Analysis and Design of Billboards PDF

Diunggah oleh

Anonymous 6yl2tnnJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Analysis and Design of Billboards PDF

Diunggah oleh

Anonymous 6yl2tnnHak Cipta:

Format Tersedia

National Conference on Recent Trends in Engineering & Technology

Comparative study of supporting system of elevated

Billboard with multi post back to back having

different configuration

K. A. Parmar M. G. Vanza

Applied Mechanics Department

Applied Mechanics Department ,

L.D. College of Engineering, Navarangpura

L.D. College of Engineering, Navarangpura,

Ahmedabad, Gujarat , INDIA

Ahmedabad, Gujarat , INDIA

mgvanza@yahoo.co.in

Kaparmar.19@gmail.com

Abstract— This paper includes four different types of supporting

system of billboard having multi post back to back with different II. LOADS AND LOADS COMBINATIONS

configuration for better selection and finally it compares Following loads are considered for analysis of supporting

deflection and cost of the system. The height of structure is taken

system.

16.75 m and Ahmedabad city is considered as location for

comparative study. Analysis and Design of supporting system is 1) Dead load

as per STAAD Pro. Which follows IS 800-2007. 2) Wind load in +z direction

3) Wind load in - z direction

Keywords: Hoarding, Billboard, Supporting system Following loading combinations are considered for analysis.

1) 1.5 D.L. + 1.5 W.L

2) 1.5 D.L. - 1.5 W.L

I. INTRODUCTION A. Wind Load Calculation:-

Billboard is located at Ahmedabad

Billboard is the common term used to describe a type of

Wind load is calculated as per IS 875(part-3)-1987

outdoor advertising found along major highways.

External pressure coefficient Cf is considered as per IS 875,

Any structure, device, light or natural object which shall be part-3,Sec.6.3.2.3

used to identify, advertise or attract attention to any object, Wind force acting on billboard (F) is 0.8156 kN/m2 as per IS

product, place, person, institution, organization, which shall 875, part-3, Sec.6.3.

display or include any letter, work, model, number, banner, Wind load is generated only on billboard surface.

and which is intended to be seen from off the premises or from

a parking lot is known as BILLBOARD. III. ANALYSIS AND DESIGN USING STAAD Pro

Main Components:- A. Billboard with Multi post back to back with horizontal

Large billboards have three main components: connector:-

1) Steel used to construct and support the frame,

2) Artwork that conveys the advertising message, and

3) Electrical equipment for lighting and other special effects.

Standard sizes for a large steel frame assembly are 6.1m x

18.3 m, 6.1 x 14.6 m or 3 x 11 m

General Consideration:-

Size of billboard is 6.1 m x 12.2 m

All supports are fixed and joints are rigid

Foundation is 1.5 m below from ground base.

Effective length of the member is taken as per IS

800-2007 by STAAD Pro.

Billboard is made up of 2 mm thick steel plate.

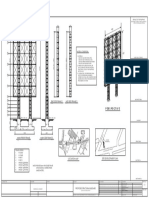

Fig. 1 Multi post back to back with horizontal connector

13-14 May 2011 B.V.M. Engineering College, V.V.Nagar,Gujarat,India

National Conference on Recent Trends in Engineering & Technology

Member Property :-

Fig. 2 Member parallel to axis X,Y,Z Fig. 3 Maximum displacement points

Members parallel to Y axis :- Built up member

having size 65 x 45 x 8 with 80 mm spacing between each B. Billboard with Multi post back to back with additional

angle is selected as vertical members (Members parallel to inclined members along with horizontal connector

Y)as shown if fig.2.

Members parallel to X axis: - Single angle 90 x 90 x

8mm is used as members parallel to X axis.

Members parallel to Z axis: - Double angle having

size 200 x 100 x 12 mm with longer leg connected back to

back with 12 mm gusset plate is selected as members parallel

to z axis from bottom to the base of billboard. Above billboard

level, angles having size 125 x 95 x 12 mm with longer leg

connected back to back with 12 mm gusset plate are used.

Steel Take-off: Following table-I shows the total weight of

steel taken for supporting system.

TABLE-I

STEEL TAKE-OFF FOR BILLBOARD WITH HORIZONTAL

CONNECTOR

PROFILE LENGTH WEIGHT

(METER) (KN )

6545880 167.50 42.050

ISA 90X90X8 73.20 7.754

2 ISA 200X100X12 22.50 11.957

2 ISA 125X95X12 15.00 5.757

Fig. 4 Multi post with additional inclined members along with horizontal

TOTAL WEIGHT = 67.519 KN connector

Nodal Displacement: - Maximum displacement nodes are

shown in fig.3 and it is due to combined effect of dead load Member Properties :

and wind load. Vertical members (Members parallel to Y):- Built up

Maximum displacement is 80.189 mm. member having size 65 x 45 x 8 with 80 mm spacing between

each angle is selected as vertical members.

13-14 May 2011 B.V.M. Engineering College, V.V.Nagar,Gujarat,India

National Conference on Recent Trends in Engineering & Technology

Members parallel to x axis: - Single angle having size Member Properties :

90 x 90 x 8 mm is used as horizontal members. Vertical members (Members parallel to Y):- Built up

Members parallel to z axis: - Double angle having member having size 90 x 60x 8 with 150 mm spacing between

size 200 x 150 x 12 mm with longer leg connected back to each angle is selected as vertical members.

back with 12 mm gusset plate is selected as members parallel Members parallel to x axis: - Single angle having size

to z axis at 3.05 m from ground level. Above 3.05 m from 90 x 90 x 8 mm is used as horizontal members.

ground level, angles are 70 x 45 x 8 mm with longer leg Inclined members: - Single angle 130 x 130x 8 mm is

connected back to back with 12 mm gusset plate. used as inclined members as shown in fig.5

Inclined members: - Single angle 100 x 100x 8 mm is

used as inclined members. Steel Take-Off: Following table-III shows the total weight

of steel taken for supporting system.

Steel Take-Off: Following table-II shows the total weight

of steel taken for supporting system. TABLE III

STEEL TAKE-OFF FOR BILLBOARD WITH INCLINED MEMBERS

TABLE-II ALONG WITH HORIZONTAL CONNECTOR

STEEL TAKE-OFF FOR BILLBOARD WITH INCLINED MEMBERS PROFILE LENGTH WEIGHT

ALONG WITH HORIZONTAL CONNECTOR (METER) (KN )

PROFILE LENGTH WEIGHT 90608150 167.5 58.52

(METER) (KN ) SA 90X90X8 36.6 3.877

6545880 167.50 42.050 ISA 130X130X8 67.98 10.556

ISA 90X 90 X 8 73.20 7.754 TOTAL WEIGHT 72.956

2 ISA 200 X 150 X 12 7.50 4.674

ISA 100 X 100 X 8 50.98 6.028 3) Nodal Displacement: - Maximum nodal displacement

2 ISA 70 X 45 X 8 30.00 3.955 nodes are shown in fig.3 and it is 106.318 mm.

TOTAL WEIGHT = 64.461 KN

D. Billboard with Multi post back to back with only

inclined members in three row:-

Nodal Displacement: - Maximum nodal displacement is at

top centre node as shown in fig.3 and it is 62.471 mm.

C. Billboard with Multi post back to back with only

inclined members in two row:-

Fig. 6 Multi post with only inclined members in three row

Member Properties :

Vertical members (Members parallel to Y):- Built up

member having size 90 x 60x 8 with 100 mm spacing between

each angle is selected as vertical members.

Members parallel to x axis: - Single angle having size

90 x 90 x 8 mm is used as horizontal members.

Fig. 5 Multi post with only inclined members in two rows Inclined members: - Single angle 110 x 110x 8 mm is

used for first two rows from top of billboard and single angle

130 x 130 x 8 mm is used for bottom row as shown in fig.6

Steel Take-Off: Following table-4 shows the total weight

of steel taken for supporting system.

13-14 May 2011 B.V.M. Engineering College, V.V.Nagar,Gujarat,India

National Conference on Recent Trends in Engineering & Technology

TABLE-IV

STEEL TAKE-OFF FOR BILLBOARD WITH INCLINED MEMBERS IN

THREE ROWS

PROFILE LENGTH WEIGHT

(METER) (KN )

90608100 167.50 58.520

ISA 90X 90 X 8 36.6 3.877

ISA 110X110X8 67.98 8.888

ISA 130X130X8 33.99 5.279

TOTAL WEIGHT 76.565

Nodal Displacement: - Maximum nodal displacement

nodes are shown in fig.3 and it is 72.70 mm.

Note: - Design of members are optimized using optimization .

From the results of above all four cases a suggestion for the

configuration of supporting system for the considered size of

billboard is that the supporting system with horizontal

connector along with inclined member (as in Case B) shows

better performance against wind load resistance and

displacement and it is economical compared to other

considered supporting system .

REFERENCES

[1] IS: 800-2007 , General construction in steel – code of practice,

Bureau of Indian Standards.

[2] IS: 875 (part-3) – 1987 Code of practice for design loads (other than

earthquake) for buildings and structures of Practice, Bureau of Indian

Standards.

[3] An Explanatory handbook on IS: 875 (part-3) – 1987 wind loads on

buildings and structures by Indian Institute of Technology Roorkee

13-14 May 2011 B.V.M. Engineering College, V.V.Nagar,Gujarat,India

Anda mungkin juga menyukai

- Bill Board CalculationsDokumen3 halamanBill Board CalculationsYaarpunjabi Jatt100% (1)

- BillboardDokumen3 halamanBillboardRob MercadoBelum ada peringkat

- Billboard PDFDokumen3 halamanBillboard PDFnouman100% (1)

- BillboardDokumen1 halamanBillboardBen OfwonoBelum ada peringkat

- NSCP 1992 PDFDokumen70 halamanNSCP 1992 PDFanon_181338447100% (1)

- Steel Frame Structure Analysis and Design by Staad-Pro (Example - 4) by Prof. Dr. Nabeel Al-BayatiDokumen3 halamanSteel Frame Structure Analysis and Design by Staad-Pro (Example - 4) by Prof. Dr. Nabeel Al-BayatiProfessor Dr. Nabeel Al-Bayati-Consultant Engineer100% (2)

- 12mx18mx24m High Commonwealth Billboard Page1Dokumen1 halaman12mx18mx24m High Commonwealth Billboard Page1Jorge Lacanilao0% (1)

- StructDesign (GFSST - LRFD - TIA222G) 3GT-40-330C-Z-340DDokumen55 halamanStructDesign (GFSST - LRFD - TIA222G) 3GT-40-330C-Z-340DMIHDI PALAPUZBelum ada peringkat

- Design of PurlinDokumen24 halamanDesign of PurlinD SRINIVAS67% (3)

- Structural ModelingDokumen21 halamanStructural ModelingWilbert ReuyanBelum ada peringkat

- Industrial Building, Design of Steel Structure Part 2, Types of LoadsDokumen36 halamanIndustrial Building, Design of Steel Structure Part 2, Types of LoadsRaju Sharma100% (3)

- ASEP NSCP SECTION 207 WIND LOADS Part 1 PDFDokumen38 halamanASEP NSCP SECTION 207 WIND LOADS Part 1 PDFJyrus Jyles CadienteBelum ada peringkat

- Drssd07 - Wind On Billboard Frame Struct - CbeDokumen23 halamanDrssd07 - Wind On Billboard Frame Struct - CbeNikki Abinoja Sumer100% (1)

- PRELIMINARY SIZING of ConcreteDokumen12 halamanPRELIMINARY SIZING of ConcreteWilbert Reuyan100% (2)

- Design of Two Way SlabDokumen180 halamanDesign of Two Way SlabGino Paolo ObsiomaBelum ada peringkat

- Design Live Loads For Passenger Cars Parking Garages With RAMPDokumen10 halamanDesign Live Loads For Passenger Cars Parking Garages With RAMPTharach JanesuapasaereeBelum ada peringkat

- Monoslope Wind NSCPDokumen8 halamanMonoslope Wind NSCPNicole100% (1)

- Billboard DesignDokumen1 halamanBillboard DesignMark Kenneth P. OntejoBelum ada peringkat

- General Notes: Concrete Notes: Abbreviations: Reinforcement Clearance DetailDokumen53 halamanGeneral Notes: Concrete Notes: Abbreviations: Reinforcement Clearance DetailbetojulioBelum ada peringkat

- Design of Column FootingDokumen14 halamanDesign of Column Footingdash1991Belum ada peringkat

- Roof Truss Sample Manual CalculationDokumen6 halamanRoof Truss Sample Manual Calculationmichellem329100% (1)

- Structural Analysis of Three Storey Commercial BuildingDokumen184 halamanStructural Analysis of Three Storey Commercial Buildingjossan doplaynaBelum ada peringkat

- Structural AnalysisDokumen51 halamanStructural AnalysisStephen A. CuizonBelum ada peringkat

- Strap Footing DesignDokumen16 halamanStrap Footing DesignWaqar Ahmed75% (4)

- Staad Stiffness and Stability Waring by Saroj BiswasDokumen10 halamanStaad Stiffness and Stability Waring by Saroj BiswasSAROJ BISWAS50% (2)

- Seismic Loads Horizontal Distribution & Torsion PDFDokumen7 halamanSeismic Loads Horizontal Distribution & Torsion PDFeplim60100% (2)

- Steel PurlinsDokumen1 halamanSteel PurlinsLaw Molina100% (1)

- Calculation of Loads For Column and Foundation DesignDokumen2 halamanCalculation of Loads For Column and Foundation DesignMandar Nadgaundi100% (1)

- Structural Analysis & Design Report - GutterDokumen10 halamanStructural Analysis & Design Report - GutterAie BantuganBelum ada peringkat

- Billboard Design Proposals3Dokumen4 halamanBillboard Design Proposals3mainakaBelum ada peringkat

- Design of Footing For Corner ColumnDokumen4 halamanDesign of Footing For Corner Columnilachezhiyan82% (11)

- Design of Steel StructureDokumen16 halamanDesign of Steel Structuresuraj kumarBelum ada peringkat

- How To Remove UBC-IBC Warning From STAAD AnalysisDokumen1 halamanHow To Remove UBC-IBC Warning From STAAD Analysisbhagat v dBelum ada peringkat

- Estimation of Wind Load in A 3-Storey Standard School BuildingDokumen24 halamanEstimation of Wind Load in A 3-Storey Standard School BuildingRbcabajes Butalon100% (1)

- Sign Board Frame Design For Offshore AreaDokumen14 halamanSign Board Frame Design For Offshore Areagery_Belum ada peringkat

- Windload Analysis For PoleDokumen6 halamanWindload Analysis For PoleJayBelum ada peringkat

- Solved Examples Based On Draft IS875pt.3-1st EdDokumen85 halamanSolved Examples Based On Draft IS875pt.3-1st Edpandian100% (1)

- An Example Problem On Wind Load Calculation According To NSCP 2010Dokumen32 halamanAn Example Problem On Wind Load Calculation According To NSCP 2010Melvin Esguerra89% (9)

- Design of Single R.C. Beams by Engr. Ben DavidDokumen14 halamanDesign of Single R.C. Beams by Engr. Ben DavidElijah Aramburo100% (1)

- Calculation Note (Rev0)Dokumen17 halamanCalculation Note (Rev0)metoo21588% (8)

- A New AISI Cold-Formed Steel Design ManualDokumen7 halamanA New AISI Cold-Formed Steel Design ManualAkshay V PatilBelum ada peringkat

- Design BDR For Load PebDokumen4 halamanDesign BDR For Load Pebknight1729Belum ada peringkat

- Design of Concrete PadDokumen3 halamanDesign of Concrete PadBeveh G SupSupBelum ada peringkat

- Asep NSCP Vol 3 - Housing DraftDokumen8 halamanAsep NSCP Vol 3 - Housing DraftKaterina PetrovaBelum ada peringkat

- Structural CalculationsDokumen46 halamanStructural CalculationsEsca FlowneBelum ada peringkat

- Pp03 - Asep - NSCP 2015 Update On Ch3 Earthworks and ExcavationsDokumen27 halamanPp03 - Asep - NSCP 2015 Update On Ch3 Earthworks and ExcavationsCarlo Joseph100% (2)

- Specifications: Design of Sag RodDokumen2 halamanSpecifications: Design of Sag RodAbby De pedroBelum ada peringkat

- STAAD 2.17.8 Design ParametersDokumen3 halamanSTAAD 2.17.8 Design ParametersFWICIPBelum ada peringkat

- Eccentric Load On Column Footing PDFDokumen11 halamanEccentric Load On Column Footing PDFReffisa JiruBelum ada peringkat

- STAAD (X) Tower TutorialsDokumen54 halamanSTAAD (X) Tower TutorialsAndreea Luca100% (2)

- Comparative Study of Supporting System of Elevated Ground Based BillboardsDokumen3 halamanComparative Study of Supporting System of Elevated Ground Based BillboardsMayank SinghBelum ada peringkat

- Comparative Study of Supporting System of Elevated Billboard (Hoarding) Structures Having Different ConfigurationDokumen5 halamanComparative Study of Supporting System of Elevated Billboard (Hoarding) Structures Having Different ConfigurationBhavin JoshiBelum ada peringkat

- Varying Angle Diagrid Structural SystemDokumen3 halamanVarying Angle Diagrid Structural SystemJatinTank0% (1)

- Irjet V2i3314 PDFDokumen8 halamanIrjet V2i3314 PDFVictor PeterBelum ada peringkat

- Transmission MonopoleDokumen71 halamanTransmission Monopolepavithra2796% (23)

- Transmission Monopole PDFDokumen71 halamanTransmission Monopole PDFHariprasad gantyala100% (3)

- SSRN Id3376351Dokumen6 halamanSSRN Id3376351Hema Chandra Reddy KarimireddyBelum ada peringkat

- Modelling and Stress Analysis of Column Bracket For Rotary Jib CraneDokumen10 halamanModelling and Stress Analysis of Column Bracket For Rotary Jib CraneFitra VertikalBelum ada peringkat

- Design and Standardization of Base Frame & Ant Vibration Mounts For Balanced Opposed Piston Air CompressorDokumen8 halamanDesign and Standardization of Base Frame & Ant Vibration Mounts For Balanced Opposed Piston Air CompressorilyaskureshiBelum ada peringkat

- FEM With Analytical Approach Based Wind and Seismic Design Recommendations For Vertical Tall Process ColumnDokumen9 halamanFEM With Analytical Approach Based Wind and Seismic Design Recommendations For Vertical Tall Process ColumnSASWAT MISHRABelum ada peringkat

- Grad Form 9Dokumen12 halamanGrad Form 9Anonymous 6yl2tnnBelum ada peringkat

- Gas Laws QuizDokumen2 halamanGas Laws QuizAnonymous 6yl2tnnBelum ada peringkat

- CURRICULUM VITAE TemplateDokumen2 halamanCURRICULUM VITAE TemplateAnonymous 6yl2tnnBelum ada peringkat

- Research Title: Gathering and Preparation of MaterialsDokumen4 halamanResearch Title: Gathering and Preparation of MaterialsAnonymous 6yl2tnnBelum ada peringkat

- 1509 04333v2 PDFDokumen88 halaman1509 04333v2 PDFMaryam OmolaraBelum ada peringkat

- Kinetic Molecular Theory of Gases PDFDokumen2 halamanKinetic Molecular Theory of Gases PDFAnonymous 6yl2tnnBelum ada peringkat

- Research Title: Gathering and Preparation of MaterialsDokumen4 halamanResearch Title: Gathering and Preparation of MaterialsAnonymous 6yl2tnnBelum ada peringkat

- Nysyh R.-N. Kelley SF-181 Fax To OMB 1-202-395-3888Dokumen12 halamanNysyh R.-N. Kelley SF-181 Fax To OMB 1-202-395-3888Will KelleyBelum ada peringkat

- CurriculamVitae Vishal ShahDokumen4 halamanCurriculamVitae Vishal ShahAndy PatelBelum ada peringkat

- GMRC AdvertisementDokumen11 halamanGMRC AdvertisementSHAH VIRALBelum ada peringkat

- BCG Hybrid Work Is The New Remote Work Sep 2020Dokumen8 halamanBCG Hybrid Work Is The New Remote Work Sep 2020khanhphamngoc1716Belum ada peringkat

- Examination Reform Policy: November 2018Dokumen56 halamanExamination Reform Policy: November 20182arunagiriBelum ada peringkat

- DIY Time & Attendance Recorder: FeaturesDokumen1 halamanDIY Time & Attendance Recorder: FeaturesVasko diBelum ada peringkat

- Might and Magic IX Prima Official EGuideDokumen257 halamanMight and Magic IX Prima Official EGuideChromeTeeBelum ada peringkat

- Hirarc Form: Chemsain Chemsain Basement Car ParkDokumen6 halamanHirarc Form: Chemsain Chemsain Basement Car Parkpro fps116Belum ada peringkat

- Mathan Internship ReportDokumen21 halamanMathan Internship ReportdeepanchackBelum ada peringkat

- CR Fire Extinguishers Catalogue Local 2019Dokumen20 halamanCR Fire Extinguishers Catalogue Local 2019Moch RioBelum ada peringkat

- PHD Dissertation University of PretoriaDokumen7 halamanPHD Dissertation University of PretoriaBuyAPaperForCollegeElgin100% (1)

- Ticket - MR MHD Anas AlmerstaniDokumen2 halamanTicket - MR MHD Anas AlmerstaniNILSON RANGELBelum ada peringkat

- Updating Bank Details For Shared Vendors in SAPDokumen5 halamanUpdating Bank Details For Shared Vendors in SAPnasuuBelum ada peringkat

- ButterWorth Filter (3 Pole Design)Dokumen14 halamanButterWorth Filter (3 Pole Design)NelsonLucioRodriguezPenagosBelum ada peringkat

- Annex 2 - 1c-Decision Chart For Det. of Req.Dokumen4 halamanAnnex 2 - 1c-Decision Chart For Det. of Req.Arly TolentinoBelum ada peringkat

- Llamas, Joshua C. - m2 At2Dokumen8 halamanLlamas, Joshua C. - m2 At2Joshua Joseph LlamasBelum ada peringkat

- Database Programming With PL/SQL 8-3: Practice Activities: Passing ParametersDokumen2 halamanDatabase Programming With PL/SQL 8-3: Practice Activities: Passing ParametersAlan V.B.Belum ada peringkat

- Fresher ECE Resume Model 213Dokumen3 halamanFresher ECE Resume Model 213shanky_cs82% (17)

- Classes and Objects Part 1Dokumen9 halamanClasses and Objects Part 1Sadiq AhmadBelum ada peringkat

- Subject: English Class: Ii: 1) My English Reader 2) Practice Book 1 Evaluation (April To August)Dokumen34 halamanSubject: English Class: Ii: 1) My English Reader 2) Practice Book 1 Evaluation (April To August)Itismita PriyadarshiBelum ada peringkat

- Direct Memory Access: Direct Memory Access (DMA) Is A Process in Which An External Device TakesDokumen21 halamanDirect Memory Access: Direct Memory Access (DMA) Is A Process in Which An External Device TakesAkheel AhmedBelum ada peringkat

- Standard Ib Clutch: Twin Disc Power Take-OffsDokumen2 halamanStandard Ib Clutch: Twin Disc Power Take-OffsLeonardo Jiménez CastellanosBelum ada peringkat

- DetailedReport Automation Anywhere Enterprise 2 Jul 2020 VeracodeDokumen118 halamanDetailedReport Automation Anywhere Enterprise 2 Jul 2020 Veracodetg82770Belum ada peringkat

- HP c6280 Users ManualDokumen35 halamanHP c6280 Users Manualzyxwv6Belum ada peringkat

- Module 12Dokumen18 halamanModule 12Zakurieh NeriBelum ada peringkat

- Doxing The Complete GuideDokumen9 halamanDoxing The Complete GuideAbdullateef IbraheemBelum ada peringkat

- Bomba - Weir - Curvas Warman Horizontais-Versão MetálicaDokumen18 halamanBomba - Weir - Curvas Warman Horizontais-Versão MetálicaWanderson Alcantara100% (1)

- QR Code Attendance SystemDokumen6 halamanQR Code Attendance Systemjenny adlaoBelum ada peringkat

- Q3 Tos English 8Dokumen1 halamanQ3 Tos English 8gayle badorayaBelum ada peringkat

- D-155 - 3 Cylinder Diesel Engine (01/75 - 12/85) 00 - Complete Machine 14-02 - Manifold, Intake-Naturally Aspirated EnginesDokumen3 halamanD-155 - 3 Cylinder Diesel Engine (01/75 - 12/85) 00 - Complete Machine 14-02 - Manifold, Intake-Naturally Aspirated EnginesMANUALESBelum ada peringkat