MasterSeries 860 Specification Sheet

Diunggah oleh

FEBCODeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

MasterSeries 860 Specification Sheet

Diunggah oleh

FEBCOHak Cipta:

Format Tersedia

ES-F-860L

S P E C I F I C AT I O N S H E E T

MasterSeries 860

Size: 212" - 10" (65mm - 250mm)

Reduced Pressure Zone Assemblies

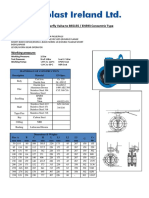

The FEBCO Master Series 860 Reduced Pressure Zone Assemblies are designed for health hazard applications. End connections Flanged ANSI B16.1 Class 125

Pressure Temperature

Max. Working Pressure: Hydrostatic Test Press: Temperature Range: 175psi (12.1 bar) 350psi (24.1 bar) 32F to 140F (0C to 60C) MODEL 860 REDUCED PRESSURE ASSEMBLY

Materials

Main Valve Body: Ductile iron Grade 65-45-12 Coating: Fusion epoxy coated internal and external AWWA C550 Shutoff Valves: NRS and OS&Y resilient wedge gate valves AWWA C509 Trim: Bronze Elastomer Discs: Clamp: EPDM AWWA C606 (10" only, 250mm) Spring: Stainless steel

Capacity

kPa psi 138 20 Headloss 103 15 69 10

212" & 3" (65mm & 80mm)

212"

3"

Approvals Standards

ANSI/AWWA (C511) - 212" - 10" Approved by the Foundation for Cross-connection Control and Hydraulic Research at the University of Southern California. - 212" - 8" (65 - 200mm)

34 5 0 80 160 240 320 400 gpm 0 304 606 910 1211 1520 lpm

kPa psi 138 20 Headloss 103 15 69 10

4" & 6" (100mm & 150mm)

1013 B64.4 212" - 10" 212" - 8" 65 - 250mm 65 - 200mm

212" - 8" 65 - 200mm

212" - 8" 65 - 200mm

Typical Installation

Model 860 / Typical Installation

34 5 0 400 800 1200 1600 2000 gpm 0 1520 3040 4540 6060 7600 lpm

kPa psi 138 20 Headloss 103 15 69 10

8" & 10" (200mm & 250mm)

34 5 0 1000 2000 3000 4000 5000 gpm 0 3800 7600 11400 15140 19000 lpm

Job Name Contractor Job Location Approval Engineer Contractors P .O. No.

Approval Representative

FEBCO product specifications in U.S. customary units and metric are approximate and are provided for reference only. For precise measurements, please contact FEBCO. FEBCO reserves the right to change or modify product design, construction, specifications, or materials without prior notice and without incurring any obligation to make such changes and modifications on FEBCO products previously or subsequently sold.

Series 860 / Materials of Construction

ITEM Description 1 Body 1.1 Pipe Plug 1.2 Bushing (21/2"-4" Only) 2 Cover 2.1 O-Ring 2.2 Cap Screw 2.3 Hex Nut 3 Seat Ring 3.1 Gasket 3.2 Socket Head Screw 3.3 Washer 3.4 Elastic Stop Nut 4 Arm 4.1 Bushing-Swing Pin 4.2 Swing Pin 5 Retaining Clip 5.1 Retaining Clip 6 Check Disk 7 Load Pin 8 Lwr Spring Retnr 9 Spring Stem 9.1 Elastic Stop Jam Nut 10 Spring 10.1 Spring 2nd Check 10.2 Spring Shim 2nd Check 11 Spring Guide 12 Upr Spring Retnr 12.1 Bushing-Spr. Stem 13 Pivot Bearing 14 Flange Gasket 15 Bearing Socket 16 Hex Jam Nut 17 Washer 18 Flange Nut 18.1 Flange Nut 20 R.V. Cover 20.1 Bleed Screw 20.2 Gasket 21 R.V. Body 22 Cover Bolt 23 Elbow 24 RV Mtg Bolt 24.1 Washer 25 RV Mtg Nut 26 Gasket 27 Lrg. Diaphragm 28 Button 28.1 Flow Washer 29 RV Spring 30 RV Stem 31 Main Guide 31.1 Main Guide O-Ring 32 Seat Disc 33 Lower Guide 34 Seat Ring 34.1 O-ring 35.1 O-Ring 35.2 Extension 37 Sm. Diaphragm 38 Retainer 38.1 Slip Ring 39 Flow Washer 40 Ball Valve 41 Nipple 41.1 Nipple 41.2 Nipple 42 Gate Valve (NRS) 60 Identification Plate 62 Drive Screw 70 Clamp Material A536 GR 65-45-12 Galv. Stl. Brass A536 GR 65-45-12 EPDM ASTM D2000 Plated Steel Plated Steel B584 Alloy C83600 EPDM ASTM D2000 18-8-SS 304 SS 18-8-SS B584 Alloy C83600 Acetal Resin 304 SS 302 SS 302 SS EPDM Coated GR, 45 Ductile Iron with A276 type 304SS stem B150 Alloy C61300 B584 Alloy C83600 304 SS 18-8 SS A313 Type 631 SS A313 Type 631 SS Acetal Resin B130 Alloy C22000 B584 Alloy C83600 Acetal Resin B585 Alloy C83600 Rubber/Fabric Acetal Resin 18-8 SS 302 SS Plated Steel Plated Steel B584 Alloy C83600 18-8 SS HDPE B584 Alloy C83600 18-8 SS A536 GR 65-45-12 Plated Steel Plated Steel Plated Steel EPDM Nitrile ASTM D2000 A240 304 SS Acetal Resin A313 Type 302 SS Acetal Resin B584 Alloy C83600 FDA EPDM EPDM AST D2000 Acetal Resin B584 Alloy C83600 FDA EPDM EPDM ASTM D2000 Acetal Resin Nitrile ASTM D2000 B584 Alloy C83600 Acetal Resin Acetal Resin B584 Alloy C84400 Brass Brass Brass AWWA C509 B36 Alloy C26000 Stainless Steel AWWA C606 (10" Only)

C D

B A

Top View

G H

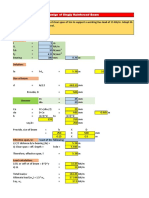

Dimensions Weight

Size: 212" - 10" (65 - 80mm)

size (DN)

A in. mm in. mm in. B mm C

Dimensions

D E F mm in. G mm in. H in. mm in. mm in. mm in.

Weight

NRS OS&Y mm lbs. kgs. lbs. kgs.

212 3 4 6 8 10

65 80 100 150 200 250

4034 4178 4614 56 65 7258

1035 1064 1175 1422 1651 1845

2512 2558 28 3434 4134 4638

648 651 711 883 1061 1178

1258 1278 1438 1878 2312 2712

321 327 365 479 570 699

10 10 1018 1234 1558 1558

254 254 257 324 397 397

1278 13 1518 2034 2678 2814

327 330 384 527 683 718

10 10 1018 1118 1214 1238

254 254 257 283 311 314

412 412 512 612 7 9

114 114 140 165 178 229

718 738 818 978 1118 1238

181 187 206 251 283 314

219 231 317 481 734 946

99 105 144 218 333 429

223 101.2 233 105.7 334 151.5 516 234.1 796 361.1 1008 457.2

Note: Dimensions shown are nominal. Allowances must be made for normal manufacturing tolerances.

Note: The gap drain is not designed to catch the maximum discharge possible from the relief valve. The installation of FEBCO air gap with the drain line terminating above a floor drain will handle any normal discharge or nuisance spitting through the relief valve. However, floor drain size may need to be designed to prevent water damage caused by a catastrophic failure condition. Do not reduce the size of the drain line from the air gap fitting.

A Watts Water Technologies Company

USA: Fresno, CA Tel: (559) 441-5300 Fax: (559) 441-5301 www.FEBCOonline.com Canada: Burlington, ON Tel: (905) 332-4090 Fax: (905) 332-7068 www.FEBCOonline.ca

ES-F-860L 1119

2011 FEBCO

Anda mungkin juga menyukai

- Series 405NRSRW Specification SheetDokumen2 halamanSeries 405NRSRW Specification SheetWattsBelum ada peringkat

- MasterSeries 880V Specification SheetDokumen4 halamanMasterSeries 880V Specification SheetFEBCOBelum ada peringkat

- MasterSeries 850 Specification SheetDokumen2 halamanMasterSeries 850 Specification SheetFEBCOBelum ada peringkat

- Series TDV Specification SheetDokumen2 halamanSeries TDV Specification SheetWattsBelum ada peringkat

- Series 860 Specification SheetDokumen2 halamanSeries 860 Specification SheetFEBCOBelum ada peringkat

- MasterSeries 876V Specification SheetDokumen4 halamanMasterSeries 876V Specification SheetFEBCOBelum ada peringkat

- Series B6400-SE Specification SheetDokumen2 halamanSeries B6400-SE Specification SheetWattsBelum ada peringkat

- Full Lift Spring Loaded Open PDFDokumen4 halamanFull Lift Spring Loaded Open PDFVenkatespatange RaoBelum ada peringkat

- Butterfly Valves Series BF-03-M2 Full Lug and BF-04-M2 Wafer Specification SheetDokumen2 halamanButterfly Valves Series BF-03-M2 Full Lug and BF-04-M2 Wafer Specification SheetWattsBelum ada peringkat

- Series G4000M1 Specification SheetDokumen2 halamanSeries G4000M1 Specification SheetWattsBelum ada peringkat

- Reduced Port Ductile Iron Dual Chamber Basic Valve: Mustang Series Basic ValvesDokumen2 halamanReduced Port Ductile Iron Dual Chamber Basic Valve: Mustang Series Basic ValvesWattsBelum ada peringkat

- Series 77F-DI-250 Specification SheetDokumen2 halamanSeries 77F-DI-250 Specification SheetWattsBelum ada peringkat

- Series ICV-125-2-2-T Specification SheetDokumen2 halamanSeries ICV-125-2-2-T Specification SheetWattsBelum ada peringkat

- Series LFB6080, LFB6081 Specification SheetDokumen2 halamanSeries LFB6080, LFB6081 Specification SheetWattsBelum ada peringkat

- Series SS07F Specification SheetDokumen2 halamanSeries SS07F Specification SheetWattsBelum ada peringkat

- Full Port Stainless Steel Single Chamber Basic ValveDokumen2 halamanFull Port Stainless Steel Single Chamber Basic ValveWattsBelum ada peringkat

- Series 408-OSYRW Specification SheetDokumen2 halamanSeries 408-OSYRW Specification SheetWattsBelum ada peringkat

- Series CSM-91 Specification SheetDokumen4 halamanSeries CSM-91 Specification SheetWattsBelum ada peringkat

- 11422Dokumen10 halaman11422balajivangaruBelum ada peringkat

- Reduced Port Stainless Steel Single Chamber Basic ValveDokumen2 halamanReduced Port Stainless Steel Single Chamber Basic ValveWattsBelum ada peringkat

- Full Port Ductile Iron Single Chamber Basic Valve With Mechanical Check FeatureDokumen2 halamanFull Port Ductile Iron Single Chamber Basic Valve With Mechanical Check FeatureWattsBelum ada peringkat

- Series 957, 957N, 957ZDokumen4 halamanSeries 957, 957N, 957ZWattsBelum ada peringkat

- Catalogo Regulador Watts Mod 152-ADokumen2 halamanCatalogo Regulador Watts Mod 152-AGuatemalan1979Belum ada peringkat

- Reduced Port Ductile Iron Single Chamber Basic Valve With Mechanical Check FeatureDokumen2 halamanReduced Port Ductile Iron Single Chamber Basic Valve With Mechanical Check FeatureWattsBelum ada peringkat

- Series 406NRSRW Specification SheetDokumen2 halamanSeries 406NRSRW Specification SheetWattsBelum ada peringkat

- Series G4000-FDA Specification SheetDokumen2 halamanSeries G4000-FDA Specification SheetWattsBelum ada peringkat

- Es 775Dokumen2 halamanEs 775WattsBelum ada peringkat

- Series IT6300, IS6301 Specification SheetDokumen2 halamanSeries IT6300, IS6301 Specification SheetWattsBelum ada peringkat

- Series 774DCDA Specification SheetDokumen2 halamanSeries 774DCDA Specification SheetWattsBelum ada peringkat

- Faslt 0020 enDokumen6 halamanFaslt 0020 enshashikanth79Belum ada peringkat

- Series G4000 Specification SheetDokumen2 halamanSeries G4000 Specification SheetWattsBelum ada peringkat

- AMRI ISORIA 16 Type Series Booklet DataDokumen20 halamanAMRI ISORIA 16 Type Series Booklet Datarudiskw456Belum ada peringkat

- Series 909RPDA Specification SheetDokumen4 halamanSeries 909RPDA Specification SheetWattsBelum ada peringkat

- Mech Van Catalogue PDFDokumen26 halamanMech Van Catalogue PDFVan Nguyen Huu VanBelum ada peringkat

- Series 805YD Specification SheetDokumen2 halamanSeries 805YD Specification SheetFEBCOBelum ada peringkat

- Virgo Welded Valve BrochureDokumen8 halamanVirgo Welded Valve BrochureHerrera Jorge AgustínBelum ada peringkat

- Válvulas Bola SegmentadaDokumen12 halamanVálvulas Bola SegmentadarehynaldoBelum ada peringkat

- Valves Bb-EDokumen4 halamanValves Bb-EMindrutauCosminBelum ada peringkat

- rc91261 G10-UscDokumen8 halamanrc91261 G10-Usceww08Belum ada peringkat

- Series U009 Specification SheetDokumen4 halamanSeries U009 Specification SheetWattsBelum ada peringkat

- Reduced Port Stainless Steel Dual Chamber Basic ValveDokumen2 halamanReduced Port Stainless Steel Dual Chamber Basic ValveWattsBelum ada peringkat

- MPVN BrochureDokumen32 halamanMPVN Brochurefernando_naciamentBelum ada peringkat

- EN6114Dokumen14 halamanEN6114akayirBelum ada peringkat

- Gate Valve CataogueDokumen4 halamanGate Valve CataogueAditya B. RyantoBelum ada peringkat

- DSM PDFDokumen8 halamanDSM PDFSlobodan AnticBelum ada peringkat

- rc33026 D12-UscDokumen7 halamanrc33026 D12-Usceww08Belum ada peringkat

- Lead Free Series SS009 Specification SheetDokumen2 halamanLead Free Series SS009 Specification SheetWattsBelum ada peringkat

- Full Port Stainless Steel Dual Chamber Basic ValveDokumen2 halamanFull Port Stainless Steel Dual Chamber Basic ValveWattsBelum ada peringkat

- Piping ComponentDokumen19 halamanPiping Componentreach_arindomBelum ada peringkat

- Series CV Specification SheetDokumen1 halamanSeries CV Specification SheetWattsBelum ada peringkat

- Gestra Check ValveDokumen4 halamanGestra Check Valvetilakthakar1Belum ada peringkat

- Butterfly Valves EgeplastDokumen4 halamanButterfly Valves EgeplastdsyashankaBelum ada peringkat

- Spirax BSA TDokumen4 halamanSpirax BSA TNang DapiBelum ada peringkat

- BTC Gate ValvesDokumen26 halamanBTC Gate ValvesCamilo Sanchez VanegasBelum ada peringkat

- 650 SchematicDokumen4 halaman650 Schematicab5951Belum ada peringkat

- Series FBV Specification SheetDokumen2 halamanSeries FBV Specification SheetWattsBelum ada peringkat

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDari EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsPenilaian: 4.5 dari 5 bintang4.5/5 (10)

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryDari EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryBelum ada peringkat

- Es RVDRDokumen1 halamanEs RVDRFEBCOBelum ada peringkat

- Masterseries Lf856: Lead FreeDokumen4 halamanMasterseries Lf856: Lead FreeFEBCOBelum ada peringkat

- Es F LF876VDokumen4 halamanEs F LF876VFEBCOBelum ada peringkat

- Es F 876VSTDokumen4 halamanEs F 876VSTFEBCOBelum ada peringkat

- 980154Dokumen2 halaman980154FEBCOBelum ada peringkat

- Es F LF866Dokumen4 halamanEs F LF866FEBCOBelum ada peringkat

- Es F LF886VDokumen4 halamanEs F LF886VFEBCOBelum ada peringkat

- Es F Lf650aDokumen2 halamanEs F Lf650aFEBCOBelum ada peringkat

- Series LF857: Lead FreeDokumen2 halamanSeries LF857: Lead FreeFEBCOBelum ada peringkat

- Es F LF860LDokumen4 halamanEs F LF860LFEBCOBelum ada peringkat

- Es F LF850LDokumen4 halamanEs F LF850LFEBCOBelum ada peringkat

- Es F LF870VDokumen4 halamanEs F LF870VFEBCOBelum ada peringkat

- Es F LF880VDokumen4 halamanEs F LF880VFEBCOBelum ada peringkat

- Es F 856STDokumen4 halamanEs F 856STFEBCOBelum ada peringkat

- 980079Dokumen1 halaman980079FEBCOBelum ada peringkat

- Series LF850 Specification SheetDokumen2 halamanSeries LF850 Specification SheetFEBCOBelum ada peringkat

- Series PRV-2 1/2" - 1" Specification SheetDokumen2 halamanSeries PRV-2 1/2" - 1" Specification SheetFEBCOBelum ada peringkat

- Series PRV-1 1/2" - 1" Specification SheetDokumen2 halamanSeries PRV-1 1/2" - 1" Specification SheetFEBCOBelum ada peringkat

- Series LF825YA Specification SheetDokumen4 halamanSeries LF825YA Specification SheetFEBCOBelum ada peringkat

- Series LF825Y Specification SheetDokumen2 halamanSeries LF825Y Specification SheetFEBCOBelum ada peringkat

- Series FPHB-1 Specification SheetDokumen2 halamanSeries FPHB-1 Specification SheetFEBCOBelum ada peringkat

- Model TK-1 Specification SheetDokumen1 halamanModel TK-1 Specification SheetFEBCOBelum ada peringkat

- Series TC1 Specification SheetDokumen1 halamanSeries TC1 Specification SheetFEBCOBelum ada peringkat

- Series LF860 Specification SheetDokumen2 halamanSeries LF860 Specification SheetFEBCOBelum ada peringkat

- Model BF-STD-1 Specification SheetDokumen1 halamanModel BF-STD-1 Specification SheetFEBCOBelum ada peringkat

- Spool Adapters Specification SheetDokumen2 halamanSpool Adapters Specification SheetFEBCOBelum ada peringkat

- Series FPTC-1 Specification SheetDokumen1 halamanSeries FPTC-1 Specification SheetFEBCOBelum ada peringkat

- Series PRV-1 11/4" - 2" Specification SheetDokumen2 halamanSeries PRV-1 11/4" - 2" Specification SheetFEBCOBelum ada peringkat

- Series SA-1 Specification SheetDokumen2 halamanSeries SA-1 Specification SheetFEBCOBelum ada peringkat

- Series PRV-2 11/4" - 2" Specification SheetDokumen2 halamanSeries PRV-2 11/4" - 2" Specification SheetFEBCOBelum ada peringkat

- Davey Dewatering AEMDokumen2 halamanDavey Dewatering AEMJohan TanBelum ada peringkat

- Hoop StressDokumen3 halamanHoop Stresskarthikraja21Belum ada peringkat

- Aerodynamics Prelim Lecture PDFDokumen4 halamanAerodynamics Prelim Lecture PDFelle liBelum ada peringkat

- Boncardo Freytag Mech 403 Final Project PresentationDokumen8 halamanBoncardo Freytag Mech 403 Final Project Presentationapi-568978327Belum ada peringkat

- Syphon For Pressure Measuring Instruments Model 910.15: ApplicationsDokumen4 halamanSyphon For Pressure Measuring Instruments Model 910.15: Applicationsluis carlos martin contrerasBelum ada peringkat

- Reciprocating Compressor Trouble Shooting GuidesDokumen3 halamanReciprocating Compressor Trouble Shooting GuidesRahul ChandrawarBelum ada peringkat

- Doors PDFDokumen34 halamanDoors PDFoz23Belum ada peringkat

- Forklift Daily Checklist ElectricDokumen2 halamanForklift Daily Checklist Electricmikel derrickBelum ada peringkat

- Multi Stage Parabolic Leaf SpringDokumen13 halamanMulti Stage Parabolic Leaf SpringahiremanojBelum ada peringkat

- Manual Controlador Lae MTR 6Dokumen3 halamanManual Controlador Lae MTR 6Anonymous 6VCG1YRd100% (2)

- Singly Reinforced Beam ExcelDokumen3 halamanSingly Reinforced Beam ExcelVEERKUMAR100% (3)

- Non-Uniform Torsional Behavior and Stability of Thin-Walled Elastic Beams With Arbitrary Cross SectionsDokumen25 halamanNon-Uniform Torsional Behavior and Stability of Thin-Walled Elastic Beams With Arbitrary Cross SectionsSimon TileBelum ada peringkat

- Grundfos Catalogue Industry and Water UtilityDokumen542 halamanGrundfos Catalogue Industry and Water UtilityAdina Mariana Costache100% (7)

- Guy Ropes DesignDokumen8 halamanGuy Ropes DesignVenkatasubramanian IyerBelum ada peringkat

- Alfa Laval BioPharm Fittings Catalog PDFDokumen102 halamanAlfa Laval BioPharm Fittings Catalog PDFcneo59Belum ada peringkat

- Date: Drawn Trac. Scale Checked Apprd.: Replacement: Replaced By: DWG: Rev.Dokumen1 halamanDate: Drawn Trac. Scale Checked Apprd.: Replacement: Replaced By: DWG: Rev.Deepak DasBelum ada peringkat

- United States Patent (19) : Ogle 11 4,177,779Dokumen11 halamanUnited States Patent (19) : Ogle 11 4,177,779Zavorra ZavorratoBelum ada peringkat

- PACCAR MX Engine Reference Sheet PDFDokumen2 halamanPACCAR MX Engine Reference Sheet PDFMalique ChamauneBelum ada peringkat

- Parts List for Vacuum Systems with Location, Brand and Model DetailsDokumen68 halamanParts List for Vacuum Systems with Location, Brand and Model DetailsJose Gregorio Lira SerranoBelum ada peringkat

- Pipe 02: by TRC - Tiger's Review CenterDokumen119 halamanPipe 02: by TRC - Tiger's Review Centerkristan7Belum ada peringkat

- Bajaj 4s ct100 Platina Boxer - XLSX 0 PDFDokumen7 halamanBajaj 4s ct100 Platina Boxer - XLSX 0 PDFgurubalaji15Belum ada peringkat

- Cadenas de Tiempo Pontiac G5Dokumen17 halamanCadenas de Tiempo Pontiac G5Jorge Antonio GuillenBelum ada peringkat

- Everything You Need to Know About Your Yanmar Diesel EngineDokumen56 halamanEverything You Need to Know About Your Yanmar Diesel EngineScott Erik Chisling100% (1)

- Forces and Motion: Basics: Not For Sale, Exclusive For Gordon College OnlyDokumen5 halamanForces and Motion: Basics: Not For Sale, Exclusive For Gordon College OnlyAlyssa FrancoBelum ada peringkat

- Innovex Lead Seal Casing Patch March2022a-1Dokumen10 halamanInnovex Lead Seal Casing Patch March2022a-1Christian MatteoBelum ada peringkat

- Hydraulic Circuit DesignDokumen17 halamanHydraulic Circuit DesignansarALLAAH100% (1)

- FLUID MECHANICS I COURSE OVERVIEWDokumen14 halamanFLUID MECHANICS I COURSE OVERVIEWOyedotun TundeBelum ada peringkat

- On-Site Operation Training Record Card: Pangkalan Susu Coal Fired Steam Power Plant Project Unit 3&4 2X200MWDokumen3 halamanOn-Site Operation Training Record Card: Pangkalan Susu Coal Fired Steam Power Plant Project Unit 3&4 2X200MWajambookBelum ada peringkat

- ROV and MOVDokumen1 halamanROV and MOVnewprocessBelum ada peringkat