Compact Heat Exchanger - 1 PDF

Diunggah oleh

Gajendra Singh RaghavJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Compact Heat Exchanger - 1 PDF

Diunggah oleh

Gajendra Singh RaghavHak Cipta:

Format Tersedia

Heat Exchangers

COMPACT HEAT EXCHANGERS — PART 1:

Designing

Plate-and-Frame

Heat Exchangers

Christopher Haslego,

Alfa Laval Use these design charts for preliminary sizing.

Graham Polley,

www.pinchtechnology.com

C onsidering available heat exchanger technolo-

gies at the outset of process design (at the

process synthesis stage) is not general prac-

tice. In fact, procedures established in some

companies preclude it. For instance, some purchasing de-

partments’ “nightmare” is having to deal with a single sup-

plier — instead they want a general specification that can

ed metal plates fitted between a thick, carbon-steel frame.

Each plate flow channel is sealed with a gasket, a weld or

an alternating combination of the two. It is not uncommon

for plate-and-frame heat exchangers to have overall heat-

transfer coefficients that are three to four times those found

in shell-and-tube heat exchangers.

This three-part series outlines the lost opportunities and

be sent to all equipment vendors, in the mistaken belief the importance of proper heat exchanger selection. This arti-

that they are then operating on a “level playing field.” cle discusses some general aspects of plate-and-frame heat

This omission is both unfortunate

and costly. It results in unnecessary cap-

ital expenditure and in reduced energy

efficiency. It also hinders the develop-

ment of energy saving technology.

Pinch analysis is the key tool used by

engineers to develop flowsheets of ener-

gy-intensive processes, where heat ex-

changer selection is particularly impor-

tant. Yet, this tool is hindering the adop-

tion of a more-progressive approach be-

cause of the way it is restricted to tradi-

tional heat exchangers.

Numerous articles have been pub-

lished regarding the advantages of com-

pact heat exchangers. Briefly, their

higher heat-transfer coefficients, com-

pact size, cost effectiveness, and unique

ability to handle fouling fluids make

them a good choice for many services.

A plate-and-frame heat exchanger

(Figure 1) consists of pressed, corrugat- ■ Figure 1. Cutaway drawing of a plate-and-frame heat exchanger.

32 www.cepmagazine.org September 2002 CEP

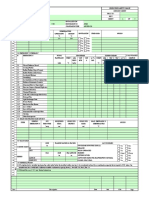

Table. Basis for heat exchanger quotation.

temperature is 115°F.” This simple statement could result

in vastly different configurations compared with the de-

Tubeside Shellside signs that would result from the original specification.

Flowrate, gal/min 500 1,800

Temperature In, °F 280 80 Design charts for plate-and-frame exchangers

Temperature Out, °F 150 92 When it comes to compact heat-transfer technology,

Allowable Pressure Drop, psi 15 15 engineers often find themselves at the mercy of the

equipment manufacturers. For example, limited litera-

exchangers, outlines a procedure for accurately estimating ture correlations are available to help in the preliminary

the required area, and shows how these units can be used to design of plate-and-frame heat exchangers.

simplify processes. Part 2 (which will appear next month) This article introduces a series of charts (Figures 2–7)

covers integrating plate-and-frame exchangers (and other that can be used for performing preliminary sizing of plate-

compact technologies) into pinch analysis for new plants, and-frame exchangers. Examples will help clarify their use.

while Part 3 (which also will appear next month) deals with The following important points should be noted regard-

the application of plate-and-frame exchangers and pinch ing the charts and their use:

technology to retrofits. 1. The heat-transfer correlations apply to single-phase,

liquid-liquid designs.

Specifying plate-and-frame heat exchangers 2. These charts are valid for single-pass units with 0.50-

Engineers often fail to realize the differences between mm-thick plates. The accuracy of the charts will not be

heat transfer technologies when preparing a specification to compromised for most materials of construction.

be sent to vendors of different types of heat exchangers. 3. Wetted-material thermal conductivity is taken as

Consider the following example. 8.67 Btu/h-ft-°F (which is the value for stainless steel).

A process stream needs to be cooled with cooling water 4. The following physical properties for hydrocarbon-

before being sent to storage. The stream requires C276, an based fluids were used for the basis: thermal conductivity

expensive high-nickel alloy, to guard against corrosion; this (k) = 0.06 Btu/h-ft-°F, density (ρ) = 55.0 lb/ft3, heat capac-

metallurgy makes the stream a candidate for the tubeside of ity (Cp) = 0.85 Btu/lb-°F. The following physical properties

a shell-and-tube heat exchanger. The cooling water is avail- for water-based fluids were used for the basis: thermal con-

able at 80°F and must be returned at a temperature no high- ductivity = 0.33 Btu/h-ft-°F, density = 62.0 lb/ft3, heat ca-

er than 115°F. The process engineer realizes that with the pacity = 0.85 Btu/lb-°F.

water flow being placed on the shellside, larger flowrates 5. Accuracy should be within ±15% of the service value

will enhance the heat-transfer coefficient. The basis for the for the overall heat-transfer coefficient, assuming a nomi-

heat exchanger quotation was specified as shown in the nal 10% excess heat-transfer area.

table. According to the engineer’s calculations, these basic 6. For fluids with viscosities between 100 and 500 cP,

parameters should result in a good shell-and-tube design use the 100 cP line on the graphs. For fluids in excess of

that uses a minimum amount of C276 material. 500 cP, consult equipment manufacturers.

A typical plate-and-frame exchanger designed to meet the Equations 1–3 are used to calculate the log-mean tem-

specification would have about 650 ft2 of area, compared to perature difference (LMTD) and number of transfer units

about 420 ft2 for a shell-and-tube exchanger. A plate-and- (NTU) for the hot and cold streams. After the local heat-

frame unit designed to the above specification is limited by transfer coefficients (h) are read from the charts, the over-

the allowable pressure drop on the cooling water. If the cool- all heat-transfer coefficient (U) is calculated by Eq. 4.

ing water flow is reduced to 655 gal/min and the outlet water

temperature allowed to rise to 115°F, the plate-and-frame

LMTD =

(T hot ,in ) (

− Tcold ,out − Thot ,out − Tcold ,in ) (1)

heat exchanger would contain about 185 ft2 of area. The unit T − Tcold ,out

is smaller and less expensive, and it uses less water. The ln hot ,in

load being transferred to the cooling tower is the same. Thot ,out − Tcold ,in

With shell-and-tube heat exchangers, increasing water

Thot ,in − Thot ,out

flow will minimize heat-transfer area. However, with com- NTUhot = (2 )

pact technologies, the effect is exactly the opposite. The LMTD

larger water flow actually drives up the cost of the unit.

Rather than supplying a rigid specification to all heat Tcold ,out − Tcold ,in

exchanger manufacturers, the engineer should have ex- NTUcold = (3)

LMTD

plained the goal for the process stream. This could have

been in the form of the following statement: “The process 1 1 ∆x 1

stream is to be cooled with cooling water. Up to 2,000 = + + ( 4)

gal/min of water is available at 80°F. The maximum return U hhot k hcold

CEP September 2002 www.cepmagazine.org 33

Heat Exchangers

Pressure Drop, kPa

50 100 150 200

h = Local Heat-Transfer Coefficient,

h = Local Heat-Transfer Coefficient,

3,500 Using the charts

Water-Based Fluids 18,000 Consider the following example.

3,000 1 cP

150,000 lb/h of water is being cooled

15,000

2,500 from 200°F to 175°F by 75,000 lb/h

Btu/h-ft2-˚F

12,000 of SAE 30 oil. The oil enters the ex-

W/m2-K

2,000 2.5 cP changer at 60°F and leaves at 168°F.

9,000 The average viscosity of the water

1,500

5 cP passing through the unit is 0.33 cP

1,000 6,000

10 cP

and the average viscosity of the oil in

3,000 the unit is 215 cP. The maximum-

500 100 cP allowable pressure drop through the

0 plate heat exchanger is 15 psi on the

5 10 15 20 25 30

hot and cold sides.

Pressure Drop, psi Step 1: Calculate the LMTD.

From Eq. 1, LMTD = [(200 – 168)

■ Figure 2. Heat-transfer correlations for water-based fluids, 0.25 < NTU < 2.0. – (175 – 60)]/ln[(200 – 168)/(175 –

60)] = 64.9°F.

Pressure Drop, kPa

Step 2: Calculate NTUhot and

NTUcold. From Eqs. 2 and 3, NTUhot =

50 100 150 200 (200 – 175)/64.9 = 0.38 and NTUcold

h = Local Heat-Transfer Coefficient,

h = Local Heat-Transfer Coefficient,

3,500

Correction: For liquids with average viscosities

18,000 = (168 – 60)/64.9 = 1.66.

3,000 less than 2.0 cP, reduce the local heat-transfer Step 3: Read hhot from the appro-

coefficient by 15% from 3.5 < NTU < 4.0.

1 cP 15,000 priate chart. Use Figure 5, the chart

2,500 Water-Based Fluids

for hydrocarbons when 0.25 < NTU

Btu/h-ft2-˚F

12,000

W/m2-K

2,000 2.5 cP < 2.0. Although there is not a vis-

9,000

cosity line for 215 cP, the line repre-

1,500 senting 100 cP can be used for vis-

5 cP

1,000 6,000 cosities up to about 400–500 cP. The

10 cP

heat exchanger will be pressure-

500 3,000 drop-limited and the heat-transfer

100 cP

coefficient will not change apprecia-

0

5 10 15 20 25 30 bly over this viscosity range for

plate-and-frame exchangers. Read-

Pressure Drop, psi

ing from the chart, a pressure drop

of 15 psi corresponds to hhot ≈ 50

■ Figure 3. Heat-transfer correlations for water-based fluids, 2.0 < NTU < 4.0. Btu/h-ft2-°F.

Step 4: Read hcold from the chart.

Pressure Drop, kPa Use Figure 2, which applies to water-

based liquids when 0.25 < NTU < 2.0.

50 100 150 200

Again, the exact viscosity line needed

h = Local Heat-Transfer Coefficient,

h = Local Heat-Transfer Coefficient,

3,500

18,000 for pure water (0.33 cP) in this case is

3,000 Water-Based Fluids not available. However, the 1.0 cP

15,000 line provides a very good estimate of

2,500 1 cP the heat-transfer coefficient for pure

Btu/h-ft2-˚F

12,000

W/m2-K

2,000 water. Reading from the chart, a pres-

2.5 cP 9,000 sure drop of 15 psi corresponds to

1,500

5 cP hcold ≈ 3,000 Btu/h-ft2-°F.

1,000 6,000 Step 5: Calculate U. Assume a

10 cP stainless steel plate with a thick-

3,000

500

100 cP

ness of 0.50 mm is being used.

0

Type 316 stainless steel has a ther-

5 10 15 20 25 30 mal conductivity of 8.67 Btu/h-ft-

°F. Then from Eq. 4, 1/U = (1/50 +

Pressure Drop, psi

0.000189 + 1/3,000) and U = 49

Btu/h-ft2-°F.

■ Figure 4. Heat-transfer correlations for water-based fluids, 4.0 < NTU < 5.0.

34 www.cepmagazine.org September 2002 CEP

Pressure Drop, kPa

50 100 150 200

h = Local Heat-Transfer Coefficient,

h = Local Heat-Transfer Coefficient,

Now let’s consider another exam- 1,000

5,400

ple. 150,000 lb/h of water is being Hydrocarbon-Based Fluids

cooled from 200°F to 100°F by 800 1 cP 4,600

150,000 lb/h of NaCl brine. The 3,800

Btu/h-ft2-˚F

brine enters the exchanger at 50°F 600

W/m2-K

and leaves at 171°F. The average 3,000

2.5 cP

viscosity of the water passing 400 2,400

through the unit is 0.46 cP and the 5 cP

average viscosity of the brine in the 1,600

200 10 cP

unit is 1.10 cP. The maximum-allow- 800

able pressure drop through the plate 100 cP

heat exchanger is 10 psi on the hot 0

5 10 15 20 25 30

(water) side and 20 psi on the cold

(brine) side. Pressure Drop, psi

The LMTD is calculated to be

38.5°F. NTUhot and NTUcold are 2.59 ■ Figure 5. Heat-transfer correlations for hydrocarbons, 0.25 < NTU < 2.0.

and 3.14, respectively. From the

charts for 2.0 < NTU < 4.0 (water

based), hhot ≈ 2,000 Btu/h-ft2-°F Pressure Drop, kPa

and hcold ≈ 2,500 Btu/h-ft2-°F. Al- 50 100 150 200

h = Local Heat-Transfer Coefficient,

1,000

h = Local Heat-Transfer Coefficient,

though the material of choice may Correction: For liquids with average viscosities 5,400

be titanium or palladium-stabilized less than 2.0 cP, reduce the local heat-transfer

titanium, the properties for stain- 800 coefficient by 15% from 3.5 < NTU < 4.0. 4,600

less steel are used for preliminary Hydrocarbon-Based Fluids

3,800

Btu/h-ft2-˚F

1 cP

sizing. U is calculated to be 918 600

W/m2-K

2 3,000

Btu/h-ft -°F.

2.5 cP 2,400

400

Implications of size reduction

5 cP 1,600

Alternative technologies offer 10 cP

200

significant size advantages over 800

shell-and-tube heat exchangers. 100 cP

Let’s now consider the implications 0

5 10 15 20 25 30

of this.

The individual exchangers are Pressure Drop, psi

smaller, and the spacing between

process equipment can be reduced. ■ Figure 6. Heat-transfer correlations for hydrocarbons, 2.0 < NTU < 4.0.

Thus, a smaller plot is needed for

the process plant. If the plant is to Pressure Drop, kPa

be housed in a building, the build-

50 100 150 200

ing can be smaller. The amount of

h = Local Heat-Transfer Coefficient,

h = Local Heat-Transfer Coefficient,

1,000

structural steel used to support the 5,400

plant can be reduced, and because 800 4,600

of the weight saving, the load on Hydrocarbon-Based Fluids

that structure is also reduced. The 3,800

Btu/h-ft2-˚F

1 cP

600

W/m2-K

weight advantage extends to the 3,000

design of the foundations used to

support the plant. Since the spac- 400 2.5 cP 2,400

ing between equipment is reduced, 5 cP 1,600

piping costs are lower. 200 10 cP

However, we stress again that the 800

100 cP

savings associated with size and

0

weight reduction can only be 5 10 15 20 25 30

achieved if these advantages are rec-

Pressure Drop, psi

ognized and exploited at the earliest

stages of the plant design.

■ Figure 7. Heat-transfer correlations for hydrocarbons, 4.0 < NTU < 5.0.

CEP September 2002 www.cepmagazine.org 35

Heat Exchangers

Reduced plant complexity

The use of alternative heat ex-

One shell-and-tube exchanger Three shell-and-tube exchangers changer technologies can signifi-

One plate exchanger One plate exchanger cantly reduce plant complexity by

200˚F 200˚F reducing the number of heat ex-

changers through improved thermal

175˚F contacting and multi-streaming.

168˚F 171˚F This adds to the savings associated

with reduced size and weight and

100˚F also has safety implications. The

simpler the plant structure, the easi-

60˚F 50˚F er it is for the process operator to

understand the plant. In addition,

No Temperature Cross Temperature Cross

plant maintenance will be safer,

easier and more straight-forward.

Mechanical constraints play a

■ Figure 8. The situation on the left does not involve a temperature cross, while the one on the right does.

significant role in the design of

shell-and-tube heat exchangers. For

instance, it is common to find that

some users place restrictions on

160˚F 160˚F tube length. Such a restriction can

Styrene, 290,285 lb/h 112˚F have important implications for the

130˚F ∆P = 9.5 psi

design. In the case of exchangers

Water, 248,655 lb/h requiring large surface areas, the

248˚F

∆P = 14.6 psi 80 ˚ F restriction drives the design toward

large tube counts. If such large tube

Styrene, 290,285 lb/h Styrene, 100˚F counts lead to low tubeside veloci-

∆Ptotal = 30 psi ty, the designer is tempted to in-

285˚F

crease the number of tubeside pass-

es in order to maintain a reasonable

■ Figure 9. A single plate-and-frame exchanger handles three process streams … tubeside heat-transfer coefficient.

Thermal expansion considerations

can also lead the designer to opt for

multiple tube passes, because the cost of a floating head

is generally lower than the cost of installing an expan-

Cooling Styrene sion bellows in the exchanger shell.

Water (Hot)

The use of multiple tube passes has four detrimental

effects. First, it leads to a reduction in the number of

tubes that can be accommodated in a given size shell,

thereby leading to increased shell diameter and cost.

Second, for bundles having more than four tube passes,

the pass-partition lanes introduced into the bundle give

rise to an increase in the quantity of shellside fluid by-

passing the tube bundle and a reduction in shellside

heat-transfer coefficient. Third, it results in wasted

tubeside pressure drop in the return headers. Finally,

and most significantly, the use of multiple tube passes

Styrene results in the thermal contacting of the streams not

(Cold) being pure counter-flow, which reduces the effective-

mean-temperature driving force and possibly produces

a temperature cross (i.e., where the outlet temperature

of the cold stream is higher than the inlet temperature

■ Figure 10. … whereas the equivalent shell-and-tube design requires of the hot stream, as shown in Figure 8). If a tempera-

six units. ture cross occurs, the designer must split the duty be-

tween multiple heat exchangers arranged in series.

36 www.cepmagazine.org September 2002 CEP

Many of the alternative heat-exchanger technologies tube design has 11,344 ft2 of surface area distributed

allow the application of pure countercurrent flow across across six separate exchangers.

all size and flow ranges. This results in better use of the

available temperature driving force and the use of single Budget pricing correlations

heat exchangers. For plate-and-frame heat exchangers with a design pres-

sure up to 150 psi and a design temperature up to 320°F,

Multi-streaming the following cost equations can be used to estimate the

The traditional shell-and-tube heat exchanger handles purchased cost.

only one hot stream and one cold stream. Some heat ex- For areas (A) less than 200 ft2:

changer technologies (most notably plate-fin and print- C = 401 A 0.4887 for Type 316 stainless steel (5)

ed-circuit exchangers) can handle many streams. It is C = 612 A 0.4631 for Grade 1 titanium (6)

not uncommon to find plate-fin exchangers transferring For areas larger than 200 ft2:

heat between ten individual processes. (The principles C = 136 A 0.6907 for Type 316 stainless steel (7)

behind the design of multi-stream exchangers and the C = 131 A 0.7514 for Grade 1 titanium (8)

operability of such units are discussed in Ref. 1.) Such Typical installation factors for plate-and-frame heat ex-

units can be considered to contain a whole heat ex- changers can range from 1.5 to 2.0, depending on the size

changer network within the body of a single exchanger. of the unit.

Distribution and recombination of process flows is un-

dertaken inside the exchanger. The result is a major re- Up next

duction in piping cost. Being able to estimate the area and prices of plate-

Engineers often overlook the opportunities of using a and-frame heat exchangers is an important first step in

plate-and-frame exchanger as a multi-stream unit. As including alternative heat-transfer technology in process

mentioned earlier, this is a common oversight when ex- synthesis. The remaining articles in this series (which

changer selection is not made until after the flowsheet will appear next month) focus on the integration of

has been developed. plate-and-frame (and other compact technology) into

A good example of multi-streaming is a plate heat ex- pinch analyses. CEP

changer that serves as a process interchanger on one side

and a trim cooler on the other. This arrangement is par-

ticularly useful for product streams that are exiting a pro-

cess and must be cooled for storage. CHRISTOPHER HASLEGO is a design engineer with the Process

Another popular function of multi-streaming is to Technology Div. of Alfa Laval (5400 International Trade Dr., Richmond,

lower material costs. Some streams, once they are cooled VA 23236; Phone: (804) 236-1318; Fax: (804) 236-1360; E-mail:

to a certain temperature, pose much less of a corrosion chris.haslego@alfalaval.com). His focus is heat transfer in the

inorganic base chemicals industry. He received a BS in chemical

risk. One side of the exchanger can be made of a more- engineering from West Virginia Univ. A member of AIChE, he also

expensive corrosion-resistant alloy while the other side maintains a website dedicated to chemical engineering entitled “The

can utilize stainless steel or a lower alloy. Chemical Engineers’ Resource Page” at www.cheresources.com.

Figure 9 shows a plate-and-frame unit applied to three

GRAHAM T. POLLEY (Phone: +44-1229-585-330; Fax: +44-1229-585-708;

process streams. A single exchanger with 1,335 ft2 of ef- E-mail: gtpolley@compuserve.com) is retired from the Univ. of

fective surface area is used. Figure 10 is the equivalent Manchester Institute of Science and Technology, Manchester, U.K.,

shell-and-tube solution — to avoid temperature crosses, where he was the director of the Centre for Process Integration. To

six individual exchangers are needed: the cooler having promote the application of process integration technology, he has

developed the website www.pinchtechnology.com. His research

two shells in series (each with 1,440 ft2 of effective sur- activities have involved condensation heat transfer, boiling heat

face area) and the heat recovery unit having four shells in transfer, heat-recovery-system design and the development of process

series (each with 2,116 ft2 of surface area). So, the plate- and equipment design methodologies. He is the current president of

and-frame design involves the use of 1,335 ft2 of surface the U.K. Heat Transfer Society. In 1990, he was awarded the Moulton

Medal by the Institution of Chemical Engineers for his work on oil

area in a single unit, whereas the equivalent shell-and- refinery revamping, and in 1992, he and Dr. Nasr were awarded the

Ackrill Trophy by the U.K. Heat Transfer Society for their work on

heat-transfer enhancement. He holds BTech, MSc and PhD degrees

in chemical engineering from Loughborough Univ. of Technology,

Literature Cited and is a member of AIChE.

1. Picon Nunez, M., and G. T. Polley, “Recent Advances in

Analysis of Heat Transfer for Fin Type Surfaces,” Chapters 9 Correlations used to formulate charts were developed by Alfa Laval

and 10, Sunden, B., and P. J. Heggs, eds., WIT Press, (formerly Alfa Laval Thermal) through comprehensive research and

Southampton, U.K. (2000). development and decades of industrial experience.

CEP September 2002 www.cepmagazine.org 37

Anda mungkin juga menyukai

- ExtraOrdinary Technology Tensor RingsDokumen6 halamanExtraOrdinary Technology Tensor RingsMiguel Angelum100% (11)

- Mars RuleDokumen32 halamanMars RuleRadha Krishnan R100% (3)

- Forced Evaporation Ponds DesignDokumen10 halamanForced Evaporation Ponds Designfotikos100% (1)

- TEMA Sheet Heat Exchanger Specification SheetDokumen3 halamanTEMA Sheet Heat Exchanger Specification SheetSonNguyenBelum ada peringkat

- Data Monitor Report - Soft DrinksDokumen26 halamanData Monitor Report - Soft DrinksKhushi SawlaniBelum ada peringkat

- Thrust Bearing CalculationsDokumen162 halamanThrust Bearing Calculationslahiru1983100% (1)

- Heat Exchanger Lectures CompleteDokumen72 halamanHeat Exchanger Lectures CompletehananBelum ada peringkat

- Preliminary Heat Exchanger Design ExampleDokumen4 halamanPreliminary Heat Exchanger Design ExamplejokishBelum ada peringkat

- Lec#09 PHT - (04 Mar 2013 - Monday) - Design of Shell & Tube Heat ExchangerDokumen30 halamanLec#09 PHT - (04 Mar 2013 - Monday) - Design of Shell & Tube Heat ExchangerQamar AbbasBelum ada peringkat

- Shell and Tube Heat Exchanger DesignDokumen5 halamanShell and Tube Heat Exchanger DesignDominic CareoBelum ada peringkat

- C:/Users/UDI/Job/PUSTEK E&T/PROJECT FOSTER/Air Cooler - Htri: 48 InchDokumen1 halamanC:/Users/UDI/Job/PUSTEK E&T/PROJECT FOSTER/Air Cooler - Htri: 48 InchFadhila Ahmad AnindriaBelum ada peringkat

- Process Design of Heat ExchangerDokumen40 halamanProcess Design of Heat ExchangeramiyachemBelum ada peringkat

- Selecting The Proper TEMA TypeDokumen3 halamanSelecting The Proper TEMA TypeMubarik AliBelum ada peringkat

- How Important Is Surface Area .?Dokumen7 halamanHow Important Is Surface Area .?john_serafica7104Belum ada peringkat

- 2.heat-Exchangers From Ch6 - Mihir's HandbookDokumen12 halaman2.heat-Exchangers From Ch6 - Mihir's HandbookThế Quang LêBelum ada peringkat

- Gas Chiller Datasheet PDFDokumen2 halamanGas Chiller Datasheet PDFidilfitriBelum ada peringkat

- Pollution Control in Oil, Gas and Chemical PlantsDokumen15 halamanPollution Control in Oil, Gas and Chemical PlantsPRAFULKUMAR PARMARBelum ada peringkat

- Shell & Tube Heat Exchanger DesignDokumen87 halamanShell & Tube Heat Exchanger DesignankitmundharaBelum ada peringkat

- Basic Heat ExchangerDokumen15 halamanBasic Heat Exchangeraw_aeBelum ada peringkat

- Melt CrystallizationDokumen10 halamanMelt Crystallizationarsh19706636Belum ada peringkat

- The Outside Diameter As Their Nominal DiameterDokumen75 halamanThe Outside Diameter As Their Nominal Diameterngutor100% (2)

- Working Principle of Shell and Tube Heat ExchangerDokumen8 halamanWorking Principle of Shell and Tube Heat ExchangersanjayBelum ada peringkat

- Design 2 ReboilerDokumen5 halamanDesign 2 ReboilerAbdulrazzaqAL-MalikyBelum ada peringkat

- Cooling Towers Design and Operation ConsiderationsDokumen10 halamanCooling Towers Design and Operation ConsiderationsLiu YangtzeBelum ada peringkat

- Energy Optimization Using Pinch Analysis: Practical ConsiderationsDokumen10 halamanEnergy Optimization Using Pinch Analysis: Practical ConsiderationsconfyBelum ada peringkat

- Pede Proj 1Dokumen28 halamanPede Proj 1Jibril hassen kedirBelum ada peringkat

- E 106Dokumen1 halamanE 106Bith SMGBelum ada peringkat

- No Yes No Yes No Yes No Yes No Yes No YesDokumen8 halamanNo Yes No Yes No Yes No Yes No Yes No YesEkundayo JohnBelum ada peringkat

- Experienced Based Rules of Chemical EngineeringDokumen33 halamanExperienced Based Rules of Chemical Engineeringintania66Belum ada peringkat

- Design of Distillation Columns - ImpDokumen13 halamanDesign of Distillation Columns - ImpAlla VijayBelum ada peringkat

- He SelectionDokumen7 halamanHe SelectionKaizerBelum ada peringkat

- Vapor Liquid Equilibrium of Water + Ethanol + GlycerolDokumen8 halamanVapor Liquid Equilibrium of Water + Ethanol + GlycerolcsandrasBelum ada peringkat

- Air Cooled HX Data SheetDokumen1 halamanAir Cooled HX Data SheetHoney TiwariBelum ada peringkat

- Stripping Notes PDFDokumen28 halamanStripping Notes PDFnimi khalidBelum ada peringkat

- Limpet Coil On Dish Design As Per PD5500Dokumen1 halamanLimpet Coil On Dish Design As Per PD5500ABIDEEN BAMNEBelum ada peringkat

- 1.6a Line Sizing SlidesDokumen24 halaman1.6a Line Sizing SlidesSanju ChauhanBelum ada peringkat

- Heat ExchangersDokumen48 halamanHeat ExchangersRiccat Shio'TangBelum ada peringkat

- Shell and Tube Heat ExchangerDokumen7 halamanShell and Tube Heat ExchangerGaurav SharmaBelum ada peringkat

- Vent Calc For Storage Tanks - CheresourcesDokumen5 halamanVent Calc For Storage Tanks - CheresourcesSteve WanBelum ada peringkat

- Improve Glass-Lined ReactorDokumen7 halamanImprove Glass-Lined ReactorRonaldo JanglinBelum ada peringkat

- Process Designing of Breather ValvesDokumen15 halamanProcess Designing of Breather ValvesGuglielmoBelum ada peringkat

- PED 2 Report Group 8Dokumen21 halamanPED 2 Report Group 8Rahul YadavBelum ada peringkat

- Design Part 3 - Sizing Orifices and PipingDokumen11 halamanDesign Part 3 - Sizing Orifices and PipingtrebsantiaBelum ada peringkat

- Liquid Valve CV CalcDokumen4 halamanLiquid Valve CV Calcamit_kt1973Belum ada peringkat

- Mean Metal TempsDokumen1 halamanMean Metal TempsThiruppathi RajanBelum ada peringkat

- Design of ReboilersDokumen24 halamanDesign of ReboilersKrishanu SahaBelum ada peringkat

- Excel Work Book For Heat ExchangersDokumen88 halamanExcel Work Book For Heat ExchangersHedi temimiBelum ada peringkat

- Valve Sizing SelectionDokumen15 halamanValve Sizing SelectionbariBelum ada peringkat

- 2.heat-Exchangers From Ch6 - Mihir's HandbookDokumen12 halaman2.heat-Exchangers From Ch6 - Mihir's HandbookThế Quang LêBelum ada peringkat

- Agitated Vessel Heat TransferDokumen7 halamanAgitated Vessel Heat TransferalokbdasBelum ada peringkat

- High-Pressure Fluid Phase Equilibria: Phenomenology and ComputationDari EverandHigh-Pressure Fluid Phase Equilibria: Phenomenology and ComputationBelum ada peringkat

- Plate Heat ExchangersDokumen7 halamanPlate Heat ExchangersBaneMarkovicBelum ada peringkat

- Step 1: Calculate The LMTD: HOT ColdDokumen34 halamanStep 1: Calculate The LMTD: HOT ColdFrancisca Hanna0% (2)

- Understand Heat Flux Limitations On Reboiler Design PDFDokumen10 halamanUnderstand Heat Flux Limitations On Reboiler Design PDFthawdarBelum ada peringkat

- Using PHEs in HENsDokumen4 halamanUsing PHEs in HENscymyBelum ada peringkat

- IC4.4 AnoushPoursartipDokumen10 halamanIC4.4 AnoushPoursartipLuis Daniel RodríguezBelum ada peringkat

- Basic Refinery Equipment - Heat Exchanger (E003/1)Dokumen27 halamanBasic Refinery Equipment - Heat Exchanger (E003/1)ebsmsart100% (1)

- Meshkat Design Heat ExchangerDokumen36 halamanMeshkat Design Heat ExchangerjdedfvBelum ada peringkat

- Lecture 6 - Heat Transfer EquipmentDokumen72 halamanLecture 6 - Heat Transfer EquipmentLouie GresulaBelum ada peringkat

- Shell and Tube Heat Exchanger - The Heat Transfer Area Design ProcessDokumen12 halamanShell and Tube Heat Exchanger - The Heat Transfer Area Design ProcessMuhammadAsimBelum ada peringkat

- Heat Recorery Systems: (I) High Overall CoefficientsDokumen9 halamanHeat Recorery Systems: (I) High Overall CoefficientsPhilip ShihBelum ada peringkat

- New Microsoft Word Document 4.1Dokumen19 halamanNew Microsoft Word Document 4.1prashantmaukaBelum ada peringkat

- Chapter 5 - Heat ExchangerDokumen48 halamanChapter 5 - Heat ExchangerHoneydaa FitraBelum ada peringkat

- Reactor Sizing FinalDokumen34 halamanReactor Sizing FinalJobb Six-steps MatheusBelum ada peringkat

- Supercritical Lang PDFDokumen131 halamanSupercritical Lang PDFAndrés Ramón LinaresBelum ada peringkat

- FoodPackagesFreePress05 PDFDokumen76 halamanFoodPackagesFreePress05 PDFAndrés Ramón LinaresBelum ada peringkat

- Advances in Flavonoid Research Since 1992Dokumen24 halamanAdvances in Flavonoid Research Since 1992Andrés Ramón LinaresBelum ada peringkat

- Design and Scale-Up of Pressurized Fluid Extractors For Food and BioproductsDokumen12 halamanDesign and Scale-Up of Pressurized Fluid Extractors For Food and BioproductsAndrés Ramón LinaresBelum ada peringkat

- Affinity Solvents For Intensified Organics Extraction Development Challenges and ProspectsDokumen10 halamanAffinity Solvents For Intensified Organics Extraction Development Challenges and ProspectsAndrés Ramón LinaresBelum ada peringkat

- A Model For Determination of Multicomponent Diffusion CoefficientDokumen10 halamanA Model For Determination of Multicomponent Diffusion CoefficientAndrés Ramón LinaresBelum ada peringkat

- Study of Solid-Liquid Extraction Kinetics of Total Polyphenols From Grape SeedsDokumen7 halamanStudy of Solid-Liquid Extraction Kinetics of Total Polyphenols From Grape SeedsAndrés Ramón LinaresBelum ada peringkat

- Time Series AnalysisDokumen635 halamanTime Series AnalysisAndrés Ramón Linares100% (8)

- Value Chain ClusterDokumen22 halamanValue Chain ClusterAndrés Ramón LinaresBelum ada peringkat

- Furnace Heater DesignDokumen6 halamanFurnace Heater DesignINDRAJIT SAOBelum ada peringkat

- Calculos em Engenharia QuimicaDokumen26 halamanCalculos em Engenharia Quimicaandengal799Belum ada peringkat

- AlfaLaval Heat Transfer TheoryDokumen15 halamanAlfaLaval Heat Transfer TheoryAndrés Ramón Linares100% (3)

- Cassava en NigeriaDokumen60 halamanCassava en NigeriaAndrés Ramón LinaresBelum ada peringkat

- Analysis of EnergyDokumen10 halamanAnalysis of EnergyAndrés Ramón LinaresBelum ada peringkat

- Cassava: International Market Profile: Competitive Commercial Agriculture in Sub-Saharan Africa (CCAA) StudyDokumen11 halamanCassava: International Market Profile: Competitive Commercial Agriculture in Sub-Saharan Africa (CCAA) Studyedwin_nyanducha3013Belum ada peringkat

- Comparison Between Experimental and Numerical Studies of Fully Encased Composite ColumnsDokumen8 halamanComparison Between Experimental and Numerical Studies of Fully Encased Composite ColumnsAbdul BariBelum ada peringkat

- Class XI PHYSICS - Class Assignment TOPIC: - Vector ProductDokumen2 halamanClass XI PHYSICS - Class Assignment TOPIC: - Vector Productsudir_phyBelum ada peringkat

- MTL 200 OutlineDokumen3 halamanMTL 200 OutlineputhiawanBelum ada peringkat

- Pspice Command SummaryDokumen26 halamanPspice Command Summarybasp914960Belum ada peringkat

- Bsep SMFDokumen6 halamanBsep SMFamirgholami1100% (1)

- Pile Foundation Analysis and Design: Geotechnical Engineering Design IiiDokumen24 halamanPile Foundation Analysis and Design: Geotechnical Engineering Design IiiFaridBelum ada peringkat

- Trigonometric Leveling - Heights and Distances Problem (Two Exercises)Dokumen1 halamanTrigonometric Leveling - Heights and Distances Problem (Two Exercises)RadhaAnanthalekshmiBelum ada peringkat

- Tie BeamDokumen8 halamanTie BeamKarma Jamtsho100% (2)

- FZG enDokumen12 halamanFZG enrbulnes2350Belum ada peringkat

- Insulation CoordinationDokumen3 halamanInsulation CoordinationsujithmohandasBelum ada peringkat

- Atomic Force Microscopy AFM Basics and Its ImportaDokumen18 halamanAtomic Force Microscopy AFM Basics and Its ImportaEmi ReyesBelum ada peringkat

- Air Blaster or CannonDokumen9 halamanAir Blaster or CannonemailidabhiBelum ada peringkat

- Viboon Psychrometric DataDokumen8 halamanViboon Psychrometric DataTian Fung WangBelum ada peringkat

- Chemistry Investigatory ProjectDokumen18 halamanChemistry Investigatory Projectvidhisha makenBelum ada peringkat

- GATE 2014 Civil Engineering Keys & Solution (Evening Session)Dokumen36 halamanGATE 2014 Civil Engineering Keys & Solution (Evening Session)Lokesh Kumar100% (1)

- 2.3 Analysing Series and Parallel CircuitsDokumen16 halaman2.3 Analysing Series and Parallel CircuitssfwongBelum ada peringkat

- Glass Refractive Index DeterminationDokumen9 halamanGlass Refractive Index Determinationmichaeljscofield24Belum ada peringkat

- Phenolphthalein NaOH KineticsDokumen7 halamanPhenolphthalein NaOH KineticsjoevinngglBelum ada peringkat

- Problemario B.E. Segundo ParcialDokumen4 halamanProblemario B.E. Segundo ParcialjorgeBelum ada peringkat

- Finite Volume MethodDokumen2 halamanFinite Volume MethodRhea MambaBelum ada peringkat

- NTN Pillow BlockDokumen54 halamanNTN Pillow BlockteguheafBelum ada peringkat

- Chemical Kinetics and Nikolay SemyonovDokumen9 halamanChemical Kinetics and Nikolay SemyonovAnastasia FedorisinBelum ada peringkat

- Six Leg Kinematic Moving MachineDokumen12 halamanSix Leg Kinematic Moving MachineShubham Bonde100% (1)

- Comparative Study of Seismic Analysis of Building With Light Weight and Conventional MaterialDokumen4 halamanComparative Study of Seismic Analysis of Building With Light Weight and Conventional MaterialIJEMR JournalBelum ada peringkat

- Pre-Strain Effect of On Fracture Performance of High-Strength Steel WeldsDokumen7 halamanPre-Strain Effect of On Fracture Performance of High-Strength Steel WeldsThiago Amaro RodriguesBelum ada peringkat

- Epi, LeopoldoDokumen4 halamanEpi, Leopoldoyeng botzBelum ada peringkat

- P Malan AIAA2009 Gamma Re ThetaDokumen14 halamanP Malan AIAA2009 Gamma Re ThetaMohammed BarahmehBelum ada peringkat