0030 Program Codes PDF

Diunggah oleh

Corel MachineryJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

0030 Program Codes PDF

Diunggah oleh

Corel MachineryHak Cipta:

Format Tersedia

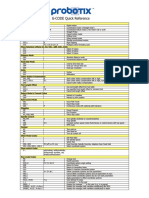

G0 Rapid Travel G53 Use Machine Coordinate System

G1 Linear Interpolation G54-59 Fixture Offsets 1-6

G2 Circular Interpolation (Clockwise) G66 Modal Subroutine Call

G3 Circular Interpolation (Counter Clockwise) G67 Modal Subroutine Cancel

G4 Dwell P= Time in Milliseconds G68 Rotation (R0= Angle, XY= Center of Rotation)

Also: Non Modal In-position Check G69 Rotation Cancel

G5 Non Modal Rapid Travel G70 Check for Inch Parameter

G8 Accelerate (No Feed Ramps) G71 Check for Metric Parameter

G9 Decelerate (Feed Ramps) G73 Peck Drill

Also: In Position Check Q= Peck Size

G10 Programmable Data Input P= Feed Distance before next Peck (optional)

L02= Fixture X, Y, Z, A, B, P= 0, 1-48 I= Initial Peck

L10= Length, P= 1-99, R0= Amount J= Reducing Value for Subsequent Pecks

L12= Diameter, P= 1-99, R0= Amount K= Minimum Peck Size

L13= Read Fixture, P= 1-24, R0= Z, R1= X, R2= Y G74 Left Hand Tap

L14= Read Length, P= 1-99, R0= Amount Format 1 Q= Thread Lead (1/pitch), F= RPM

Program Code Quick Reference

L15= Read Diameter, P= 1-99, R0= Amount Format 2 S= RPM, F= Feed (Lead * RPM)

L100 to L109= R Values, P= Amount G74.1 Left Hand Rigid Tap

G15 YZ Circular Interpolation with the A Axis Format 1 Q= Thread Lead (1/pitch), F= RPM

G17 XY Plane Selection Format 2 S= RPM, F= Feed (Lead * RPM)

Also: Y Axis Cam Wrapping G74.2 Prepare for G74.1

Q= A Axis Ratio/ [5p (cam dia. in inches)] G75 Tapping Head Cycle

Q= A Axis Ratio/ [(5/25.4p (cam dia. in mm)] Format 1 Q= Thread Lead (1/pitch), F= RPM

P0= A Axis, P1= B Axis Format 2 S= RPM, F= Feed (Lead * RPM)

Fadal

G17.1 A/B Word Swap On G76 Fine Boring

G17.2 A/B Word Swap Off Q= Amount of Y+ Shift or

G18 ZX Plane I= Amount & Direction of X Shift

G19 YZ Plane J= Amount & Direction of Y Shift

G20 Check for Inch Parameter Setting G80 Fixed Cycle Cancel

G Codes

G21 Check for Metric Parameter Setting G81 Drill, Spot Drill

G28 Return to Zero G82 Center Drill, Counterbore

G28.1 Return from Jog Away P= Dwell Time in Milliseconds

G29 Return from Zero 180,000/RPM= Dwell time for 3 revolutions

G31 Probe Touch Function G83 Deep Hole Cycle

G31.1 Probe No Touch Function Q= Peck Size

Fadal Machining Centers

G40

G41

Cutter Radius Compensation Cancel

Cutter Radius Compensation Left (climb)

P= Feed Distance before next Peck (optional)

I= Initial Peck

G42 Cutter Radius Compensation Right (conve.) J= Reducing Value for Subsequent Pecks

G43 Tool Length Compensation Positive K= Minimum peck Size

G44 Tool Length Compensation Negative G84 Right Hand Tap

G45 Tool Length Offset Single Expansion Format 1 Q= Thread Lead (1/pitch), F= RPM

G46 Tool Length Offset Single Reduction Format 2 S= RPM, F= Feed (Lead * RPM)

G47 Tool Length Offset Double Expansion G84.1 Right Hand Rigid Tap

G48 Tool Length Offset Double Reduction Format 1 Q= Thread Lead (1/pitch), F= RPM

G49 Tool Length Offset Cancel Format 2 S= RPM, F= Feed (Lead * RPM)

G50 Ramp Slope Control Cancel G84.2 Prepare for G84.1

G50.1 Mirror Image Cancel G85 Bore In / Out

G51 Ramp Slope Control G86 Bore In / Spindle Off / Rapid Out

R0= Ramp Speed Value of .5 - 2. G87 Bore In / Out

R0+= Z Axis, R0-= XY Axis G88 Bore In / Dwell / Out, P= Milliseconds

G51.1 Mirror Image G89 Bore In / Dwell / Out, P= Milliseconds

G51.2 Tool Load Compensation G90 Absolute Positioning

State Feed Rate Before the G51.2 Line G91 Incremental Positioning

R1= Target Spindle Load G91.1 High Speed Execution (-2 System Only)

R2= Min. Percentage Feed Rate Reduction G91.2 High Speed Execution Cancel

R3= Max. Percentage Feed Rate Increase Also: Binary Compress / Analyzer End Point

R4= Time at Min. Feed Rate to Initiate Slide Hold G91.3 Binary Compress / Analyzer Start Point

G51.3 Axis Scaling G92 Absolute Preset

R1= Program (All three axes) G93 1/T Feed Rate Specification (Inverse Time)

R2= X G94 Feed Rate Specification DPM, IPM

R3= Y G98 Return to Initial Plane

R4= Z G99 Return to R0 Clearance Plane

G52 Coordinate System Shift

Fixed Subroutines

L9101 Probe Functions

R1+1-10, See User’s Manual for details

L9201 Engraving:

R1+0= Standard font

R1+1= Stencil font

R1+2= Serialized standard

R1+3= Serialized stencil

R2+= Height of letters

R3+= Angle of word

R4+= Serial increment

R0= Clearance plane Z= Final depth F= Feed rate

L93NN Bolt Circle

R0= 1 (incremental X distance and direction from 1st position to center)

R1= J (incremental Y distance and direction from 1st position to center)

R2= Angular step between holes (+ angles for CCW, - angles for CW)

NN= Amount of holes

L94NN Mill Boring cycle CCW:

R0+= Feed, R1+= Diameter of hole, NN= Repetitions

L95NN Mill Boring cycle CW:

Program Code Quick Reference

R0+= Feed, R1+= Diameter of hole, NN= Repetitions

L9601 Rectangular pocket CCW:

R0+= Feed, R1+= Corner radius on tool, R2+= X, R3+= Y

L9701 Rectangular pocket CW:

R0+= Feed, R1+= Corner radius on tool, R2+= X, R3+= Y

L9801 Circular pocket CCW:

R0+= Feed, R1+= Corner radius on tool, R2+= Diameter of hole

L9901 Circular pocket CW:

R0+= Feed, R1+= Corner radius on tool, R2+= Diameter of hole

Note: Input the tool diameter in the tool table before using fixed subroutines, and use the D word in Format 2.

Fadal

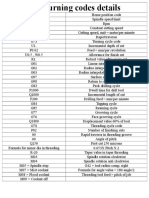

M Codes

M0 Program Stop M48.2 Dual Rotary Pot Active Pallet A

M1 Optional Stop M48.3 Dual Rotary Pot Active Pallet B

M2 End of Program M49 Feed Rate and RPM Pot Inactive

M3 Spindle On Clockwise M49.1 Servo Coolant Pot Inactive

M3.1 Sub–Spindle On Ignore Magnet CW M49.2 Dual Rotary Pot Inactive Pallet A

M3.2 Acknowledge Spindle Magnet M49.3 Dual Rotary Pot Inactive Pallet B

M4 Spindle On Counter Clockwise User Attached Devices

M60-69

M4.1 Sub–Spindle On Ignore Magnet CCW M60 A Axis Brake On M65 TS-20 Probe Active

M4.2 Acknowledge Spindle Magnet M61 A Axis Brake Off M66 MP-12 Probe Active

M5 Spindle Off M62 B Axis Brake On M67 Laser Probe Active

Tool Change M63 B Axis Brake Off M68 Delta Motor

M6

M7.1

M8 Fadal Machining Centers

Servo Coolant On

Coolant On

Servo Coolant On

M80

M64 MP Probe Active

Automatic Doors Open

M69 Wye Motor

M8.1 M81 Automatic Doors Close

M9 Coolant Off Default Gain (from SV Command)

M90

M10 Cancel Reciprocation Advanced Feed Forward Gain Enable P=Gain (50-250)

M90.1

M11 X Axis Reciprocation Normal Gain

M91

M12 Y Axis Reciprocation Intermediate Gain

M92

M13 Z Axis Reciprocation Feed Forward

M94

M14 B Axis Reciprocation P= Angle Tolerance

M15 A Axis Reciprocation Q= Line Length (Moves less than this not checked)

M16 C Axis Reciprocation Example: M94 P91 Q.002

M17 End of Subroutine

Cycle Cushman Indexer

M94.1 Feed Forward by Feed Rate Modification

M18 State Feed Rate Before M94.1 Line

M19 Spindle Stop/Orient

P= Angle

M20 Cycle General Purpose Indexer Q= Percentage change each modification

Also: Automatic Doors Close R0+= Min. Feed Rate Modification

Also: Toggle On/Off Hydrosweep R1+= Length to ignore M94.1

M30 End of all Subroutines R2+= Modify feed every, this angle, from P

Also: End of Program (Format 2) Example: M94.1 P170 Q10. R0+50. R1+1. R2+15.

M31 Exchange Pallets M94.2 Advanced Feed Forward On,

M32 Store/Load Pallet A P= Ramp, Q= Detail Window

M32.1 Load and Verify Pallet A M95 Feed Forward Cancel

M33 Store/Load Pallet B M95.1 Feed Forward Modify Cancel

M33.1 Load and Verify Pallet B M95.2 Advanced Feed Forward Cancel

M41 Low Range RPM M96 Roll CRC

M42 High Range RPM M97 Intersectional CRC

M98 Execute Sub Program

M45 Execute Fixed Cycle

P= Program #

M46 Positive Approach On

L= # of Repetitions

M47 Cancel Positive Approach

M99 End of Sub Program

M48 Feed Rate and RPM Pot Active

Also: Line Jump, P= Line #, Example: M99 P#

M48.1 Servo Coolant Pot Active

3/00

Anda mungkin juga menyukai

- THAI NGUYEN UNIVERSITY OF TECHNOLOGYeeeeDokumen14 halamanTHAI NGUYEN UNIVERSITY OF TECHNOLOGYeeeeTrung HoàngBelum ada peringkat

- G Codes and M Codes ListDokumen3 halamanG Codes and M Codes ListWilliam Avila AguilarBelum ada peringkat

- G CodeDokumen10 halamanG CodeJuan Carlos BurgosBelum ada peringkat

- Cnclab S2Dokumen4 halamanCnclab S2noreen tonogBelum ada peringkat

- G-CODE Quick Reference ChartDokumen1 halamanG-CODE Quick Reference ChartKrocodileBelum ada peringkat

- CNC programming basicsDokumen24 halamanCNC programming basicsprinilBelum ada peringkat

- Code Description Milling Turning (M) (T) G00 Rapid Positioning M TDokumen12 halamanCode Description Milling Turning (M) (T) G00 Rapid Positioning M TjokoBelum ada peringkat

- CNC G-Code and M-Code Reference List For CNC MillsDokumen5 halamanCNC G-Code and M-Code Reference List For CNC Millssangu1434Belum ada peringkat

- List of GCODES AND MCODESDokumen3 halamanList of GCODES AND MCODESNoceja, Mark Allen L.Belum ada peringkat

- Fanuc G-Code List - Helman CNCDokumen2 halamanFanuc G-Code List - Helman CNCkais kaskar100% (3)

- G Code List OkumaDokumen10 halamanG Code List OkumaPham Long50% (2)

- Table 3 G Code List (1/2) G Code Group FunctionDokumen2 halamanTable 3 G Code List (1/2) G Code Group FunctionGuillermo Romo ChavezBelum ada peringkat

- 00 A CNC Lab Manual NIT APDokumen4 halaman00 A CNC Lab Manual NIT APDevesh RehanBelum ada peringkat

- Fanuc Series 0i-Model D - 0i Mate-Model D Operator's Manual (For Machining Center System)Dokumen2 halamanFanuc Series 0i-Model D - 0i Mate-Model D Operator's Manual (For Machining Center System)Mrunal Salve100% (2)

- Cam-Lab: Assignment-1Dokumen8 halamanCam-Lab: Assignment-1Rohit KumarBelum ada peringkat

- Canned cycle grinding program formatDokumen65 halamanCanned cycle grinding program formatMetalurgica VISILUBelum ada peringkat

- G & M-Code Cheat SheetDokumen3 halamanG & M-Code Cheat SheetORGONERBelum ada peringkat

- FANUC G Code of LatheDokumen2 halamanFANUC G Code of Latheteam1 M y B100% (1)

- G Code Table Explained: List and FunctionsDokumen86 halamanG Code Table Explained: List and FunctionsEmanuelBelum ada peringkat

- G CodeDokumen1 halamanG CodeALEX ALEJANDRO ANDRANGO PAILLACHOBelum ada peringkat

- G Code ListDokumen3 halamanG Code ListRautoiu AndreiBelum ada peringkat

- CNC Milling: Programming for Milling OperationsDokumen90 halamanCNC Milling: Programming for Milling OperationsJanric AltuveBelum ada peringkat

- G CodeDokumen15 halamanG CodeBaljeet SinghBelum ada peringkat

- FANUC 0M-A Interpolation and Canned CyclesDokumen3 halamanFANUC 0M-A Interpolation and Canned CyclesSanchai ProgaeewBelum ada peringkat

- Sect 1 SummaryDokumen20 halamanSect 1 SummarymarchmtetBelum ada peringkat

- Fanuc CodeDokumen11 halamanFanuc CoderlwersalBelum ada peringkat

- G&M Codes For NC ProgrmDokumen2 halamanG&M Codes For NC ProgrmMohit SinghalBelum ada peringkat

- G Codes: 3.1. Rapid Velocity RateDokumen52 halamanG Codes: 3.1. Rapid Velocity RatedunhaBelum ada peringkat

- Milltronics G Code List For Machining CentersDokumen3 halamanMilltronics G Code List For Machining CentersRandyBelum ada peringkat

- (SN) G-C Codes PDFDokumen24 halaman(SN) G-C Codes PDFSebastianAndrade13Belum ada peringkat

- G and M Codes - Turning and MillingDokumen4 halamanG and M Codes - Turning and MillingmettayugeshreddyBelum ada peringkat

- M&G CodesDokumen11 halamanM&G CodesÇağdaş Akalınlı100% (1)

- CNC Programming G CodeDokumen1 halamanCNC Programming G CodeMohd Ali AbimansorBelum ada peringkat

- G Code:-: CNC Lathe G & M CodesDokumen3 halamanG Code:-: CNC Lathe G & M CodesCIPETBelum ada peringkat

- G Codes CommandsDokumen45 halamanG Codes CommandsordamBelum ada peringkat

- Fadal - Podręcznik UżytkownikaDokumen579 halamanFadal - Podręcznik UżytkownikaMaciek KBelum ada peringkat

- Feeds and Speeds Calculator: G-Code and M-Code Reference for MillingDokumen6 halamanFeeds and Speeds Calculator: G-Code and M-Code Reference for MillingShakirJaafarBelum ada peringkat

- CAD/CAM Lab G and M CodesDokumen2 halamanCAD/CAM Lab G and M Codes55511223344Belum ada peringkat

- 2-C101-G-codes-M-codesDokumen5 halaman2-C101-G-codes-M-codesRomizBelum ada peringkat

- Gcode & M CodeDokumen5 halamanGcode & M Codejayanth.raoBelum ada peringkat

- G-Codes and M-Functions - MillingDokumen1 halamanG-Codes and M-Functions - MillingBilal IbrahimBelum ada peringkat

- RichAuto Systems Supported G CodesDokumen2 halamanRichAuto Systems Supported G CodessunethpfBelum ada peringkat

- Machine Tool Pocket Guide 190215 PDFDokumen50 halamanMachine Tool Pocket Guide 190215 PDFHarish ChandrashekarBelum ada peringkat

- G Codes GSK983MDokumen2 halamanG Codes GSK983MYuazaBelum ada peringkat

- FANUC G Code of LatheDokumen25 halamanFANUC G Code of LatheHùng LêBelum ada peringkat

- G CodesDokumen1 halamanG CodesEr Vinay SinghBelum ada peringkat

- Master List of CNC G and M CodesDokumen2 halamanMaster List of CNC G and M CodesChong Yee HowBelum ada peringkat

- Buku Manual Pemrograman TurningDokumen50 halamanBuku Manual Pemrograman TurningDwi Ratna KurniawatiBelum ada peringkat

- Coding G PartDokumen2 halamanCoding G PartGertschBelum ada peringkat

- Preparatory Functions (G-Codes) SummaryDokumen24 halamanPreparatory Functions (G-Codes) Summaryhasan alsarrafBelum ada peringkat

- G-codes for milling machine operationsDokumen1 halamanG-codes for milling machine operationsmaximinogz1Belum ada peringkat

- G-Codes (Preparatory Functions/codes) Code Function Code FunctionDokumen1 halamanG-Codes (Preparatory Functions/codes) Code Function Code FunctionRushi vedeBelum ada peringkat

- Survey CNC G-Code CommandsDokumen1 halamanSurvey CNC G-Code CommandsvictorBelum ada peringkat

- Code Meaning Letter MeaningDokumen1 halamanCode Meaning Letter MeaningJagadeesh KundrapuBelum ada peringkat

- M700-70 Series Programming Manual M-Type-IB1500072-F (196-289) (44-69) (23-26)Dokumen4 halamanM700-70 Series Programming Manual M-Type-IB1500072-F (196-289) (44-69) (23-26)David Perez LajasBelum ada peringkat

- G CODE CHART FOR LATHESDokumen2 halamanG CODE CHART FOR LATHESAleksander VargaBelum ada peringkat

- CNC Turning CodesDokumen1 halamanCNC Turning CodesGurupreet SinghBelum ada peringkat

- PCMCIA SRAM Card DatasheetDokumen33 halamanPCMCIA SRAM Card DatasheetCorel MachineryBelum ada peringkat

- (9145)Dokumen233 halaman(9145)Guillermo RamirezBelum ada peringkat

- Instruction Manual: 9.ECO.01.ANGDokumen67 halamanInstruction Manual: 9.ECO.01.ANGCorel MachineryBelum ada peringkat

- Error Code Reference GuideDokumen2 halamanError Code Reference GuideCorel MachineryBelum ada peringkat

- Rockwell Catalog1973 74Dokumen18 halamanRockwell Catalog1973 74Roland ErdőhegyiBelum ada peringkat

- Toolpost Attachment For A High Speed Rotary ToolDokumen32 halamanToolpost Attachment For A High Speed Rotary Toolkokisko100% (1)

- Amem201 Lecture1Dokumen11 halamanAmem201 Lecture1Jorge MndzBelum ada peringkat

- Machining Center Master Catalog 7060 A96-181Dokumen977 halamanMachining Center Master Catalog 7060 A96-181Araviinda YereseemeBelum ada peringkat

- Unleash Your Speed: Thinking Forward. Challenging LimitsDokumen3 halamanUnleash Your Speed: Thinking Forward. Challenging Limitsanon_19722876Belum ada peringkat

- PUMA Air Compressor Tools CatalogueDokumen40 halamanPUMA Air Compressor Tools CatalogueGabriel BatistaBelum ada peringkat

- Leading Rock Drilling Tools & Accessories SupplierDokumen13 halamanLeading Rock Drilling Tools & Accessories SupplierGmedrillsBelum ada peringkat

- Oilfield PDC Drill Bits Atlas CopcoDokumen8 halamanOilfield PDC Drill Bits Atlas CopcoElgi Alam PangestuBelum ada peringkat

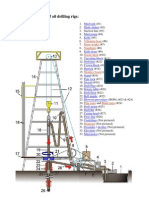

- Oil Rig Components ExplainedDokumen7 halamanOil Rig Components ExplainedJennifer Màrtin100% (5)

- Sonatrach Drilling EquipmentsDokumen82 halamanSonatrach Drilling EquipmentsUsama Bin SabirBelum ada peringkat

- BR3 001 - Rex 2000,3000,5000,9000 Series Roller BearDokumen5 halamanBR3 001 - Rex 2000,3000,5000,9000 Series Roller BearRodrigo Jechéla BarriosBelum ada peringkat

- Maersk Convincer PDFDokumen8 halamanMaersk Convincer PDFAarón CespedesBelum ada peringkat

- Machine Stops-Trips and Locking Devices 1913 PDFDokumen52 halamanMachine Stops-Trips and Locking Devices 1913 PDFjohn silverBelum ada peringkat

- Equipment Inspection ChecklistDokumen13 halamanEquipment Inspection ChecklistFebrian TamaraBelum ada peringkat

- Varco BJ Catalog - Rotary & Hoisting Tools - Parts & AssembliesDokumen109 halamanVarco BJ Catalog - Rotary & Hoisting Tools - Parts & AssembliesSetyohdWBelum ada peringkat

- Knuth Part 1Dokumen100 halamanKnuth Part 1Mesias GuamantarioBelum ada peringkat

- Workshop Practice Skills: Fitting, Forging, Carpentry & Sheet MetalDokumen59 halamanWorkshop Practice Skills: Fitting, Forging, Carpentry & Sheet MetalKalyana Chakravarthy89% (18)

- Tools Checklist For WorkshopDokumen44 halamanTools Checklist For Workshopdehane abdelazizBelum ada peringkat

- 3D Printed Gun InstructionsDokumen5 halaman3D Printed Gun InstructionsWilla Frej100% (1)

- Econ 6Dokumen7 halamanEcon 6ceejay RedondiezBelum ada peringkat

- Find the Right Neobiotech Drill Kit Online in 40 CharactersDokumen16 halamanFind the Right Neobiotech Drill Kit Online in 40 CharacterssalehalsadiBelum ada peringkat

- Risk Assessment - Installation and Testing of Motorized Fire & Smoke DamperDokumen10 halamanRisk Assessment - Installation and Testing of Motorized Fire & Smoke Dampernsadnan50% (2)

- Challenges FOR Implementing Advanced Blasting Technology in IndiaDokumen10 halamanChallenges FOR Implementing Advanced Blasting Technology in IndiaJoseMarianoTomayTeranBelum ada peringkat

- Topp k200 Manual EngDokumen56 halamanTopp k200 Manual EngOscar GarciaBelum ada peringkat

- Tool Selector 2021Dokumen48 halamanTool Selector 2021tuancapecc3Belum ada peringkat

- Electrical Power ToolsDokumen32 halamanElectrical Power ToolsMa Cecelia Borja100% (1)

- Drilling Boring Reaming and TappingDokumen24 halamanDrilling Boring Reaming and TappingPuneeth KumarBelum ada peringkat

- Icreate Soft Tech: CONTACT: 04142242872,8012352681Dokumen16 halamanIcreate Soft Tech: CONTACT: 04142242872,8012352681Anonymous MCGeold0e0Belum ada peringkat

- 116.atlas Copco Roc d7 - HandbookDokumen8 halaman116.atlas Copco Roc d7 - Handbookadamajaks198575% (4)

- T450 Hurricane Shutter DesignDokumen0 halamanT450 Hurricane Shutter DesignlesgiuBelum ada peringkat