1978 ARRJ Dickinson

Diunggah oleh

Anil SuryawanshiHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

1978 ARRJ Dickinson

Diunggah oleh

Anil SuryawanshiHak Cipta:

Format Tersedia

E.J.

DICKINSON

THE DESIGN OF

BITUMINOUS PLANT MIXES FOR

ROAD AND AIRFIELD PAVING

ABSTRACT

(2) good light reflectance properties, particularly

The formulation of dense bituminous concrete type mixes when wet; and

by the conventional procedures of using modified 'max- (3) good resistance to wear.

imum density' aggregate gradings and empirical

laboratory compaction and mechanical testing pro- Bitumen of petroleum origin has generally been

cedures (such as those of the Marshall method) is out- used as the binder and, although it is an

lined. The advantages and limitations of such procedures economically viable adhesive for large-scale use in

are indicated, particularly in relation to the degree of

paving materials, it suffers from the disadvantage

compaction which is obtained in the mix at laydown and in

service. The design of porous 'friction' courses with deep

that its deformation behaviour is very dependent on

macrotexture for improved skid resistance at high vehicle temperature and its tensile breaking strength is low.

speed is also discussed. More basic design procedures This, and the availability of locally-produced ag-

founded on service requirements and the packing proper- gregates, impose important limitations on the

ties, shape and surface texture of available mineral ag- design of the bitumen-mineral aggregate composite

gregates are then considered and progress by the and the composition finally selected is often a com-

Australian Road Research Board in this direction indi- promise between the various requirements listed

cated. above.

Developments in the laboratory design of the

INTRODUCTION composite have generally followed developments in

the understanding of the packing properties of

Thin layers of bituminous plant mix have been used mineral aggregates, and the development of

for many years in Australia for the surfacing of pave- laboratory compaction procedures which bear

ments and, more recently, greater depths have been some relation to the compaction obtained at

laydown and in the pavement after trafficking.

laid to form part of the load spreading structure.

Because of the important requirements of

In this paper attention is directed to the design

durability and air and water impermeability, attention

of the mix composition (aggregate grading and ag-

has been directed mainly to dense composites, and

gregate, filler and binder proportions) and it is

the design of these will be considered first.

assumed that the quality of the mix constituents is

acceptable. Design of the mix composition (and, to a

certain extent, the acceptable quality of the consti-

tuents) depends not only on the situation of the DESIGN OF CONTINUOUSLY GRADED

material in the pavement but also on the climatic DENSE MIXES

conditions and the expected traffic at the site.

The general requirements of the material are: Laboratory design of continuously graded dense

(a) ability to resist shoving in hot weather under the plant mix has been based on the work of Fuller and

imposed traffic; Thompson (1907) who determined, by experiment,

relationships between the particle size distribution

(b) durability; (PSD) of mineral aggregates and their packing pro-

(c) air and water impermeability (with the exception perties. In order to obtain a high density of packing,

of porous 'friction' courses on the surface); and they found that the PSD should conform to the rela-

(d) ability to follow small movements in the pave- tionship

ment without cracking (flexibility).

M2 [d2

Special requirements of the surface course are:

M1 d1

(1) good skid resistance characteristics when wet;

Paper presented to the Symposium and Workshop on

where M, and M, are the percentages of aggregate

Design and Construction of Bituminous Concrete Pave- passing sieves with openings d, and d, respectively

ments for Roads and Airfields, November 9-10. and n has a value between 0.4 and 0.6.

32 AUSTRALIAN ROAD RESEARCH, Vol 8, No. 2, June 1978

DICKINSON — PLANT MIXES FOR ROADS AND AIRFIELDS

Having obtained a 'near maximum' density PSD, THE MARSHALL METHOD

the next consideration has been the partial filling of This method was developed by the U.S. Corps of

the voids in this packed aggregate with bitumen. Engineers who chose a testing machine and method

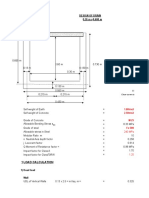

The volume/mass relationship of a typical com- of design conceived by Bruce Marshall of the

pacted continuously graded dense plant mix is Mississippi State Highway Department (McFadden

shown in Fig. 1. The voids in the mineral aggregate and Ricketts 1948).

(VMA) should not be completely filled with bitumen;

otherwise, the compacted mix becomes unstable The essential features of the testing procedure

and is easily sheared when warm. are shown in Fig. 3. Trial mixes covering a range of

bitumen contents are impact compacted in a mould

— A air voids 4.0% Yo by mass with a standard hammer. Usually, 50 hammer blows

VM on the two opposing faces of the cylindrical speci-

(17.7 °/D 6.0 men are specified but, for surface courses for sites

where there is a large number of heavy vehicles with

high tyre pressures, 75 hammer blows on each face

might be used.

52.0

Total vol. TEST AND APPARATUS COMPACTION

NORMAL TEST

PROCEDURE METHOD

MARSHALL

LOAD

34.6 Specimen compressed

at 51 mm/min at 60 C

Impact by Marshall

hammer (4.54 kg falling

-,

1:::\ , Specimen

Maximum load -,_ 102 mm dia through 457 mm).

(stability) and defor- x 64 mm high Number of blows

mation at maximum •._ normally 50 or 75 on

load (flow value) each face

4-- 7.4 determined

Fig. 1 — Volume/mass relationship for a typical compacted MODIFIED HUBBARD-FIELD

bituminous concrete

LOAD

Specimen extruded at Tamping with finishing

a rate of 61 mm/min at

60C. Maximum force

Il 47_,.__A Specimen

compressive load of

45 kN for two

Given an acceptable aggregate grading and determined -- It 152 mm dia minutes

volumetric proportions of aggregate, bitumen and ' 1,4 x 76 mm high

air voids, the next design step has been to assess

the resistance of the compacted mix to shearing

(shoving). Various mechanical tests were

Fig. 3 —Common mechanical tests for bituminous mixtures

developed to do this and those of Marshall (McFad-

den and Ricketts 1948) and Hubbard and Field

(1935) are the most familiar.

The air void content of the cylinders is deter-

A flow chart of the entire design procedure is mined by weighing them in air and in water (waxed

shown in Fig. 2. There are no established tests for specimens are sometimes used) and then determin-

assessing the workability, compactibility and resis- ing their solid density by breaking them up (after

tance to segregation of the different particle sizes warming) and finding the weight of water displaced

when handled and these important characteristics by the disintegrated mix. The VMA is the fractional

are assessed subjectively during the laboratory volume of the cylinder occupied by air and bitumen.

handling and later in trial mixes. Both the Hubbard-

Field method and the Marshall method are used in Resistance to shoving when warm is determined

Australia, but the latter is more popular. by heating the cylinders to 60°C in a water bath and

then compressing them diametrically at a constant

SELECT speed. The maximum force developed during com-

(al COARSE AGGREGATES

lb/ FINE AGGREGATES

cl FILLER

pression (Marshall Stability) and the movement to

reach this maximum force (Marshall Flow) are

DETERMINE SELECT

measured.

COMBINATION TO NEW AGGREGATES

PRODUCE 'NEAR

MAX DENSITY'

GRADING Typical test results for a series of mixtures are

shown in Fig. 4. As the bitumen content increases,

MAKE UP A SERIES

OF TRIAL MIXES Marshall Stability and density pass through a max-

WITH A RANGE OF

BITUMEN CONTENTS imum. Marshall Flow and the percentage of the VMA

WORKABILITY

AND COMPACTIBILITY

SUBJECTIVELY

filled with bitumen increases and the air voids

ASSESSED

COMPACT ALTER PROPORTIONS

OF COARSE AND FINE

decrease.

MIXES UNDER SELECTED

AGGREGATES AND/OR

AND CONTROLLED CONDITIONS

FILLER

Examples of specification by the Marshall

MEASURE AIR VOIDS;

VMA AND STABILITY design procedure are given in Table I (airfield sur-

TO SHOVING WHEN

WARM facings) and Table II (road surfacings) (NAASRA

1978). In both cases there is a requirement of

ACCEPT minimum stability, maximum flow and a range of air

MIX WITH 'OPTIMUM'

BITUMEN CONTENT

void content with an absolute minimum of air voids

of 3 or 4 per cent. Both specifications also control

Fig. 2 — Design flow chart the fraction of the VMA filled with bitumen.

AUSTRALIAN ROAD RESEARCH, Vol. 8, No. 2, June 1978

33

DICKINSON — PLANT MIXES FOR ROADS AND AIRFIELDS

10 8 From test data such as that shown in Fig.4 a

bitumen content is chosen such that the require-

FLOWVA LUE(60 C )-mm

ments of a specification are met. This is usually

STAB ILITY(60 C) - k N

9 6

0 done by taking the following bitumen contents and

°

calculating their mean:

°

8 4 (a) mean for limits of percentage of air voids;

(b) maximum stability;

(c) maximum density; and

7 2

(d) mean of limits for per cent voids filled (if used).

a b

THE MODIFIED HUBBARD-FIELD METHOD

6 0

5 6 7 5 6 7 The essential features of this method are shown in

Fig. 3. Mix compaction is by tamping, followed by

compression and the cylindrical specimen at 60°C

2.48 6

is then extruded axially through a ring at a constant

speed. The maximum force (stability) developed

9 during extrusion is measured. Like the Marshall pro-

f(\ -o

cedure, design criteria are based on specification of

a minimum stability, range of air void content and

range of VMA filled with bitumen.

TABLE I

2.36 AIRFIELD PAVEMENTS

5 6 7 5 6 7

Marshall Design Criteria

BINDER CONTENT - Modified from U.S. Corps of Engineers Specification

per cent

Traffic Tyre Pressure (kPa) Up to 700 In excess

Cl)

of 700

O

Specimen Compaction (blows each end) 50 75

• 90

t— cc Test Property and Type of Mix Min. Max. Min. Max.

<

O 0

w z Stability (kN)

cr E 80 Bituminous concrete surface course 2.2 8.0

Binder or basecourse 2.2 8.0

<

Flow (mm)

O 0 70 Bituminous concrete surface course 3.0 4.0

w 5 6 7

Binder or basecourse 5.0 4.0

< BINDER CONTENT

I— U- Air Voids (°o)

2 per cent

Bituminous concrete surface course 4 7 4 7

0 Binder or basecourse 4 10 4 10

U.1

0- Voids Binder Filled (°o)

Bituminous concrete surface course 65 80 65 80

Fig. 4 — Typical Marshall testing results Binder or basecourse 60 80 60 80

TABLE II

ROAD PAVEMENTS

Marshall Design Criteria

(50 Blow Cornpactive Effort)

Maximum Size

of Aggregate

(mm) 7 10 13 20

Property Min. Max. Min. Max. Min. Max. Min. Max.

Stability

(DRN) 5.5 6.5 6.5 6.5

Flow (mm) 2.0 3.5 2.0 3.5 2.0 3.5 2.0 3.5

Air Voids

( Vol.)

(a) Wearing

Course 4 7 4 7 4 7 4 7

(b) Inter-

mediate or

basecourse 3 6 3 6 3 6 3 6

Voids in

Mineral

Aggregate

( Vol.) 18 17 16 15

34 AUSTRALIAN ROAD RESEARCH, Vol 8, No. 2, June 1978

DICKINSON — PLANT MIXES FOR ROADS AND AIRFIELDS

THE LIMITATIONS OF THE MARSHALL- Two other factors militate against the general

use of the Marshall-type mix design. Firstly, the

TYPE DESIGN PROCEDURES macrotexture of a wearing course is too shallow for

good (high speed) skid resistance and light reflec-

Despite the fact that the laboratory compaction is tance properties when wet. Secondly, the relatively

very different from the compaction the material low bitumen content of the mixes (low average bitu-

receives at laydown and under traffic, and that the men film thickness) makes them less flexible and

mechanical testing bears little relation to traffic

less resistant to fatigue than other compositions.

stressing in service, the Marshall-type design has

proved very useful in practice. Pavement construc-

tion and maintenance authorities have, in general,

RECENT DEVELOPMENTS IN DESIGN

only used it as a basis for a final design; modifying DENSE GAP-GRADED MATERIALS

the aggregate grading and volumetric proportions

of the constituents to suit locally available aggreg- The first dense plant mix materials to be used exten-

ates and pavement conditions. An example of such sively were the stone filled sheet asphalts of which

modification was described in a recent paper by the 'Hot Rolled Asphalt' (HRA), now used for many

Phillips and Bethune (1976) which outlines the years in U.K., is an example (British Standards In-

evolution of the Marshall design for use on main stitution 1973). An HRA surface course is essen-

roads in the State of Victoria. tially a mortar of fine aggregate (`sharp natural

sand), inert filler (material passing the 75 um sieve)

Apart from the limitation of dealing only with and a hard bitumen which is extended with 30 to 35

dense, continuously graded mixtures, mixes per cent of coarse aggregate. A typical composition

designed by the Marshall-type method are very de- for a surface course to be laid 40 mm thick (and

pendent on very good compaction at laydown or chipped after spreading to produce an acceptable

compaction by traffic afterwards to attain the design

surface macrotexture) is as follows.

air voids. If this degree of compaction is not at-

Per cent

tained, the hardening of the bitumen in the layer is Mass

relatively rapid and it becomes inflexible and prone

Coarse aggregate i10-14 mm size) :3 o

to cracking.

Fine sand (90 passing the 1 18 mm sieve) 53

Filler (ground limestone) 9

8.0 Bitumen ('50 pen 1

10 50 Suitable fine aggregates and compositions for this

material were found by trial-and-error and no

laboratory design procedure was involved.

2.5

AIR This type of material is known, however. to be

VOIDS 6

more durable and more flexible than the con-

(0/0 VOL.) 4—DESIGN

tinuously graded Marshall-type design and is more

easily compacted to its final density at laydown. The

SLOW LANE I FAST LANE concern was that the empirical compositions found

2

shoulder edge median edge to be satisfactory for U.K. conditions would have

poor resistance to shoving in hotter climates.

0 1 2 3 4 5 6 7

—*TRANSVERSE POSITION (m) The fine aggregate is the major aggregate com-

ponent and has an important influence on the

Fig. 5 — Compaction of bituminous concrete by traffic `stability' when warm, so its PSD, particle shape and

particle surface texture are important. Brien (1 972)

Fig. 5 shows the compaction condition across a proposed a simple flow test to assess these proper-

wearing course after three years of traffic (Oliver ties and used rutting in a wheel tracking machine,

1976a ). The mix was a 10 mm nominal size Marshall such as that shown in Fig. 6, to assess resistance to

design laid to an average thickness of 24 mm on one shoving. He also established an approximate rela-

carriageway of the dual-carriageway road. This car- tionship between wheel tracking at 60°C and

riageway is currently carrying about 13 000 Marshall Stiffness (Marshall Stability/Marshall

veh/day (7 per cent heavy vehicles). The slow lane Flow).

has been evenly compacted to about 1 per cent air

voids above the design value, but there is an area •—chart recorder

between the wheel tracks of the fast lane where

compaction is only at the 8.5 per cent air voids

level. As might be expected, compaction of the

material near the edges of the carriageway is very displacement displacement

poor. transducer

pivot

The effect of this differential compaction on

bitumen hardening is indicated by the numbers

above the arrows in Fig. 5. These are the number of

times the viscosity of the bitumen at laydown has in- moving 46, :prn z:7- 6 457.11

,2 1 0 load

creased during the three years. Further traffic com- platform

paction, particularly in the areas where there are specimen 300 x 300 x 25 rnr

high air voids and hardened bitumen, is unlikely. Fig. 6 —The wheel tracking test

AUSTRALIAN ROAD RESEARCH, Vol. 8, No. 2, June 1978

35

DICKINSON — PLANT MIXES FOR ROADS AND AIRFIELDS

Marais (1974) confirmed the work of Brien and With the high bitumen content recommended,

proposed the following Marshall design criteria (75 careful control of mixing temperature is required to

blows compaction) for gap-graded wearing courses avoid drainage of the mix during handling, and 1 per

to be used in hot climates. cent of hydrated lime should be included in the filler

fraction to reduce the tendency of the bitumen to

Min. Max. strip from the aggregate by water and traffic action.

Marshall stiffness at 60°C (MN .rn) 1.5 Neither Marshall testing procedures nor wheel

Marshall stability at 60°C (kN) 125 tracking tests are suitable for assessing the resis-

Air voids 1 Vol ) 2.0 tance of these mixes to shoving when warm. Both

procedures have indicated low stability where ser-

Marais has also proposed that the average film vice performance has been satisfactory. A good key

thickness of the bitumen in the mix should not be between the friction course and the substrate is im-

less than 6.0 µm (calculated for the various grad- portant to prevent 'sliding'. The water immersion

ings and bitumen contents by using the surface area wheel tracking test (United Kingdom 1962) should

factors recommended by the Asphalt Institute be suitable for assessing the resistance of the com-

(1963) ) and that the filler/bitumen ratio by mass pacted mix to stripping, but this method does not

should not be less than one. Mixes based on these appear to be suitable for dense materials. Air void

design criteria and using selected fine aggregates content of the field-compacted material is prefera-

are now used for surfacing main roads in South bly determined by mensuration of cores together

Africa. with 'solid' density measurements.

POROUS FRICTION COURSES FOR SURFACING HIGH- A porous friction course laid on the Southern

SPEED ROADS AND AIRFIELD RUNWAYS

Cross Drive freeway in Sydney in 1969 (Department

As already mentioned, Marshall-type mix designs of Main Roads, N.S.W. 1970) is still in satisfactory

give a very shallow surface macrotexture and are condition, although the voids in it have been par-

not ideal for the surfacing of high-speed roads and tially filled with detritus. The design experience of

airfield runways because their skid resistance at the Country Roads Board (CRB), Victoria with this

high speed when wet is relatively poor. A deep type of surfacing is described in a recent paper by

macrotexture and, preferably, a porous composite is Currie and Bethune (1976).

desirable so that water can be expelled readily from LEES' WORK ON THE PACKING PROPERTIES OF

beneath the vehicle tyre and drained away quickly AGGREGATES

from the top of the surfacing to reduce ponding.

Improvement in design methods can come from a

Open-graded mixes are being successfully used better understanding of the packing properties of

for this type of surfacing and currently the design (coated) aggregates and finding laboratory test pro-

approach to them is mainly empirical. They can be cedures which imitate the compaction a mix

expected to be less durable than dense composites receives at laydown and subsequently under traffic.

and, because of their porosity, should be laid on an Lees (1970) has proposed a new method for

impervious substrate. designing maximum density aggregate gradings and

a critical assessment of this method has been given

A design procedure has been proposed which is by Dickinson and Oliver (1976). The method is

based on measurement of the void content of the based on laboratory compaction of dry aggregate

(dry) coarse aggregate (10 to 2.36 mm) after

laboratory compaction by vibration (Smith, Rice and

Spelman 1974). These voids are partially filled with

bitumen (about 6 per cent by mass of the mix) and

with the fine aggregate and filler (not more than 15 /

per cent by mass of the total aggregate) such that at 80

least 15 per cent air voids remain. The fine aggreg-

% PASS ING SIEVE SIZE

ate and filler play an important 'chocking' role for the

coarse aggregate and should be continuously

60

graded. The volume/mass relationship for the 7

various constituents of a typical porous friction zz

course is shown in Fig. 7. Lees z/

40

air voids 17% %by mass Fuller

VMA 29%

/ y(itr$7/1?/0/ / • 6

20

\•r‘

Total vol. 1\\ t

• 80 6.7 13.2

% 0.075 0.15

I

0.30 0.60

I I

1.18

I

2.36

t

4.75

I I

9.5

I I 1

19.0

•) 10.5

A.S. SIEVE SIZE ( m m )

\ .

"r1 a!g e a e 70 •":„.„...- 3.5 2 3 4

—

filler 3% SIEVE OPENING (Log( m)

Fig. 7 — Volume/mass relationship of a typical porous friction Fig. 8 — Comparison of maximum density gradings from Lees'

course procedure and 'Fuller' curve

36 AUSTRALIAN ROAD RESEARCH, Vol 8, No. 2, June 1978

DICKINSON — PLANT MIXES FOR ROADS AND AIRFIELDS

fractions under vibration and the calculation pro- The effect of the number of passes of the roller

cedures proposed only apply to 'one size' fractions. on the degree of compaction of a Marshall designed

The method, however, can be used by matching dense, continuously graded wearing course

combinations of industrial fractions to gradings material 25 mm thick is shown in Fig. 10. Six passes

calculated from data on one-sized fractions or by were needed to attain construction compaction (10

determining the maximum density of successive per cent air voids) and 44 passes to attain the com-

two-component combinations of fractions by ex- paction after three years of traffic (6.5 per cent air

periment. voids). These two degrees of compaction are cur-

rently being used to assess the compactibility of

trial mix designs.

A comparison of a Lees' maximum density grad-

ing (40 mm nominal size) with a Fuller grading (n =

0.5) is shown in Fig. 8. Although the two gradings 12

achieve approximately the same density, the Lees' 0

design contains more of the finer sizes and, when 10 construction

coated with bitumen, is much less prone to segrega- 4-

tion than the Fuller grading. a)

8

Lees' procedures are more general than the 0 three years under traffic

0

Marshall-type method and could be applied to gap-

graded materials and porous friction courses. They 0

can also be used to find the maximum density com-

L.. 4

binations which can be synthesised from a limited

choice of industrial fractions. His experimental

method for measuring the compaction of a mixture of

dry aggregates suffers, however, from the disadvan-

T1 •

_16

2 4 8 16 32 64

tage that the degree of compaction obtained is Number of roller passes (log scale]

significantly less than that produced when the ag- Laboratory Roller Compaction

gregates are coated with bitumen and compacted

under service conditions. The Australian Road Fig. 10 — Australian Road Research Board laboratory rolling

to obtain construction and 'after traffic' compaction

Research Board (ARRB) is currently investigating

vibration compaction procedures done in the pre- Apart from assessing compactibility, the pro-

sence of either water or light oil. cedure produces a slab large enough to carry out

duplicate wheel tracking tests in order to assess

ARRB LABORATORY MIX COMPACTION PROCEDURES resistance to shoving when warm and also measure-

ments of surface macrotexture. Slabs 75 mm thick

In an attempt to imitate service compaction condi- have been manufactured with 40 mm nominal size

tions more closely, ARRB has developed a compac- designs.

tion procedure using a footpath (vibrating) roller on

a layer of mix 600 mm square (Oliver 1976b ). The

procedure is shown diagrammatically in Fig. 9. CONCLUSIONS

Different thicknesses can be compacted by inser-

tion of aluminium spacer plates into the mould and This outline of current plant mix design procedures

the uppermost plate is heated electrically to main- and of new developments has indicated that the es-

tain mix temperature. sentially static position after the establishment of

the Marshall-type design at the end of the Second

World War is now changing. This has been brought

footpath, vibrating roller

about by the following factors:

(a) the realisation that Marshall-type designs do not

always produce durable and flexible surfacings;

(b) the need for a deep macrotexture on the surface

specimen 600 x 600 x 25 mm of high-speed roads and runways;

heated spacer (c) the realisation that a mix must be designed for

Al spacer

plate the anticipated trafficking and that degree of

plates compaction and compactibility of a design are

steel mould important considerations; and

(d) a method for assessing the compactibility of

Fig. 9 — Australian Road Research Board compaction method designs needs to be developed.

REFERENCES BRIEN, D. (1972). A design method for gap graded asphaltic mixes. Roads Road Constr. May,

pp. 140-45.

BRITISH STANDARDS INSTITUTION (1973). Specifications for Rolled Asphalt (Hot Process) for

Roads and Other Paved Areas. British Standard 594.

CURRIE, D.T. and BETHUNE, J.D. (1976). Design and use of open-graded friction course asphalt for

road surfacing. Proc. 8th ARRB Conf. 8(4), Session 17, pp. 1-7.

DEPARTMENT OF MAIN ROADS, N.S.W. (1970). Deep asphalt pavement on Southern Cross Drive.

Main Roads. September, p. 8.

AUSTRALIAN ROAD RESEARCH, Vol. 8, No. 2, June 1978 37

DICKINSON — PLANT MIXES FOR ROADS AND AIRFIELDS

DICKINSON, E.J. and OLIVER, J.W.H. (1976). An assessment of Lees' procedures for designing

maximum density aggregate gradings. Aust. Rd Res. 6(1), pp. 12-21.

FULLER, W.B. and THOMPSON, S.E. (1907). The laws of proportioning concrete. Trans. Am. Soc.

Civ. Eng. 59, pp. 67-172.

HUBBARD, P. and FIELD, F.C. (1935). The rational design of asphalt paving mixtures. Asphalt Inst.

Res. Series 1.

LEES, G. (1970). The rational design of aggregate gradings for dense asphaltic compositions.

Proc. Assoc. Asphalt Paving Technol. 39, pp. 60-90.

MARAIS, C.P. (1974). Tentative mix design criteria for gap graded bituminous surfacings. Transp.

Res. Rec. No. 515, pp. 132-45.

McFADDEN, G. and RICKETTS, W.C. (1948). Design and field control of asphalt paving mixtures for

military installations. Proc. Assoc. Asphalt Paving Technol., 17, pp. 93-113.

NATIONAL ASSOCIATION OF AUSTRALIAN STATE ROAD AUTHORITIES (1978). Principles and

Practice of Bituminous Surfacing. Vol. 2 'Plant Mix Work'. Section 3.

OLIVER, J.W.H. (1976a ). Traffic compaction of bituminous concrete: An initial survey. Australian

Road Research Board. Internal Report, AIR 178-6.

(1976b ). Design of bituminous plant mixes. Progress Report. Australian Road Research

Board. Internal Report, AIR 178-3.

PHILLIPS, B.L. and BETHUNE, J.D. (1976). Design and use of asphalt mixes. Proc. 8th ARRB Conf.

8(4), Session 16, pp. 11-17.

SMITH, R.W., RICE, J.M. and SPELMAN, S.R. (1974). Design of open graded asphalt friction

courses. Report No. FHWA-RD-74-2. Fed. Highw. Admin. Offices of Res. and Devt, Washington

D.C.

THE ASPHALT INSTITUTE (1963). Mix Design Methods for Asphalt Concrete and Other Hot-Mix

Types. Asphalt Institute Manual Series 2.

UNITED KINGDOM. DEPARTMENT OF SCIENTIFIC AND INDUSTRIAL RESEARCH. ROAD

RESEARCH LABORATORY (1962). Immersion Trafficking Tests — Bituminous Materials in

Road Construction. Chapter 5, pp. 80-1. (HMSO: London.)

After graduating from Oxford in 1941, Dr

Dickinson joined the staff of the Road

Research Laboratory, U.K. In 1951, he moved

to the newly formed Bituminous Binder

Research Unit, CS1R, South Africa. Following

three years as Technical Officer with the Bri-

tish Road Tar Association, he returned to

South Africa to take charge of the Bituminous

Division of the National Institute for Road

Research. He spent three years with Burt,

E.J. Dickinson Boulton and Hayward Ltd in London before

M.A.. B.Sc.(Oxon). joining the staff of the ARRB in 1964.

Ph.D..

C.Chem., F.R.I.C. Throughout his career he has been concerned

with research on bituminous paving materials

and its application and has published many

papers particularly on the properties of paving

tars and bitumens. He is currently group

leader of the bituminous surfacing research

work being done by the Board.

This paper is presented with the permission of the Executive Director of the Australian Road

ACKNOWLEDGEMENT Research Board, Dr M.G. Lay. The views expressed are those of the author and do not necessarily

represent those of the Australian Road Research Board.

AUSTRALIAN ROAD RESEARCH, Vol 8, No. 2, June 1978

38

Anda mungkin juga menyukai

- The Fabrication of Materials: Materials TechnologyDari EverandThe Fabrication of Materials: Materials TechnologyPenilaian: 5 dari 5 bintang5/5 (1)

- Gyratory Compacting SuperpaveDokumen7 halamanGyratory Compacting SuperpaveGoran MišanovićBelum ada peringkat

- Mix Design For Wearing Course of Flexible Road Pavement by Marshall MethodDokumen6 halamanMix Design For Wearing Course of Flexible Road Pavement by Marshall MethodVenkat Ramana reddyBelum ada peringkat

- Ijret20130213036 PDFDokumen6 halamanIjret20130213036 PDFRajen KoleyBelum ada peringkat

- Performance Evaluation of Dense Bituminous MacadamDokumen6 halamanPerformance Evaluation of Dense Bituminous MacadamInternational Journal of Research in Engineering and TechnologyBelum ada peringkat

- Laboratory Evaluation of SDBC, DBC and OGPC MixesDokumen6 halamanLaboratory Evaluation of SDBC, DBC and OGPC MixesfunkyBelum ada peringkat

- Laboratory Simulation of Compaction of Bituminous Concrete Mix For Refusal Density CriteriaDokumen10 halamanLaboratory Simulation of Compaction of Bituminous Concrete Mix For Refusal Density CriteriaMuhammad Maad RazaBelum ada peringkat

- Mashal TestDokumen13 halamanMashal TestPhemmy JibadeBelum ada peringkat

- An Application of The Michaelis-Menten Model To Analyze The Curing Process of Cold Recycled Bituminous MixturesDokumen13 halamanAn Application of The Michaelis-Menten Model To Analyze The Curing Process of Cold Recycled Bituminous MixturesharBelum ada peringkat

- Construction and Building Materials: Muhammad ArshadDokumen14 halamanConstruction and Building Materials: Muhammad Arshadchristian ricaldiBelum ada peringkat

- Laboratory Compaction Methods for Asphalt ConcreteDokumen12 halamanLaboratory Compaction Methods for Asphalt ConcreteEdivaldo PaciênciaBelum ada peringkat

- Module 3 NotesDokumen11 halamanModule 3 NotesRakshith SBelum ada peringkat

- Effect of Temperature On The RuttingDokumen8 halamanEffect of Temperature On The RuttingPiyush SharmaBelum ada peringkat

- BT Mix DesignDokumen5 halamanBT Mix DesignGhaffar LaghariBelum ada peringkat

- CTB PaperDokumen9 halamanCTB PaperAmmar AliBelum ada peringkat

- Selection of Cutback Asphalts: Standard Practice ForDokumen3 halamanSelection of Cutback Asphalts: Standard Practice ForD IZomer Oyola-GuzmánBelum ada peringkat

- Study of Cement Treated Base Agreagate Properties For Pavement StructureDokumen9 halamanStudy of Cement Treated Base Agreagate Properties For Pavement StructureOrlando RojasBelum ada peringkat

- EFFECT OF FILLERS On Bituminous Paving Mixex PDFDokumen8 halamanEFFECT OF FILLERS On Bituminous Paving Mixex PDFDipendra AwasthiBelum ada peringkat

- International Society For Soil Mechanics and Geotechnical EngineeringDokumen7 halamanInternational Society For Soil Mechanics and Geotechnical EngineeringPushpendra BhardwajBelum ada peringkat

- April 2013 1366124011 113f4 50 CRMBDokumen2 halamanApril 2013 1366124011 113f4 50 CRMBramudu oneBelum ada peringkat

- Department of Civil and Environmental Engineering, School of Engineering Cedat, Makerere UniversityDokumen50 halamanDepartment of Civil and Environmental Engineering, School of Engineering Cedat, Makerere UniversityBAMSBelum ada peringkat

- Construction and Building Materials: Xinxin Ding, Changyong Li, Yangyang Xu, Fenglan Li, Shunbo ZhaoDokumen7 halamanConstruction and Building Materials: Xinxin Ding, Changyong Li, Yangyang Xu, Fenglan Li, Shunbo ZhaoMekides KassayeBelum ada peringkat

- Effects of Mixture Proportioning, Curing, and Finishing On Concrete Surface HardnessDokumen8 halamanEffects of Mixture Proportioning, Curing, and Finishing On Concrete Surface HardnessHuaman Chavez Jesus AngelBelum ada peringkat

- Sustainability 14 11189 v2 PDFDokumen25 halamanSustainability 14 11189 v2 PDFZhiger KurmangalievBelum ada peringkat

- A Review On Bituminous Mix Design by Adding Different Percentages of Crumb Rubber For Improving Strength of PavementsDokumen14 halamanA Review On Bituminous Mix Design by Adding Different Percentages of Crumb Rubber For Improving Strength of PavementsEditor IJTSRDBelum ada peringkat

- Prediction of Compaction Parameters A ReviewDokumen1 halamanPrediction of Compaction Parameters A ReviewGaurav VermaBelum ada peringkat

- Deb AshishDokumen115 halamanDeb AshishAafan ShahidBelum ada peringkat

- Rutting Performance of Rubberized Porous Asphalt Using Finite ElementDokumen10 halamanRutting Performance of Rubberized Porous Asphalt Using Finite ElementRobel TeweldeBelum ada peringkat

- Shrinkage and Cracking Behavior of Cement Stabilized MaterialDokumen6 halamanShrinkage and Cracking Behavior of Cement Stabilized MaterialDem HasiBelum ada peringkat

- Construction and Building Materials: S.N. Suresha, George Varghese, A.U. Ravi ShankarDokumen7 halamanConstruction and Building Materials: S.N. Suresha, George Varghese, A.U. Ravi ShankarNUR AZIERA BINTI ZAMSHAHARIBelum ada peringkat

- Strength and Behaviour of Roller Compacted Concrete Using Crushed DustDokumen10 halamanStrength and Behaviour of Roller Compacted Concrete Using Crushed DustRidwanBelum ada peringkat

- Characterization of Recycled Asphalt Pavement (RAP) For Use in Flexible PavementDokumen16 halamanCharacterization of Recycled Asphalt Pavement (RAP) For Use in Flexible PavementAhmed Al-mohammdiBelum ada peringkat

- Study On Bituminous Mix Design With Different Percentages of Crumb Rubber To Improve Pavement StrengthDokumen12 halamanStudy On Bituminous Mix Design With Different Percentages of Crumb Rubber To Improve Pavement StrengthEditor IJTSRDBelum ada peringkat

- Cement-Bound Granular Materials Crack Propagation Reinforced FibersDokumen13 halamanCement-Bound Granular Materials Crack Propagation Reinforced FibersSatish Kumar GautamBelum ada peringkat

- Key Concept Source 2Dokumen9 halamanKey Concept Source 2John Michael GeneralBelum ada peringkat

- 131 r1 Sec PaperDokumen6 halaman131 r1 Sec PaperArijit BanerjiBelum ada peringkat

- Soil-Cement Mixture Properties and Design Consideratios For Reinforced Excavation by Fan, Wang y Qian 2017Dokumen7 halamanSoil-Cement Mixture Properties and Design Consideratios For Reinforced Excavation by Fan, Wang y Qian 2017Juan BetancurBelum ada peringkat

- How To Characterize The Mechanical Response of Bitumen Stabilized MaterialDokumen10 halamanHow To Characterize The Mechanical Response of Bitumen Stabilized MaterialMax Cedeño De LeónBelum ada peringkat

- Construction and Building MaterialsDokumen11 halamanConstruction and Building MaterialsAmit ShawBelum ada peringkat

- Strength Parameters of Various Soils With AdmixtureDokumen4 halamanStrength Parameters of Various Soils With AdmixtureSaksham KumarBelum ada peringkat

- Evaluations of SomeDokumen11 halamanEvaluations of SomeEris DBelum ada peringkat

- Experimental Study of the Effect of Tack Coats on pavementsDokumen15 halamanExperimental Study of the Effect of Tack Coats on pavementsRob DamhuisBelum ada peringkat

- Analyzing Coir Fiber's Effect on Bituminous MixturesDokumen6 halamanAnalyzing Coir Fiber's Effect on Bituminous MixturesJungle BookBelum ada peringkat

- Jurnal 1 GeotekDokumen7 halamanJurnal 1 Geotekputrielsari26Belum ada peringkat

- Bituminous MixesDokumen13 halamanBituminous MixesRanjit SinghBelum ada peringkat

- Coatings 11 01234Dokumen16 halamanCoatings 11 01234harBelum ada peringkat

- Chapter 2 c5 FinalDokumen29 halamanChapter 2 c5 FinalSamsuz ZamanBelum ada peringkat

- Fiber 22Dokumen15 halamanFiber 22حسين الشهريBelum ada peringkat

- Mechanical Performance of Strain-Hardening Geopolymer CompositesDokumen16 halamanMechanical Performance of Strain-Hardening Geopolymer CompositesMirza BasitBelum ada peringkat

- Design of Hot Mix Asphalt Using Bailey Method of Gradation: Manjunath K.R, Poornachandra Dev N.BDokumen8 halamanDesign of Hot Mix Asphalt Using Bailey Method of Gradation: Manjunath K.R, Poornachandra Dev N.BErick CarvalhoBelum ada peringkat

- 1 s2.0 S0950061816318141 MainDokumen9 halaman1 s2.0 S0950061816318141 MainahmadBelum ada peringkat

- Impact of Aggregate Gradation and Type oDokumen10 halamanImpact of Aggregate Gradation and Type oBank NutchanonBelum ada peringkat

- High-Speed Railway Embankments Stabilization by UsDokumen9 halamanHigh-Speed Railway Embankments Stabilization by Usajay kr gondBelum ada peringkat

- Construction and Building MaterialsDokumen16 halamanConstruction and Building MaterialsAnkush KumarBelum ada peringkat

- Article ExpDokumen13 halamanArticle ExpPravin BadarayaniBelum ada peringkat

- Effect of Aggregate Properties On Asphalt Mixtures Stripping and Creep BehaviorDokumen14 halamanEffect of Aggregate Properties On Asphalt Mixtures Stripping and Creep BehaviorHafiz IrzaBelum ada peringkat

- Journal of Rock Mechanics and Geotechnical Engineering: Mohammad Reza Azadi, Ali Taghichian, Ali TaheriDokumen15 halamanJournal of Rock Mechanics and Geotechnical Engineering: Mohammad Reza Azadi, Ali Taghichian, Ali TaheriFaheem SadiqBelum ada peringkat

- Construction and Building Materials: Xunhao Ding, Luchuan Chen, Tao Ma, Haixia Ma, Linhao Gu, Tian Chen, Yuan MaDokumen6 halamanConstruction and Building Materials: Xunhao Ding, Luchuan Chen, Tao Ma, Haixia Ma, Linhao Gu, Tian Chen, Yuan MaCamila GómezBelum ada peringkat

- Mello Saraiva Caldeira 2014Dokumen11 halamanMello Saraiva Caldeira 2014jon harfaBelum ada peringkat

- Construction and Building MaterialsDokumen12 halamanConstruction and Building MaterialsApoorva AgarwalBelum ada peringkat

- Irc - Gov.in.086.2018 Geometric Design Standards For Roads and StreetsDokumen52 halamanIrc - Gov.in.086.2018 Geometric Design Standards For Roads and StreetsMeenu TomsonBelum ada peringkat

- Ffirkm: S (RFFDokumen12 halamanFfirkm: S (RFFAnil SuryawanshiBelum ada peringkat

- Irc 129 2019Dokumen40 halamanIrc 129 2019Madabhushi MadhusudanBelum ada peringkat

- Cost Estimate of WarehouseDokumen16 halamanCost Estimate of WarehouseAnil SuryawanshiBelum ada peringkat

- Irc 108 2014Dokumen37 halamanIrc 108 2014Anil SuryawanshiBelum ada peringkat

- Irc - Gov.in.086.2018 Geometric Design Standards For Roads and StreetsDokumen52 halamanIrc - Gov.in.086.2018 Geometric Design Standards For Roads and StreetsMeenu TomsonBelum ada peringkat

- Irc 105 2019Dokumen36 halamanIrc 105 2019Anil SuryawanshiBelum ada peringkat

- Irc 128 2019Dokumen44 halamanIrc 128 2019Madabhushi Madhusudan100% (1)

- Irc 121 2017Dokumen37 halamanIrc 121 2017Anil SuryawanshiBelum ada peringkat

- MSRIP Phase 2 EnvDokumen26 halamanMSRIP Phase 2 EnvAnil SuryawanshiBelum ada peringkat

- One Stop Solution For Streetlight Poles ....Dokumen20 halamanOne Stop Solution For Streetlight Poles ....Sambit MohapatraBelum ada peringkat

- Box Truss and Cantilever Sign FoundationDokumen27 halamanBox Truss and Cantilever Sign FoundationUros LukovacBelum ada peringkat

- 4.structure Est (07.07.2016)Dokumen43 halaman4.structure Est (07.07.2016)Anil SuryawanshiBelum ada peringkat

- Road EstmateDokumen27 halamanRoad EstmateAnil SuryawanshiBelum ada peringkat

- Deterministic shallow foundation design using SPT dataDokumen4 halamanDeterministic shallow foundation design using SPT dataZahira HeloBelum ada peringkat

- Cost estimate for road drainage structuresDokumen45 halamanCost estimate for road drainage structuresAnil SuryawanshiBelum ada peringkat

- Items To Be Considered in Structure WorkDokumen1 halamanItems To Be Considered in Structure WorkAnil SuryawanshiBelum ada peringkat

- Building Design PDFDokumen71 halamanBuilding Design PDFAnil SuryawanshiBelum ada peringkat

- Upto Date Status of Feasibility Study Under: PKG-2 AS ON 14.07.2020Dokumen1 halamanUpto Date Status of Feasibility Study Under: PKG-2 AS ON 14.07.2020Anil SuryawanshiBelum ada peringkat

- Irc SP 114 2018 PDFDokumen144 halamanIrc SP 114 2018 PDFAnil SuryawanshiBelum ada peringkat

- SE Calculations ExcleDokumen4 halamanSE Calculations ExcleAnil SuryawanshiBelum ada peringkat

- Irc - Gov.in.080.1981pickup Bus StopsDokumen14 halamanIrc - Gov.in.080.1981pickup Bus StopsAnonymous ESjaOhiBelum ada peringkat

- IRC Highway Research Journal January-June 2018 PDFDokumen60 halamanIRC Highway Research Journal January-June 2018 PDFAnil SuryawanshiBelum ada peringkat

- Drain Design Analysis and Reinforcement DetailsDokumen68 halamanDrain Design Analysis and Reinforcement DetailsAnil SuryawanshiBelum ada peringkat

- Maintanance Circular of NHAI - FA 1Dokumen1 halamanMaintanance Circular of NHAI - FA 1Anil SuryawanshiBelum ada peringkat

- 09 Stabilization of Slope PDFDokumen43 halaman09 Stabilization of Slope PDFAnil SuryawanshiBelum ada peringkat

- Indian Highways Vol.47 6 June 19Dokumen68 halamanIndian Highways Vol.47 6 June 19harnishtanna212Belum ada peringkat

- Compiled Office Manual-IIIDokumen157 halamanCompiled Office Manual-IIIShazaman SaiyedBelum ada peringkat

- Procedure of Inserting RH Girder Method in RUB PDFDokumen4 halamanProcedure of Inserting RH Girder Method in RUB PDFAnil SuryawanshiBelum ada peringkat

- Cost Reduce in Construction by Using Cut & Cover Method in Sub-WayDokumen7 halamanCost Reduce in Construction by Using Cut & Cover Method in Sub-WayAnil SuryawanshiBelum ada peringkat

- Reclamation of Recycled Aggregate Base (RAB) Material: Standard Practice ForDokumen5 halamanReclamation of Recycled Aggregate Base (RAB) Material: Standard Practice ForRed RedBelum ada peringkat

- Methodology For Storm WaterDokumen25 halamanMethodology For Storm WaterTheodore Teddy KahiBelum ada peringkat

- Tranportation All ExperimentDokumen55 halamanTranportation All ExperimentMaiwand KhanBelum ada peringkat

- White Topping Solution for Pavement RehabilitationDokumen23 halamanWhite Topping Solution for Pavement RehabilitationLohith Kumar HPBelum ada peringkat

- Layers of Flexible PavementDokumen52 halamanLayers of Flexible Pavementsavan chavanBelum ada peringkat

- Walk-Behind Roller: A 2-In-1 MachineDokumen2 halamanWalk-Behind Roller: A 2-In-1 MachineAndré LinharesBelum ada peringkat

- AASHTO M 320 Asphalt PGDokumen7 halamanAASHTO M 320 Asphalt PGDavid MazdaBelum ada peringkat

- Rheological Properties of The Polymer Modified Bitumen With Emphasis On SBS Polymer and Its MicrostructureDokumen8 halamanRheological Properties of The Polymer Modified Bitumen With Emphasis On SBS Polymer and Its MicrostructureMEHDI FARROKHIBelum ada peringkat

- DBM Mix DesignDokumen22 halamanDBM Mix DesignImran Khan56% (9)

- Me Exam NotesDokumen22 halamanMe Exam NotesMae Ann GonzalesBelum ada peringkat

- BS 3533 PDFDokumen22 halamanBS 3533 PDFKarunakaran Nallasingam100% (2)

- Revised Schedule of Fees and Charges for Laboratory Testing of Construction MaterialsDokumen18 halamanRevised Schedule of Fees and Charges for Laboratory Testing of Construction MaterialsMt. Apo TravelsBelum ada peringkat

- Pavement Design Manual Jan 09Dokumen72 halamanPavement Design Manual Jan 09Dr. Ir. R. Didin Kusdian, MT.100% (2)

- Factory Address: Luohuang Industrial Park, Jiangjin Dist., Chongqing, China E-Mail: TelDokumen23 halamanFactory Address: Luohuang Industrial Park, Jiangjin Dist., Chongqing, China E-Mail: Telmarouane benbelaidBelum ada peringkat

- HINCOL Bitumen Primer-2 (Web)Dokumen2 halamanHINCOL Bitumen Primer-2 (Web)Tk SubhashBelum ada peringkat

- Alumanation 301 Za PDFDokumen2 halamanAlumanation 301 Za PDFAntonio MarrufoBelum ada peringkat

- Experimental Study on Using Chrome Shavings in MicrosurfacingDokumen5 halamanExperimental Study on Using Chrome Shavings in MicrosurfacingDwijendra ChanumoluBelum ada peringkat

- Sampling Bituminous Paving Mixtures: Standard Practice ForDokumen4 halamanSampling Bituminous Paving Mixtures: Standard Practice ForShaker Qaidi100% (1)

- Building SSR 2009 10Dokumen477 halamanBuilding SSR 2009 10Raja ShekharBelum ada peringkat

- Viscosity Penetration Test ReportDokumen7 halamanViscosity Penetration Test ReportMoganraj100% (3)

- Mash East MaronderaDokumen22 halamanMash East Maronderatapiwanaishe maunduBelum ada peringkat

- DPWH Standard Specification On Aggregate Sub Base CourseDokumen4 halamanDPWH Standard Specification On Aggregate Sub Base CourseLance LanceBelum ada peringkat

- Bs EN-12697-8 PDFDokumen12 halamanBs EN-12697-8 PDFMorched TounsiBelum ada peringkat

- Bituminous Geomembrane: Waterproofing and Civil EngineeringDokumen6 halamanBituminous Geomembrane: Waterproofing and Civil EngineeringEba SitorusBelum ada peringkat

- Implement Indian Roads Congress IRC:116-2014 To Solve Pothole Problem Across IndiaDokumen20 halamanImplement Indian Roads Congress IRC:116-2014 To Solve Pothole Problem Across IndiaProf. Prithvi Singh Kandhal100% (2)

- Bituminized Expansion Joint Filler BoardsDokumen2 halamanBituminized Expansion Joint Filler BoardsalokaBelum ada peringkat

- Soil Mechanics in Pavement EngineeringDokumen44 halamanSoil Mechanics in Pavement EngineeringalexgomezsBelum ada peringkat

- Method Statement - Asphaltic Concrete Works: April 2018Dokumen11 halamanMethod Statement - Asphaltic Concrete Works: April 2018Shahab Bashir KhanBelum ada peringkat

- Emerald BOQ Abstract RoadsDokumen8 halamanEmerald BOQ Abstract RoadsyogeshBelum ada peringkat

- Modified Asphalt Binders: Need of Present PavementsDokumen85 halamanModified Asphalt Binders: Need of Present PavementsPalika ChopraBelum ada peringkat

- Crossings: How Road Ecology Is Shaping the Future of Our PlanetDari EverandCrossings: How Road Ecology Is Shaping the Future of Our PlanetPenilaian: 4.5 dari 5 bintang4.5/5 (10)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationDari EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationPenilaian: 4 dari 5 bintang4/5 (18)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansDari EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansBelum ada peringkat

- To Engineer Is Human: The Role of Failure in Successful DesignDari EverandTo Engineer Is Human: The Role of Failure in Successful DesignPenilaian: 4 dari 5 bintang4/5 (137)

- Matrix Methods of Structural AnalysisDari EverandMatrix Methods of Structural AnalysisPenilaian: 4.5 dari 5 bintang4.5/5 (8)

- The Great Bridge: The Epic Story of the Building of the Brooklyn BridgeDari EverandThe Great Bridge: The Epic Story of the Building of the Brooklyn BridgePenilaian: 4.5 dari 5 bintang4.5/5 (59)

- Summary of Neil Postman's Amusing Ourselves to DeathDari EverandSummary of Neil Postman's Amusing Ourselves to DeathPenilaian: 4 dari 5 bintang4/5 (2)

- Cable Supported Bridges: Concept and DesignDari EverandCable Supported Bridges: Concept and DesignPenilaian: 5 dari 5 bintang5/5 (1)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansDari EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansPenilaian: 4.5 dari 5 bintang4.5/5 (21)

- Methodology for Estimating Carbon Footprint of Road Projects: Case Study: IndiaDari EverandMethodology for Estimating Carbon Footprint of Road Projects: Case Study: IndiaBelum ada peringkat

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Shallow Foundations: Discussions and Problem SolvingDari EverandShallow Foundations: Discussions and Problem SolvingPenilaian: 5 dari 5 bintang5/5 (1)

- Transportation Engineering: Theory, Practice, and ModelingDari EverandTransportation Engineering: Theory, Practice, and ModelingBelum ada peringkat

- Principles of Forensic Engineering Applied to Industrial AccidentsDari EverandPrinciples of Forensic Engineering Applied to Industrial AccidentsBelum ada peringkat

- Introducing Structures: A Textbook for Students of Civil and Structural Engineering, Building and ArchitectureDari EverandIntroducing Structures: A Textbook for Students of Civil and Structural Engineering, Building and ArchitecturePenilaian: 4.5 dari 5 bintang4.5/5 (11)

- Climate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingDari EverandClimate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingBelum ada peringkat

- Professional Surveyors and Real Property Descriptions: Composition, Construction, and ComprehensionDari EverandProfessional Surveyors and Real Property Descriptions: Composition, Construction, and ComprehensionBelum ada peringkat

- Ground Improvement Case Histories: Embankments with Special Reference to Consolidation and Other Physical MethodsDari EverandGround Improvement Case Histories: Embankments with Special Reference to Consolidation and Other Physical MethodsBelum ada peringkat