belum ada peringkat

- Ref Flow Charts Layout InspectionDokumen1 halamanRef Flow Charts Layout Inspectionrajesh.bBelum ada peringkat

- Performance Task 1st Quarter Poetry Writing WorkshopDokumen3 halamanPerformance Task 1st Quarter Poetry Writing WorkshopNicole john ZuluetaBelum ada peringkat

- Receiving Inspection ProcedureDokumen2 halamanReceiving Inspection ProcedureErwin SantosoBelum ada peringkat

- .013-00-Checking AidsDokumen3 halaman.013-00-Checking Aidsdaniel_sasikumarBelum ada peringkat

- SOP FPA and LPADokumen15 halamanSOP FPA and LPASuresh Kumar Rana100% (1)

- Inprocess Inspection ReportDokumen8 halamanInprocess Inspection Reportpardeep kumarBelum ada peringkat

- AE-QA-02 - First Piece Inspection ReportDokumen1 halamanAE-QA-02 - First Piece Inspection ReportKarthi ThiyagarajanBelum ada peringkat

- APQP OS Procedure ExampleDokumen8 halamanAPQP OS Procedure Exampleali qaBelum ada peringkat

- Doc. 0715 - 01.0422 Revised As Per IATFDokumen7 halamanDoc. 0715 - 01.0422 Revised As Per IATFdevendra shuklaBelum ada peringkat

- 004 - QMS - Inspection DivisionDokumen18 halaman004 - QMS - Inspection DivisionSittie Fatma ReporsBelum ada peringkat

- UPSRTC Ticket 00000009D6E0Dokumen2 halamanUPSRTC Ticket 00000009D6E0GAURAV SHARMABelum ada peringkat

- I Ntia L / Inline Ins Pectio N Report Supplier: Factory: Or/ No: Tod: Order Cutting: Sewing: Finishing: Packed: CheckedDokumen1 halamanI Ntia L / Inline Ins Pectio N Report Supplier: Factory: Or/ No: Tod: Order Cutting: Sewing: Finishing: Packed: CheckedGAURAV SHARMABelum ada peringkat

- N.N Fasion Quality Assurance ManualDokumen42 halamanN.N Fasion Quality Assurance ManualGAURAV SHARMABelum ada peringkat

- Kay Hardware New GST CertificateDokumen3 halamanKay Hardware New GST CertificateGAURAV SHARMABelum ada peringkat

- UntitledDokumen2 halamanUntitledGAURAV SHARMABelum ada peringkat

- Quality Assurance SOP TemplateDokumen3 halamanQuality Assurance SOP TemplateGAURAV SHARMABelum ada peringkat

- Acceptable Quality LimitDokumen2 halamanAcceptable Quality LimitGAURAV SHARMABelum ada peringkat

- Abc Iso-Iec-20000-1-2018Dokumen1 halamanAbc Iso-Iec-20000-1-2018GAURAV SHARMABelum ada peringkat

- Weekly Quality GoalDokumen1 halamanWeekly Quality GoalGAURAV SHARMABelum ada peringkat

- Abc Iso-50001-2018Dokumen1 halamanAbc Iso-50001-2018GAURAV SHARMABelum ada peringkat

- Vallabh Metal Inc: Supplier Performance Rating Score CardDokumen3 halamanVallabh Metal Inc: Supplier Performance Rating Score CardGAURAV SHARMABelum ada peringkat

- Cutting Section SOP: Fabrics Relaxation ProcedureDokumen1 halamanCutting Section SOP: Fabrics Relaxation ProcedureGAURAV SHARMA100% (1)

- Saran Impex Chemical List: STFC Chemical Inventory For Area Maintained byDokumen2 halamanSaran Impex Chemical List: STFC Chemical Inventory For Area Maintained byGAURAV SHARMABelum ada peringkat

- Corrective Action Form-qs-141ADokumen1 halamanCorrective Action Form-qs-141AGAURAV SHARMABelum ada peringkat

- Quality Improvement Programme - : Participants Meeting Points: DateDokumen1 halamanQuality Improvement Programme - : Participants Meeting Points: DateGAURAV SHARMABelum ada peringkat

- Vendor Registration FormDokumen10 halamanVendor Registration FormGAURAV SHARMABelum ada peringkat

- Social and Professional Issues Pf2Dokumen4 halamanSocial and Professional Issues Pf2DominicOrtegaBelum ada peringkat

- Report Liquid Detergent BreezeDokumen12 halamanReport Liquid Detergent BreezeDhiyyah Mardhiyyah100% (1)

- Explicit Lesson PlanDokumen10 halamanExplicit Lesson PlanBanjo De Los SantosBelum ada peringkat

- Application of Geosynthetics in Pavement DesignDokumen7 halamanApplication of Geosynthetics in Pavement DesignAnonymous kw8Yrp0R5rBelum ada peringkat

- December 2022 Issue: More Transparency, P S An R T e R o M, y C en Ar P P, y PDokumen24 halamanDecember 2022 Issue: More Transparency, P S An R T e R o M, y C en Ar P P, y Pwpp8284Belum ada peringkat

- GlobalisationDokumen8 halamanGlobalisationdummy12345Belum ada peringkat

- Led Matrix A-788bsDokumen5 halamanLed Matrix A-788bsjef fastBelum ada peringkat

- AYURVEDA Products CatalogDokumen17 halamanAYURVEDA Products CatalogFoutanke TorodoBelum ada peringkat

- Direct MessagesDokumen338 halamanDirect Messages1Ksubs with a cod trickshotBelum ada peringkat

- EmbOS GenericDokumen324 halamanEmbOS Genericbogd33Belum ada peringkat

- Pte Lastest QuestionsDokumen202 halamanPte Lastest QuestionsIelts Guru ReviewBelum ada peringkat

- Authority To TravelDokumen39 halamanAuthority To TraveljoraldBelum ada peringkat

- Department of Education: Republic of The PhilippinesDokumen6 halamanDepartment of Education: Republic of The PhilippinesLalaine QuitoBelum ada peringkat

- TTC 1000Dokumen2 halamanTTC 1000svismaelBelum ada peringkat

- Essentials of Repertorization Tiwari Link PageDokumen11 halamanEssentials of Repertorization Tiwari Link PageBibin TSBelum ada peringkat

- Mrs. Saba Khan 15 Shahbad Diwan Khana, Bareilly, City, Bareilly, Bareilly, Utt AR PRADESH, 243003,9219172265Dokumen28 halamanMrs. Saba Khan 15 Shahbad Diwan Khana, Bareilly, City, Bareilly, Bareilly, Utt AR PRADESH, 243003,9219172265amitBelum ada peringkat

- Particle FilterDokumen16 halamanParticle Filterlevin696Belum ada peringkat

- Monorail Hoist SystemDokumen17 halamanMonorail Hoist SystemypatelsBelum ada peringkat

- RenewalPremium 1123186Dokumen1 halamanRenewalPremium 1123186Suhas Renu85Belum ada peringkat

- PapernathazDokumen26 halamanPapernathazAbelardo LapathaBelum ada peringkat

- Module 1-Mathematics As A Language: Maribel D. Cariñ0Dokumen4 halamanModule 1-Mathematics As A Language: Maribel D. Cariñ0KhalidBelum ada peringkat

- Dinengdeng RecipeDokumen1 halamanDinengdeng RecipeFuBelum ada peringkat