Schomburg Schomburg: Aquafin - P4

Diunggah oleh

Muhammad WaseemJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Schomburg Schomburg: Aquafin - P4

Diunggah oleh

Muhammad WaseemHak Cipta:

Format Tersedia

SCHOMBURG GmbH & Co.

KG

Aquafinstrasse 2 – 8

D-32760 Detmold - Germany

SCHOMBURG Product

Building

Systems

phone + 49 - 5231- 953- 00

fax + 49 - 5231- 953-108

mail export@schomburg.de

web www.schomburg.de/en Technical Data Sheet

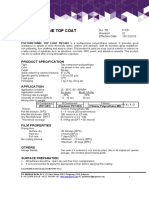

AQUAFIN®-P4 Art.-No. 2 05091

Elastic polyurethane injection resin

Properties: Application temperature: between 6 - 40° C

AQUAFIN-P4 is a solvent-free thin liquid, two-component Gelling time/

polyurethane resin. AQUAFIN-P4 is slow-reacting and hardening time: At +8° C: 17.5 ± 2.0 h

hardens to a non-foaming, non-rigid, pore-free material At +15° C: 15.0 ± 1.5 h

which slightly foams when put into contact with water. At +23° C: 13.0 ± 1.0 h

AQUAFIN-P4 bonds to a dry, moist surface and offers an Shore-A-Hardness: 60 – 70

excellent adhesion and tear resistance. AQUAFIN-P4

has a low glass transition temperature and resists to Tensile strength (acc. To DIN 53455) approx. 3 MPa.

winter temperatures without causing embrittlement and Elongation (acc. To DIN 53455) 110 – 150 %.

widening of cracks due to low temperatures without

tearing. Cleaning:

Clean tools properly immediately after use and

Areas of application: thoroughly with the cleaning agent ASO-R006.

AQUAFIN-P4 is used for the close, waterproofing and After work has finished or in case of longer interruptions

elastic connection of cracks, joints and cavities in the injection equipment is to be cleaned. Material must

construction made of concrete, natural stone or bricks. not dry out in the equipment and plug up vital machine

AQUAFIN-P4 is suitable for the waterproofing of car components. The cleaning resp. solvent agent should

parks, concrete tanks, inner shells, construction joints, have a flash point exceeding +21° C, we recommend

furthermore, for the waterproofing injection using injection the use of ASO-R006 (see technical data sheet).

hoses, AQUAFIN-CJ1 and AQUAFIN-CJ2 in concreting

joints. The procedure is as follows:

Due to its mixing ratio of 1:1 parts by volume • Pump off the remaining injection material out of the

AQUAFIN-P4 is perfectly suited for the injection with the injection unit

two-component-pump. AQUAFIN-P4 can be injected via • Rinse the top container with ASO-R006

packers or embedded injection hoses AQUAFIN-CJ1 and • Clean the injection pump, the top container and the

AQUAFIN-CJ2. The evaluation report of the KTW for tubes for 5 to 10 minutes with ASO-R006 in

small-area waterproofings is available. circulation.

• Afterwards pump the cleaning mixture into a container

Technical Data: and rinse again with ASO-R006.

Basis: Polyurethane resin • In case of longer resting times the pump, the top

Mixing ratio: 1:1 parts by volume container and the tubes have to be filled with the

Density: Comp. A at +23° C flushing oil ASO-R007.

0.975 ± 15 g/ml • Before the injection unit is used again the oil has to be

Comp. B at +23° C removed.

1.122 ± 15 g/ml

Mix viscosity: At +8° C: 450 ± 75 m Pa·S Packaging:

At +18° C: 280 ± 60 mPa·S AQUAFIN-P4 is supplied in packs of:

At +23° C: 190 ± 50 mPa·S • 2.20 kg (1.00 kg A-component and 1.20 kg

Pot life: At +8° C: 50 – 60 minutes B-component)

At +15° C: 40 – 50 minutes • 10.5 kg (5.00 kg A-component and 5.50 kg

At +23° C: 25 – 35 minutes B-component) and

AQUAFIN®-P4

• 21 kg (10.00 kg A-component and 11.kg B- Example:

component). Component A and component B are 1. Existing cracks (crack width approx. 0.2 mm) have to

supplied in the predetermined mixing ratio. be bored in a distance of approx. 20 to 30 cm.

2. The boreholes have to be cleaned with oilfree

Storage: pressure air from the dust.

24 months in unopened original packs, in a cool and 3. Place the injection packers

dry place between +10 and +30° C. Storage has to be 4. If required pre-isolate the packers and the crack zone

effected in accordance with the regulations for the on the surface, for example with ASODUR-EK98. Strip

storage of water hazardous substances. width: approx. 15 cms, consumption: approx.

300 g/m2.

Surface condition: 5. After hardening of the crack insulation inject the

The following criteria are to be fulfilled: thoroughly mixed AQUAFIN-P4 with suitable press.

Cement-based surfaces Vertical cracks: begin injecting from the bottom.

Quality of the concrete: at least B 25 Horizontal cracks: start the injection from the left side.

Quality of the screed: at least ZE 30 Consumption: approx. 1.000 g/l.

Quality of the plaster: P III 6. If necessary, remove the injection packers after

Age: at least 28 days thorough hardening of AQUAFIN-P4 and close the

Tensile strength: >=1.5 N/mm2 boreholes with ASOCRET-RN.

Product preparation: Health and safety:

Component A (polyol) and component B (isocyanate) are Once cured ASODUR-P4 is physically harmless. The

already supplied in a predetermined mix ratio. Tip B- liquid component is harmful; Symbol Xn. In any case the

component into the A-component. Ensure that the government health and safety protective directive, data

hardener drains completely from its container. Mixing of sheet M 044, should be observed as well as the advice

components is to be carried out with a mixer at approx. on the packaging.

300 Rpm (for example drilling machine with mixer). It is

important to also stir thoroughly from the sides and the Important advice:

bottom. Stir until the mix is a homogenous, the two Protect areas which are not to be treated against

components are to be mixed quickly. AQUAFIN-P4. Applications which are not clearly

explained in this data sheet may only be carried out

Processing tools: with and written confirmation from the Technical Servive

Hand lever press, foot lever press, 1 component pump Department.

(airless or piston pump) or 2-component pump (working Disposal: Liquid remainders: EAK 08 01 11 paints and

with the 2-component pump requires the use of the metal lacquers containing organic solvents or other dangerous

special mixer when correct product quality is to be substances.

guaranteed). Cured product remainders: EAK 17 02 03 plastics.

Method of application / consumption: See valid European Materials Safety Data Sheet.

Generally the mixed injection resin is injected via (MSDS)

boreholes and packers into the cracks to be

waterproofed, until the material comes out of the control GISCODE: RU40

holes.

This technical data sheet is a translation from German and does not consider local building codes or legal requirements. It shall be used as general reference for the product.

Legally binding is only the latest German technical data sheet or the latest data sheet from one of our foreign subsidiaries inside their sales territory.

45/06 Hs/SLG/JD

Anda mungkin juga menyukai

- Apcothane 676 AlDokumen3 halamanApcothane 676 AlJOSEPH GRAHAMSENGGBelum ada peringkat

- TDS Tankguard 412 English (Uk) Issued.22.05.2009Dokumen4 halamanTDS Tankguard 412 English (Uk) Issued.22.05.2009Ahmed NabilBelum ada peringkat

- TD Puas-620-2k WBDokumen3 halamanTD Puas-620-2k WBRizki PutriBelum ada peringkat

- Polyinject PU: Highly Flexible 2-Component Polyurethane Injection ResinDokumen2 halamanPolyinject PU: Highly Flexible 2-Component Polyurethane Injection ResinVaittianathan MahavapillaiBelum ada peringkat

- PC 1262 - Asian Epoxy HB CoatingDokumen3 halamanPC 1262 - Asian Epoxy HB CoatingHithayathulla KhanBelum ada peringkat

- 3 - PC 7049 - Apcodur MioDokumen3 halaman3 - PC 7049 - Apcodur Miosujay AvatiBelum ada peringkat

- Nerothane 1000Dokumen1 halamanNerothane 1000nimish.aquamarine0% (1)

- Apcomin 100Dokumen3 halamanApcomin 100mrbeleBelum ada peringkat

- PC 7091 - Apcothane CF 675 FinishDokumen3 halamanPC 7091 - Apcothane CF 675 Finishonshore purchaseBelum ada peringkat

- Apcodur CF 699: Product DescriptionDokumen4 halamanApcodur CF 699: Product DescriptionShravana PrasadBelum ada peringkat

- Properties:: F9200 Is A Ready-To-Use Dryblend Mortar Based On Cement, Which HardensDokumen3 halamanProperties:: F9200 Is A Ready-To-Use Dryblend Mortar Based On Cement, Which HardensMuhsin KhanBelum ada peringkat

- Basf 9665 Conipur M 865 Z enDokumen3 halamanBasf 9665 Conipur M 865 Z enMarijana JukicBelum ada peringkat

- CONIPROOF PUA 401 (En)Dokumen3 halamanCONIPROOF PUA 401 (En)maxlumctBelum ada peringkat

- Apcothane CF 678: PolyurethaneDokumen3 halamanApcothane CF 678: Polyurethanerumi_2kBelum ada peringkat

- MC-Injekt 1264 Compact EN EN TDSDokumen3 halamanMC-Injekt 1264 Compact EN EN TDSEvgeny ZakharinBelum ada peringkat

- Neromastic 4000Dokumen2 halamanNeromastic 4000m pallonjiBelum ada peringkat

- PC 7298 - Apcodur 804Dokumen3 halamanPC 7298 - Apcodur 8048mzpdsjzsdBelum ada peringkat

- PC 4033 - Epoxy Mio CoatingDokumen3 halamanPC 4033 - Epoxy Mio CoatingUmesh ShengalBelum ada peringkat

- Nerothane PU Topcoat: Scope Application DetailsDokumen1 halamanNerothane PU Topcoat: Scope Application DetailsTanvir Ahmed KhanBelum ada peringkat

- PC 0443 - Apcothane CF 675 - Apcothane 675 Latest PDSDokumen3 halamanPC 0443 - Apcothane CF 675 - Apcothane 675 Latest PDSonshore purchaseBelum ada peringkat

- Penguard HBDokumen4 halamanPenguard HBhedisanjayaBelum ada peringkat

- Intersleek 1100SR: Advanced Fluoropolymer Foul Release CoatingDokumen4 halamanIntersleek 1100SR: Advanced Fluoropolymer Foul Release CoatingYanyan2009Belum ada peringkat

- PC 4050 - Apcofine 910Dokumen3 halamanPC 4050 - Apcofine 910rohitBelum ada peringkat

- Rust O Cap: Surface Tolerant EpoxyDokumen3 halamanRust O Cap: Surface Tolerant EpoxySanthana SaravanaBelum ada peringkat

- PC 1752 - Asian Bituminous CoatingsDokumen3 halamanPC 1752 - Asian Bituminous CoatingsRamesh BabuBelum ada peringkat

- Apcoguard SF 725Dokumen3 halamanApcoguard SF 725kiran vargheseBelum ada peringkat

- ck-54 - SF - Aramco - Apcs PolymerDokumen1 halamanck-54 - SF - Aramco - Apcs PolymerMohammad RussellBelum ada peringkat

- Unibar Shopprimer LV: BarilDokumen2 halamanUnibar Shopprimer LV: BarilFlori SmăduBelum ada peringkat

- TD Epg 233 2K Ext WB PDFDokumen3 halamanTD Epg 233 2K Ext WB PDFLevina VaniaBelum ada peringkat

- Cds TM 9910 Pouring-Concrete-Uw en 2015-09Dokumen2 halamanCds TM 9910 Pouring-Concrete-Uw en 2015-09mihabubu80Belum ada peringkat

- Interfine 691: Isocyanate-Free FinishDokumen4 halamanInterfine 691: Isocyanate-Free FinishTrịnh Minh KhoaBelum ada peringkat

- Proguard CN 100 Iso TDSDokumen3 halamanProguard CN 100 Iso TDSm_f_deathBelum ada peringkat

- Neromastic 800: Scope Application DetailsDokumen1 halamanNeromastic 800: Scope Application DetailsTanvir Ahmed Khan100% (1)

- TDS-PENGUARD HB-EnglishDokumen4 halamanTDS-PENGUARD HB-EnglishthirdBelum ada peringkat

- PC 7078 Apcosil 605 Primer - Apcosil 601Dokumen3 halamanPC 7078 Apcosil 605 Primer - Apcosil 601onshore purchaseBelum ada peringkat

- Asian Epoxy HB CoatingDokumen1 halamanAsian Epoxy HB CoatingNS2 Engineering and ConstructionBelum ada peringkat

- Penguard FC: Technical DataDokumen4 halamanPenguard FC: Technical DataMohamed FarhanBelum ada peringkat

- PFT-213-2K SF: Polyfloor Epoxy Top Coat Solvent FreeDokumen3 halamanPFT-213-2K SF: Polyfloor Epoxy Top Coat Solvent FreeDodi Tri WibowoBelum ada peringkat

- Semstone 145 SL: Selection & Specification DataDokumen3 halamanSemstone 145 SL: Selection & Specification DataSHAIK ASIMUDDINBelum ada peringkat

- PC 0443 - Apcothane CF 675Dokumen3 halamanPC 0443 - Apcothane CF 675Gunjan GaganBelum ada peringkat

- Asian Apcodur Epoxy Mio PaintDokumen3 halamanAsian Apcodur Epoxy Mio PaintPrinceRaghavBelum ada peringkat

- PC 2569 Apcomin Industrial Rozc PrimerDokumen3 halamanPC 2569 Apcomin Industrial Rozc PrimerAshishKumar RavalBelum ada peringkat

- ITPR23 Aplicación de PinturaDokumen3 halamanITPR23 Aplicación de PinturaVictor ArcigaBelum ada peringkat

- 112.025 - SUMAZINC S-659 PRIMER RICO EM ZINCO - Inglês PDFDokumen2 halaman112.025 - SUMAZINC S-659 PRIMER RICO EM ZINCO - Inglês PDFFernando VittoBelum ada peringkat

- Apcoglass Mastic 2000Dokumen3 halamanApcoglass Mastic 2000replyrajanBelum ada peringkat

- Attachment-4 Sikagard 63 N PDSDokumen3 halamanAttachment-4 Sikagard 63 N PDSnoto.sugiartoBelum ada peringkat

- Sikagard 63 N PDS enDokumen3 halamanSikagard 63 N PDS ennoto.sugiartoBelum ada peringkat

- Sikadur - 52 inDokumen3 halamanSikadur - 52 inRavi Kumar KadivetiBelum ada peringkat

- PC 0246 - Asian Epoxy Finish PaintDokumen3 halamanPC 0246 - Asian Epoxy Finish PaintHithayathulla KhanBelum ada peringkat

- Apcosil 605 IzssDokumen3 halamanApcosil 605 IzssPavul RajBelum ada peringkat

- Interzinc 75V: Zinc-Rich EpoxyDokumen4 halamanInterzinc 75V: Zinc-Rich EpoxyTrịnh Minh KhoaBelum ada peringkat

- Eh6280 (HS)Dokumen2 halamanEh6280 (HS)anminsungBelum ada peringkat

- Econ 60 TBDokumen2 halamanEcon 60 TBfivade5459Belum ada peringkat

- Rust O Cap PDFDokumen1 halamanRust O Cap PDFTitus PraveenBelum ada peringkat

- Watertite 400 PU Blackline - TDSDokumen3 halamanWatertite 400 PU Blackline - TDSSheila AbiaBelum ada peringkat

- Apcodur 220Dokumen3 halamanApcodur 220JOSEPH GRAHAMSENGGBelum ada peringkat

- Indoprotect 490ZCDokumen3 halamanIndoprotect 490ZCSwapnil KupaleBelum ada peringkat

- Cleverproof™ 2Kw Pu: Two Component Polyurethane Based, Solvent-Free, Liquid Waterproofing Membrane For Water TanksDokumen2 halamanCleverproof™ 2Kw Pu: Two Component Polyurethane Based, Solvent-Free, Liquid Waterproofing Membrane For Water TanksAarif TanwarBelum ada peringkat

- Tds - Penguard HB - English (GB) - Issued.24.06.2005Dokumen4 halamanTds - Penguard HB - English (GB) - Issued.24.06.2005BBelum ada peringkat

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDari EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitBelum ada peringkat

- Ma Et Al.Dokumen12 halamanMa Et Al.lnhipulanBelum ada peringkat

- 0 2015 - 04-16-18!32!05 T The Production of Rigid Polyurethane FoamDokumen46 halaman0 2015 - 04-16-18!32!05 T The Production of Rigid Polyurethane Foamshub56jain100% (2)

- HPU Rigids Product Range PDFDokumen2 halamanHPU Rigids Product Range PDFA MahmoodBelum ada peringkat

- Hi Tech Projects Magazine Dec'2011-Jan'2012Dokumen45 halamanHi Tech Projects Magazine Dec'2011-Jan'2012eiribooksBelum ada peringkat

- Plastic: Organic Polymers Molecular MassDokumen28 halamanPlastic: Organic Polymers Molecular MassAJAY100% (1)

- Polyurethane Additives: Typical Physical Properties Suggested ApplicationsDokumen1 halamanPolyurethane Additives: Typical Physical Properties Suggested Applicationsdangcongsan50% (2)

- Finish Epoxy Propan PUT-603Dokumen2 halamanFinish Epoxy Propan PUT-603Yusuf KhoirBelum ada peringkat

- Pre-Engineered Steel BuildingsDokumen40 halamanPre-Engineered Steel BuildingsHelen Kate SaccuanBelum ada peringkat

- Glair G30 Series Tech Data Sheet 2017 PBDokumen3 halamanGlair G30 Series Tech Data Sheet 2017 PBBowser DoskaBelum ada peringkat

- Brochure PollypigDokumen4 halamanBrochure Pollypigjuan.ojedaBelum ada peringkat

- 2023 Eco Friendlier and Non Isocyanate Based Polyurethane Materials For Space ApplicationsDokumen12 halaman2023 Eco Friendlier and Non Isocyanate Based Polyurethane Materials For Space Applicationsmaria.maya2Belum ada peringkat

- Elastuff 120Dokumen5 halamanElastuff 120pravi3434Belum ada peringkat

- Sikafix® Pu: Flexible Polyurethane GroutDokumen2 halamanSikafix® Pu: Flexible Polyurethane GroutPrakashBelum ada peringkat

- Industrial CoatingDokumen20 halamanIndustrial CoatingDuc Nguyen100% (1)

- Nitofill WS60: Uses PropertiesDokumen4 halamanNitofill WS60: Uses PropertiesVenkata RaoBelum ada peringkat

- Synthetic Polymers in SportDokumen12 halamanSynthetic Polymers in SportSN2-0622 YONG SHENG HUIBelum ada peringkat

- ETHACURE 100-Plus TDSDokumen1 halamanETHACURE 100-Plus TDSsriatul2006Belum ada peringkat

- Tegostab® B 4690: Tegostab® Tegostab® Tegostab® Tegostab®Dokumen3 halamanTegostab® B 4690: Tegostab® Tegostab® Tegostab® Tegostab®yilong luoBelum ada peringkat

- The Chemistry of A Football Shirt: Polyester ElastaneDokumen1 halamanThe Chemistry of A Football Shirt: Polyester ElastaneJelenaBelum ada peringkat

- Bio-Based Routes To Synthesize Cyclic Carbonates and Polyamines Precursors of Non-Isocyanate PolyurethanesDokumen17 halamanBio-Based Routes To Synthesize Cyclic Carbonates and Polyamines Precursors of Non-Isocyanate PolyurethanesKpopersssBelum ada peringkat

- L Brochures Literature Flyers Tds Brochure Pdfs SWM Argotec Film Overview BrochureDokumen8 halamanL Brochures Literature Flyers Tds Brochure Pdfs SWM Argotec Film Overview BrochureLuis ArciaBelum ada peringkat

- Materials Data BookDokumen41 halamanMaterials Data Bookkundanno1100% (1)

- ASEJ-D-19-00186-Comments From Reviewer No. 1Dokumen19 halamanASEJ-D-19-00186-Comments From Reviewer No. 1Ismacahyadi Mohamed JaisBelum ada peringkat

- Loctite Max 2018Dokumen6 halamanLoctite Max 2018Frank OnermoBelum ada peringkat

- Handbook Adhesive TechnologyDokumen29 halamanHandbook Adhesive TechnologyVansala GanesanBelum ada peringkat

- Bicycle Lifecycle StudyDokumen22 halamanBicycle Lifecycle StudyAlex Rosas100% (1)

- ElastomersDokumen42 halamanElastomersAkash YadavBelum ada peringkat

- Stabaxol LDokumen3 halamanStabaxol LnazarienBelum ada peringkat

- Sprayfoam20131112 DLDokumen106 halamanSprayfoam20131112 DLMehmet Emre BastopcuBelum ada peringkat

- Pentens Industrial Flooring Catalogue Final FA (LR)Dokumen24 halamanPentens Industrial Flooring Catalogue Final FA (LR)chengkkBelum ada peringkat