TK-99D Installation Instructions

Diunggah oleh

WattsHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

TK-99D Installation Instructions

Diunggah oleh

WattsHak Cipta:

Format Tersedia

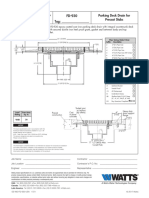

IS-TK-99D

Watts TK-99D

Digital Backflow Preventer Test Kit Delta Lite

Features

Compact hand-held size for ease of use State-of-the-art accuracy of .25% of full scale for reliable testing of all types of backflow prevention assemblies. Easy to read high contrast LCD Display Low Battery Indicator shows when batteries are needed Automatic shutdown feature conserves battery life by turning test kit off after 15 minutes without pressure on the gauge. Large 58" Differential Character Display insures accurate reading of the gauge Durable High Impact ABS case provides water resistance Adjustable hand and shoulder straps for field use Color-coded hoses to assist tester in using test kit Corrosion resistant Stainless Steel needle valves with renewable seats Inlet pressure readout to assist in troubleshooting Separate A and B readings for duplex type readings

(Low) Needle Valve B (Vent) Needle Valve C Connections C On/Off Buttons

Specifications

Maximum working pressure - 200 PSIG Maximum working temperature - 210F Differential Pressure Readout - 0-200psi Separate inlet pressure readout - 0-200psi Adapters included Hoses - Three 36" color-coded hoses with female swivel couplings One moisture resistant instruction guide High contrast LCD display .25% Full scale accuracy Needle Valves - Three Stainless Steel needle valves Adjustable packing gland High impact ABS housing

AB

LCD Display

Battery Case

Hand Strap

Note: To replace batteries remove (2) battery case set screws. Test Kit serial number is located on inside of battery case.

Caution: To avoid freeze damage to the test kit, it

The Watts TK-99D hand-held digital test kit is an advanced test instrument designed to test PVBS, SVBS, DCVAS, DCDAS, RPS, and RPDAS. The TK-99D features a high contrast LCD display with a large 5/8" height Differential Character. This compact test kit features .25% Full Scale Accuracy in addition to a low battery indicator and an automatic shutdown feature to conserve battery life.

should be stored in a dry, warm area when not in use.

Test Procedure for Anti-Spill Vacuum Breaker

The following test procedure is one of several that is recognized throughout the United States for verification of the functioning of Backflow Preventers. The following procedure is not a specific recommendation. The Watts series of test kits are capable of performing any of the recognized Backflow Preventer test procedures. Note: For all of the following tests the test kit must be held at the same level as the assembly being tested. A. Before starting test, all needle valves on the test kit must be closed. B. Flush test cocks before testing.

Step 10 Visually inspect that the vent is fully open to pass test. Step 11 Replace hood and two screws on top of assembly. Step 12 Restore valve to original working condition. Note: After test, leave all valves on test kit must be fully open and hose removed to prevent freeze damage to test kit.

Test Procedure for Reduced Pressure Assembly

A. B. C. All needle valves must be closed on test kit. Open test cock No. 4 and flush test cocks Nos. 1, 2 and 3 on reduced pressure assembly. Close test cock No. 4. Attach hoses as shown. High side hose between TC #2 and low side hose to TC #3 and close No. 2 shutoff. Bleed air from kit by opening TC #4 to establish flow through the backflow preventer and prevent premature opening of the relief valve. Open TC#3, needle valve B , and vent needle valve. Close needle valve B. Open TC#2 and needle valve A, close needle valve A and TC #4. Attach vent (yellow) hose to TC#4 and vent needle valve. Open TC #4 and loosen hose at vent needle valve connection bleeding air from test kit. Re-tighten hose to vent needle valve.

Low (blue)

High (red)

Test Cock

High (red)

Bypass (yellow)

Test No. 1 and 2, Watts 008QT shown

Turn Test Kit On Test No. 1 - Differential Test Requirement: Differential pressure across check must be 1.0 PSID or above. Step 1 Remove two screws on top of hood then remove hood. Step 2 Install hose between test cock and connection A high side (red) of test kit. Step 3 Open test cock then open needle valve A and vent or bypass needle valve. Bleed air from hose then close vent needle valve. Step 4 Close shutoff valve No. 2 then shutoff valve No. 1 on the assembly. Step 5 Slowly unscrew bleed screw on spill proof vacuum breaker body to relieve pressure down stream of check (about 3 turns) Step 6 When dripping from bleed screw stops and gauge stabilizes, record the differential pressure and retighten bleed screw. Test No. 2 - Air Inlet - Vent Opening Requirement: Air inlet must start to open when supply pressure is 1.0psi or above. Air inlet must be fully open when supply pressure is atmospheric. Step 7 Slowly open vent needle valve until gauge reads 1.0 PSID then close vent needle valve holding pressure at 1.0 PSID. Step 8 Visually inspect that the vent on top is slightly open, about 132", to pass test. Step 9 Open vent needle valve fully until dripping from vent connection stops.

909QT-S shown

Turn Test Kit On Test No. 1 - Check Valve No. 2 Purpose: To test check valve No. 2 for tightness against reverse flow. Requirements: Valve must be tight against reverse flow under all pressure differentials. Step 1 With vent needle valve open, slowly open needle valve A. (keep B closed) Step 2 Indicated pressure differential will decrease slightly. If pressure differential continues to decrease (until the relief valve opens) the No. 2 check valve is reported as leaking. Test No. 2 - Shutoff Valve No. 2 Purpose: To test shutoff valve No. 2 for tightness. Step 1 After passing Test No. 1, continue to test No. 2 by closing test cock No. 2. Step 2 The indicated pressure differential will decrease slightly. If pressure differential continues to decrease (approaching Zero), the No. 2 shutoff valve is reported to be leaking. Note: A leaking No. 2 shutoff will give a false reading in tests No. 3 and 4. Test No. 3 - To test No. 1 check valve Purpose: To test check valve No. 1 for tightness. Requirements: Valve must be tight against reverse flow under all pressure differentials. Step 1 Close needle valve A high side (red) and open test cock No. 2

Step 2

Close test cock No. 4. Disconnect bypass hose (yellow) at test cock No. 4. Close vent needle valve. Step 3 Open needle valve B and vent or bypass needle valve, bleeding to atmosphere, then closing needle valve B restores the system to a normal static condition. Step 4 Observe the pressure differential gauge. If there is a decrease in the indicated value, the No. 1 check valve is reported as leaking. Test No. 4 - Pressure Differential Relief Valve Purpose: To test Operation of pressure differential relief valve Requirements: The pressure differential relief valve must operate to maintain the zone between the two check valves at least 2psi less than the supply pressure. Step 1 Close vent or bypass needle valve Step 2 Open needle valve A high side. Step 3 Open needle valve B low very slowly until the differential reading starts to drop. Step 4 Hold the valve at this position and observe the reading at the moment the first discharge is noted from the relief valve. Record this as the opening differential pressure of the relief valve. Note: it is important the differential reading drop slowly. Step 5 Close test cocks Nos. 2 and 3. Step 6 Use bypass hose (yellow) to relieve pressure from test kit by opening needle valve A, B, and vent needle valve. Step 7 Remove all test equipment and open No. 2 shutoff valve of the device.

Step 5 Step 6 Step 7 Step 8 Step 9

Close shutoff valve No. 2 then shutoff valve No. 1. Slowly open vent needle valve just as air inlet opens. Record differential pressure. Close test cock No. 2 and remove hose. Close vent needle valve. Open shutoff valve No. 1.

High (red) Test Cock No. 1 Test Cock No. 2

Test No. 2 800M4QT shown

Test Procedure for Pressure Type Vacuum Breaker

Note: For both of the following tests the test kit must be held at the same level as the assembly being tested. A. Before starting test all needle valves must be closed. B. Flush test cock #2 and #1.

Test No. 2 - Test check Valve Pressure Drop Requirement: Supply pressure drop must be 1.0 PSID or more when water flow stops from test cock No. 2. Step 10 Install hose between test cock No.1 and connection A high side (red) on test kit. Step 11 Open test cock No. 1 and bleed valve by opening vent needle valve. Bleed air from hose then shut vent needle valve Step 12 Close shutoff valve #1. Step 13 Open test cock No. 2. When flow of water out of test cock No. 2 stops, the differential reading is the pressure drop reading. Step 14 Close test cock No. 1 and test cock No. 2. Remove hoses. Step 15 Replace hood and two screws on top of hood. Note: After test, all valves must be open and hoses removed to prevent damage to test kit.

High (red)

Test Cock No. 2 Test Cock No. 1

Test Procedure for Double Check Valve Assembly

A. Before starting test, all needle valves on test kit must be closed. B. Flush test cocks before test. Turn Test Kit On

Test No. 1 800M4QT shown

Turn Test Kit On Test No. 1 - Air Inlet Requirement: Air inlet must start to open when down stream pressure is 1.0psi or above. Step 1 Remove two screws on top of hood and remove hood. Step 2 Install hose between test cock No. 2 and connection A on high side(red) on test kit. Step 3 Open test cock No. 2 and needle valve A high side (red) on test kit. Step 4 Open vent needle valve and bleed air from hose. Then close vent valve.

Low (blue) Bypass (yellow) High (red) 007 shown Test No. 1

Test No. 1 - Check Valve No. 1 Step 1 Insure shutoff No. 1 is open, shutoff No. 2 is closed. Step 2 Install high side hose between connection A high side and test cock No. 3, low side hose between B low side and test cock No. 2 and open both test cock No. 2 and No. 3. Step 3 Open vent needle valve and bleed air by opening needle valve A. Close A then open needle valve B bleeding air and then closing B. Step 4 Connect bypass hose between vent needle valve and loosely connect to test cock No. 1. Open needle valve A high side and vent needle valve to vent air from bypass hose. Tighten bypass hose at test cock No. 1, open test cock No. 1. Step 5 Close shutoff No. 1. Slowly loosen hose connection at TC# 2 until differential gauge rises to about 2psi then tighten. If the differential reading does not decrease record check valve as tight. Step 6 Close all test cocks. Then close needle valves A, B, and vent needle valve. Test No. 2 - Check Valve No. 2 Step 7 Move the high side hose to test cock No. 4, low side hose to test cock No. 3 and open both test cock No. 3 and 4. Remove bypass hose from test cock No. 1, open shutoff valve No. 1. Step 8 Open vent needle valve and needle valve A to bleed air. Close needle valve A. Open needle valve B to bleed air and then close B and vent needle valve. Step 9 Connect bypass hose loosely to test cock No. 1. Open needle valves Ahigh side and vent needle valve to relieve air from the bypass hose. Tighten bypass hose at test cock No. 1, open test cock No. 1. Step 10 Close shutoff No. 1. Slowly loosen hose connection at TC#3 until differential gauge rises to about 2psi, then tighten. If the differential reading does not decrease record check as tight. Close all test cocks and remove hoses. Note: The assembly will fail both the first and second check valve tests above, if shutoff No. 2 leaks excessively. To test for a leaky No. 2 shutoff, use the following procedure.

Low (blue)

Bypass (yellow) High (red) 007 shown

Test No. 2

Test for Leaky No. 2 Shutoff Step 11 Connect the high side hose to test cock No. 1, low side hose to test cock No. 4. Open test cocks No. 1 and 4. Close shutoffs No. 1 and 2. Step 12 Close vent needle valve. Open needle valve A high side, then open needle valve B low side + turn, loosen hose at test cock No. 4 to remove air. Retighten hose. Step 13 If the differential gauge rises above 0 there is excessive leakage at shutoff No. 2 and it must be replaced to test the assembly.

High (red)

Low (blue)

007 shown

Test for Leaky No. 2 Shutoff

Calibration Repair Centers

Nicholson Labs

11423 Queen City Ave. Cincinnatai, OH 45214 Tel: (513) 251-8378 Fax: (513) 251-4388

BAVCO

20435 S. Susana Road Long Beach, CA 90810-1136 Tel: (310) 639-5231 Fax: (310) 639-0721

TechEn, Inc.

115 Cedar Street Milford, MA 01757 Tel: (508) 478-0042 Fax: (508) 634-3208 email: rontk99@techen.com

Limited Warranty: Watts Regulator Co. (the Company) warrants each product to be free from defects in material and workmanship under normal usage for a period of one year from the date of original shipment. In the event of such defects within the warranty period, the Company will, at its option, replace or recondition the product without charge. THE WARRANTY SET FORTH HEREIN IS GIVEN EXPRESSLY AND IS THE ONLY WARRANTY GIVEN BY THE COMPANY WITH RESPECT TO THE PRODUCT. THE COMPANY MAKES NO OTHER WARRANTIES, EXPRESS OR IMPLIED. THE COMPANY HEREBY SPECIFICALLY DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. The remedy described in the first paragraph of this warranty shall constitute the sole and exclusive remedy for breach of warranty, and the Company shall not be responsible for any incidental, special or consequential damages, including without limitation, lost profits or the cost of repairing or replacing other property which is damaged if this product does not work properly, other costs resulting from labor charges, delays, vandalism, negligence, fouling caused by foreign material, damage from adverse water conditions, chemical, or any other circumstances over which the Company has no control. This warranty shall be invalidated by any abuse, misuse, misapplication, improper installation or improper maintenance or alteration of the product. Some States do not allow limitations on how long an implied warranty lasts, and some States do not allow the exclusion or limitation of incidental or consequential damages. Therefore the above limitations may not apply to you. This Limited Warranty gives you specific legal rights, and you may have other rights that vary from State to State. You should consult applicable state laws to determine your rights. SO FAR AS IS CONSISTENT WITH APPLICABLE STATE LAW, ANY IMPLIED WARRANTIES THAT MAY NOT BE DISCLAIMED, INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED IN DURATION TO ONE YEAR FROM THE DATE OF ORIGINAL SHIPMENT.

Backflow Prevention Products

USA: 815 Chestnut St., No. Andover, MA 01845-6098; www.watts.com Canada: 5435 North Service Rd., Burlington, ONT. L7L 5H7; www.wattscanada.ca

IS-TK-99D 0829

EDP# 1910812

Watts, 2008

Anda mungkin juga menyukai

- 01 Pressure Gauge CalibrationDokumen3 halaman01 Pressure Gauge CalibrationSantosh Odiyar0% (1)

- Instrumentation Question & AnswerDokumen65 halamanInstrumentation Question & AnswerBalakumar100% (2)

- Atlas Copco-Compressed Air SystemDokumen30 halamanAtlas Copco-Compressed Air SystemILKINBelum ada peringkat

- SPM Flow Control Products CatalogDokumen61 halamanSPM Flow Control Products CatalogCampo Elias QBelum ada peringkat

- Fugitive Emission Testing Procedures for 1Dokumen15 halamanFugitive Emission Testing Procedures for 1Nitin AggarwalBelum ada peringkat

- Well Maintenance ProcedureDokumen14 halamanWell Maintenance ProcedureVlassis Sarantinos100% (1)

- Boiler Hydro TestDokumen26 halamanBoiler Hydro TestKuntal Satpathi83% (6)

- Melag Vacu 23-31 - Fault DiagnosisDokumen25 halamanMelag Vacu 23-31 - Fault DiagnosisFrepa_AL100% (3)

- Manual Gas Shut-Off Valve and Plumbing Terms GuideDokumen102 halamanManual Gas Shut-Off Valve and Plumbing Terms Guidesarmad009Belum ada peringkat

- Water Heater InstallDokumen24 halamanWater Heater Installmcx_usa100% (1)

- 2954 2510 04 - C13 - HP - en PDFDokumen104 halaman2954 2510 04 - C13 - HP - en PDFseanBelum ada peringkat

- Autoclave ManualDokumen14 halamanAutoclave ManualMigue ZabaletaBelum ada peringkat

- Instrumentation Interview QuestionsDokumen72 halamanInstrumentation Interview QuestionsGowtham An94% (18)

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGDari EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGBelum ada peringkat

- Unit - IV Hydraulics and PneumaticsDokumen26 halamanUnit - IV Hydraulics and PneumaticsRavindra_1202Belum ada peringkat

- Chiller Compressor MaintenanceDokumen90 halamanChiller Compressor MaintenanceBabak GhavidelBelum ada peringkat

- NPSH Calculation PumpDokumen3 halamanNPSH Calculation PumpYosses Sang NahkodaBelum ada peringkat

- Deluge Valve Technical DataDokumen14 halamanDeluge Valve Technical DataKeshodbana KeshodBelum ada peringkat

- Buxton-IOM TEST PUMP S10G-M THRU S30G-M TestUnits IOM rvB1 2Dokumen16 halamanBuxton-IOM TEST PUMP S10G-M THRU S30G-M TestUnits IOM rvB1 2WayneBelum ada peringkat

- Valve) - 2. End Fittings For ClosureDokumen10 halamanValve) - 2. End Fittings For ClosureNaveen Vel100% (1)

- BSEE Test ProcedureDokumen35 halamanBSEE Test ProcedureNatraji100% (2)

- Operation Instruction of AF-type Screw PumpDokumen27 halamanOperation Instruction of AF-type Screw PumpNazar KhanBelum ada peringkat

- Test Bench For Safety ValveDokumen8 halamanTest Bench For Safety ValvekhairurBelum ada peringkat

- 0299 504 1 Sys Hy en 144Dokumen168 halaman0299 504 1 Sys Hy en 144api-1948325050% (4)

- Prevention of Actuator Emissions in the Oil and Gas IndustryDari EverandPrevention of Actuator Emissions in the Oil and Gas IndustryBelum ada peringkat

- TK-99E Backflow Preventer Test Kit Installation InstructionsDokumen4 halamanTK-99E Backflow Preventer Test Kit Installation InstructionsWattsBelum ada peringkat

- Series TK-1 Installation InstructionsDokumen4 halamanSeries TK-1 Installation InstructionsFEBCOBelum ada peringkat

- Series TK-9A Installation InstructionsDokumen4 halamanSeries TK-9A Installation InstructionsWattsBelum ada peringkat

- TK-DL Installation InstructionsDokumen8 halamanTK-DL Installation InstructionsWattsBelum ada peringkat

- Test Stand Technical ManualDokumen51 halamanTest Stand Technical Manualewhf weGJO100% (1)

- Pacakage Aircon MaintenanceDokumen15 halamanPacakage Aircon Maintenancerjv.premi74Belum ada peringkat

- Vane Presiune DN40 - DN250Dokumen28 halamanVane Presiune DN40 - DN250iza66bellBelum ada peringkat

- Series 808Y Installation InstructionsDokumen4 halamanSeries 808Y Installation InstructionsFEBCOBelum ada peringkat

- SquareD 9013F G TroubleshootingDokumen8 halamanSquareD 9013F G TroubleshootingMelissa DorseyBelum ada peringkat

- Additel 918 ManualDokumen2 halamanAdditel 918 ManualAnonymous ffje1rpaBelum ada peringkat

- SamplingDokumen1 halamanSamplingPopa Costin AugustinBelum ada peringkat

- H9 Installation GuideDokumen33 halamanH9 Installation Guidegerente soportecBelum ada peringkat

- Butterfly Valve Cycle TestDokumen4 halamanButterfly Valve Cycle TestParthiban MechanicalBelum ada peringkat

- Deluge Valve ADokumen14 halamanDeluge Valve APatel MehulkumarBelum ada peringkat

- Computer Control Horizontal Valve Test Bench MachineDokumen12 halamanComputer Control Horizontal Valve Test Bench Machineahsun habibBelum ada peringkat

- Purpora Engineering PV TESTER MANUALDokumen18 halamanPurpora Engineering PV TESTER MANUALPeterBelum ada peringkat

- Manifold Burst Pressure TestDokumen3 halamanManifold Burst Pressure TestrajeshBelum ada peringkat

- SOP Gas AbsorptionDokumen19 halamanSOP Gas AbsorptionKevin EsmunaldoBelum ada peringkat

- Flow ExpDokumen5 halamanFlow ExpLawson IdukuBelum ada peringkat

- Ldu 11Dokumen17 halamanLdu 11tvbm100Belum ada peringkat

- Sur-Flo Products Control Valve Liquid Turbine Meter RunDokumen40 halamanSur-Flo Products Control Valve Liquid Turbine Meter RunCheng HuangBelum ada peringkat

- Deluge Valve Technical Data SheetDokumen14 halamanDeluge Valve Technical Data SheetSiddharth GupteBelum ada peringkat

- Rockwell Center hydrostatic testingDokumen2 halamanRockwell Center hydrostatic testingfelipeBelum ada peringkat

- Procedure Manual: Ball Valve Hydro TestDokumen5 halamanProcedure Manual: Ball Valve Hydro Testnima_h10Belum ada peringkat

- Fault Finding HydraulicSystemsDokumen7 halamanFault Finding HydraulicSystemsahmedBelum ada peringkat

- Alarm ValveDokumen6 halamanAlarm ValveAnonymous ZPTCAz9Belum ada peringkat

- 21 ED Plus - Safety Valve - Test With SteamDokumen5 halaman21 ED Plus - Safety Valve - Test With SteamAiman WewBelum ada peringkat

- Ldu 11 Eun 7696 en 25042005Dokumen16 halamanLdu 11 Eun 7696 en 25042005Thiago FernandesBelum ada peringkat

- API 682 Short Guide Most Common Plans and Operational InformationDokumen40 halamanAPI 682 Short Guide Most Common Plans and Operational InformationFarhan TalibBelum ada peringkat

- Procedure Leak Test Dan VacuumDokumen5 halamanProcedure Leak Test Dan VacuumwahyuBelum ada peringkat

- Piping Works Hydrostatic Testing GuideDokumen2 halamanPiping Works Hydrostatic Testing GuideBilly DuenasBelum ada peringkat

- TuttnauerManSterilizers PDFDokumen10 halamanTuttnauerManSterilizers PDFspaske_Belum ada peringkat

- CCB 2092 Experiment 3 - Fluid StaticsDokumen6 halamanCCB 2092 Experiment 3 - Fluid StaticsFahmi EsaBelum ada peringkat

- Calibration and Leak-By Test ProceduresDokumen2 halamanCalibration and Leak-By Test Proceduresromi_hamdaniBelum ada peringkat

- HPI-4N1 Performance EvaluationDokumen14 halamanHPI-4N1 Performance EvaluationMarco Antonio Lopez BalderasBelum ada peringkat

- Pressure and Leakage TestsDokumen4 halamanPressure and Leakage TestsgunsakBelum ada peringkat

- Gas Utility Services: Regulator Inspection & TestingDokumen59 halamanGas Utility Services: Regulator Inspection & Testingaliyah khalidBelum ada peringkat

- Bioreactor Sartorius Biostat Cplus (5L) InstructionsDokumen8 halamanBioreactor Sartorius Biostat Cplus (5L) Instructionshulki özelBelum ada peringkat

- Experiment No 7Dokumen7 halamanExperiment No 7Faizan Ahmed67% (3)

- AQT-56 Manual PDFDokumen20 halamanAQT-56 Manual PDFFiorella BravoBelum ada peringkat

- Armstrong Installation, Start-Up and Operating Instructions Armstrong Differential Condensate ControllerDokumen4 halamanArmstrong Installation, Start-Up and Operating Instructions Armstrong Differential Condensate ControllerWalid SaifBelum ada peringkat

- Pressure SwitchDokumen3 halamanPressure Switchpriva002Belum ada peringkat

- Installation GuideDokumen42 halamanInstallation GuideMubashir RajpootBelum ada peringkat

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDari EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitBelum ada peringkat

- Es OfpsysDokumen2 halamanEs OfpsysWattsBelum ada peringkat

- Es WD Li 12 LT UsaDokumen1 halamanEs WD Li 12 LT UsaWattsBelum ada peringkat

- Es Oftwh CDokumen2 halamanEs Oftwh CWattsBelum ada peringkat

- Es WD TD 300 UsaDokumen1 halamanEs WD TD 300 UsaWattsBelum ada peringkat

- Es WQ PwfgacDokumen2 halamanEs WQ PwfgacWattsBelum ada peringkat

- Es FHBDokumen1 halamanEs FHBWattsBelum ada peringkat

- Es WQ PwfcalDokumen2 halamanEs WQ PwfcalWattsBelum ada peringkat

- Es WQ PWSRDokumen2 halamanEs WQ PWSRWattsBelum ada peringkat

- Series LFFHB Specification SheetDokumen2 halamanSeries LFFHB Specification SheetWattsBelum ada peringkat

- Series 97FB-FSFE Specification SheetDokumen2 halamanSeries 97FB-FSFE Specification SheetWattsBelum ada peringkat

- Es WQ PwsrtaDokumen2 halamanEs WQ PwsrtaWattsBelum ada peringkat

- Es WQ PWFMZDokumen2 halamanEs WQ PWFMZWattsBelum ada peringkat

- Is WD DLSZ InstallationDokumen1 halamanIs WD DLSZ InstallationWattsBelum ada peringkat

- Es 757isrDokumen2 halamanEs 757isrWattsBelum ada peringkat

- Is WD DLSZ InstallationDokumen1 halamanIs WD DLSZ InstallationWattsBelum ada peringkat

- Es Lfemvii 6400SSDokumen4 halamanEs Lfemvii 6400SSWattsBelum ada peringkat

- Es WD FD 930 UsaDokumen1 halamanEs WD FD 930 UsaWattsBelum ada peringkat

- ES PW SmartStream ADokumen4 halamanES PW SmartStream AWattsBelum ada peringkat

- Es BD911Dokumen2 halamanEs BD911WattsBelum ada peringkat

- Es BD1156FDokumen2 halamanEs BD1156FWattsBelum ada peringkat

- Es 957isrDokumen2 halamanEs 957isrWattsBelum ada peringkat

- ES WD DeadLevel S USADokumen1 halamanES WD DeadLevel S USAWattsBelum ada peringkat

- Basic Construction Operation Troubleshooting: WarningDokumen2 halamanBasic Construction Operation Troubleshooting: WarningWattsBelum ada peringkat

- Es WD Hy 800 CanDokumen1 halamanEs WD Hy 800 CanWattsBelum ada peringkat

- Es Lf474aDokumen2 halamanEs Lf474aWattsBelum ada peringkat

- Es Lf474aDokumen2 halamanEs Lf474aWattsBelum ada peringkat

- ES WD DeadLevel Z USADokumen1 halamanES WD DeadLevel Z USAWattsBelum ada peringkat

- Es-Of1465tm 1665TMDokumen3 halamanEs-Of1465tm 1665TMWattsBelum ada peringkat

- Es LFMMV HTKDokumen2 halamanEs LFMMV HTKWattsBelum ada peringkat

- Es LFRC105Dokumen2 halamanEs LFRC105WattsBelum ada peringkat

- CCJ Issue 55 PDFDokumen94 halamanCCJ Issue 55 PDFMariano Salomon PaniaguaBelum ada peringkat

- Hywa-Pt ValveDokumen2 halamanHywa-Pt Valvemanoj_doshi_1Belum ada peringkat

- Hvac Munchkin Vision 1 Manual 0712-7 Lp-102Dokumen32 halamanHvac Munchkin Vision 1 Manual 0712-7 Lp-102Douglas Hopkins100% (1)

- Newco Product Line BrochureDokumen8 halamanNewco Product Line BrochureshahganBelum ada peringkat

- Sample Quotation: Fire Diesel Pump With Accessories, Patterson Pump, UL/FMDokumen4 halamanSample Quotation: Fire Diesel Pump With Accessories, Patterson Pump, UL/FMJuleousBelum ada peringkat

- Installation Instruction 3-Sep 0,5rev2Dokumen20 halamanInstallation Instruction 3-Sep 0,5rev2Ignacio SantanaBelum ada peringkat

- Group 2 - Basic MeDokumen117 halamanGroup 2 - Basic MeFrances Dale CapulongBelum ada peringkat

- Bronze & Steel Water Gage Valve SetsDokumen8 halamanBronze & Steel Water Gage Valve SetsWvaner WagnerBelum ada peringkat

- Taschenbuch GB 02Dokumen416 halamanTaschenbuch GB 02giromadBelum ada peringkat

- Henry-Technologies E1 Catalogue Interactive LowDokumen140 halamanHenry-Technologies E1 Catalogue Interactive LowManuel Guardia AraujoBelum ada peringkat

- Ascott Service Manual Iss - Part 2Dokumen42 halamanAscott Service Manual Iss - Part 2Le BachBelum ada peringkat

- Gestra - Technical-Information-2016 enDokumen194 halamanGestra - Technical-Information-2016 enAlexanderBelum ada peringkat

- CG 2015132 00 - 20167 Hydraulic Control ValveDokumen4 halamanCG 2015132 00 - 20167 Hydraulic Control ValveAri PutraBelum ada peringkat

- Reliance Water Controls Hoseguard Bib Tap HTAP217008 520-041-0001Dokumen2 halamanReliance Water Controls Hoseguard Bib Tap HTAP217008 520-041-0001AdvancedWaterCompanyBelum ada peringkat

- Oec Material Submittal StatusDokumen2 halamanOec Material Submittal Statussaqib_dar16620Belum ada peringkat

- Service Manual Series V14: Effective: October 2010 Supersedes: March 2010Dokumen44 halamanService Manual Series V14: Effective: October 2010 Supersedes: March 2010fuclaBelum ada peringkat

- SPM-740 Desalter - Simtronics SPM SeriesDokumen7 halamanSPM-740 Desalter - Simtronics SPM Seriesmoh4medkhribtBelum ada peringkat

- Operating, Installation & Maintenance Manual FOR Series 210 MK - Ii Sample ProbeDokumen44 halamanOperating, Installation & Maintenance Manual FOR Series 210 MK - Ii Sample ProbeSenterver Equipos IndustrialesBelum ada peringkat

- Thermosiphon 2020 EN FinalDokumen73 halamanThermosiphon 2020 EN FinalJose OlaBelum ada peringkat

- Tower Crane DiscussionsDokumen18 halamanTower Crane DiscussionsGelbert SilotBelum ada peringkat

- BBU For Yard PipingDokumen6 halamanBBU For Yard Pipingkalyanm203515Belum ada peringkat