M110-14, M1110-14 Specification Sheet

Diunggah oleh

WattsDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

M110-14, M1110-14 Specification Sheet

Diunggah oleh

WattsHak Cipta:

Format Tersedia

02/09

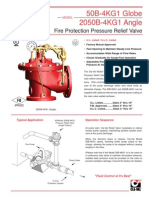

Mustang series

Standard Components

Options & Accessories

Schematics

12541 Gulf Freeway Houston, Texas 77034 (Ph) 713.943.0688 (Fx) 713.944.9445 www.watts.com

910 link

M110-14 (Globe)

M1110-14 (Angle)

Operations

ON-OFF FLOAT CONTROL VALVE

(4 and Smaller)

1 Main Valve (Single Chamber)

2 On-Off Float Control

3A High Level Adjustment Stop

3B Low Level Adjustment Stop

1

X

Y/FC

2

3A

3B

P/L

X

CLOSES VALVE

OPENS VALVE

FLOW

X Isolation Cocks

FC Flo-Clean Strainer

Y Y-Strainer (Replaces Flo-Clean)

ACS Adjustable Closing Speed

(Replaces Fixed Orifce)

AOS Adjustable Opening Speed

P Position Indicator

L Limit Switch

Opens when foat reaches low level stop

Closes when foat reaches high level stop

Low and High Level stop collars are adjustable

Standard 3 & Smaller

Standard 4 & Larger

Optional All Sizes

(3)

(2)

(1)

(3)

(3)

(3)

(3)

(2)

(2)

(1)

The On-Off Float Control Valve is designed to open fully or close drip-tight as commanded by the Float

Control Pilot. The Float Pilot may be either valve or remote mounted. The valve closes drip tight when water

level reaches the adjustable high-level setpoint, and opens fully when water level is below the adjustable

low-level setpoint, allowing a calculated draw-down of water level to increase tank circulation. The On-Off

Float Pilot commands the routing of fuid and pressure into and out of the cover chamber of the main valve.

When water level reaches the adjustable high-level setpoint, the Float Pilot connects the cover chamber

of the valve to upstream pressure, closing the valve drip tight. The valve remains closed as water level

decreases. When water level reaches the adjustable low-level setpoint, the Float Pilot connects the cover

chamber of the valve to atmosphere (wet drain), opening the valve fully. High and low levels are separately

adjustable by positioning stop collars on the foat rod(s) at desired opening and closing setpoints.

If desired, the on-off action of the valve can be reversed by modifying the hydraulic connections of the On-

Off Float Pilot.

MUSTANG SERIES

12541 Gulf Freeway Houston, Texas 77034 (Ph) 713.943.0688 (Fx) 713.944.9445 www.watts.com

M110-14 (Globe)

M1110-14 (Angle)

Body & Cover: Ductile Iron ASTM A536

Coating: NSF Listed Fusion Bonded

Epoxy Lined and Coated

Trim: 316 Stainless Steel

Elastomers: Buna-N (standard)

EPDM

Viton

Stem, Nut & Stainless Steel

Spring:

Materials

L

K

K

D

K

A

B

C

E

F

G

H I J

Globe Angle

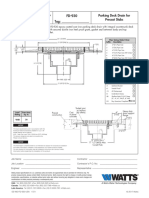

Dimensions

A B C D E F G H I J K L

VALVE

SIZE

GLOBE

THRD.

GLOBE

150#

GLOBE

300#

COVER TO

CENTER

ANGLE

THRD.

ANGLE

150#

ANGLE

300#

ANGLE

THRD.

ANGLE

150#

ANGLE

300#

PORT

SIZE

PORT

SIZE

SHIPPING

WEIGHTS*

1-1/4 7-1/4 - - 5-1/2 3-1/4 - - 1-7/8 - - 3/8 1/4 20

1-1/2 7-1/4 8-1/2 9 5-1/2 3-1/4 4 4-1/4 1-7/8 4 4-1/4 3/8 1/4 25

2 9-3/8 9-3/8 10 6-1/2 4-3/4 4-3/4 5 3-1/4 3-1/4 3-1/2 3/8 1/2 40

2-1/2 11 11 11-5/8 7-1/2 5-1/2 5-1/2 5-7/8 4 4 4-5/16 1/2 1/2 65

3 12-1/2 12 13-1/4 8-1/4 6-1/4 6 6-3/8 4-1/2 4 4-3/8 1/2 1/2 95

4 - 15 15-5/8 10-5/8 - 7-1/2 7-7/8 - 5 5-5/16 3/4 3/4 190

6 - 20 21 13-3/8 - 10 10-1/2 - 6z 6-1/2 3/4 3/4 320

8 - 25-3/8 26-3/8 16 - 12-3/4 13-1/4 - 8 8-1/2 1 1 650

10 - 29-3/4 31-1/8 17-1/8 - 14-7/8 15-9/16 - 8-5/8 9-5/16 1 1 940

For larger sizes consult factory

Valve Size (in) 1-1/4 1-1/2 2 2-1/2 3 4 6 8 10

f.oz. 4 4 4 10 10 22 70 - -

U.S. Gal - - - - - - - 1-1/4 2-1/2

Valve Cover Chamber Capacity

Valve Size (in) 1-1/4 1-1/2 2 2-1/2 3 4 6 8 10

Travel (in) 3/8 3/8 1/2 5/8 3/4 1 1-1/2 2 2-1/2

Valve Travel

Operating Pressure

Threaded = 400 psi

150 Flanged = 250 psi

300 Flanged = 400 psi

Operating Temperature

Buna-N: 160F Maximum

EPDM: 300F Maximum

Viton: 250F Maximum

Tubing & Fittings

Copper / Brass (Standard)

Stainless Steel (Optional)

Pilot System

Float Control

Brass (Standard)

Float Ball

Polyethylene (6 dia.)

Float Rods

(2) 12 Rods (Standard)

MUSTANG SERIES

12541 Gulf Freeway Houston, Texas 77034 (Ph) 713.943.0688 (Fx) 713.944.9445 www.watts.com

Sizing

Size (in)

1-1/4 1-1/2 2 2-1/2 3 4 6 8 10

Maximum Continuous (GPM) 95 130 210 300 485 800 1850 3100 5000

Maximum Intermittent (GPM) 119 161 265 390 590 1000 2300 4000 6250

CV Factor GPM (Globe) 25 30 45 75 100 175 490 770 1200

CV Factor GPM (Angle) 26 27 57 91 125 215 571 990 1530

Maximum continuous fow based on velocity of 20 ft. per second.

Maximum intermittent fow based on velocity of 25 ft. per second.

2

-

1

/

2

4

1

0

6 8 2 3

1

2

1

4

1

6

2

-

1

/

2

4

1

0

6 8 2 3

1

2

1

4

1

6

1

-

1

/

4

1

-

1

/

2

1

-

1

/

4

1

-

1

/

2

Flow Rate - Gallons per minute

P

r

e

s

s

u

r

e

D

r

o

p

(

p

.

s

.

i

.

)

Angle

Globe

2 4 6 8 10 20 40 60 80 100 200 500 1000 2000 5000 10000 20000 100000

Maximum continuous flow based on velocity of 20 ft. per second.

Maximum intermittent flow based on velocity of 25 ft. per second.

The C

v

Factor of a value is the flow rate in US GPM at 60 F that will cause a 1 psi drop in pressure.

The factors stated are based upon a fully open valve.

Cv factor can be used in the following equations to determine Flow (Q) and Pressure Drop ( P):

Q (Flow) = C

v

P P (Pressure Drop) = (Q/C

V

)

2

Headloss

NOTE: The above chart is a suggested guide. Inlet pressure, outlet pressure, minumum, normal and maximum fow rates should

be considered for specifc valve sizing. Contact Watts ACV for details.

100

80

60

40

30

20

10

8

6

4

3

2

M110-14 (Globe)

M1110-14 (Angle)

2 4 6 8 10 20 40 60 80 100 200 500 1000 2000 5000 10000 20000 100000

MUSTANG SERIES

12541 Gulf Freeway Houston, Texas 77034 (Ph) 713.943.0688 (Fx) 713.944.9445 www.watts.com

Cross-Sectional Detail

2

3

4

5

6

7

8

9

10 1

11

12

13

14

15

16

17

* Contained in Main Valve Repair Kit

ITEM DESCRIPTION MATERIAL

1 Cover ASTM A536 65-45-12 Epoxy Coated Ductile Iron

2 Cover Bearing ASTM A276 304 Stainless Steel

3 Shaft / Stem ASTM A276 304 Stainless Steel

4 Stud ASTM A570 Gr.33 Zinc Plated Steel

5 Cover Nut ASTM A570 Gr.33 Zinc Plated Steel

6 Diaphragm* Buna-N (Nitrile)

7 Body ASTM A536 65-45-12 Epoxy Coated Ductile Iron

8 Seat Disc* Buna-N (Nitrile)

9 Seat Ring ASTM A743 CF8M (316) Stainless Steel

10 Spring ASTM A276 302 Stainless Steel

11 Stem Nut ASTM A276 304 Stainless Steel

12 Spring Washer ASTM A276 304 Stainless Steel

13 Diaphragm Washer ASTM A536 65-45-12 Epoxy Coated Ductile Iron

14 Disc Retainer ASTM A536 65-45-12 Epoxy Coated Ductile Iron

15 Spacer Washer* Fiber*

16 Disc Guide ASTM A743 CF8M (316) Stainless Steel

17 Seat Gasket* Buna-N (Nitrile)

Main Valve

M110-14 (Globe)

M1110-14 (Angle)

2 4 6 8 10 20 40 60 80 100 200 500 1000 2000 5000 10000 20000 100000

MUSTANG SERIES

12541 Gulf Freeway Houston, Texas 77034 (Ph) 713.943.0688 (Fx) 713.944.9445 www.watts.com

M110-14 (Globe)

M1110-14 (Angle)

Proper Automatic Control Valve start-up requires bringing the valve into service in a controlled manner. All adjustments

to control pilots and speed controls should be made slowly, allowing the valve to respond and the system to stabilize.

NOTE: Control Valves should be setup in a dynamic (fowing) condition for proper startup. Provisions for

fow must be made to insure proper settings.

If Float Control is remote mounted, feld installed control lines should be 3/8 minimum copper tubing for dis-

tances no greater than 10 feet. For greater distances use 1/2 minimum copper tubing or pipe.

Remote mount without Accelerator (4 and smaller): Port 1 = Supply Pressure

Port C = Valve Cover

Port 2 = Atmosphere

Remote Mount with Accelerator (6 and larger): Port 1 = Atmosphere

Port C = Accelerator Cover

Port 2 = Supply

1. Close upstream and downstream valves to isolate the valve from line pressure. Open all Isolation Ball Valves,

if so equipped. If valve is ftted with adjustable speed controls, turn needle(s) in (clockwise) until seated, and

return out (counterclockwise) 11/2 to 21/2 turns. These are approximate settings, and should be fne tuned to

suit system requirements after level adjustments have been made.

2. Slowly open upstream isolation valve to allow controlled flling of the valve. Vent entrapped air by carefully

loosening control tubing or pipe plug at the highest point possible. If valve is equipped with a Position Indicator,

open Air Bleed Petcock to vent air. Water will be milky in appearance and will begin to clear as air is vented.

Re-tighten when water vents clearly.

3. Setting Float Control: Install desired number of Float Rods and Low and High Level Stop Collars (less Float).

Manually position Float Control to the center point in its travel and balance by positioning Counterweight in or

out until Float Control holds in position. Proper balance is achieved when Float Control moves to the down/

on or up/off position with minimal force or drag. The position of Counterweight on the Counterweight Rod

will vary based upon the number and material of Float Rods being used. Install Float.

4. Position Low and High Level Stop Collars on Float Rods to match desired valve opening and closing levels.

Slowly open downstream isolation valve.

5. Fine tune Speed Controls (if equipped) to suit system requirements. Adjust Closing Speed Control clockwise

for slower closure and counterclockwise for faster closure. Adjust Opening Speed Control clockwise for slower

opening and counterclockwise for faster opening.

Start-Up

Installations

Prior to installation, fush line to remove debris.

Install valve horizontally in line (cover facing UP), so fow arrow matches fow through the line. Avoid installing

valves 6 and larger vertically. Consult factory prior to ordering if installation is other than described.

Install inlet and outlet isolation valves. NOTE: When using butterfy valves, insure disc does not contact control

valve. Damage or improper valve seating may occur.

Provide adequate clearance for valve servicing and maintenance.

Install pressure gauge to monitor valve inlet pressure.

Provide adequate drain for cover chamber discharge. Consult Valve Cover Capacity chart on appropriate main

valve Engineering Bulletin.

If OnOff Float Pilot is remotely mounted it should be feld connected with 3/8 minimum copper tubing in accordance

with factory piping schematic.

Float Pilot, Rods, and Ball should be mounted in a feld installed stilling well for protection against surface turbu-

lence and interference.

Additional 12 Float Rods available. Consult Factory.

910 Ops & Inst

2 4 6 8 10 20 40 60 80 100 200 500 1000 2000 5000 10000 20000 100000

MUSTANG SERIES

12541 Gulf Freeway Houston, Texas 77034 (Ph) 713.943.0688 (Fx) 713.944.9445 www.watts.com

Specifcations

M110-14 (Globe)

M1110-14 (Angle)

The On-Off Float Control Valve shall be a pilot operated diaphragm valve designed to open fully or close drip-tight

as commanded by the Float Control Pilot. The Float Pilot may be either valve or remote mounted. The valve shall

close drip tight when water level reaches the adjustable high-level setpoint, and open fully when water level is be-

low the adjustable low-level setpoint, allowing a calculated draw-down of water level to increase tank circulation.

The main valve shall be a hydraulically operated, single diaphragm actuated, globe or angle pattern valve. Y-

pattern valves shall not be permitted. The valve shall contain a disc and diaphragm assembly that forms a sealed

chamber below the valve cover, separating operating pressure from line pressure. The diaphragm shall be con-

structed of nylon reinforced Buna-N, and shall not seal directly against the valve seat and shall be fully supported

by the valve body and cover. Rolling diaphragm construction will not be allowed and there shall be no pistons

operating the main valve or any pilot controls.

The main valve body and cover shall be Ductile Iron ASTM A536, and all internal cast components shall be Duc-

tile Iron or CF8M (316) Stainless Steel. All Ductile Iron components, including the body and cover, shall be lined

and coated with an NSF 61 Certifed Epoxy Coating applied by the electrostatic heat fusion process. All main

valve trim and throttling components (cover bearing, valve seat and disc guide) shall be Stainless Steel. The

valve body and cover must be machined with a 360-degree locating lip to assure proper alignment.

The disc and diaphragm assembly shall contain a Buna-N synthetic rubber disc with a rectangular cross-section

that is securely retained on 3-1/2 sides by a disc retainer and disc guide. Diaphragm assemblies utilizing bolts or

cap screws for component retention will not be permitted.

The exposed portion of the seat disc shall contact the valve seat and seal drip-tight. The disc and diaphragm as-

sembly must be guided by two separate bearings, one installed in the valve cover and one concentrically located

within the valve seat, to avoid defection and assure positive disctoseat contact. Center guided valves will not

be permitted. All necessary repairs shall be made from the top of the valve while the body remains in line.

Pilot control systems for valves 3 and smaller shall contain a Flow Clean Strainer, On-Off Float Pilot, (2) 12 Float

Rods and a Float Ball. Pilot control systems for 4 valves shall contain an On-Off Float Pilot, (2) 12 Float Rods,

Float Ball, an external Y-Strainer and Isolation Ball Valves on all body connections. All pilot control systems shall

utilize copper tubing and brass fttings regardless of valve size.

The valve shall be Watts ACV Model M110-14 (Globe) or M1110-14 (Angle) On-Off Float Control Valve.

Other Watts ACV Float Control Valves

M110-14 / M1110-14 On-Off Float Control Valve (6 and Larger)

910 Ops & Inst

Anda mungkin juga menyukai

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDari EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsPenilaian: 4.5 dari 5 bintang4.5/5 (10)

- ASV 10 20 BrochureDokumen8 halamanASV 10 20 BrochureThomas Duane DavidsonBelum ada peringkat

- GE - M60 Motor Relay - ManualDokumen382 halamanGE - M60 Motor Relay - ManualKrishnan GovindarajBelum ada peringkat

- Modulating Float ValvesDokumen4 halamanModulating Float ValvesJayakrishnan RadhakrishnanBelum ada peringkat

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGDari EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGBelum ada peringkat

- Apco Airvacuum Valves Avv Sales 601Dokumen8 halamanApco Airvacuum Valves Avv Sales 601Jhony MedranoBelum ada peringkat

- Digital Control ValveDokumen8 halamanDigital Control Valvecnrk777100% (1)

- Project Proposal - PresentationDokumen27 halamanProject Proposal - PresentationAmir DillawarBelum ada peringkat

- CLAVAL Pressure Reducing ValveDokumen4 halamanCLAVAL Pressure Reducing ValvermgatocBelum ada peringkat

- AV-C Butterfly ValveDokumen20 halamanAV-C Butterfly ValveSopon SrirattanapiboonBelum ada peringkat

- 'C' Series Control ValvesDokumen12 halaman'C' Series Control Valvesابزار دقیق100% (1)

- STEP 7 - System and Standard Functions For S7-300 and S7-400Dokumen662 halamanSTEP 7 - System and Standard Functions For S7-300 and S7-400TetsusaigaBelum ada peringkat

- Es Acv M115F M1115FDokumen4 halamanEs Acv M115F M1115FWattsBelum ada peringkat

- Regulador American Meter PDFDokumen6 halamanRegulador American Meter PDFjmcg1974Belum ada peringkat

- F110-14, F1110-14 Specification SheetDokumen6 halamanF110-14, F1110-14 Specification SheetWattsBelum ada peringkat

- Mustang Series M115-74 (Globe), M1115-74 (Angle) Specification SheetDokumen7 halamanMustang Series M115-74 (Globe), M1115-74 (Angle) Specification SheetWattsBelum ada peringkat

- Mustang Series M115 (Globe), M1115 (Angle) Specification SheetDokumen7 halamanMustang Series M115 (Globe), M1115 (Angle) Specification SheetWattsBelum ada peringkat

- Mustang Series M115-7 (Globe), M1115-7 (Angle) Specification SheetDokumen8 halamanMustang Series M115-7 (Globe), M1115-7 (Angle) Specification SheetWattsBelum ada peringkat

- Classic Series F115-74 (Globe), F1115-74 (Angle) Specification SheetDokumen7 halamanClassic Series F115-74 (Globe), F1115-74 (Angle) Specification SheetWattsBelum ada peringkat

- Mustang Series M115-3 (Globe), M1115-3 (Angle) Specification SheetDokumen7 halamanMustang Series M115-3 (Globe), M1115-3 (Angle) Specification SheetWattsBelum ada peringkat

- M110-14, M1110-14 Specification SheetDokumen6 halamanM110-14, M1110-14 Specification SheetWattsBelum ada peringkat

- Classic Series F518 (Globe), F1518 (Angle) Specification SheetDokumen2 halamanClassic Series F518 (Globe), F1518 (Angle) Specification SheetWattsBelum ada peringkat

- F113-6RFP, F1113-6RFP Specification SheetDokumen16 halamanF113-6RFP, F1113-6RFP Specification SheetWattsBelum ada peringkat

- RedvalvE 90 01Dokumen4 halamanRedvalvE 90 01Rizal FalevyBelum ada peringkat

- 134-05 EsDokumen2 halaman134-05 EsFreddy Ibañez PeñaBelum ada peringkat

- 100G - 2100G ClavalDokumen2 halaman100G - 2100G Clavale1901bBelum ada peringkat

- Es Acv 1116FMDokumen4 halamanEs Acv 1116FMWattsBelum ada peringkat

- Series 909 Specification SheetDokumen4 halamanSeries 909 Specification SheetWattsBelum ada peringkat

- Series 825Y Specification SheetDokumen2 halamanSeries 825Y Specification SheetFEBCOBelum ada peringkat

- Fire HydrantDokumen6 halamanFire HydrantdileepsiddiBelum ada peringkat

- Series LF909 Specification SheetDokumen4 halamanSeries LF909 Specification SheetWattsBelum ada peringkat

- RVC 05 NPT Product SpecsDokumen6 halamanRVC 05 NPT Product SpecsAnonymous WVJNMWBelum ada peringkat

- ACV 113-6RFP Specification SheetDokumen4 halamanACV 113-6RFP Specification SheetWattsBelum ada peringkat

- Control Valve System: PN 16 / 40 DN 15 - 150 ApplicationDokumen0 halamanControl Valve System: PN 16 / 40 DN 15 - 150 Applicationcico_ctBelum ada peringkat

- 61fSTO PStopperDokumen2 halaman61fSTO PStopperBenjamin BrownBelum ada peringkat

- ASCO 35-1 General Service 3-Way Valves PDFDokumen36 halamanASCO 35-1 General Service 3-Way Valves PDFprsiva2420034066Belum ada peringkat

- PVR-108-2 Fueling Model SheetDokumen2 halamanPVR-108-2 Fueling Model SheetLetycia RosalesBelum ada peringkat

- Valvula de Alivio WatsonDokumen2 halamanValvula de Alivio WatsonLuis Panti EkBelum ada peringkat

- 50B4KGDokumen2 halaman50B4KGonin007Belum ada peringkat

- Technical Bulletin: Valtek Mark One Control ValvesDokumen20 halamanTechnical Bulletin: Valtek Mark One Control ValvesOscar CruzBelum ada peringkat

- Fisher Globe ValveDokumen16 halamanFisher Globe ValvePhornlert WanaBelum ada peringkat

- Fisher 9500 Butterfly Control ValveDokumen12 halamanFisher 9500 Butterfly Control ValveOscarBelum ada peringkat

- Fisherr 8510 and 8510B Eccentric Disc Control Valves (EMA) : FeaturesDokumen20 halamanFisherr 8510 and 8510B Eccentric Disc Control Valves (EMA) : FeaturesFabián HerreraBelum ada peringkat

- PRV SizingDokumen4 halamanPRV SizingTiffany CombsBelum ada peringkat

- Feed Water Heater - Isolation System: Features & BenefitsDokumen9 halamanFeed Water Heater - Isolation System: Features & BenefitsAkash PatilBelum ada peringkat

- 3105 B 26Dokumen3 halaman3105 B 26ParIs MoRanBelum ada peringkat

- Suction Guide & Flo-Trex Valve Series: Pump TrimDokumen8 halamanSuction Guide & Flo-Trex Valve Series: Pump Trimsiva_nagesh_2Belum ada peringkat

- Es Lfu009Dokumen4 halamanEs Lfu009WattsBelum ada peringkat

- Bulletin 1301Dokumen8 halamanBulletin 1301Syed Haris Bin AkhterBelum ada peringkat

- Catalog Keystone Butterfly ValveDokumen4 halamanCatalog Keystone Butterfly ValvePawrij Suriyaaroonroj100% (2)

- Series 825YD Specification SheetDokumen2 halamanSeries 825YD Specification SheetFEBCOBelum ada peringkat

- Butterfly Valve, Grooved End, Globe, Model GLR300GDokumen9 halamanButterfly Valve, Grooved End, Globe, Model GLR300Grahu2260Belum ada peringkat

- Electro Válvula Del CompresorDokumen4 halamanElectro Válvula Del CompresorneumaticoBelum ada peringkat

- RUELCO - Diff Pressure SwitchDokumen2 halamanRUELCO - Diff Pressure SwitchAiman Hilmi Aiman HilmiBelum ada peringkat

- Air Eliminators 13WS WHS-Technical InformationDokumen2 halamanAir Eliminators 13WS WHS-Technical Informationsugandaraj522Belum ada peringkat

- E 50B 4KG1 - Fire PDFDokumen2 halamanE 50B 4KG1 - Fire PDFdocrafiBelum ada peringkat

- Series 909 Specification SheetDokumen4 halamanSeries 909 Specification SheetWattsBelum ada peringkat

- Series 806YD Specification SheetDokumen2 halamanSeries 806YD Specification SheetFEBCOBelum ada peringkat

- 14 400E 6DC Final Valvula BermadDokumen4 halaman14 400E 6DC Final Valvula Bermadmax_powerBelum ada peringkat

- Tyco Alarm ValveDokumen22 halamanTyco Alarm ValveMohammed BaquarBelum ada peringkat

- Mustang Series M114-2 or M6114-2 (Globe), M1114-2 or M61114-2 (Angle) Installation InstructionsDokumen2 halamanMustang Series M114-2 or M6114-2 (Globe), M1114-2 or M61114-2 (Angle) Installation InstructionsWattsBelum ada peringkat

- Es WD TD 300 UsaDokumen1 halamanEs WD TD 300 UsaWattsBelum ada peringkat

- Es WQ PWSRDokumen2 halamanEs WQ PWSRWattsBelum ada peringkat

- Es WD Li 12 LT UsaDokumen1 halamanEs WD Li 12 LT UsaWattsBelum ada peringkat

- Es OfpsysDokumen2 halamanEs OfpsysWattsBelum ada peringkat

- Es WQ PwfgacDokumen2 halamanEs WQ PwfgacWattsBelum ada peringkat

- Es WQ PwfcalDokumen2 halamanEs WQ PwfcalWattsBelum ada peringkat

- Es Oftwh CDokumen2 halamanEs Oftwh CWattsBelum ada peringkat

- Series 97FB-FSFE Specification SheetDokumen2 halamanSeries 97FB-FSFE Specification SheetWattsBelum ada peringkat

- Series LFFHB Specification SheetDokumen2 halamanSeries LFFHB Specification SheetWattsBelum ada peringkat

- Es FHBDokumen1 halamanEs FHBWattsBelum ada peringkat

- Es WQ PwsrtaDokumen2 halamanEs WQ PwsrtaWattsBelum ada peringkat

- Es WQ PWFMZDokumen2 halamanEs WQ PWFMZWattsBelum ada peringkat

- ES PW SmartStream ADokumen4 halamanES PW SmartStream AWattsBelum ada peringkat

- Is WD DLSZ InstallationDokumen1 halamanIs WD DLSZ InstallationWattsBelum ada peringkat

- Es BD1156FDokumen2 halamanEs BD1156FWattsBelum ada peringkat

- Es WD Hy 800 CanDokumen1 halamanEs WD Hy 800 CanWattsBelum ada peringkat

- Es 757isrDokumen2 halamanEs 757isrWattsBelum ada peringkat

- Is WD DLSZ InstallationDokumen1 halamanIs WD DLSZ InstallationWattsBelum ada peringkat

- Es Lfemvii 6400SSDokumen4 halamanEs Lfemvii 6400SSWattsBelum ada peringkat

- Es 957isrDokumen2 halamanEs 957isrWattsBelum ada peringkat

- Es Lf474aDokumen2 halamanEs Lf474aWattsBelum ada peringkat

- Es BD911Dokumen2 halamanEs BD911WattsBelum ada peringkat

- Es Lf474aDokumen2 halamanEs Lf474aWattsBelum ada peringkat

- ES WD DeadLevel S USADokumen1 halamanES WD DeadLevel S USAWattsBelum ada peringkat

- Es-Of1465tm 1665TMDokumen3 halamanEs-Of1465tm 1665TMWattsBelum ada peringkat

- ES WD DeadLevel Z USADokumen1 halamanES WD DeadLevel Z USAWattsBelum ada peringkat

- Basic Construction Operation Troubleshooting: WarningDokumen2 halamanBasic Construction Operation Troubleshooting: WarningWattsBelum ada peringkat

- Es WD FD 930 UsaDokumen1 halamanEs WD FD 930 UsaWattsBelum ada peringkat

- Es LFRC105Dokumen2 halamanEs LFRC105WattsBelum ada peringkat

- Es LFMMV HTKDokumen2 halamanEs LFMMV HTKWattsBelum ada peringkat

- CMS Cables AceleracionDokumen20 halamanCMS Cables AceleracionMarcel BaqueBelum ada peringkat

- Advantest U3741-U3751Dokumen16 halamanAdvantest U3741-U3751Nur HalimBelum ada peringkat

- HD44780 LCD Datasheet ExplainedDokumen1 halamanHD44780 LCD Datasheet ExplainedAnkit Daftery100% (4)

- M 7Dokumen41 halamanM 7gbenga0% (1)

- Software Developer or Software Engineer or Computer Programmer oDokumen3 halamanSoftware Developer or Software Engineer or Computer Programmer oapi-77545596Belum ada peringkat

- APOS: - Dell Shiping Date To After 1 Year Price.: Model NPOS Upsell Service Description PriceDokumen1 halamanAPOS: - Dell Shiping Date To After 1 Year Price.: Model NPOS Upsell Service Description PriceGhugguBelum ada peringkat

- Bajaj Parts ListDokumen411 halamanBajaj Parts ListKundan Modi0% (2)

- 2nd Sem - Module G11 (CSS)Dokumen40 halaman2nd Sem - Module G11 (CSS)Daniel Daryl CalingBelum ada peringkat

- Datasheet PDFDokumen2 halamanDatasheet PDFJosemiguel TavarezBelum ada peringkat

- Solid Works 2006 FundamentalsDokumen50 halamanSolid Works 2006 FundamentalsDennis Li100% (2)

- STM32Journal DSPC PDFDokumen9 halamanSTM32Journal DSPC PDFNguyen Ho LongBelum ada peringkat

- Mc9500 Configurations Accessories GuideDokumen21 halamanMc9500 Configurations Accessories GuidejorgokuBelum ada peringkat

- Bitmaps and BitbltsDokumen12 halamanBitmaps and BitbltsPrashant BajpaiBelum ada peringkat

- E-Disha: Project ObjectivesDokumen9 halamanE-Disha: Project Objectivessidd1066Belum ada peringkat

- IC PackagesDokumen17 halamanIC PackagesS.V.SubrahmanyamBelum ada peringkat

- Chapter 1 Calc Sinlge MultiDokumen444 halamanChapter 1 Calc Sinlge Multiwhy2k6Belum ada peringkat

- R2RDokumen2 halamanR2RGabriel PerazaBelum ada peringkat

- OBI9000E Installation Sheet WEBDokumen2 halamanOBI9000E Installation Sheet WEBrene chapdelaineBelum ada peringkat

- Trendnet: 8-Port Stackable Rack Mount KVM Switch With OsdDokumen2 halamanTrendnet: 8-Port Stackable Rack Mount KVM Switch With OsdAlmir HoraBelum ada peringkat

- SmartOffice PS396Dokumen2 halamanSmartOffice PS396Dipa Nusantara ArthaBelum ada peringkat

- Gecko G320 WiringDokumen1 halamanGecko G320 WiringjahiponuBelum ada peringkat

- Professional PMV A250 MonitorDokumen34 halamanProfessional PMV A250 MonitorAlfonso CalderonBelum ada peringkat

- 1st Monthly - Computer 2Dokumen7 halaman1st Monthly - Computer 2Mye BeltranBelum ada peringkat

- Deepak KumarDokumen3 halamanDeepak KumarDeepa YadavBelum ada peringkat

- Network DevicesDokumen8 halamanNetwork DevicesrevathiBelum ada peringkat

- It Workshop Lab ManualDokumen85 halamanIt Workshop Lab Manualbalajiyadav0456Belum ada peringkat

- Week 1 Question - Operating SystemDokumen1 halamanWeek 1 Question - Operating SystemSt. Joseph's Technical Institute KisubiBelum ada peringkat