Av3 CD Automobile PDF

Diunggah oleh

Chetan DalviJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Av3 CD Automobile PDF

Diunggah oleh

Chetan DalviHak Cipta:

Format Tersedia

ATI MUMBAI CURRICULUM DOCUMENT TC/AVTS/AV.03/01 Ver 1.

Course BASIC CAR MAINTAINANCE

Title

Purpose To acquire practical knowledge on Maintaining Vehicles.

Eligibility 1. Degree/Diploma in relevant branch of engineering or NTC/NAC with 2-3 years relevant

trade experience.

2. SSC with Valid Driving License.

Duration 01 week

Location ADVANCED TRAINING INSTITUTE, MUMBAI

Learning After completion of training the candidate will

outcomes 1. Able to Perform Basic Maintenance of Cars/Vehicles.

2. Perform Basic Checks like, Checking Engine Oil, Brake oil etc.

Teaching 1 Lectures in class room.

methods 2 Practice sessions

3 Group exercises

4 Demonstrations.

Assessment Formative Assessment Consist of Following Things.

methods Srl No Criteria for Assessment Maximum Marks

1-A Attendance & Punctuality 20

2-B Sincerity 20

3-C Ability to Grasp the Topic 10

Summative Assessment through objective type Question consist of following things

Srl No Criteria for assessment Maximum Marks

1 Acquired Practical Knowledge 30

2 Test consist of theoretical knowledge 20

Course DAY FORENOON SESSION AFTERNOON

schedule (9.00 am – 1.00 pm) SESSTION

(1.30 pm – 5.30)

1 Admission/ Introduction of the course subject. Car Layout.

Safety Precautions, Identify Different

Parts in Vehicle.

2 Corrosion Prevention, Changing of Fuse, Checking

Corrosion in Car

Body and

Chassis. Testing

of Fuses.

3 Battery, Types, Servicing and Maintenance Practical on

Battery, Servicing

& Testing of

Spark Plug

4 Engine Tune up, Requirement and Procedure of Engine Check and

Tune up. Pollution Control Norms. Replace Fuel and

Ignition system

parts.

5 Brake Adjustment, Tyre Pressure, Proper Inflation of Feedback /

Tyres, Greasing of Suspension System, Wheel Validation

Replacement, Fan Belt Replacement

PREPARED BY REVIEWED AND APPROVED BY ISSUED BY

ATI MUMBAI CURRICULUM DOCUMENT TC/AVTS/AV.03/01 Ver 1.0

AIDS LCD projector, white board, Vehicle in Running Condition, Nitrogen Tyre Inflator, Battery Charger,

Spark Plug Testing & Cleaning Machine, Diesel Smoke meter, 5 Gas Analyzer, Measuring

Instruments/machines/material for practice sessions, laptop.

Instruction TD/AVTS/AV.03/01/CM

material TD/AVTS/AV.03/01/PPT

PREPARED BY REVIEWED AND APPROVED BY ISSUED BY

ATI MUMBAI CURRICULUM DOCUMENT TC/AVTS/AV.03/01 Ver 1.0

Course MAINTENANCE, SERVICING AND OVERHAULING OF AUTOMOTIVE PETROL ENGINE.

Title

Purpose To acquire practical knowledge to repair/maintain the petrol engine.

Eligibility 1. Degree/Diploma in relevant branch of engineering or NTC/NAC with 2-3 years relevant trade

experience

Duration 02 week

Location ADVANCED TRAINING INSTITUTE, MUMBAI

Learning On completion of the course the participant will able to repair/maintain the petrol engine.

outcomes

Teaching 1 Lectures in class room.

methods 2 Practice sessions

3 Group exercises

4 Demonstrations.

Assessment Formative Assessment Consist of Following Things.

methods Srl No Criteria for Assessment Maximum Marks

1-A Attendance & Punctuality 20

2-B Sincerity 20

3-C Ability to Grasp the Topic 10

Summative Assessment through objective type Question consist of following things

Srl No Criteria for assessment Maximum Marks

1 Acquired Practical Knowledge 30

2 Test consist of theoretical knowledge 20

Course DAY FORENOON SESSION AFTERNOON SESSTION

schedule (9.00 am – 1.00 pm) (1.30 pm – 5.30)

1 Admission/ Introduction of the course subject. Practical

Safety Precautions,

2 Engine: Specification, Components, Starting and stopping of engine.

Disassembly, Inspection repair and assembly.

3 Intake and exhaust system: Air intake quality, Disassembling the engine.

Air cleaner, manifold, PCV device.

4 Fuel: Difference between leaded petrol and Decarbonising valve, refacing , grinding

unleaded petrol and product of combustion. etc.

5 Fuel system: Carburettor, specification, Inspection, repair / replace the engine

components, adjustment, disassembly, components.

inspection repair and assembly MPFI.

6 Lubrication system: Oil pump and oil filter. Assembling the engine.

7 Cooling system: Description, water pump, Start the engine.

thermostat, radiator, coolant properties and

coolant classification.

8 Ignition system: Battery, distributor, operation, Compression test.

components, disassembly, inspection, assembly,

adjustment, test and installation, ignition coil, H.T

wires, spark plug.

9 Turbo engine: Function and operation of turbo Pollution control system, euro norms.

charger, maintenance and trouble shooting of

turbo charger.

PREPARED BY REVIEWED AND APPROVED BY ISSUED BY

ATI MUMBAI CURRICULUM DOCUMENT TC/AVTS/AV.03/01 Ver 1.0

10 Engine specified parts tightening torque, Feedback / Validation

engine tune up, service specifications.

AIDS LCD projector, white board, Vehicle in Running Condition, ECU Diagnostic Machine, Ultrasonic

Injector Cleaner, 5 Gas Analyzer, Measuring Instruments/machines/material for practice sessions,

laptop.

Instruction TD/AVTS/AV.03/02/CM

material TD/AVTS/AV.03/02/PPT

PREPARED BY REVIEWED AND APPROVED BY ISSUED BY

ATI MUMBAI CURRICULUM DOCUMENT TC/AVTS/AV.03/01 Ver 1.0

Course MAINTENANCE , SERVICING AND OVERHAULING OF AUTOMOTIVE DIESEL ENGINE.

Title

Purpose To acquire practical knowledge to repair/maintain the diesel engine.

Eligibility 1. Degree/Diploma in relevant branch of engineering or NTC/NAC with 2-3 years relevant trade

experience

Duration 02 week

Location ADVANCED TRAINING INSTITUTE, MUMBAI

Learning On completion of the course the participant will able to repair/maintain the diesel engine.

outcomes

Teaching 1 Lectures in class room.

methods 2 Practice sessions

3 Group exercises

4 Demonstrations.

Assessment Formative Assessment Consist of Following Things.

methods Srl No Criteria for Assessment Maximum Marks

1-A Attendance & Punctuality 20

2-B Sincerity 20

3-C Ability to Grasp the Topic 10

Summative Assessment through objective type Question consist of following things

Srl No Criteria for assessment Maximum Marks

1 Acquired Practical Knowledge 30

2 Test consist of theoretical knowledge 20

Course DAY FORENOON SESSION AFTERNOON SESSTION

schedule (9.00 am – 1.00 pm) (1.30 pm – 5.30)

1 Admission/ Introduction of the course subject. Practical

Safety Precautions,

2 Engine: Specification, Components, Disassembly Starting and stopping of engine.

,Inspection repair and assembly.

3 Intake and exhaust system: Air intake quality, Air Disassembling the engine.

cleaner, manifold, PCV device, super charging, turbo

charging.

4 Fuel system: FIP (inline and rotary), types of injectors Decarbonising valve refacing ,

and testing, fuel filter and fuel lines. grinding etc.

5 Lubrication system: Oil pump and oil filter. Inspection , repair / replace the

engine components.

6 Cooling system: Description, water pump, Overhaul the oil pump, oil filter,

thermostat, radiator, coolant properties and coolant cleaning oil passage, pipes, water

classification. pumps, servicing fuel system etc.

7 Engine specified parts tightening torque, engine Assembling the engine.

tune up, service specifications.

8 Turbo charger, Automatic timer. Bleeding fuel system.

9 PUC control system, product of combustion of diesel Starting the engine.

fuel.

10 Euro norms. Feedback / Validation

PREPARED BY REVIEWED AND APPROVED BY ISSUED BY

ATI MUMBAI CURRICULUM DOCUMENT TC/AVTS/AV.03/01 Ver 1.0

AIDS LCD projector, white board, Vehicle in Running Condition, ECU Diagnostic Machine, FIP Test Bench,

Injector Testing Machine, Diesel Smoke meter, 5 Gas Analyzer, Measuring

Instruments/machines/material for practice sessions, laptop.

Instruction TD/AVTS/AV.03/03/CM

material TD/AVTS/AV.03/03/PPT

PREPARED BY REVIEWED AND APPROVED BY ISSUED BY

ATI MUMBAI CURRICULUM DOCUMENT TC/AVTS/AV.03/01 Ver 1.0

Course MAINTENANCE ,SERVICING OF AUTO ELECTRICAL / ELECTRONIC SYSTEM.

Title

Purpose To acquire practical knowledge to trouble shoot, repair auto electrical / electronic system.

Eligibility 1. Degree/Diploma in relevant branch of engineering or NTC/NAC with 2-3 years relevant trade

experience

Duration 02 week

Location ADVANCED TRAINING INSTITUTE, MUMBAI

Learning On completion of the course the participant will able to trouble shoot, repair auto electrical /

outcomes electronic system.

Teaching 1 Lectures in class room.

methods 2 Practice sessions

3 Group exercises

4 Demonstrations.

Assessment Formative Assessment Consist of Following Things.

methods Srl No Criteria for Assessment Maximum Marks

1-A Attendance & Punctuality 20

2-B Sincerity 20

3-C Ability to Grasp the Topic 10

Summative Assessment through objective type Question consist of following things

Srl No Criteria for assessment Maximum Marks

1 Acquired Practical Knowledge 30

2 Test consist of theoretical knowledge 20

Course DAY FORENOON SESSION AFTERNOON SESSTION

schedule (9.00 am – 1.00 pm) (1.30 pm – 5.30)

1 Admission/ Introduction of the course subject. Practical

Safety Precautions,

2 General electrical/ electronic as applied to automobile, self Wiring practice of automobile.

induction, theory of magnetism, generation of EMF, wiring,

earthing system, basic electronics and application of

electronics.

3 Battery- specification, construction, chemical reactions, Measuring voltage drop in wiring

types and testing for the state of charge test. system.

4 Starting system –starter motor, types of starter motor, Maintenance, charging and

testing of starter motor, solenoid switches, current drop test testing of lead acid batteries.

and starter control circuit.

5 Charging system- principle of charging system and charging Repair of starter motor, dynamo,

circuit. alternator.

6 Operation and construction of dynamo/alternator, Ignition system maintenance.

regulation of the output of dynamo, alternator, diode

testing.

7 Lighting , signalling and wiring- Head light, parking light, Adjustment and testing of

brake light, fog light, beacon lamp, flasher unit, festoon lamp distributor, spark plug, ignition

, ISI colour code, indicators. coil, setting ignition timing.

8 Electrical / electronic ignition system-ignition circuit, ignition Adjustment of head light.

switches, ignition coil, distributor, condenser, spark plug,

automatic advanced mechanism, magnetos and electronic

PREPARED BY REVIEWED AND APPROVED BY ISSUED BY

ATI MUMBAI CURRICULUM DOCUMENT TC/AVTS/AV.03/01 Ver 1.0

ignition systems.

9 Electrical / electronics accessories- Horn, electrical gauges, Repair and maintenance of

relays, wiper, heater, fans, washer and wiper reversing electrical gauges and accessories.

switches and pulse tachometer.

10 Insulated return system. Feedback / Validation.

Power window and locking system- central locking system.

Fault finding of central locking system.

AIDS LCD projector, white board, Vehicle in Running Condition, Auto Electrical Test Bench, ECU

Diagnostic Machine, Battery Charger, Spark Plug Cleaning & Testing Machine, Ignition Coil

Tester, Measuring Instruments/machines/material for practice sessions, laptop.

Instruction TD/AVTS/AV.03/04/CM

material TD/AVTS/AV.03/04/PPT

PREPARED BY REVIEWED AND APPROVED BY ISSUED BY

ATI MUMBAI CURRICULUM DOCUMENT TC/AVTS/AV.03/01 Ver 1.0

Course MAINTENANCE & SERVICING OF VEHICLE AIR CONDITIONING SYSTEM AND POLLUTION

Title CONTROL SYSTEM

Purpose To acquire Practical knowledge to maintain and Service Vehicle Air Condition and Pollution

Control System of Vehicles.

Eligibility 3. Degree/Diploma in relevant branch of engineering or NTC/NAC with 2-3 years relevant

trade experience.

Duration 01 week

Location ADVANCED TRAINING INSTITUTE, MUMBAI

Learning After completion of training the candidate will

outcomes 3. Able to Perform Repair, Test and maintain Car Air Conditioning System and Pollution

Control System

4. Able to Operate Gas Charging Machine.

5. Able to Operate PUC Machine.

Teaching 1 Lectures in class room.

methods 2 Practice sessions

3 Group exercises

4 Demonstrations

Assessment Formative Assessment Consist of Following Things.

methods Srl No Criteria for Assessment Maximum Marks

1-A Attendance & Punctuality 20

2-B Sincerity 20

3-C Ability to Grasp the Topic 10

Summative Assessment through objective type Question consist of following things

Srl No Criteria for assessment Maximum Marks

1 Acquired Practical Knowledge 30

2 Test consist of theoretical knowledge 20

Course DAY FORENOON SESSION AFTERNOON

schedule (9.00 am – 1.00 pm) SESSTION

(1.30 pm – 5.30)

1 Admission/ Introduction of the course subject. Basic Air

Safety Precautions, Conditioning

Principles.

Refrigerants

Types & uses.

2 HVAC Car Layout, Components, AC Compressors, Identification of

Thermostatic Expansion Valve, RD Bottle, Evaporator, Air Conditioning

Condenser. Components.

Carryout

Performance test

on AC Unit.

PREPARED BY REVIEWED AND APPROVED BY ISSUED BY

ATI MUMBAI CURRICULUM DOCUMENT TC/AVTS/AV.03/01 Ver 1.0

Checking charged

state of

refrigerant

3 AC Gas Charging Machine use & Maintenance. Identify

Abnormal Noise

from

Compressor,

Magnetic Clutch,

and Blower

Motor. Replacing

Engine Drive Belt.

Diagnosis test

and topping up

of AC Gas using

AC Gas Charging

Machine.

4 Emission Standards, EURO and Bharat Norms, Evaporative Monitoring

Emission Control, Catalytic Conversion, Crankcase Emissions

Emission Control, Diesel Particulate Filter, EGR & SCR, procedure by use

of Engine Gas

Analyser or

Smoke meter.

Checking &

Cleaning a PCV

Valve. Inspection

of EVAP Canister

Purge valve by

use of scan tool.

EGR/SCR valve

removal and

Installation.

5 Procedure of Repair. Inspection & Fault Finding. Feedback /

Repair/Maintenance Validation

AIDS LCD projector, white board, Vehicle in Running Condition, AC Gas Charging Machine, Diesel

Smoke meter, 5 Gas Analyzer, Measuring Instruments/machines/material for practice sessions,

laptop.

Instruction TD/AVTS/AV.03/05/CM

material TD/AVTS/AV.03/05/PPT

PREPARED BY REVIEWED AND APPROVED BY ISSUED BY

ATI MUMBAI CURRICULUM DOCUMENT TC/AVTS/AV.03/01 Ver 1.0

Course MAINTENANCE & SERVICING OF VEHICLE CONTROL SYSTEM (STEERING, WHEEL BALANCING &

Title ALIGNMENT, BRAKE SYSTEM

Purpose Acquire Skills to understand the working of Steering , Brake System and Wheel Balancing & Wheel

Alignment system of Vehicles and Perform Repair/Overhaul of Vehicle Control System.

Eligibility 1. Degree/Diploma in relevant branch of engineering or NTC/NAC with 2-3 years relevant trade

experience

Duration 01 week

Location ADVANCED TRAINING INSTITUTE, MUMBAI

Learning After completion of training the candidate will

outcomes 1. Able to Perform Service and Maintenance of Vehicle Brake & Steering System

2. Able to Perform Wheel Balancing & Wheel Alignment.

Teaching 1 Lectures in class room.

methods 2 Practice sessions

3 Group exercises

4 Demonstrations.

Assessment Formative Assessment Consist of Following Things.

methods Srl No Criteria for Assessment Maximum Marks

1-A Attendance & Punctuality 20

2-B Sincerity 20

3-C Ability to Grasp the Topic 10

Summative Assessment through objective type Question consist of following things

Srl No Criteria for assessment Maximum Marks

1 Acquired Practical Knowledge 30

2 Test consist of theoretical knowledge 20

Course DAY FORENOON SESSION AFTERNOON

schedule (9.00 am – 1.00 pm) SESSTION

(1.30 pm – 5.30)

1 Admission/ Introduction of the course subject. Description &

Safety Precautions, Function of

Steering & Types

of Steering Gear

Box.

2 Steering arm and Components. Hydraulic and Electrical Identification of

Assisted Steering System. Steering System

Components.

Practice on

Removing Steering

Wheel and

Steering Gear Box.

PREPARED BY REVIEWED AND APPROVED BY ISSUED BY

ATI MUMBAI CURRICULUM DOCUMENT TC/AVTS/AV.03/01 Ver 1.0

3 Wheel Alignment Principles. Wheels and Tyres, Check and adjust

Construction and Characteristics. power steering

fluid. Inspect &

adjust engine

drive belt.

Practice on

removing wheels

from vehicle,

dismantle tyre

and tubes and

check for

puncture for

tubed and

tubeless tyre.

Perform Wheel

Balancing and

Wheel Alignment

4 Braking Systems. Different Types of Brakes. Braking Practice on

System Components. Drum Brakes and Disk Brakes Adjusting Brake

pedal play.

Overhaul/Repair

Drum and Disc

Brakes. Adjust Air

Brake and locate

air leaks-General

Maintenance.

Bleeding of

Hydraulic Brake

and Disc Brakes.

5 ABS and ESP. Procedure of Repair. Inspection & Fault Feedback /

Finding. Repair/Maintenance Validation

AIDS LCD projector, white board, Vehicle in Running Condition, Wheel Alignment Machine, Wheel

Balancing Machine, Measuring Instruments/machines/material for practice sessions, laptop.

Instruction TD/AVTS/AV.03/06/CM

material TD/AVTS/AV.03/06/PPT

PREPARED BY REVIEWED AND APPROVED BY ISSUED BY

Anda mungkin juga menyukai

- AURLTE102 - Written Knowledge Questioning - Assessment Task1 - V2Dokumen34 halamanAURLTE102 - Written Knowledge Questioning - Assessment Task1 - V2MUHAMMAD UMARBelum ada peringkat

- Competency Based Learning Material-AutomotiveDokumen7 halamanCompetency Based Learning Material-AutomotiveMarx Engel Monreal Juntado100% (1)

- Uc 3 Perform Periodic Maintenance of Drive TrainDokumen70 halamanUc 3 Perform Periodic Maintenance of Drive Trainbelinda Espano100% (3)

- CBLM DieselDokumen77 halamanCBLM DieselCoach Jimmy Garage100% (2)

- FYP 1 ReportDokumen20 halamanFYP 1 ReportAsyraf BaharudinBelum ada peringkat

- 11 Demonstration With Oral Questioning ChecklistDokumen4 halaman11 Demonstration With Oral Questioning ChecklistCelso Amoto0% (2)

- Make Yeast StarterDokumen2 halamanMake Yeast StarterAlexandraBelum ada peringkat

- Finding Targets PDFDokumen9 halamanFinding Targets PDFSteve TangBelum ada peringkat

- Automobile Engine Diagnosis and TestingDokumen7 halamanAutomobile Engine Diagnosis and TestingwolerosBelum ada peringkat

- Course Title: Vehicle Testing Lab Course Code: 6058 Course Category: A Periods/Week: 6 Periods/Semester: 90 Credits: 3Dokumen2 halamanCourse Title: Vehicle Testing Lab Course Code: 6058 Course Category: A Periods/Week: 6 Periods/Semester: 90 Credits: 3VaisakVenugopalBelum ada peringkat

- Competency Based Curriculum NC3 AutomotiveDokumen10 halamanCompetency Based Curriculum NC3 AutomotiveGilbert MendozaBelum ada peringkat

- (Revisi) Task A - Engine Petrol Tune - Competitor Instructor PDFDokumen4 halaman(Revisi) Task A - Engine Petrol Tune - Competitor Instructor PDFTeknik OtomotifBelum ada peringkat

- Title 9057.02.: Plant)Dokumen52 halamanTitle 9057.02.: Plant)SaraBelum ada peringkat

- Final Cits TractorDokumen22 halamanFinal Cits Tractorparveenrathee123Belum ada peringkat

- AAiT IC Engine and Reciprocating Machines Course Outline PDFDokumen3 halamanAAiT IC Engine and Reciprocating Machines Course Outline PDFYoseph MershaBelum ada peringkat

- Automobile TechnologyDokumen7 halamanAutomobile Technologypurusottam2765Belum ada peringkat

- Overhaul BrakesDokumen50 halamanOverhaul BrakesjovenalBelum ada peringkat

- Measurement of Effects of Automotive Engine Oils On Fuel Economy of Passenger Cars and Light-Duty Trucks in Sequence VID Spark Ignition EngineDokumen65 halamanMeasurement of Effects of Automotive Engine Oils On Fuel Economy of Passenger Cars and Light-Duty Trucks in Sequence VID Spark Ignition EngineJuan F AlvarezBelum ada peringkat

- 9 CBLMDokumen20 halaman9 CBLMMarlonProvidoCancillerBelum ada peringkat

- Automotive Fuel and Carburetor Automotive MechanicsDokumen23 halamanAutomotive Fuel and Carburetor Automotive MechanicsTim schroderBelum ada peringkat

- D 6894 - 03 - Rdy4otqDokumen13 halamanD 6894 - 03 - Rdy4otqNguyễn Bằng NộiBelum ada peringkat

- 3 - Task A-Engine Tune Up EFIDokumen3 halaman3 - Task A-Engine Tune Up EFIdarkim ajahBelum ada peringkat

- D 6709 - 03 - Rdy3mdkDokumen38 halamanD 6709 - 03 - Rdy3mdkNguyễn Bằng NộiBelum ada peringkat

- 6.automobile Engineering Lab - IDokumen7 halaman6.automobile Engineering Lab - IAmrithBelum ada peringkat

- D 6709 - 03 Rdy3mdktmdmDokumen55 halamanD 6709 - 03 Rdy3mdktmdmNORMABelum ada peringkat

- CBLM Gas NC IDokumen77 halamanCBLM Gas NC ICoach Jimmy Garage100% (1)

- Tuneup Gas EngineDokumen104 halamanTuneup Gas EngineFranz Martinez100% (1)

- Module & Sesion Plan IIDokumen23 halamanModule & Sesion Plan IIGODBelum ada peringkat

- Competency Based Learning Material: Servicing BrakesDokumen33 halamanCompetency Based Learning Material: Servicing BrakesMelvy de la Torre100% (2)

- Mot Inspection Manual Classes 1 2Dokumen79 halamanMot Inspection Manual Classes 1 2P JBelum ada peringkat

- D 6709 - 03 Rdy3mdktukveDokumen44 halamanD 6709 - 03 Rdy3mdktukveNORMABelum ada peringkat

- IgnitionDokumen79 halamanIgnitionJM Llaban RamosBelum ada peringkat

- Lks 2018 - A-Tune Up EfiDokumen6 halamanLks 2018 - A-Tune Up EfiahmadbandrexBelum ada peringkat

- What Is The Purpose of Turbine?Dokumen7 halamanWhat Is The Purpose of Turbine?sathesh waranBelum ada peringkat

- Guide TRS Automotive OccupationsDokumen2 halamanGuide TRS Automotive Occupationshunegnaw shegawBelum ada peringkat

- Assembling and Testing Manual TransmissionDokumen64 halamanAssembling and Testing Manual TransmissionAlvinBelum ada peringkat

- P1-PPsp - TSMDokumen7 halamanP1-PPsp - TSMmariah09071964Belum ada peringkat

- Servicing Differential & Front AxleDokumen38 halamanServicing Differential & Front AxleAlex J RoblesBelum ada peringkat

- COC Level-4Dokumen30 halamanCOC Level-4Nebiyu88% (8)

- BoschDokumen4 halamanBosch068 RakeshBelum ada peringkat

- Evaluation of Engine Oils For Roller Follower Wear in Light-Duty Diesel EngineDokumen19 halamanEvaluation of Engine Oils For Roller Follower Wear in Light-Duty Diesel Enginemohammed karasnehBelum ada peringkat

- CBLM Cooling SystemDokumen109 halamanCBLM Cooling SystemVanessa ParasBelum ada peringkat

- SC SystemDokumen80 halamanSC Systemgillian marbebe0% (1)

- D 6837 - 04 - Rdy4mzcDokumen60 halamanD 6837 - 04 - Rdy4mzcNguyễn Bằng NộiBelum ada peringkat

- Evaluation of Automotive Engine Oils in The Sequence VIII Spark-Ignition Engine (CLR Oil Test Engine)Dokumen39 halamanEvaluation of Automotive Engine Oils in The Sequence VIII Spark-Ignition Engine (CLR Oil Test Engine)ahmed100% (1)

- Service Cooling SystemDokumen121 halamanService Cooling Systemgillian marbebe100% (1)

- AT212 Engine Tune-Up (Gasdiesel) PDFDokumen6 halamanAT212 Engine Tune-Up (Gasdiesel) PDFJsy LangBelum ada peringkat

- Amod Amod-612 TrabajofinalDokumen3 halamanAmod Amod-612 TrabajofinalMario Gonzales Garay0% (2)

- 3 - Task A-Engine Tune Up EFI-dikonversiDokumen3 halaman3 - Task A-Engine Tune Up EFI-dikonversiekoBelum ada peringkat

- Module Perform-Pre-Delivery-InspectionDokumen56 halamanModule Perform-Pre-Delivery-InspectionRonaldo CruzBelum ada peringkat

- Pe ME 4105 CurriculumDokumen9 halamanPe ME 4105 CurriculumROHANBelum ada peringkat

- D 6681 - 01 - Rdy2odeDokumen96 halamanD 6681 - 01 - Rdy2odedangod01Belum ada peringkat

- Diagnose Faults and Overhaul A Cummins PT Diesel Fuel Injection PumpDokumen4 halamanDiagnose Faults and Overhaul A Cummins PT Diesel Fuel Injection PumpOmkar ChogaleBelum ada peringkat

- D&F AxleDokumen38 halamanD&F Axlegillian marbebeBelum ada peringkat

- Measurement of Effects of Automotive Engine Oils On Fuel Economy of Passenger Cars and Light-Duty Trucks in Sequence VIB Spark Ignition EngineDokumen60 halamanMeasurement of Effects of Automotive Engine Oils On Fuel Economy of Passenger Cars and Light-Duty Trucks in Sequence VIB Spark Ignition EngineMohanadBelum ada peringkat

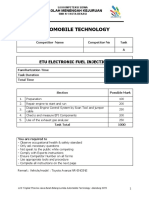

- Automobile Technology: Etu Electronic Fuel InjectionDokumen3 halamanAutomobile Technology: Etu Electronic Fuel InjectionAtep WarsitaBelum ada peringkat

- Servicing BrakesDokumen33 halamanServicing BrakesJoe Vane Niñal AntifuestoBelum ada peringkat

- Birla Institute of Technology and Science-Pilani - Hyderabad CampusDokumen3 halamanBirla Institute of Technology and Science-Pilani - Hyderabad CampusAgtBelum ada peringkat

- 6) Perform Underchassis Preventive MaintenanceDokumen52 halaman6) Perform Underchassis Preventive MaintenanceROSAN YUMANGBelum ada peringkat

- Pump Operator Cum Mechanic: Syllabus of Semester SystemDokumen27 halamanPump Operator Cum Mechanic: Syllabus of Semester SystemTeamkbkBelum ada peringkat

- TP 301R 02 PDFDokumen46 halamanTP 301R 02 PDFClaudiu LupuBelum ada peringkat

- The Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1Dari EverandThe Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1Penilaian: 4.5 dari 5 bintang4.5/5 (2)

- Sop GC6890 MS5973Dokumen11 halamanSop GC6890 MS5973Felipe AndrinoBelum ada peringkat

- Filling The Propylene Gap On Purpose TechnologiesDokumen12 halamanFilling The Propylene Gap On Purpose Technologiesvajidqc100% (1)

- Shift Registers NotesDokumen146 halamanShift Registers NotesRajat KumarBelum ada peringkat

- Surge Protection Devices CatalogueDokumen134 halamanSurge Protection Devices CatalogueNguyen Doan QuyetBelum ada peringkat

- Optimizing Stata For Analysis of Large Data SetsDokumen29 halamanOptimizing Stata For Analysis of Large Data SetsTrần Anh TùngBelum ada peringkat

- Performance Comparison of VxWorks Linux RTAI and Xenomai in A Hard Real-Time ApplicationDokumen5 halamanPerformance Comparison of VxWorks Linux RTAI and Xenomai in A Hard Real-Time ApplicationsatyanaryanakBelum ada peringkat

- Aectp 300 3Dokumen284 halamanAectp 300 3AlexBelum ada peringkat

- EEE301 Digital Electronics Lecture 1 Part 3: Dr. A.S.M. MohsinDokumen6 halamanEEE301 Digital Electronics Lecture 1 Part 3: Dr. A.S.M. MohsinAaa AaaBelum ada peringkat

- Mba633 Road To Hell Case AnalysisDokumen3 halamanMba633 Road To Hell Case AnalysisAditi VarshneyBelum ada peringkat

- INJkon 01 4.0 ManualDokumen93 halamanINJkon 01 4.0 ManualJansirani SelvamBelum ada peringkat

- Caroline G Babin: Undergraduate Degree at Louisiana State University in Baton Rouge, Louisiana - Currently EnrolledDokumen2 halamanCaroline G Babin: Undergraduate Degree at Louisiana State University in Baton Rouge, Louisiana - Currently EnrolledCaroline BabinBelum ada peringkat

- Sociology of Crimes and Ethics Suggested Answer "A"Dokumen34 halamanSociology of Crimes and Ethics Suggested Answer "A"Bernabe Fuentes Jr.Belum ada peringkat

- Concrete Casting - Pump Station ADokumen13 halamanConcrete Casting - Pump Station ABright MuzaBelum ada peringkat

- TinkerPlots Help PDFDokumen104 halamanTinkerPlots Help PDFJames 23fBelum ada peringkat

- Unit 13 Dialogue Writing: ObjectivesDokumen8 halamanUnit 13 Dialogue Writing: ObjectivesAkg GuptBelum ada peringkat

- Chemical Engineering & Processing: Process Intensi Fication: ArticleinfoDokumen9 halamanChemical Engineering & Processing: Process Intensi Fication: Articleinfomiza adlinBelum ada peringkat

- Thesis - A Surlyn® Ionomer As A Self-Healing and Self-Sensing Composite - 2011 - UKDokumen194 halamanThesis - A Surlyn® Ionomer As A Self-Healing and Self-Sensing Composite - 2011 - UKAhmedBelum ada peringkat

- HP Scanjet Pro 2500 F1 Flatbed Scanner: Boost Productivity With Fast, Versatile ScanningDokumen2 halamanHP Scanjet Pro 2500 F1 Flatbed Scanner: Boost Productivity With Fast, Versatile ScanningParesh BabariaBelum ada peringkat

- Comparative Study On Analysis of Plain and RC Beam Using AbaqusDokumen9 halamanComparative Study On Analysis of Plain and RC Beam Using Abaqussaifal hameedBelum ada peringkat

- Field and Laboratory Evaluation of A Soft Clay Southern IraqDokumen14 halamanField and Laboratory Evaluation of A Soft Clay Southern Iraqvidyaranya_bBelum ada peringkat

- Dayco-Timing Belt Training - Entrenamiento Correa DentadaDokumen9 halamanDayco-Timing Belt Training - Entrenamiento Correa DentadaDeiby CeleminBelum ada peringkat

- Dpb6013 HRM - Chapter 3 HRM Planning w1Dokumen24 halamanDpb6013 HRM - Chapter 3 HRM Planning w1Renese LeeBelum ada peringkat

- LQZLQM ) So"L/L6H Klans LN : Sfof (No K - Of) HGSF) Nflu DFQDokumen5 halamanLQZLQM ) So"L/L6H Klans LN : Sfof (No K - Of) HGSF) Nflu DFQSAJAL KOIRALABelum ada peringkat

- Ateneo de Naga University: Professional Training For Teacher 4.0Dokumen10 halamanAteneo de Naga University: Professional Training For Teacher 4.0Rosemarie BrionesBelum ada peringkat

- Matsusada DC-DC ConvertersDokumen4 halamanMatsusada DC-DC ConvertersAP SinghBelum ada peringkat

- JVC tm1010pnDokumen4 halamanJVC tm1010pnPer VigiloBelum ada peringkat

- Most Dangerous City - Mainstreet/Postmedia PollDokumen35 halamanMost Dangerous City - Mainstreet/Postmedia PollTessa VanderhartBelum ada peringkat