A275 - A275M 08 (2013) - STD - Practice - For - MPI - of - Steel - Forging

Diunggah oleh

Niking ThomsanJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

A275 - A275M 08 (2013) - STD - Practice - For - MPI - of - Steel - Forging

Diunggah oleh

Niking ThomsanHak Cipta:

Format Tersedia

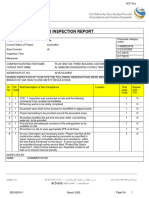

Designation: A275/A275M − 08 (Reapproved 2013)

Standard Practice for

Magnetic Particle Examination of Steel Forgings1

This standard is issued under the fixed designation A275/A275M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 1.6 This standard does not purport to address all of the

2

1.1 This practice covers a procedure for magnetic particle safety concerns, if any, associated with its use. It is the

examination of steel forgings. The procedure will produce responsibility of the user of this standard to establish appro-

consistent results upon which acceptance standards can be priate safety and health practices and determine the applica-

based. This practice does not contain acceptance standards or bility of regulatory limitations prior to use.

recommended quality levels.

2. Referenced Documents

1.2 Only direct current or rectified alternating (full or half

2.1 ASTM Standards:3

wave) current shall be used as the electric power source for any

A508/A508M Specification for Quenched and Tempered

of the magnetizing methods. Alternating current is not permit-

Vacuum-Treated Carbon and Alloy Steel Forgings for

ted because its capability to detect subsurface discontinuities is

Pressure Vessels

very limited and therefore unsuitable.

E709 Guide for Magnetic Particle Testing

1.2.1 Portable battery powered electromagnetic yokes are

E1444/E1444M Practice for Magnetic Particle Testing

outside the scope of this practice.

2.2 Other Document:

NOTE 1—Guide E709 may be utilized for magnetic particle examination Recommended Practice No. SNT-TC-1A, Supplement

in the field for machinery components originally manufactured from steel

forgings. B-Magnetic Particle Method4

1.3 The minimum requirements for magnetic particle ex- 3. Terminology

amination shall conform to practice standards of Practice

E1444/E1444M. If the requirements of this practice are in 3.1 Definitions:

conflict with the requirements of Practice E1444/E1444M, the 3.1.1 indication—the visual magnetic particle buildup re-

requirements of this practice shall prevail. sulting from leakage fields in the magnetic field.

3.1.2 linear indication—an indication in which the length is

1.4 This practice and the applicable material specifications

at least three times the width. The minimum length of

are expressed in both inch-pound units and SI units. However,

indications to be considered linear shall be 1⁄16 in. [1.6 mm].

unless the order specifies the applicable “M” specification

designation [SI units], the material shall be furnished to 3.1.3 magnetic flux—the product of the magnetic induction

inch-pound units. and the area of a surface (or cross section) when the magnetic

induction is uniformly distributed and normal to the plane of

1.5 The values stated in either SI units or inch-pound units the surface. The concept that the magnetic field is flowing

are to be regarded separately as standard. The values stated in along the lines of force suggests that these lines are therefore

each system may not be exact equivalents; therefore, each “flux” lines, and they are called magnetic flux.

system shall be used independently of the other. Combining

values from the two systems may result in non-conformance 3.1.4 magnetic particle method of examination—a method

with the standard. for detecting discontinuities on or near the surface in suitably

magnetized materials, which employs finely divided magnetic

particles that tend to congregate in regions of leakage fields.

1

This practice is under the jurisdiction of ASTM Committee A01 on Steel,

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

3

A01.06 on Steel Forgings and Billets. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved April 1, 2013. Published April 2013. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1944. Last previous edition approved in 2008 as A275/A275M – 08. Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/A0275_A0275M-08R13. the ASTM website.

2 4

For ASME Boiler and Pressure Vessel Code applications see related Method Available from American Society for Nondestructive Testing (ASNT), P.O. Box

SA-275/SA-275M in Section II of that Code. 28518, 1711 Arlingate Ln., Columbus, OH 43228-0518, http://www.asnt.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

Copyright by ASTM Int'l (all rights reserved); 1

A275/A275M − 08 (2013)

3.1.5 nonrelevant indications—indications produced by clamping pressure to allow the required current to flow without

leakage fields. However, the conditions causing them are damaging (burning) the part being examined.

present by design or accident, or other features of the part 8.2 Portable electromagnetic (ac-dc) yokes may be used in

having no relation to the damaging flaws being sought. The the dc mode as a magnetizing apparatus, provided the sensi-

term signifies that such an indication has no relation to the tivity to detect crack-like defects is demonstrated to be at least

discontinuities that might constitute defects. equivalent to that of the direct-magnetization method.

8.2.1 Portable battery powered electromagnetic yokes are

4. Significance and Use not included in the scope of this practice.

4.1 For ferromagnetic materials, magnetic particle examina-

tion is widely specified for the detection of surface and near 9. Magnetic Particles

surface discontinuities such as cracks, laps, seams, and linearly 9.1 The inspection medium shall consist of finely divided

oriented nonmetallic inclusions. Such examinations are in- ferromagnetic particles, which may be suspended in a suitable

cluded as mandatory requirements in some forging standards liquid medium, or used in dry powder form.

such as Specification A508/A508M. 9.2 The size and shape of the particles, and their magnetic

4.2 Use of direct current or rectified alternating (full or half properties, both individually and collectively, are important

wave) current as the power source for magnetic particle (see Section 12).

examination allows detection of subsurface discontinuities.

10. Surface Preparation

5. Basis of Application 10.1 The sensitivity of the magnetic particle examination

5.1 When in accordance with the requirements of the will depend to a considerable extent upon the condition of the

inquiry, contract, order, or specifications, forgings are fur- surface being tested. Defects may be satisfactorily revealed on

nished subject to magnetic particle examination, the manufac- shot-blasted or otherwise cleaned forged surfaces, or on

turer and the purchaser shall be in agreement concerning the surfaces having small amounts of heat-treating scale without

following: any special surface preparation; however, loose scale must be

5.1.1 The locations on the forgings that are to be subjected removed. To reveal fine defects, the surfaces to be inspected

to magnetic particle examination. should be smooth machined to at least a 250-µin. [6.35-µm]

5.1.2 The type, size, number, location, and orientation of finish.

indications that are to be considered injurious. 10.2 The surfaces shall be free of grease, oils, or other

5.1.3 The method of application of magnetic particles, substances to which the particles may adhere.

demagnetization requirements and magnetic field strengths. 10.3 Rough surfaces hamper the mobility of magnetic

5.2 In cases where large undercuts in the forgings are to be powders due to mechanical trapping which in turn produces

taken by the purchaser, the manufacturer shall be given the false indications. Such areas should be surface ground. If

privilege (when the design permits) of machining slots or grinding is impractical, a paper tape overlay (as described in

grooves in the rough-machined forging to explore the internal 15.1.1.2) may eliminate the problem.

conditions prior to shipping.

11. Methods of Magnetization

5.3 Acceptance standards.

11.1 The forging may be magnetized either by passing

6. Personnel Requirements current through the piece or by inducing a magnetic field by

means of a central conductor or by coils.

6.1 Personnel performing the magnetic particle examination 11.1.1 Continuous Method—In the continuous method, the

to this practice shall be qualified and certified in accordance inspection medium is applied to the surface under inspection

with a written procedure conforming to Recommended Prac- while the current is still flowing. The current source generates

tice No. SNT-TC-1A or another national standard that is high amperage current in pulses of up to 1-s duration. The

acceptable to both the purchaser and the supplier. duration of this flow shall allow at least three pulses of current

or in the case where machines supply continuous current flow

7. Stage of Inspection a minimum shot of 1⁄5 to 1⁄2-s duration should be applied.

7.1 Unless otherwise specified by the purchaser, acceptance 11.1.2 Surge Method—In the surge method a high-

inspection shall be performed on a forging in the final magnetizing force is applied and then reduced to a lower

machined surface condition and final thermally treated condi- continuous value, which is maintained during application of

tion (including stress relief) or within 0.030 in. [0.8 mm] of the the inspection medium.

final machined surface. 11.2 At least two separate examinations shall be carried out

on each area. The second examination shall be with the lines of

8. Magnetizing Apparatus magnetic flux approximately perpendicular to those used for

8.1 Rectified alternating (full or half wave) or direct-current the first examination in that area. A different means of

electric power sources may be used. When current is passed magnetizing may be used for the second examination. Magne-

through the part itself, the equipment shall consist of contact- tizing in more than one direction cannot be accomplished

ing or clamping elements with sufficient surface area and simultaneously.

Copyright by ASTM Int'l (all rights reserved); 2

A275/A275M − 08 (2013)

NOTE 2—An exception to the above rule is overall sequential multi-

vector magnetization whereby several magnetizing circuits are provided

for sequentially magnetizing a part in multiple directions depending upon

the locations of the current connectors. By this technique, flaws of any

orientation can be detected with a single application of magnetic particles.

11.3 The two general types of magnetization with regard to

direction are longitudinal and circular, as follows:

11.3.1 Longitudinal—When a forging is magnetized

longitudinally, the magnetic flux lines are usually parallel to

the axis of the piece. A longitudinally magnetized piece always

has definite poles readily detectable by compass or magnetom-

eter. Longitudinal magnetization is usually accomplished by

placing the forging within a solenoid, often formed by wrap-

ping cable around the piece (Fig. 1). For special applications, FIG. 2 Longitudinal Magnetization, with Yoke

magnetic yokes can be used (Fig. 2) when requirements of 8.2

are met.

11.3.2 Circular—Circular magnetization is obtained by

passing a current directly through the piece (Fig. 3), or induced

through a conductor (Fig. 4), or conductors threaded (Fig. 5)

through an opening in the piece. Localized circular magenti-

zation may be obtained by passing current through the local

areas by use of prod-type contacts (Fig. 6).

11.4 The magnetic field is confined almost entirely to the

piece and there may be no external manifestation of the

magnetized condition. Indications will appear strongest in the FIG. 3 Circular Magnetization, Current Directly Through Forging

direction perpendicular to the direction of the magnetic field.

11.5 Field Strength—The minimum field strength that will

reveal and permit classification of all objectionable defects

shall be used. The maximum field strengths practical are the

ones just below the point at which excessive adherence of the

particles begins to occur over the surface being inspected.

11.5.1 Coil Magnetization—When coil magnetization is

used, the magnetic field strength is directly proportional to the

current (ampere-turns if a coil or solenoid is used) and

inversely proportional to the thickness of the section being FIG. 4 Circular Magnetization, Current Through a Conductor

inspected.

11.5.1.1 Longitudinal Magnetization—For encircling coils

(Fig. 1), the turns of the coil shall be kept closely together. The

field strength decreases as distance from the coil increases and

long parts must be magnetized in sections. If the area to be

inspected extends beyond 6 in. [150 mm] on either side of the

coils, the adequacy of the field shall be demonstrated by the use

of field indicators (see 11.5.6).

FIG. 5 Circular Magnetization, Current Through Conductors

Threaded Through Forging

(1) Small Forgings—Magnetizing force shall be 35 000

ampere-turns divided by the sum of 2 plus the “length over

diameter” ratio of the test part. For example, a part 10 in.

[250 mm] long by 2 in. [50 mm] in outside diameter has an L/D

ratio of 5. Therefore, 35 000/(2 + 5) = 5000 ampere-turns; if a

5-turn coil is used, the current required is 5000/5 or 1000 A.

This formula provides an adequate field strength on small parts

FIG. 1 Longitudinal Magnetization having an L/D ratio of 4 or greater. For parts having a smaller

Copyright by ASTM Int'l (all rights reserved); 3

A275/A275M − 08 (2013)

been examined by clamping contacts to the wall thickness the

adequacy of the field in the circumferential direction shall also

be determined by the field indicator.

11.5.3 Prod Magnetization—When prods are used to circu-

larly magnetize a local area, the field strength is directly

proportional to the amperage used but also varies with the prod

spacing and thickness of section being inspected.

11.5.3.1 A magnetizing force of 75 to 100 A per linear inch

FIG. 6 Circular Magnetization with “Prod” Type Contact Elec-

trodes [3 to 4 A per millimetre] of prod spacing shall be used for

material under 3⁄4 in. [20 mm] thick, and 100 to 125 A per linear

L/D ratio, adequate field strengths shall be demonstrated by the inch [4 to 5 A per millimetre] of prod spacing shall be used for

use of a field indicator (see 11.5.6). The graph in Fig. 7 may be material 3⁄4 in. [20 mm] and over in thickness.

used to determine the ampere-turns required for each L/D 11.5.3.2 Prod spacing shall be a maximum of 8 in. [200

relationship. mm]. Prod spacing less than 3 in. [75 mm] usually is not

(2) Large Forgings—For large forgings the magnetizing feasible due to banding of the particles around the prods. Care

force shall be in the range from 1200 to 4500 ampere-turns. A shall be taken to prevent local overheating or burning of the

field indicator (see 11.5.6) shall be used to demonstrate the surface being examined. Steel- or aluminum-tipped prods or

presence of an adequate field strength over the area to be copper-brush-type prods rather than solid copper-tipped prods

inspected. are recommended where the magnetizing voltage is over 25 V

11.5.1.2 Circular Magnetization (Fig. 5)—For circular mag- open circuit (bad contact) in order to avoid copper penetration.

netization with through coils, use the current with amperage as Permanent magnetic leeches may be used as a pair or in

specified in 11.5.2 divided by the number of turns in the coil. conjunction with a prod. Leeches should not be used in excess

11.5.2 Direct Magnetization—When current is passed di- of 1500 A because loss of magnetization occurs.

rectly through the part to be examined, the current shall be 11.5.3.3 A remote control switch, which may be built into

between 100 and 900 A per inch [4 and 35 A per millimetre] of the prod handles, shall be provided to permit the current to be

diameter or cross section (per inch or millimetre of greatest turned on after the prods have been properly positioned and to

width in a plane at right angles to current flow). For hollow turn if off before the prods are removed in order to prevent

parts this would be wall thickness when cables are clamped to arcing.

the wall. Suggested current for diameters or sections up to 5 in. 11.5.3.4 Examination Coverage—Examinations shall be

[125 mm] are 600 to 900 A per inch [25 to 35 A per millimetre]; conducted with sufficient overlap to assure 100 % coverage at

for diameters or sections between 5 and 10 in. [125 to the established sensitivity.

250 mm], 400 to 600 A per inch [15 to 25 A per millimetre];

and 100 to 400 A per inch [4 to 15 A per millimetre] for outside 11.5.3.5 Direction of Magnetization—At least two separate

diameters or sections over 10 in. [250 mm]. If it is not practical examinations shall be carried out on each area. The prods shall

to obtain these current levels for diameters over 10 in. be placed so that the lines of flux during one examination are

[250 mm], the presence of an adequate field strength shall be approximately perpendicular to the lines of flux during the

demonstrated using a field indicator. In all other instances the other.

adequacy of the magnetizing force shall be demonstrated by 11.5.4 Indirect circular magnetization of the bores of shaft

means of a field indicator (see 11.5.6). When large parts have forgings (Fig. 4) shall be performed using a current of 100 to

125 A per inch [4 to 5 A per millimetre] of bore diameter.

11.5.5 A suitable instrument such as an ammeter shall be

used to measure the specified or agreed upon current.

11.5.6 A magnetic particle field indicator (Fig. 8) where

necessary shall be used to establish adequacy of the magnetic

field. The magnetizing current shall be sufficient to develop the

pattern in the indicator clearly.

11.5.6.1 The magnetic particle field indicator shall be used

by positioning the indicator on the forging being examined

while applying the required current and ferromagnetic par-

ticles. The production of a pattern (usually a cross) of discern-

ible ferromagnetic particles indicates that adequate field

strength has been generated in the forging being examined.

11.5.7 Yoke Magnetization—When electromagnetic yokes

are used to magnetize a local area, a longitudinal field is

formed between the poles.

11.5.7.1 Equipment—Yokes may be of the fixed or articu-

FIG. 7 Longitudinal Magnetization lated leg types.

Copyright by ASTM Int'l (all rights reserved); 4

A275/A275M − 08 (2013)

FIG. 8 Magnetic Particle Field Indicator

11.5.7.2 Yoke Qualification—Permitted direct-current elec- 12.2.1 Oil—The material for the wet method is usually

tromagnetic yokes shall have a lifting power of at least 40 lbf supplied in concentrate form, and the inspection medium shall

[175 N] at a pole spacing of 3 to 6 in. [75 to 150 mm]. be prepared by mixing the concentrate with a suitable light oil.

11.5.7.3 Direction of Magnetization—At least two separate The liquid recommended for the inspection vehicle is a well

examinations shall be carried out on each area. In the second refined, light, petroleum distillate having a relatively high flash

examination, the lines of magnetic flux shall be approximately point. The approximate characteristics of a suitable liquid are

perpendicular to those used for the first examination in that as follows:

area. API gravity, ° 46

11.5.7.4 Pole Spacing—Pole spacing shall be limited to 2 to Viscosity, SUS 31

Flash point (Tag Open Cup), °F [°C] 155 to 175 [65 to 80]

8 in. [50 to 200 mm]. Initial boiling point, °F [°C] 390 [200]

11.5.7.5 Inspection Area—Inspection area is limited to a End point, °F [°C] 490 [255]

maximum distance of one quarter of the pole spacing on either Color, Saybolt 25

side of a line joining the two poles. Overlapping of pole A suspension of from 1 to 2 % solid material by volume shall

spacing shall be at least 1 in. [25 mm]. generally be used. The inspection medium shall be flowed or

sprayed over the area being inspected. The color of the

12. Application of Particles particles should be chosen to provide suitable contrast.

12.1 While the forging is properly magnetized, the particles 12.2.2 Water—Magnetic particles suspended in clean water,

may be applied by one of the following methods: or clean water with suitable wetting agents may be used.

12.1.1 Dry Method—In the dry method the particles shall be Suspension of from 2 to 21⁄2 % solid material by volume shall

applied from a hand shaker (such as a shaker can), mechanical generally be used.

shaker, bulb blower, or mechanical blower. The use of the 12.3 Fluorescent Method—Fluorescent magnetic particle

shaker shall be limited to flat and nearly horizontal surfaces, inspection is a variation of the wet method. A concentrate,

whereas the blowers may be used on vertical or overhead similar to that used in the wet method, shall be used, except

surfaces. The powder shall be applied evenly on the surface of that the magnetic particle shall be coated with material that

the forging. The color of the dry powder should be chosen to fluoresces when activated by “black” light.

provide suitable contrast. Too much powder is disadvantageous 12.3.1 The same procedure specified when mixing the wet

as it masks the patterns. medium shall be followed, except that the suspension shall

12.1.2 Care shall be exercised in blowing off excess powder contain 0.1 to 0.7 % of solid material by volume when

so as not to disturb the indications. petroleum distillate or water is used.

12.2 Wet Methods: 12.3.2 The vehicle shall not be fluorescent.

Copyright by ASTM Int'l (all rights reserved); 5

A275/A275M − 08 (2013)

12.3.3 If fluorescent particles are used, the examination 14.3.1.3 Flakes (thermal ruptures caused by entrapped hy-

shall be conducted in a darkened area using “black light,” and drogen) can occur in areas that have been machined away.

the light intensity shall be at least 1000 µW/cm2 at a distance They are characterized by irregular, scattered indications.

of 15 in. from the lamp. The “black light” shall emit ultraviolet 14.3.1.4 Heat-Treating Crack indications are strong and

radiation of a wavelength within the range from 3300 to occur at corners, notches, and changes of section.

3900 Å. The particles shall emit a brilliant fluorescence when 14.3.1.5 Shrinkage Crack indications are very strong and

subjected to this light. The bulb shall be allowed to warm up sharp, usually continuous with few branches, and occur at

for a minimum of 5 min prior to its use in examination. changes of section.

14.3.1.6 Grinding Crack indications usually occur in groups

13. Demagnetization at right angles to the direction of grinding.

13.1 When specified, parts shall be sufficiently demagne- 14.3.1.7 Etching or Plating Cracks produce strong indica-

tized after inspection so that the residual field will not interfere tions in a direction perpendicular to residual stresses.

with future welding or machining operations, magnetic instru- 14.3.2 Subsurface defects produce less distinct or fuzzy

ments used in the proximity of the part, or so that leakage fields patterns which are broad rather than sharp, and are less tightly

will not occur in areas of dynamic contact surfaces. held. They generally produce the following characteristic

13.2 When direct current is used, demagnetizing may usu- indications:

ally be accomplished by repeatedly reversing and progressively 14.3.2.1 Stringers of Nonmetallic Inclusions often have

decreasing the magnetizing current. The initial field strength strong indications like surface seams but are usually discon-

used during demagnetization shall be equal to or greater than tinuous or short and occur in groups. These indications follow

the original magnetizing force. When the current has been the grain flow in forgings. The indications show only when the

reduced to the vanishing point, the part should be practically defects are near the surface.

demagnetized. Direct current is recommended for demagnetiz- 14.3.2.2 Large Nonmetallics produce indications ranging

ing large parts. from sharp to diffuse, which may occur anywhere in a section.

13.3 When alternating current is used, it is necessary merely 14.3.2.3 Cracks in Underbeads of Welds produce indica-

to decrease the magnetizing current in small steps or continu- tions that occur in broad diffuse patterns.

ously to a very low current. 14.3.2.4 Forging Bursts produce irregular and diffuse indi-

13.4 Demagnetization will not be necessary if the piece is to cations.

be subject to an austenitizing treatment prior to future use or 14.3.3 Nonrelevant or “false” indications are generally con-

machining. fusing but can usually be identified, as follows:

14.3.3.1 Magnetic Writing indications are fuzzy and will be

14. Interpretation and Evaluation of Indications destroyed by demagnetization. These indications are caused by

14.1 The following shall not be used as a standard for contact with other steel or magnets while magnetized.

rejection or acceptance of a part, but may be used as an aid in 14.3.3.2 Changes in Section are indications that are broad

interpreting and evaluating indications obtained. Examples of and fuzzy and caused by concentration of magnetic field in

discontinuities and reference photographs of magnetic particle gear teeth, fillets, keyways, etc.

indications may be found in Guide E709. 14.3.3.3 Edge of Weld indications are caused by change of

magnetic properties due to diffusion. These indications are not

14.2 Factors that must be considered in interpreting an

tightly adherent.

indication as to its cause are as follows:

14.2.1 Appearance of the indication. 14.3.3.4 Flow Lines are large groups of parallel indications

14.2.2 Direction and shape of the indication. that occur particularly in forgings examined by means of

excessive currents.

14.2.3 Type of material from which the part is made.

14.2.4 Processing history of the part, type of machining, 14.3.4 Any indication that is believed to be nonrelevant

heat treatment, etc. shall be regarded as unacceptable until the indication is either

14.2.5 Past experience with similar parts based on destruc- eliminated by surface conditioning or it is reexamined by the

tive tests such as sectioning, etching, fracturing, chipping, same or other nondestructive means and demonstrated to be

grinding, etc. nonrelevant.

14.3 The indications may be grouped into three broad 15. Report of Indications

classes:

14.3.1 Surface defects that produce sharp, distinct, clear- 15.1 Record the size, number, and location of all linear

cut, tightly adhering patterns. These may generally be inter- indications. Use sketches to show location, direction, and

preted from characteristic indications as follows: frequency of indications. The report shall indicate the type of

14.3.1.1 Laminar Defects give strong indications which are magnetization and location of contacts.

parallel to the surface. 15.1.1 Permanent Recording of Data:

14.3.1.2 Forging Laps and Folds are indications that may 15.1.1.1 A permanent record of the indications may be made

not be very heavy, and are not straight. They follow metal flow by carefully covering the surface with transparent, adhesive-

lines. backed, cellophane tape. The tape is then removed with the

Copyright by ASTM Int'l (all rights reserved); 6

A275/A275M − 08 (2013)

particle indication adhering to it. The tape may then be placed current flow and remove the tape; this will leave an exact

on white paper or cardboard and photographed or otherwise replica of the powder buildup adhering to it.

reproduced.

15.1.1.2 If a more accurate reproduction of the indication is 16. Acceptance Standards

desired the following technique may be used. Once an indica-

tion has been detected using the normal examining technique, 16.1 The standards for acceptance of defects detected by

remove the accumulated powder and place a piece of white magnetic particle examination shall be as specified in the

paper tape with a gloss surface and a gum adhesive backing applicable ASTM product specification, contract, or order.

over the area containing the indication; reapply the current and

dust the tape surface with the powder. Immediately the 17. Keywords

particles will collect over the discontinuity, and with the 17.1 circular magnetization; d c magnetization; dry method;

current still passing through the test piece, spray the tape fluorescent method; longitudinal magnetization; steel forgings;

surface with a thin coating of acrylic lacquer. Terminate the surface flaw detection; wet method

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org). Permission rights to photocopy the standard may also be secured from the ASTM website (www.astm.org/

COPYRIGHT/).

Copyright by ASTM Int'l (all rights reserved); 7

Anda mungkin juga menyukai

- Sae Ams-I-83387b-2016 PDFDokumen23 halamanSae Ams-I-83387b-2016 PDFiipmnpti iipmBelum ada peringkat

- 000.200.0077 Criticality Rating SystemDokumen8 halaman000.200.0077 Criticality Rating Systemvladimir rosas ayalaBelum ada peringkat

- Acceptance Sampling PlansDokumen31 halamanAcceptance Sampling PlansMalaika QaiserBelum ada peringkat

- Acupressure Immunity PointsDokumen30 halamanAcupressure Immunity PointsSubramanya Seshagiri100% (3)

- Acupressure Immunity PointsDokumen30 halamanAcupressure Immunity PointsSubramanya Seshagiri100% (3)

- Astm A380-17Dokumen13 halamanAstm A380-17EmekaBelum ada peringkat

- BS 5998-83Dokumen8 halamanBS 5998-83GaneshBelum ada peringkat

- Your Mind and Its MysteriesDokumen8 halamanYour Mind and Its MysteriesSamy Gonzalez100% (5)

- Ams 2680BDokumen19 halamanAms 2680BSen SeyBelum ada peringkat

- Additives in Lubricant - Types and Chemical CompositionDokumen39 halamanAdditives in Lubricant - Types and Chemical Compositionmilica18Belum ada peringkat

- Sampling Procedure For Impact Testing of Structural SteelDokumen5 halamanSampling Procedure For Impact Testing of Structural Steelrodrigo nuñezBelum ada peringkat

- AMS2643 Structural Examination of Titanium Alloys Chemical Etch Inspection Procedure Rev. EDokumen5 halamanAMS2643 Structural Examination of Titanium Alloys Chemical Etch Inspection Procedure Rev. ERubén Eduardo Galindo CarmonaBelum ada peringkat

- QAP FormatDokumen3 halamanQAP FormatSaravana Kumar100% (2)

- Astm B166 2019Dokumen9 halamanAstm B166 2019reza acbariBelum ada peringkat

- Ductile Iron Castings: Standard Reference Radiographs ForDokumen2 halamanDuctile Iron Castings: Standard Reference Radiographs ForJorge ToribioBelum ada peringkat

- ASTM A275-A275M-15 Magnetic Particle Examination of Steel ForgingsDokumen7 halamanASTM A275-A275M-15 Magnetic Particle Examination of Steel ForgingsDiego Egoávil Méndez100% (3)

- BS EN ISO 9934-1 Current CalculationDokumen3 halamanBS EN ISO 9934-1 Current Calculationbhavin178Belum ada peringkat

- AMS 5571 J-2012 - Eng.Dokumen6 halamanAMS 5571 J-2012 - Eng.TetianaBelum ada peringkat

- E1817 PDFDokumen3 halamanE1817 PDFalfonso_comimsaBelum ada peringkat

- Sae Ams 5387Dokumen8 halamanSae Ams 5387desingbuschprojectsBelum ada peringkat

- PT and MT SpecificationsDokumen2 halamanPT and MT SpecificationsAnonymous KfS1AiNhRBelum ada peringkat

- Magnetic Particle Testing: Standard Practice ForDokumen22 halamanMagnetic Particle Testing: Standard Practice ForKevin Reyes VegaBelum ada peringkat

- SALIFU BABA ISSAKA, 00511556, 335-RRC InternationalDokumen5 halamanSALIFU BABA ISSAKA, 00511556, 335-RRC InternationalBaba SalifuBelum ada peringkat

- CBLM Common Prepare Construction MaterialsDokumen50 halamanCBLM Common Prepare Construction MaterialsEfren Farinas75% (4)

- E 214 - 01 - Rtixna - PDFDokumen3 halamanE 214 - 01 - Rtixna - PDFLeón SuárezBelum ada peringkat

- Leave and License Agreement Sample FormatDokumen6 halamanLeave and License Agreement Sample FormatNiking ThomsanBelum ada peringkat

- E 215 - 98 R04 - Rtixnq - PDFDokumen7 halamanE 215 - 98 R04 - Rtixnq - PDFLeón SuárezBelum ada peringkat

- Quality Maintenance Training Programme: Concept & ImplementationDokumen46 halamanQuality Maintenance Training Programme: Concept & Implementationdeepak sharmaBelum ada peringkat

- A TextBook of Fluid Mechanics and Hydraulic Machines - Dr. R. K. Bansal PDFDokumen287 halamanA TextBook of Fluid Mechanics and Hydraulic Machines - Dr. R. K. Bansal PDFPullavartisrikanthChowdaryBelum ada peringkat

- Astm B76Dokumen6 halamanAstm B76tsliaBelum ada peringkat

- 1 E-1742Dokumen15 halaman1 E-1742punitg_2Belum ada peringkat

- Total Quality Management (Course Slides)Dokumen141 halamanTotal Quality Management (Course Slides)zia uddin khattak100% (1)

- E1209-10 Standard Practice For Fluorescent Liquid Penetrant Testing Using The Water-Washable ProcessDokumen7 halamanE1209-10 Standard Practice For Fluorescent Liquid Penetrant Testing Using The Water-Washable ProcessManuel Andres Mantilla DuranBelum ada peringkat

- Astm G47Dokumen6 halamanAstm G47brunodrBelum ada peringkat

- Liquid Penetrant Testing: Standard Practice ForDokumen11 halamanLiquid Penetrant Testing: Standard Practice ForMandy NormanBelum ada peringkat

- E1815-01 Film System Classification PDFDokumen6 halamanE1815-01 Film System Classification PDFalisyalalaBelum ada peringkat

- External Pipe Wrapping - Inspection and Test Plan: Description of LocationDokumen2 halamanExternal Pipe Wrapping - Inspection and Test Plan: Description of LocationDavidBelum ada peringkat

- Laboratory Testing Manual (2000) PDFDokumen330 halamanLaboratory Testing Manual (2000) PDFandressaoliveira2301100% (8)

- TRB Fungsi 2 SinduDokumen82 halamanTRB Fungsi 2 Sinduinovia darnaBelum ada peringkat

- SB 548Dokumen5 halamanSB 548Edson Julio S RBelum ada peringkat

- ASTM TablesDokumen185 halamanASTM Tableslahiru198367% (3)

- Astm E-164 (2019)Dokumen24 halamanAstm E-164 (2019)AnaBelum ada peringkat

- Mech NDTDokumen23 halamanMech NDTSai DashBelum ada peringkat

- ASTM-E-1742-Radiographic - Examination-Eddy Current TestingDokumen14 halamanASTM-E-1742-Radiographic - Examination-Eddy Current TestingVysakh Vasudevan100% (1)

- Industrial radiography A Complete Guide - 2019 EditionDari EverandIndustrial radiography A Complete Guide - 2019 EditionBelum ada peringkat

- Anx - B - Technical Specification, No. SR-152 PDFDokumen559 halamanAnx - B - Technical Specification, No. SR-152 PDFCedie PamplonaBelum ada peringkat

- Aar M-916-51 Clean Silica SandDokumen2 halamanAar M-916-51 Clean Silica SandNiking Thomsan88% (8)

- Hollow Bars (ISO2938)Dokumen8 halamanHollow Bars (ISO2938)suku maranBelum ada peringkat

- Astm E1001Dokumen10 halamanAstm E1001Jon DownBelum ada peringkat

- Ferrite Measurement PDFDokumen2 halamanFerrite Measurement PDFESWARANM91Belum ada peringkat

- E243 13 PDFDokumen6 halamanE243 13 PDFDaniel Mauricio Prieto ValderramaBelum ada peringkat

- Radiography of Cast Metallic Surgical Implants: Standard Practice ForDokumen2 halamanRadiography of Cast Metallic Surgical Implants: Standard Practice ForSüleyman ÖzkahramanBelum ada peringkat

- Astm e 2446Dokumen9 halamanAstm e 2446김경은Belum ada peringkat

- E3022-15 Standard Practice For MeasuremPPTDokumen8 halamanE3022-15 Standard Practice For MeasuremPPTManuel Andres Mantilla DuranBelum ada peringkat

- Standard Test Method For Radioscopic Examination of WeldmentsDokumen5 halamanStandard Test Method For Radioscopic Examination of WeldmentsWagner Renato AraújoBelum ada peringkat

- E1936-97 Evaluating Digitization SystemsDokumen4 halamanE1936-97 Evaluating Digitization SystemsNDT Div, MedequipBelum ada peringkat

- Radiologic Examination of Semiconductors and Electronic ComponentsDokumen4 halamanRadiologic Examination of Semiconductors and Electronic ComponentsERNESTO ENRIQUE FERNANDEZ BAPTISTABelum ada peringkat

- Quenched and Tempered Carbon and Alloy Steel Forgings For Pressure Vessel ComponentsDokumen5 halamanQuenched and Tempered Carbon and Alloy Steel Forgings For Pressure Vessel ComponentsJose PerezBelum ada peringkat

- E2297-04 (2010) Standard Guide For Use of UV-A and Visible Light Sources and Meters Used in The Liquid Penetrant and Magnetic Particle Methods PDFDokumen5 halamanE2297-04 (2010) Standard Guide For Use of UV-A and Visible Light Sources and Meters Used in The Liquid Penetrant and Magnetic Particle Methods PDFAnonymous PEHDuKRjoBelum ada peringkat

- E1219 Red.1332366 1 PDFDokumen7 halamanE1219 Red.1332366 1 PDFedapo79Belum ada peringkat

- Is 9902 2004 PDFDokumen11 halamanIs 9902 2004 PDFAgniva DuttaBelum ada peringkat

- ASTM E2660 RadiographyDokumen5 halamanASTM E2660 RadiographyalirezaattariBelum ada peringkat

- A345 PDFDokumen4 halamanA345 PDFaxis inspection solutionsBelum ada peringkat

- ASTM E1916 - 97 Identificación Positiva Materiales PDFDokumen3 halamanASTM E1916 - 97 Identificación Positiva Materiales PDFCristian OtivoBelum ada peringkat

- Pipe Schedule ChartDokumen1 halamanPipe Schedule ChartNejat AbabayBelum ada peringkat

- A498Dokumen13 halamanA498rgi178Belum ada peringkat

- Astm E1962 19Dokumen4 halamanAstm E1962 19Mohamed AboelkhierBelum ada peringkat

- Non-Oriented Fully Process Electrical Steel - ASTMDokumen28 halamanNon-Oriented Fully Process Electrical Steel - ASTMhpham2005Belum ada peringkat

- Tc-1a 1975Dokumen11 halamanTc-1a 1975Waron100% (1)

- High-Strength Copper-Base and Nickel-Copper Alloy Castings: Standard Reference Radiographs ForDokumen5 halamanHigh-Strength Copper-Base and Nickel-Copper Alloy Castings: Standard Reference Radiographs ForSarita SharmaBelum ada peringkat

- High-Strength Copper-Base and Nickel-Copper Alloy Castings: Standard Reference Radiographs ForDokumen5 halamanHigh-Strength Copper-Base and Nickel-Copper Alloy Castings: Standard Reference Radiographs ForSarita SharmaBelum ada peringkat

- Stainless Chromium Steel-Clad Plate: Standard Specification ForDokumen6 halamanStainless Chromium Steel-Clad Plate: Standard Specification Forist93993Belum ada peringkat

- E390-11 Standard Reference Radiographs For Steel Fusion WeldsDokumen4 halamanE390-11 Standard Reference Radiographs For Steel Fusion WeldsAhmed Shaban KotbBelum ada peringkat

- ASTM E340-95 Standard Method of Macroetch Metal AlloyDokumen11 halamanASTM E340-95 Standard Method of Macroetch Metal Alloynearmiss82100% (1)

- Astm E1025 PDFDokumen6 halamanAstm E1025 PDFmga_4566472Belum ada peringkat

- E1030-00 Examination of Metallic Castings-Radiography PDFDokumen11 halamanE1030-00 Examination of Metallic Castings-Radiography PDFShrinath BhatBelum ada peringkat

- Shallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceDari EverandShallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceBelum ada peringkat

- Proceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987Dari EverandProceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987W. R. TysonBelum ada peringkat

- Impact of Non-Destructive Testing: Proceedings of the 28th Annual British Conference on Non-Destructive Testing, Sheffield, UK, 18-21 September 1989Dari EverandImpact of Non-Destructive Testing: Proceedings of the 28th Annual British Conference on Non-Destructive Testing, Sheffield, UK, 18-21 September 1989C. BrookBelum ada peringkat

- A 275 - A 275M - 98 Qti3ns05oaDokumen7 halamanA 275 - A 275M - 98 Qti3ns05oaFadjar ZulkarnainBelum ada peringkat

- Vipshana in HindiDokumen24 halamanVipshana in HindiNiking ThomsanBelum ada peringkat

- RDSO - Specification No.M&C NDT 125 2004 Rev IDokumen6 halamanRDSO - Specification No.M&C NDT 125 2004 Rev INiking ThomsanBelum ada peringkat

- Density of Lube Oil PDFDokumen1 halamanDensity of Lube Oil PDFNiking ThomsanBelum ada peringkat

- Fuel DilutionDokumen1 halamanFuel DilutionNiking ThomsanBelum ada peringkat

- Diesel Shed LogoDokumen1 halamanDiesel Shed LogoNiking ThomsanBelum ada peringkat

- Untitled 1Dokumen1 halamanUntitled 1Niking ThomsanBelum ada peringkat

- Rubber Testing PDFDokumen7 halamanRubber Testing PDFNiking ThomsanBelum ada peringkat

- Untitled 11Dokumen1 halamanUntitled 11Niking ThomsanBelum ada peringkat

- Screenshot 20180221-173925 2 PDFDokumen1 halamanScreenshot 20180221-173925 2 PDFNiking ThomsanBelum ada peringkat

- Air Brake RDSO Report 0159 Rev - 0 Jan - 2013Dokumen149 halamanAir Brake RDSO Report 0159 Rev - 0 Jan - 2013Niking Thomsan0% (1)

- 5s Audit Check ListDokumen5 halaman5s Audit Check ListNiking ThomsanBelum ada peringkat

- Rubber TestingDokumen7 halamanRubber TestingNiking ThomsanBelum ada peringkat

- Ammonium Cerric SulphateDokumen1 halamanAmmonium Cerric SulphateNiking ThomsanBelum ada peringkat

- The Magic Touch The Simple Guide To Acupressure From Your Own Home 2157 7595.1000177 PDFDokumen4 halamanThe Magic Touch The Simple Guide To Acupressure From Your Own Home 2157 7595.1000177 PDFBilici EcaterinaBelum ada peringkat

- Ess Ess CatalougeDokumen104 halamanEss Ess CatalougeNiking ThomsanBelum ada peringkat

- Step Process To Link Aadhaar With PANDokumen4 halamanStep Process To Link Aadhaar With PANNiking ThomsanBelum ada peringkat

- AMCOL MCST TR HeviSand Sieve Comparison ChartDokumen1 halamanAMCOL MCST TR HeviSand Sieve Comparison ChartNiking ThomsanBelum ada peringkat

- Pivot Table and ChartsDokumen21 halamanPivot Table and ChartsNiking ThomsanBelum ada peringkat

- AbdDokumen1 halamanAbdNiking ThomsanBelum ada peringkat

- DSF 1104801 1758 3690 Env PRC 012 - 0Dokumen21 halamanDSF 1104801 1758 3690 Env PRC 012 - 0Goulet KostBelum ada peringkat

- Quality Inspection & Assurance: Basic BriefingDokumen12 halamanQuality Inspection & Assurance: Basic Briefingsyed sardar hussain shahBelum ada peringkat

- Naukri RohinLohat (10y 0m) PDFDokumen5 halamanNaukri RohinLohat (10y 0m) PDFayesha siddiquiBelum ada peringkat

- Fir 1210231937276121Dokumen2 halamanFir 1210231937276121layaljamal2Belum ada peringkat

- Solutions Catalog EN 2015-08 ScreenDokumen17 halamanSolutions Catalog EN 2015-08 ScreenEvogif PrestBelum ada peringkat

- Civil Engineering Construction Inspection ChecklistDokumen8 halamanCivil Engineering Construction Inspection ChecklistAditya ConstructionBelum ada peringkat

- Non Destructive TestiDokumen8 halamanNon Destructive TestiBen JoeBelum ada peringkat

- Checking Fixture STDDokumen12 halamanChecking Fixture STDSandip PatilBelum ada peringkat

- Kineski Limovi Q PDFDokumen10 halamanKineski Limovi Q PDFssteticBelum ada peringkat

- A Guide To Whole-School Evaluation in Primary Schools: Evaluation Support and Research UnitDokumen32 halamanA Guide To Whole-School Evaluation in Primary Schools: Evaluation Support and Research UnitAnnie A ShahBelum ada peringkat

- Ge Mentor Visual Iq Specifications Spec Sheet Iv11Dokumen7 halamanGe Mentor Visual Iq Specifications Spec Sheet Iv11AngelBelum ada peringkat

- Checklist - Transformer Location Inspection ChecklistDokumen3 halamanChecklist - Transformer Location Inspection ChecklistSachin wakeBelum ada peringkat

- QC Inspector - General (To Be Shortlisted Based On RespectiveDokumen2 halamanQC Inspector - General (To Be Shortlisted Based On RespectiveMd ShariqueBelum ada peringkat

- Module & Sesion Plan IIDokumen23 halamanModule & Sesion Plan IIGODBelum ada peringkat

- 4.2.3 Bulk Plant MaintenanceDokumen4 halaman4.2.3 Bulk Plant Maintenancejose jonathan oyola solorzanoBelum ada peringkat

- Hilti PD 4 Laser Range MeterDokumen15 halamanHilti PD 4 Laser Range MeterRaman IyerBelum ada peringkat

- June 2013 Pressure Points - CVN Exemption PDFDokumen4 halamanJune 2013 Pressure Points - CVN Exemption PDFMario MolinaBelum ada peringkat

- Project PPT - OKDokumen28 halamanProject PPT - OKkrushna NikamBelum ada peringkat