An Experimental Study On Strength Properties of Concrete Using Recycled Aggregate As Replacement in Coarse Aggregate

Diunggah oleh

momin sialJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

An Experimental Study On Strength Properties of Concrete Using Recycled Aggregate As Replacement in Coarse Aggregate

Diunggah oleh

momin sialHak Cipta:

Format Tersedia

International Journal for Research in Applied Science & Engineering Technology (IJRASET)

ISSN: 2321-9653; IC Value: 45.98; SJ Impact Factor : 6.887

Volume 6 Issue II, February 2018- Available at www.ijraset.com

An Experimental Study on Strength Properties of

Concrete using Recycled Aggregate as Replacement

in Coarse Aggregate

A. Naga Sai1, P.P.V. Kishore2

1

Asst.Professor, Department of Civil Engineering, Aditya college of Engineering & Technology, Suramaplem, Kakinada, A.P.,

India.

2

PG scholar, Department of Civil Engineering, Aditya College of Engineering & Technology, Suramaplem, Kakinada, A.P., India.

Abstract: It is very important and crucial time to conserve our natural resources mainly in constructions. Concrete is second

most consumable material after water compared to its volume. Concrete is mostly containing with aggregates. This report will try

to observe the mechanical properties and durability properties of concrete using Recycled Aggregate (RA) in concrete specimens

like cubes, cylinders and beams. So that Recycled Aggregate is taken in samples with respect to Natural Coarse Aggregate (NCA)

in percentage basis like 0%, 20%, 40%, 60%, 80% and 100% replacement. Initially preliminary tests like sieve analysis, specific

gravity, impact value and los angels abrasion test are performed on aggregates. And concrete strength is observed by conducting

mechanical properties of concrete like compressive strength test, split tensile strength test and flexural strength test. Durability

tests are conducted on concrete by treating recycled aggregate in acids like H2SO4 and HCL. Here Recycled Aggregate is

submerged in 0.1 mole of H2SO4 and HCL solutions for 24 hours and then cleaned the treated recycled aggregate with potable

tap water is to be used for performing the durability test. In this report, all the test specimens are prepared for M30 and M40

grade of concrete. After conducting the test it is observed and concluded that in preliminary tests, the grading zone of sand is

from ZONE-II and its fineness modulus is 2.79, the recycled course aggregate strength is observed in impact and abrasion

testing machines and the from the results it is concluded that in road constructions recycled course aggregate is used in all

courses except in the top wearing course. In all the mechanical properties it is observed that the replacement of recycled

aggregate strength is lesser than concrete with natural course aggregate but up to 40% replacement of recycled aggregate will

show better results and more than that will cause lesser strength and it may affect the design mix also. And in durability tests on

concrete using recycled aggregate treated with acids like H2SO4 and HCL will give better performance than untreated recycled

aggregate but aggregate treated with H2SO4 will give higher strength than aggregate treated with HCL. From the overall report

it is concluded that the use of recycled course aggregate up to 40% in natural course aggregate will not cause any serious

strength reduction. And based on this report it is a better recommendation for makig a code of practice on recycled aggregate

will be useful for future scope.

Keywords: Recycled Aggregate, Natural Aggregate, Recycled Aggregate treated with H2SO4, Recycled Aggregate treated with

HCL, compression strength, split tensile strength and flexural strength.

I. INTRODUCTION

Concrete is a construction material having the ingredients like cement, fine aggregate, coarse aggregate with water and some

admixtures if any, will gave strength and durability properties. Concrete is very useful construction material since 20th century

because of it is molding into any shape before setting.

About 70% to 75 % of volume is filled by coarse aggregate. We need to take care about naturally occurring coarse aggregate

because of lack of availability of coarse aggregate in some countries.

Aggregate separated from construction and demolition waste will contain hardened mortar around its surface is called it as Recycled

aggregate. The use of recycled aggregate will reduce the environmental losses and this type of re-usage will become an Eco-

friendly construction material. To reduce large quantity of waste material it is a better step to introduce recycled aggregate. The cost

of recycled aggregate concrete may be 20% to 30% less than natural aggregate concrete in some regions.

Recently Delhi Metro Rail Corporation (DMRC) takes a step to initiate towards environmental conservation and recycling of

construction waste scientifically. Delhi Metro Rail Corporation commissioned at Rohini for Recycling C & DW from construction

©IJRASET (UGC Approved Journal): All Rights are Reserved 665

International Journal for Research in Applied Science & Engineering Technology (IJRASET)

ISSN: 2321-9653; IC Value: 45.98; SJ Impact Factor : 6.887

Volume 6 Issue II, February 2018- Available at www.ijraset.com

works. This project report will try to use Recycled aggregate for constructions. And how the strength variations are obtained will be

studied.

A. Literature Review

Saravanakumar el.al (2012) studied the possibility of using recycled concrete aggregate from construction and demolition

waste(C&DW) and also studied the effect of admixed concrete using recycled aggregate on fresh and hardened stage. Author taken

four series of concrete mixes with natural aggregate and recycled aggregate in three kinds of age of demolition like five years, ten

years and fifteen years and are prepared for the experimental studies And are used with three different combinations like 0% Fly

Ash, 20% Fly Ash and 25% Fly Ash with super plasticizers. The concrete grade for all this mixes are M25 grade. Author observed

the maximum reduction at 15% was noticed in the case of compressive strength in all the age of Recycled Aggregate Concrete

(RAC) and it shall be acceptable in practice. And it is proved to be used with the help of super plasticizers (SP) and Fly Ash (FA) to

produce good quality of RAC for satisfying the strength requirements in concrete. The involvement of Super plasticizer with Fly

Ash shows a reduction of 5% only in strength compared with RAC. The addition of SP reduces W/C ratio. The addition of only FA

with concrete reduces the tensile strength in the range of 5 to 10% for the age of 5 to 15 years of Recycled Aggregate.

Vivian el al (2002) studied the pre-soaking approaches to clean the hardened mortar on the surface of Recycled Aggregate. The pre-

soaking approaches are done with HCL, H2SO4 and H3PO solutions for removing mortar on its surface of Recycled Aggregate.

Author observed from their experimental results, the water absorption of pre treated recycled aggregates significantly reduced

compared to untreated RA and the mechanical properties for RA concrete are improved. Alkalinities of RAC, chloride and sulphate

contents of RA have not been adversely affected. Author concluded finally that the pre-treating of RA is more effective method to

improve the quality of RA for higher grade utilization and it is usable for wider application of RA for construction purpose. Revathi

Purushothaman et al (2014) studied the strength characteristics and the performance of Recycled Aggregate Concrete with influence

of treatment methods. Author taken six series of concrete mixes and are prepared using Natural Aggregate, Recycled Aggregate,

Recycled aggregate treated with H2SO4 solution and RA treated with HCL solution. Sample of Recycled aggregate is obtained after

Scrubbing treatment, heating and Scrubbing treatment. The six series of concrete mixes are prepared for determining its physical

properties and mechanical properties of concrete. Using these all aggregates, the performance of Recycled Aggregate Concrete is

observed. Author concluded from the results the aggregate treated with H2SO4 and heating and scrubbing yield aggregate with

reduced water absorption and other desired properties of Natural Aggregate. The concrete made by treating aggregate are able to

improve the strength and performance characteristics with Natural Aggregate Concrete (NAC). Saravanakumar et al(2013) studied

the strength properties of High- Volume Fly Ash (FA) based concrete of M50 grade using Recycled Aggregate (RA) were studied.

The replacement of Natural Aggregate (NA) with RA is performed in different percentages like 25%, 50% and 100% to study the

effect of RAC on compressive strength and tensile strength characteristics. Also Author replaced the amount of cement with Fly

Ash in different proportions like 40%, 50% and 60% to study the effect of Fly ash on compressive strength and tensile strength of

concrete at an age of 28days. Only lesser percentage of reduction was observed to show the improvement. The reduction of

compressive strength is in the range from 20 % to 37% due to replacement of NA with RA from 25%to 100% at an age of 28 days.

B. Objectives of The Study

In this study, the objectives are initially conducting the preliminary tests for aggregates. Design mix is prepared from the

preliminary tests, and recycled aggregate is replaced in coarse aggregate like percentage basis in multiples of 20 from 0% to 100%.

In this study, the mechanical properties of Recycled Aggregate Concrete(RAC) such as compressive strength, split tensile strength

and Flexural strength is observed and durability of concrete using recycled aggregate treated with H2SO4 and HCL are performed

for M30 and M40 grade of concrete. For compressive strength of cubes samples are tested at an age of 7days and 28days and for

Split tensile strength and Flexural strength of concrete cylinders and beams are tested at an age of 28 days.

C. Experimental Investigation

1) Materials used

2) Cement: Ordinary Portland cement of 53 grade was used. The Cement used has been tested for various proportions as per ISIS

4031-1988 and found to be confirming to various specifications of 12269-1987.

3) Fine Aggregate: The material which passes through BIS test sieve number 4 (4.75mm) is termed as fine aggregate The sample

of fine aggregate is taken from Godavari River. After conducting tests like specific gravity, sieve analysis it could be found that

the fine aggregate is from Zone II and its Fineness modulus is around 2.79. It conforms to IS: 383 1970 comes under zone II.

©IJRASET (UGC Approved Journal): All Rights are Reserved 666

International Journal for Research in Applied Science & Engineering Technology (IJRASET)

ISSN: 2321-9653; IC Value: 45.98; SJ Impact Factor : 6.887

Volume 6 Issue II, February 2018- Available at www.ijraset.com

4) Coarse Aggregate: Coarse aggregate crushed angular granite metal of 12 mm, 20mm size was used.

D. Recycled Aggregate

For this experimental study, recycled aggregate is collected from different age group of structural destructions like 1year, 10 years

and 15 years. Sample of recycled aggregate is collected manually because of small quantity.

E. Acids

The collected recycled aggregate contains mortar all around. For durability considerations recycled aggregate is to be treated by

submerging in H2SO4 and HCL with 0.1 moles for 24 hrs. Then aggregate is used for concrete mix after washing in tap water. By

this treatment the surface mortar gets reduced in a certain amount. So that recycled aggregate concrete strength variations are to be

observed by comparing untreated recycled aggregate.

F. Water

Concrete mix requires potable water. It doesn’t contain salt so sea water is not allowed for concrete mixes. Unless until if places

having lack of fresh water and full of sea water and where structures are not considered the effect of dampness and efflorescence we

use sea water. Generally water user for construction having PH of 6.5 to 8.5 is the best range. For this project water is used from tap

drinking water is used in concrete mix.

©IJRASET (UGC Approved Journal): All Rights are Reserved 667

International Journal for Research in Applied Science & Engineering Technology (IJRASET)

ISSN: 2321-9653; IC Value: 45.98; SJ Impact Factor : 6.887

Volume 6 Issue II, February 2018- Available at www.ijraset.com

Table No-1 will show the physical properties of aggregates.

S.N Properties Values

o FA NCA RCA

1 Specific 2.63 2.644 2.545

gravity

2 Water - 1.515 6.93

absorption

3 Grading ZONE- - -

zone II

4 Fineness 2.79 - -

Modulus

5 Size and - 20mm, 20mm,

grading of Single Single

CA size size

6 Impact - 21.48% 30.20%

value

7 Abrasion - 16.6% 25.86%

value

Table No-1

II. EXPERIMENTAL PROGRAM:

A. Mix Designs

For concrete mix design based on the percentage replacement of RA in CA, twelve design mixes are prepared for M30 and M40

grade of concrete. Mix proportions were prepared as per IS-10262-2009. For this experimental program OPC 53 grade cement,

Natural fine aggregate from Godavari river, Coarse aggregate of size not More than 20mm, Recycled Aggregate from local

destructive structures are used. The experimental program is to observe the mechanical properties of concrete such as Compressive

strength, Split tensile strength and Flexural strength and also Durability of concrete using Recycled aggregate treated with H2SO4

and HCL solutions.

Table no-2 will show the mix proportions for 12 design mixes

Mix Concrete grade Cement FA CA Water

1 M30 0%RA 372 695 1143 186

2 M30 20%RA 372 695 1134 186

3 M30 40%RA 372 695 1125 186

4 M30 60%RA 372 695 1117 186

5 M30 80%RA 372 695 1109 186

6 M30 100%RA 372 695 1110 186

7 M40 0%RA 389 700 1169 175

8 M40 20%RA 389 700 1160 175

9 M40 40%RA 389 700 1151 175

10 M40 60%RA 389 700 1142 175

11 M40 80%RA 389 700 1134 175

12 M40 100%RA 389 700 1125 175

©IJRASET (UGC Approved Journal): All Rights are Reserved 668

International Journal for Research in Applied Science & Engineering Technology (IJRASET)

ISSN: 2321-9653; IC Value: 45.98; SJ Impact Factor : 6.887

Volume 6 Issue II, February 2018- Available at www.ijraset.com

B. Compressive Strength of Cubes

The results of compressive strength are mainly used to determine that the mixture of concrete as delivered on site to meet the

requirement of the requirement of the specified strength. The test is based on American Society for Testing Materials ASTM C31

standard practice of concrete.

Concrete compressive strength is carried on cubes and cylinders. For this project compressive strength is carried on cube of standard

size 150mm in compressive testing machine. In America compressive strength is performed on Cylinders. In fact compressive

strength of concrete cylinders maintains better accuracy than tested on concrete cubes. The ratio of compressive strength of cylinder

and cube is 0.85. In this project, for the 12 design mixes 48 cubes are tested in compressive testing machine at n age of 7days and

28days.

Compressive strength of concrete cubes using RA replaced at 0%,20%,40%,60%,80% and 100% in CA are tested for M30 and M40

grade. The test observations are represented in the following table no 3 & 4.

Table no3 will show the Compressive Strength of concrete cubes for M30 grade of concrete

S.NO Percentage of Compressive strength at Compressive strength at

RCA 7days,Mpa 28days,Mpa

1 0% 28.355 41.498

2 20% 27.745 40.844

3 40% 26.71 39.195

4 60% 23.725 35.685

5 80% 19.685 34.62

6 100% 20.04 29.911

Table No-3

©IJRASET (UGC Approved Journal): All Rights are Reserved 669

International Journal for Research in Applied Science & Engineering Technology (IJRASET)

ISSN: 2321-9653; IC Value: 45.98; SJ Impact Factor : 6.887

Volume 6 Issue II, February 2018- Available at www.ijraset.com

Table no 4 will show the Compressive Strength of concrete cubes for M40 grade of concrete

S.NO Percentage Compressive Compressive

of RCA strength at strength at

7days,Mpa 28days,Mpa

1 0% 33.325 49.24

2 20% 31.06 47.285

3 40% 29.91 43.685

4 60% 27.08 41.415

5 80% 25.06 38.353

6 100% 24.795 38.555

Table No-4

C. Split Tensile Strength of concrete Cylinders

Generally split tensile strength of concrete is 8 to 10 % more than direct tensile strength of concrete. This test is conducted on

cylinder having 150mm diameter and 300 mm height. The application of load on cylinder is done by compressive action on

periphery of cylinder in longitudinal direction. Concrete is very strong in compressive action and very week in carrying tensile

strength due to brittleness of concrete. Generally concrete tensile strength is 10 to 15 % of compressive strength of concrete. In this

experimental study 12 concrete cylinders are tested from 12 design mixes at an age of 28days. Split tensile strength of concrete

cylinders using RA replaced at 0%,20%,40%,60%,80% and 100% in CA are tested for M30 and M40 grade. The test observations

are represented in the following table no 5 & 6.

Table no 5 will show the Split tensile Strength of concrete cubes for M30 grade of concrete

S.NO Percentage of RCA Split tensile strength at

28days,Mpa

1 0% 1.97

2 20% 1.86

3 40% 1.67

4 60% 1.34

5 80% 1.02

6 100% 0.95

©IJRASET (UGC Approved Journal): All Rights are Reserved 670

International Journal for Research in Applied Science & Engineering Technology (IJRASET)

ISSN: 2321-9653; IC Value: 45.98; SJ Impact Factor : 6.887

Volume 6 Issue II, February 2018- Available at www.ijraset.com

Table no 6 will show the Split tensile Strength of concrete cubes for M40 grade of concrete

S.NO Percentage of Split tensile strength at

RCA 28days,Mpa

1 0% 2.709

2 20% 2.55

3 40% 2.389

4 60% 2.018

5 80% 1.89

6 100% 1.55

Table No - 6

D. Flexural Strength of concrete beam

Flexural strength of concrete is tested on concrete beams having their dimensions 0.1m x 0.1m x 0.5m. Third point load is applied

on beam using Flexural strength Testing Machine (FTM) for determining flexural strength of concrete. The loading value of ‘P’ is

increased from ‘0’ to value corresponding to which first crack developed at the bottom fiber. In this project, total 12 beams from 12

design mixes are tested at an age of 28 days. Two point loading system is performed to determine Flexural strength of concrete

beam. The following table no 7 & 8 will show the test results for Flexural strength.

Table no 7 will show the Flexural Strength of concrete beams for M30 grade of concrete

S.NO Percentage of RCA Flexural strength at

28days,Mpa

1 0% 5.1

2 20% 4.76

3 40% 4.82

4 60% 4.38

5 80% 3.88

6 100% 3.26

Table No- 7

©IJRASET (UGC Approved Journal): All Rights are Reserved 671

International Journal for Research in Applied Science & Engineering Technology (IJRASET)

ISSN: 2321-9653; IC Value: 45.98; SJ Impact Factor : 6.887

Volume 6 Issue II, February 2018- Available at www.ijraset.com

Table no 8 will show the Flexural Strength of concrete beams for M40 grade of concrete

S.NO Percentage of RCA Flexural strength at 28days,Mpa

1 0% 5.82

2 20% 5.56

3 40% 5.44

4 60% 5.18

5 80% 4.76

6 100% 4.5

Table No-8

III. DISCUSSIONS AND RESULTS

A. Compressive Strength Of Concrete Cubes

After completion of tests on concrete cubes, the graph between percentage replacement of RCA with NCA and compressive strength

will show that the strength variation up to 20% replacement of RCA is satisfactory and between 20% and 40% is reasonably

satisfactory but above 40% replacement of RCA till 100% will affect the strength of concrete cubes in a greater extent.

Graph No 1 will show the Compressive strength variation for M30 grade of concrete at 7days and 28days

compressive strength of cubes at 7th day

and 28th day test for M30

Compressive strength

50

40

30

20

10 7 days

0

28days

0% 50% 100% 150%

% replacement of RCA with in NCA

Graph No-1

©IJRASET (UGC Approved Journal): All Rights are Reserved 672

International Journal for Research in Applied Science & Engineering Technology (IJRASET)

ISSN: 2321-9653; IC Value: 45.98; SJ Impact Factor : 6.887

Volume 6 Issue II, February 2018- Available at www.ijraset.com

Graph No 2 will show the Compressive strength variation for M40 grade of concrete at 7days and 28days

compressive strength of cubes at 7th day

and 28th day test for M40

compressive strength

60

50

40

30

20 7 days

10 28days

0

0% 50% 100% 150%

% replacement of RCA with in NCA

Graph No 2

B. Split Tensile Strength Of Concrete

After the experimental results it is found from the graph that up to 30 % replacement of RCA will not affect the strength of concrete

after that the strength gets reduced in a greater extent.

Graph No 3 will show the Split tensile strength variation for M30 grade of concrete at 28days

split tensile strength test of cylinders at

28 days for M30

split tensile strength

3

2 28days

1

0

0% 50% 100% 150%

% replacement of RCA with in NCA

Graph No - 3

Graph No 4 will show the Split tensile strength variation for M40 grade of concrete at 28days

split tensile strength test of cylinders at

28 days for M40

split tensile strength

3

2.5

2

1.5

1 28days

0.5

0

0% 50% 100% 150%

% replacement of RCA with in NCA

Graph No – 4

©IJRASET (UGC Approved Journal): All Rights are Reserved 673

International Journal for Research in Applied Science & Engineering Technology (IJRASET)

ISSN: 2321-9653; IC Value: 45.98; SJ Impact Factor : 6.887

Volume 6 Issue II, February 2018- Available at www.ijraset.com

C. Flexural strength of concrete beams

In an overall observation, by using recycled aggregate in flexural strength, after completion of test results the graphs will show that

up to 40 % replacement of RCA there is no greater difference of their strength reduction. But from 40 % to 100% replacement of

RCA the strength variations are much reduced.

Graph No 5 will show the Flexural strength variation for M30 grade of concrete at 28days

flexural strength of beam at 28 days for

M30

flexural strength

6

5

4

3

2 28days

1

0

0% 50% 100% 150%

% replacement of RCA with in NCA

Graph No – 5

Graph No 6 will show the Flexural strength variation for M40 grade of concrete at 28days

flexural strength of beam at 28 days for

M40

8

flexural strength

6

4

2 28days

0

0% 50% 100% 150%

% replacement of RCA with in NCA

Graph No - 6

Graph No 7 will show the Durability variation of concrete using RA treated with H2SO4 for M30 grade of concrete at 7days and

28days

Durability of concrete cubes using

H2SO4 at 7 and 28 days for M30

50

compressive strength

40

30

20

7 days

10

0 28days

0% 50% 100% 150%

% replacement of RCA with in NCA

Graph No 8 will show the Durability variation of concrete using RA treated with H2SO4 for M40 grade at 7days and 28days

©IJRASET (UGC Approved Journal): All Rights are Reserved 674

International Journal for Research in Applied Science & Engineering Technology (IJRASET)

ISSN: 2321-9653; IC Value: 45.98; SJ Impact Factor : 6.887

Volume 6 Issue II, February 2018- Available at www.ijraset.com

Durability of concrete cubes using

H2SO4 at 7 and 28 days for M40

compressive strength

60

50

40

30

20 7 days

10 28days

0

0% 50% 100% 150%

% replacement of RCA with in NCA

Graph No – 8

Graph No 9 will show the Durability variation of concrete using RA treated with HCL for M30 grade at 7days and 28days

Durability of concrete cubes using HCL

at 7 and 28 days for M30

compressive strength

50

40

30

20 7 days

10 28days

0

0% 50% 100% 150%

% replacement of RCA with in NCA

Graph No – 9

Graph No 10 will show the Durability variation of concrete using RA treated with HCL for M40 grade at 7days and 28days

Durability of concrete cubes using HCL

at 7 and 28 days for M40

compressive strength

60

50

40

30

20 7 days

10 28days

0

0% 50% 100% 150%

% replacement of RCA with in NCA

Graph No - 10

©IJRASET (UGC Approved Journal): All Rights are Reserved 675

International Journal for Research in Applied Science & Engineering Technology (IJRASET)

ISSN: 2321-9653; IC Value: 45.98; SJ Impact Factor : 6.887

Volume 6 Issue II, February 2018- Available at www.ijraset.com

IV. CONCLUSIONS

From the tested results the following points are to be concluded. Hope this project report will be used for usage of recycled

aggregate as a construction material again. The conclusion is based on primary properties of aggregate and mechanical properties of

concrete and durability properties of concrete using acid treatment Recycled Aggregate.

A. Recycled course aggregate (RCA) is replaced with Natural course aggregate (NCA) in percentage basis like 0%, 20%, 40%,

60%, 80% and 100%. The test results will show that up to 20 to 40% replacement of RCA will give better results.

B. Durability of concrete cubes using RCA treated with H2SO4 will give more strength values than the durability of concrete

using RCA treated with HCL.

C. Compared to untreated recycled aggregate in concrete, the acid treated recycled aggregate using H2SO4 and HCL will give

better results but in actual practice the treatment process may increase the cost of the project so that the usage of recycled

aggregate in percentage replacement will be a better choice for economic criteria.

D. In mechanical properties of concrete like compressive strength, split tensile strength, flexural strength, the strength is gradually

reduced but it is lesser reduction up to 40% and grater reduction is observed in concrete by replacement of RCA more than

40%.

E. The attachment of mortar around the recycled aggregate will affect the specific gravity and water absorption. Therefore in

calculation of design mix care should be taken in water cement ratio.

F. Finally, it is concluded that the usage of recycled aggregate will a better choice for constructions. And the wastage of natural

resources is reduced in a little extent.

V. FUTURE SCOPE

A. From the results it is observed that by making a proper design mix and using proper percentage of recycled aggregate we can

gain the strength and also reducing the usage of natural course aggregate.

B. It can be possible to reduce the waste disposal by using recycled aggregate in construction again.

C. By preparing code of practice it will be encouraging for use of recycled aggregate in a greater extent.

REFERENCES

[1] Amnon Katz. 2004. “Treatments for the Improvement of Recycled Aggregate”. Journal of materials in civil engineering, 16(6), 597–603.

[2] D. K. Gandhi, A. Gudadhe., M. T. Ramteke., N. Thakur., C. R. Deshpande. 2014. “Environmental Sustainability by Use of Recycled Aggregates - An

Overview”, International Journal of Engineering Research and Applications, 4(5), 09-14.

[3] J.-Zh. Xiao·J.-B. Li·Ch. Zhang. 2006. “On relationships between the mechanical properties of recycled aggregate concrete: An overview”. Materials and

Structures, 39, 655–664.

[4] RevathiPurushothaman., Ramesh RuthirapathyAmirthavalli., Lavanya Karan. 2014. Influence of treatment methods on the strength and performance

characteristics of recycled aggregate concrete, Journal of Materials in Civil Engineering, DOI:10.1061/(ASCE)MT.19435533.0001128.

[5] Saravanakumar, P., Dhinakaran, G. 2014. Durability aspects of HVFA based Recycled Aggregate Concrete, Magazine of Concrete Research, 66(4), 186 – 195.

[6] Saravanakumar, P., Dhinakaran, G. 2013. Durability characteristics of recycled aggregate concrete, Structural Engineering and Mechanics, 47(5), 701 – 711.

[7] Shi-congKou., Chi-sun Poon., Francisco Agrela. 2011. Comparisons of natural and recycled aggregate concretes prepared with the addition of different mineral

admixture. Cement and Concrete Composites, 33, 788795.

©IJRASET (UGC Approved Journal): All Rights are Reserved 676

Anda mungkin juga menyukai

- Eco-efficient Rendering Mortars: Use of Recycled MaterialsDari EverandEco-efficient Rendering Mortars: Use of Recycled MaterialsBelum ada peringkat

- A Review On Recycled Aggregate Concrete Reinforced With FibersDokumen6 halamanA Review On Recycled Aggregate Concrete Reinforced With FibersIJRASETPublicationsBelum ada peringkat

- Techniques To Improve The Performance of Recycled Aggregate ConcreteDokumen7 halamanTechniques To Improve The Performance of Recycled Aggregate ConcreteIJRASETPublicationsBelum ada peringkat

- Studies On Suitability of CDokumen10 halamanStudies On Suitability of CShivam sanooBelum ada peringkat

- Development of M20 and M30 Grade of Recycled Aggregate Concrete by Replacing 100% Virgin Aggregates With Recycled AggregatesDokumen7 halamanDevelopment of M20 and M30 Grade of Recycled Aggregate Concrete by Replacing 100% Virgin Aggregates With Recycled AggregatesmynameisgunaBelum ada peringkat

- Ijstev2i5028 PDFDokumen6 halamanIjstev2i5028 PDFindian royalBelum ada peringkat

- Investigations On Fresh and Hardened Properties of Recycled Aggregate Self Compacting ConcreteDokumen7 halamanInvestigations On Fresh and Hardened Properties of Recycled Aggregate Self Compacting ConcreteramBelum ada peringkat

- Teara 2018 IOP Conf. Ser. Mater. Sci. Eng. 342 012062Dokumen6 halamanTeara 2018 IOP Conf. Ser. Mater. Sci. Eng. 342 012062Hammad ZafarBelum ada peringkat

- Literature Review: 2.1 Literature Review On Aggregates Obtained From C&D WasteDokumen6 halamanLiterature Review: 2.1 Literature Review On Aggregates Obtained From C&D Waste14C151 SWATHI B.Belum ada peringkat

- Building RubbleDokumen30 halamanBuilding RubbleJericko Allen ResusBelum ada peringkat

- Ijciet: ©iaemeDokumen9 halamanIjciet: ©iaemeIAEME PublicationBelum ada peringkat

- Research Papers On Concrete PDFDokumen5 halamanResearch Papers On Concrete PDFafnkdjwhaedkbq100% (1)

- Ijet V4i3p30 PDFDokumen5 halamanIjet V4i3p30 PDFInternational Journal of Engineering and TechniquesBelum ada peringkat

- Ukeri Concrete Papaer - 595Dokumen12 halamanUkeri Concrete Papaer - 595indian royalBelum ada peringkat

- Investigate The Potential of Hypo Sludge and Steel Fiber, Which Can Be Partially Mixed Into The ConcreteDokumen4 halamanInvestigate The Potential of Hypo Sludge and Steel Fiber, Which Can Be Partially Mixed Into The ConcreteResearch ParkBelum ada peringkat

- Experimental Investigation of Green Conc PDFDokumen12 halamanExperimental Investigation of Green Conc PDFElaya RajaBelum ada peringkat

- Recycled AggregateDokumen15 halamanRecycled AggregateBishal MitraBelum ada peringkat

- Experimental Study On Blended Concrete in R.C.C Beam and Its Behaviour Phase-Ii Review-1Dokumen17 halamanExperimental Study On Blended Concrete in R.C.C Beam and Its Behaviour Phase-Ii Review-1HemapriyaBelum ada peringkat

- Impact Test On Geopolymer Concrete Slabs: T Kiran, Sadath Ali Khan Zai, Srikant Reddy SDokumen7 halamanImpact Test On Geopolymer Concrete Slabs: T Kiran, Sadath Ali Khan Zai, Srikant Reddy SAce NovoBelum ada peringkat

- Shahjalal JournalDokumen18 halamanShahjalal JournalMd ShahjalalBelum ada peringkat

- Ms Research ProposalDokumen8 halamanMs Research ProposalAsif HameedBelum ada peringkat

- Partialreplacementof Waste Ceramicpowderby Usingfine AggregateDokumen6 halamanPartialreplacementof Waste Ceramicpowderby Usingfine AggregateGokul SBelum ada peringkat

- Project Phase-1 PDFDokumen19 halamanProject Phase-1 PDFSanjay EvaneBelum ada peringkat

- Research Paper (Recycled Concrete)Dokumen9 halamanResearch Paper (Recycled Concrete)Abhimanyu KumarBelum ada peringkat

- Materials and Design: Adel Gorjinia Khoshkenari, Payam Shafigh, Mahmoud Moghimi, Hilmi Bin MahmudDokumen10 halamanMaterials and Design: Adel Gorjinia Khoshkenari, Payam Shafigh, Mahmoud Moghimi, Hilmi Bin MahmudmynameisgunaBelum ada peringkat

- Optimizing The Performance of Construction Using Demolished Waste ConcreteDokumen9 halamanOptimizing The Performance of Construction Using Demolished Waste ConcreteIJRASETPublicationsBelum ada peringkat

- Mechanical, Fracture and Durability Properties of Self-Compacting High Strength Concrete Containing Recycled Polypropylene Particles PDFDokumen12 halamanMechanical, Fracture and Durability Properties of Self-Compacting High Strength Concrete Containing Recycled Polypropylene Particles PDFCristina HleonBelum ada peringkat

- IJSER JournalpaperDokumen5 halamanIJSER JournalpaperPatricia LunaBelum ada peringkat

- MaterialsDokumen22 halamanMaterialsTeslim SulaimanBelum ada peringkat

- Experimental Study On Behaviour of Concrete by Using Silica Fume and Saw Dust in ConcreteDokumen9 halamanExperimental Study On Behaviour of Concrete by Using Silica Fume and Saw Dust in ConcreteIJRASETPublicationsBelum ada peringkat

- Replacement of Cement Using Fly AshDokumen22 halamanReplacement of Cement Using Fly Ashkaushal yadavBelum ada peringkat

- Torsional Behavior of Recycled Aggregate Based Glass Fiber Reinforced Self-Compacting ConcreteDokumen26 halamanTorsional Behavior of Recycled Aggregate Based Glass Fiber Reinforced Self-Compacting Concretegdjwoqy bsysvwvBelum ada peringkat

- Utilization of Recycled Concrete Aggregate and Quarry Dust in ConcreteDokumen25 halamanUtilization of Recycled Concrete Aggregate and Quarry Dust in ConcreteNeel100% (1)

- 20 Wjert 659Dokumen16 halaman20 Wjert 659Ashwini KotaBelum ada peringkat

- Influence of Graphene Oxide On The Mechanical Properties, Fracture Toughness, and Microhardness of Recycled ConcreteDokumen14 halamanInfluence of Graphene Oxide On The Mechanical Properties, Fracture Toughness, and Microhardness of Recycled ConcreteAdemar GrossBelum ada peringkat

- 4576 25627 1 PB PDFDokumen17 halaman4576 25627 1 PB PDFNasir AyazBelum ada peringkat

- IJTRA1801039Dokumen7 halamanIJTRA1801039Hidayat Ullah-17BNCIV0897Belum ada peringkat

- Materials Today: Proceedings: Mycherla Chaitanya, G. RamakrishnaDokumen4 halamanMaterials Today: Proceedings: Mycherla Chaitanya, G. Ramakrishnachaitanya mycherlaBelum ada peringkat

- Experimental Studies On High Strength Concrete by Using Recycled Coarse AggregateDokumen10 halamanExperimental Studies On High Strength Concrete by Using Recycled Coarse AggregateinventyBelum ada peringkat

- Effectiveness of Using Recycled Coarse Aggregates (Rca) in Making High Strength ConcreteDokumen5 halamanEffectiveness of Using Recycled Coarse Aggregates (Rca) in Making High Strength ConcreteSelva PrakashBelum ada peringkat

- Strength and WorkabilityDokumen12 halamanStrength and WorkabilitytonydisojaBelum ada peringkat

- Developing A Sustainable Concrete Using Sugarcane Bagasse Ash (SBA) With Partial Replacement of Fine Aggregate and CementDokumen12 halamanDeveloping A Sustainable Concrete Using Sugarcane Bagasse Ash (SBA) With Partial Replacement of Fine Aggregate and CementIJRASETPublicationsBelum ada peringkat

- Use of SCC and Rca For Sustainable ConstructionDokumen5 halamanUse of SCC and Rca For Sustainable ConstructionesatjournalsBelum ada peringkat

- Experimental Study On Use of Hypo Sludge and Nylon Fibre in Paver BlockDokumen6 halamanExperimental Study On Use of Hypo Sludge and Nylon Fibre in Paver BlockIJRASETPublicationsBelum ada peringkat

- Exposure Effect of Mgso4 and HCL On Strength Properties of Ceramic Waste Powder by Partial Replacement With CementDokumen8 halamanExposure Effect of Mgso4 and HCL On Strength Properties of Ceramic Waste Powder by Partial Replacement With CementIJIRSTBelum ada peringkat

- Literature Review On High Performance ConcreteDokumen6 halamanLiterature Review On High Performance Concreteafmzfmeeavndqe100% (1)

- Effec T ofWasteGlassasPartialReplacementforCoarseAggregateinConcreteDokumen12 halamanEffec T ofWasteGlassasPartialReplacementforCoarseAggregateinConcreteHa Biba DoukhaneBelum ada peringkat

- 1 s2.0 S2214785323006636 MainDokumen6 halaman1 s2.0 S2214785323006636 MainAbinash Chandra PalBelum ada peringkat

- Evaluation of Self Compacting Concrete With Partial Replacement of Recycled AggregatesDokumen7 halamanEvaluation of Self Compacting Concrete With Partial Replacement of Recycled AggregatesDinesh RamoBelum ada peringkat

- Construction and Building MaterialsDokumen12 halamanConstruction and Building MaterialsApoorva AgarwalBelum ada peringkat

- Bond Strength of FRP Bars in Recycled-Aggregate ConcreteDokumen13 halamanBond Strength of FRP Bars in Recycled-Aggregate ConcreteAlexandre RochaBelum ada peringkat

- On Manufactured AggregatesDokumen15 halamanOn Manufactured AggregatesprafulBelum ada peringkat

- 2019 - Amardeep Singh - Incorporating Recycled Aggregatesin Self Compacting Concrete A ReviewDokumen26 halaman2019 - Amardeep Singh - Incorporating Recycled Aggregatesin Self Compacting Concrete A ReviewTarun KumarBelum ada peringkat

- Performance of High-Strength Concrete Made With Recycled Ceramic AggregatesDokumen10 halamanPerformance of High-Strength Concrete Made With Recycled Ceramic AggregatesJoão Felipe João F.Belum ada peringkat

- Study On Partial Replacement of CAnewFADokumen14 halamanStudy On Partial Replacement of CAnewFAGokul SBelum ada peringkat

- Assessment of Behaviour of High Performance Concrete On Incorporation of Waste MaterialsDokumen6 halamanAssessment of Behaviour of High Performance Concrete On Incorporation of Waste MaterialsIJRASETPublicationsBelum ada peringkat

- A Review Paper On Strength and Durability Studies On Concrete Fine Aggregate Replaced With Recycled Crushed GlassDokumen4 halamanA Review Paper On Strength and Durability Studies On Concrete Fine Aggregate Replaced With Recycled Crushed GlassIAEME PublicationBelum ada peringkat

- Combine Effect of Rice Husk Ash and Fly Ash On Concrete by 30% Cement ReplacementDokumen10 halamanCombine Effect of Rice Husk Ash and Fly Ash On Concrete by 30% Cement ReplacementMuhammad BasitBelum ada peringkat

- Literature Review On Concrete BlocksDokumen6 halamanLiterature Review On Concrete Blocksafdtftloi100% (1)

- Irjet V7i4845Dokumen9 halamanIrjet V7i4845N SanthoshBelum ada peringkat

- Onchari Amos OnchiriDokumen76 halamanOnchari Amos Onchirimomin sialBelum ada peringkat

- Lecture - 15 (Hydrology) Borehole Pumping TestDokumen4 halamanLecture - 15 (Hydrology) Borehole Pumping Testmomin sialBelum ada peringkat

- Onchari Amos OnchiriDokumen76 halamanOnchari Amos Onchirimomin sialBelum ada peringkat

- Asce2 Damar2Dokumen16 halamanAsce2 Damar2shahbazalam4a5Belum ada peringkat

- Summer Internship Report: Universal Buildwell Pvt. LTD Gurgaon, HaryanaDokumen36 halamanSummer Internship Report: Universal Buildwell Pvt. LTD Gurgaon, HaryanaDharmaraaj RajalinggamBelum ada peringkat

- Project Report On R M CDokumen41 halamanProject Report On R M Csunny84% (77)

- Ahmad Raza Final Internship ReportDokumen20 halamanAhmad Raza Final Internship ReportAsad AliBelum ada peringkat

- Cricket Coaching TipsDokumen36 halamanCricket Coaching TipsSankar100% (3)

- Ode 6Dokumen12 halamanOde 6Sandy SBelum ada peringkat

- Computer Science Elec Ba BSC PDFDokumen4 halamanComputer Science Elec Ba BSC PDFusmanBelum ada peringkat

- TaylorDokumen7 halamanTaylorChenette Ahorro FerrerBelum ada peringkat

- Sight Distance (Highway Engineering)Dokumen8 halamanSight Distance (Highway Engineering)MAND33P50% (2)

- EIA E Top1 Chart PDFDokumen1 halamanEIA E Top1 Chart PDFmomin sialBelum ada peringkat

- All You Need To Know About UBL Funds ATM Redemption CardDokumen3 halamanAll You Need To Know About UBL Funds ATM Redemption CardMohammad UsmanBelum ada peringkat

- Evaporation Pan: Operating InstructionsDokumen3 halamanEvaporation Pan: Operating Instructionsmomin sialBelum ada peringkat

- Sight Distance (Highway Engineering)Dokumen8 halamanSight Distance (Highway Engineering)MAND33P50% (2)

- Road DesignDokumen48 halamanRoad DesignshingkeongBelum ada peringkat

- Pms Overviews 0709Dokumen58 halamanPms Overviews 0709Hajarath Prasad AbburuBelum ada peringkat

- 02.13 Surface Runoff, Percolation, Total Runoff and Evaporation From Precipitation (2013 Edition)Dokumen21 halaman02.13 Surface Runoff, Percolation, Total Runoff and Evaporation From Precipitation (2013 Edition)momin sialBelum ada peringkat

- HGD QP SolutionDokumen68 halamanHGD QP Solutionmomin sialBelum ada peringkat

- Road Design RPDM - Chapter3Dokumen97 halamanRoad Design RPDM - Chapter3jignesh shahBelum ada peringkat

- Enough To Transportation Engineering IDokumen76 halamanEnough To Transportation Engineering IManoj DurairajBelum ada peringkat

- Lec 15Dokumen1 halamanLec 15momin sialBelum ada peringkat

- Study of Compressive Strength of Various Grades of Concrete Using Different Sizes of CubesDokumen6 halamanStudy of Compressive Strength of Various Grades of Concrete Using Different Sizes of Cubesmomin sialBelum ada peringkat

- Study of Compressive Strength of Various Grades of Concrete Using Different Sizes of CubesDokumen6 halamanStudy of Compressive Strength of Various Grades of Concrete Using Different Sizes of Cubesmomin sialBelum ada peringkat

- TestDokumen1 halamanTestjkwascomBelum ada peringkat

- An Experimental Study On Strength Properties of Concrete Using Recycled Aggregate As Replacement in Coarse AggregateDokumen12 halamanAn Experimental Study On Strength Properties of Concrete Using Recycled Aggregate As Replacement in Coarse Aggregatemomin sialBelum ada peringkat

- sm43 PDFDokumen98 halamansm43 PDFElakkiya Karthic0% (1)

- Il Lin: Production NoteDokumen54 halamanIl Lin: Production Notemomin sialBelum ada peringkat

- M2.2.9 Critical Review and Selection of NDT MethodsDokumen13 halamanM2.2.9 Critical Review and Selection of NDT MethodsAldy Bagus PratamaBelum ada peringkat

- Sandvik: 11/2019 PME F Additional Comments For Hydrabolt Option & HH200Dokumen1 halamanSandvik: 11/2019 PME F Additional Comments For Hydrabolt Option & HH200Elber Luis Chavez BarriosBelum ada peringkat

- Brain Controlled Car For Disabled Using Artificial IntelligenceDokumen17 halamanBrain Controlled Car For Disabled Using Artificial IntelligenceMdkhanzBelum ada peringkat

- Dji Phantom 4 RTK Book F-2Dokumen18 halamanDji Phantom 4 RTK Book F-2Liu Purnomo100% (1)

- Check List For Chilled Water Secondary Pump: Sl. No Description RemarksDokumen2 halamanCheck List For Chilled Water Secondary Pump: Sl. No Description Remarkssiruslara6491Belum ada peringkat

- Concrete Mix Design 10Dokumen1 halamanConcrete Mix Design 10Rexter UnabiaBelum ada peringkat

- IoT - Building Blocks, Applications and ChallengesDokumen60 halamanIoT - Building Blocks, Applications and ChallengesRamanamurthy Saripalli0% (1)

- Led Linear Emergency 2021Dokumen4 halamanLed Linear Emergency 2021Sugumaran LakshmananBelum ada peringkat

- CRX Seat Diassembly & Assembly 1Dokumen9 halamanCRX Seat Diassembly & Assembly 1ocdank19806116Belum ada peringkat

- Froth Flush ProcessDokumen33 halamanFroth Flush ProcessnivasssvBelum ada peringkat

- Catalog C60H-DCDokumen6 halamanCatalog C60H-DCNae MocioiBelum ada peringkat

- Bhanu Brose Excursion ReportDokumen6 halamanBhanu Brose Excursion ReportBhanu Pratap SinghBelum ada peringkat

- Bolts TheoryDokumen30 halamanBolts TheoryIbrahim Mesfin100% (1)

- Riso Rp310 Panel MessagesDokumen44 halamanRiso Rp310 Panel MessagesKhin Zaw50% (2)

- 2005-07 Ranger 500 EFI 2X4 4X4 Service ManualDokumen345 halaman2005-07 Ranger 500 EFI 2X4 4X4 Service ManualBrian Cook100% (5)

- Module 3 Density Altitude ExperimentDokumen3 halamanModule 3 Density Altitude ExperimentIvan100% (1)

- Pipe Color CodeDokumen1 halamanPipe Color CodePatricia de los SantosBelum ada peringkat

- Dual Draw/Dual Return Fuel System TroubleshootingDokumen4 halamanDual Draw/Dual Return Fuel System Troubleshootinginformer techBelum ada peringkat

- Electroplating of Silver, Zinc and IronDokumen13 halamanElectroplating of Silver, Zinc and IronTahira AzamBelum ada peringkat

- Roofing SafetyDokumen38 halamanRoofing SafetyDhârâñî KûmârBelum ada peringkat

- Transistor IRFP350Dokumen7 halamanTransistor IRFP350MiguelAngelCedanoBurrolaBelum ada peringkat

- E4-E5 CM (3G Operational Issues)Dokumen42 halamanE4-E5 CM (3G Operational Issues)VIKAS NIGAMBelum ada peringkat

- 496 - SSP481 - Audi A7 Onboard Power Supply and Networking PDFDokumen40 halaman496 - SSP481 - Audi A7 Onboard Power Supply and Networking PDFbenjaminhuku100% (5)

- A320 Documentation (1 CMP) PDFDokumen198 halamanA320 Documentation (1 CMP) PDFRamakrishnan AmbiSubbiah75% (4)

- Q45U Ultrasonic Sensors With Analog Outputs (Short Range) : DatasheetDokumen8 halamanQ45U Ultrasonic Sensors With Analog Outputs (Short Range) : DatasheetMohammad IsmailBelum ada peringkat

- Physics I Problems PDFDokumen1 halamanPhysics I Problems PDFbosschellenBelum ada peringkat

- EnglishDokumen6 halamanEnglishThineswary Siva naiduBelum ada peringkat

- Reason Key CommandsDokumen6 halamanReason Key CommandsVijay KumarBelum ada peringkat

- Hexadecimal To DecimalDokumen7 halamanHexadecimal To DecimalMushfik ArafatBelum ada peringkat

- Potsdam Village Police Dept. Blotter April 12, 2018Dokumen2 halamanPotsdam Village Police Dept. Blotter April 12, 2018NewzjunkyBelum ada peringkat

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansDari EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansBelum ada peringkat

- To Engineer Is Human: The Role of Failure in Successful DesignDari EverandTo Engineer Is Human: The Role of Failure in Successful DesignPenilaian: 4 dari 5 bintang4/5 (138)

- Crossings: How Road Ecology Is Shaping the Future of Our PlanetDari EverandCrossings: How Road Ecology Is Shaping the Future of Our PlanetPenilaian: 4.5 dari 5 bintang4.5/5 (10)

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsDari EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsBelum ada peringkat

- Troubleshooting and Repair of Diesel EnginesDari EverandTroubleshooting and Repair of Diesel EnginesPenilaian: 1.5 dari 5 bintang1.5/5 (2)

- The Great Bridge: The Epic Story of the Building of the Brooklyn BridgeDari EverandThe Great Bridge: The Epic Story of the Building of the Brooklyn BridgePenilaian: 4.5 dari 5 bintang4.5/5 (59)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansDari EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansPenilaian: 4.5 dari 5 bintang4.5/5 (21)

- Structural Cross Sections: Analysis and DesignDari EverandStructural Cross Sections: Analysis and DesignPenilaian: 4.5 dari 5 bintang4.5/5 (19)

- The Finite Element Method: Linear Static and Dynamic Finite Element AnalysisDari EverandThe Finite Element Method: Linear Static and Dynamic Finite Element AnalysisPenilaian: 5 dari 5 bintang5/5 (3)

- Summary of Neil Postman's Amusing Ourselves to DeathDari EverandSummary of Neil Postman's Amusing Ourselves to DeathPenilaian: 4 dari 5 bintang4/5 (2)

- Geotechnical Engineering Calculations and Rules of ThumbDari EverandGeotechnical Engineering Calculations and Rules of ThumbPenilaian: 4 dari 5 bintang4/5 (17)

- Cable Supported Bridges: Concept and DesignDari EverandCable Supported Bridges: Concept and DesignPenilaian: 5 dari 5 bintang5/5 (1)

- Rocks and Minerals of The World: Geology for Kids - Minerology and SedimentologyDari EverandRocks and Minerals of The World: Geology for Kids - Minerology and SedimentologyPenilaian: 4.5 dari 5 bintang4.5/5 (5)

- Finite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesDari EverandFinite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesBelum ada peringkat

- Construction Innovation and Process ImprovementDari EverandConstruction Innovation and Process ImprovementAkintola AkintoyeBelum ada peringkat

- Rock Fracture and Blasting: Theory and ApplicationsDari EverandRock Fracture and Blasting: Theory and ApplicationsPenilaian: 5 dari 5 bintang5/5 (2)

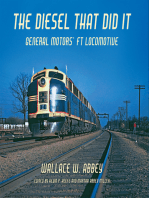

- The Diesel That Did It: General Motors' FT LocomotiveDari EverandThe Diesel That Did It: General Motors' FT LocomotiveBelum ada peringkat

- Summary of Taiichi Ohno's Taiichi Ohno's Workplace ManagementDari EverandSummary of Taiichi Ohno's Taiichi Ohno's Workplace ManagementBelum ada peringkat