7 PDFsam Valve

Diunggah oleh

mechfreeHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

7 PDFsam Valve

Diunggah oleh

mechfreeHak Cipta:

Format Tersedia

Valve - Wikipedia https://en.wikipedia.

org/wiki/Valve

Four-port valves

A 4-port valve is a valve whose body has four ports equally spaced round the body and

the disc has two passages to connect adjacent ports. It is operated with two positions.

It can be used to isolate and to simultaneously bypass a sampling cylinder installed on a

pressurized water line. It is useful to take a fluid sample without affecting the pressure of

a hydraulic system and to avoid degassing (no leak, no gas loss or air entry, no external

contamination)....

Schematic 3 way

Control ball valve:

L-shaped ball right,

Many valves are controlled manually with a handle attached to the stem. If the handle is T-shaped left

turned ninety degrees between operating positions, the valve is called a quarter-turn

valve. Butterfly, ball valves, and plug valves are often

quarter-turn valves. If the handle is circular with the stem

as the axis of rotation in the center of the circle, then the

handle is called a handwheel. Valves can also be

controlled by actuators attached to the stem. They can be

electromechanical actuators such as an electric motor or

solenoid, pneumatic actuators which are controlled by air

pressure, or hydraulic actuators which are controlled by

the pressure of a liquid such as oil or water. Actuators can

be used for the purposes of automatic control such as in

washing machine cycles, remote control such as the use of

A sailor aboard a ship operates the wheel

a centralised control room, or because manual control is

controlling a fuel valve.

too difficult such as when the valve is very large.

Pneumatic actuators and hydraulic actuators need

pressurised air or liquid lines to supply the actuator: an inlet line and an outlet line. Pilot valves are valves which

are used to control other valves. Pilot valves in the actuator lines control the supply of air or liquid going to the

actuators.

The fill valve in a toilet water tank is a liquid level-actuated valve. When a high water level is reached, a mechanism

shuts the valve which fills the tank.

In some valve designs, the pressure of the flow fluid itself or pressure difference of the flow fluid between the ports

automatically controls flow through the valve.

Other considerations

Valves are typically rated for maximum temperature and pressure by the manufacturer. The wetted materials in a

valve are usually identified also. Some valves rated at very high pressures are available. When a designer, engineer,

or user decides to use a valve for an application, he/she should ensure the rated maximum temperature and

pressure are never exceeded and that the wetted materials are compatible with the fluid the valve interior is

exposed to. In Europe, valve design and pressure ratings are subject to statutory regulation under the Pressure

Equipment Directive 97/23/EC (PED).[2]

Some fluid system designs, especially in chemical or power plants, are schematically represented in piping and

instrumentation diagrams. In such diagrams, different types of valves are represented by certain symbols.

7 of 10 23/07/2019, 10:59 AM

Anda mungkin juga menyukai

- Assignment - Trent 900Dokumen59 halamanAssignment - Trent 900AzriSafwanRusli100% (3)

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingDari EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingPenilaian: 5 dari 5 bintang5/5 (3)

- TLB890 Hydraulic Pressure Testing PDFDokumen13 halamanTLB890 Hydraulic Pressure Testing PDFjwd50% (2)

- Module 4Dokumen67 halamanModule 4Achsah K VijuBelum ada peringkat

- Hassan SalahDokumen10 halamanHassan SalahAsst. Prof. Dr. Ahmed Hameed KaleelBelum ada peringkat

- Wip Control Valves Types, SelectionDokumen11 halamanWip Control Valves Types, SelectionAkshay SalweBelum ada peringkat

- Control Components in Hydraulic SystemDokumen68 halamanControl Components in Hydraulic SystemYashwanth Mg100% (1)

- Control ValveDokumen37 halamanControl Valvevipin12krishnan100% (2)

- Valves PDFDokumen13 halamanValves PDFShehab NaeemBelum ada peringkat

- Control Valve Working, Components & TypesDokumen4 halamanControl Valve Working, Components & TypesHeri Fadli SinagaBelum ada peringkat

- VALVE TYPES AssignmentDokumen10 halamanVALVE TYPES Assignmentbabe100% (2)

- ValvesDokumen10 halamanValvesDaniaBelum ada peringkat

- What Is Control ValveDokumen4 halamanWhat Is Control ValveshahzafBelum ada peringkat

- Valves: Presented by D.Nagababu (Get-Pp)Dokumen54 halamanValves: Presented by D.Nagababu (Get-Pp)SatishSathyamevaJayatheBelum ada peringkat

- Pneumatic ValvesDokumen25 halamanPneumatic ValvesGurmeet MehmaBelum ada peringkat

- Unit 3 Control Components in Hydraulic SystemDokumen16 halamanUnit 3 Control Components in Hydraulic SystemAbhishek KumbalurBelum ada peringkat

- Valve Selection & MaintenanceDokumen120 halamanValve Selection & MaintenanceOmar Khaled100% (1)

- Hydraulic Valve and Why Do You Need ItDokumen15 halamanHydraulic Valve and Why Do You Need ItDebasish BhattacharjeeBelum ada peringkat

- An Introduction To Air Operated ValvesDokumen1 halamanAn Introduction To Air Operated ValvesSurya VamsiBelum ada peringkat

- Valves and Their Uses: University of Engineering and Technology Lahore (FSD Campus)Dokumen6 halamanValves and Their Uses: University of Engineering and Technology Lahore (FSD Campus)mjunaidBelum ada peringkat

- Unit 3 - Control Components in Hydraulic SystemDokumen63 halamanUnit 3 - Control Components in Hydraulic SystemRishiJpBelum ada peringkat

- Hydraulic Control ValvesDokumen2 halamanHydraulic Control Valvesandrija_ganzbergerBelum ada peringkat

- Activity No.1 AMT 121Dokumen2 halamanActivity No.1 AMT 121Lion ManabatBelum ada peringkat

- ValvesDokumen9 halamanValvesHarrabyy RÂwaaBelum ada peringkat

- ValveDokumen5 halamanValveJayson GeraldoBelum ada peringkat

- Control ValvesDokumen11 halamanControl ValvesKrushnasamy SuramaniyanBelum ada peringkat

- Check Valve: Valve Fluid Liquid GasDokumen5 halamanCheck Valve: Valve Fluid Liquid GasMarcelene Justine DionisioBelum ada peringkat

- Fluid Laboratory: Student Name: ىردب ريمس ريتابولف Student Number: 278 Section number: 7Dokumen28 halamanFluid Laboratory: Student Name: ىردب ريمس ريتابولف Student Number: 278 Section number: 7philopater samirBelum ada peringkat

- Flow Control ValveDokumen3 halamanFlow Control ValvealphadingBelum ada peringkat

- Hydraulic Lab FinalDokumen12 halamanHydraulic Lab FinalHafiz MellianiBelum ada peringkat

- Types of ValvesDokumen5 halamanTypes of ValvesMuhamad FakhrurrazziBelum ada peringkat

- THE GATE VALVE (See Figure: 13)Dokumen7 halamanTHE GATE VALVE (See Figure: 13)vikrantsingh2908Belum ada peringkat

- Control ValvesDokumen23 halamanControl ValvesVincent SuanBelum ada peringkat

- Unit 3 - Control Components in Hydraulic SystemDokumen10 halamanUnit 3 - Control Components in Hydraulic SystemDagnachee TeguBelum ada peringkat

- Control ValveDokumen31 halamanControl ValveMohammed AhmedBelum ada peringkat

- Directional Control ValveDokumen6 halamanDirectional Control Valvevishnu kumarBelum ada peringkat

- Chapter 8Dokumen19 halamanChapter 8Ronald Zapata VásquezBelum ada peringkat

- 5 Actuation SystemsDokumen78 halaman5 Actuation Systemsteklaykibrom3Belum ada peringkat

- VALVES (1) Principles of Communication EngineeringPrinciples of Communication EngineeringPrinciples of Communication EngineeringDokumen5 halamanVALVES (1) Principles of Communication EngineeringPrinciples of Communication EngineeringPrinciples of Communication Engineeringkateey27Belum ada peringkat

- Instrumentation and Process Control (2150504)Dokumen16 halamanInstrumentation and Process Control (2150504)Ignesh ChislaBelum ada peringkat

- Pneumatic Control ValvesDokumen2 halamanPneumatic Control ValvesMuhammad Attiq Ur RahmanBelum ada peringkat

- Pneumatic Valves and CylindersDokumen38 halamanPneumatic Valves and CylindersRedgie PotenciandoBelum ada peringkat

- Instrumentation Course 2.Dokumen67 halamanInstrumentation Course 2.FACE BOOK100% (1)

- LR3CDokumen3 halamanLR3CJerome SamuelBelum ada peringkat

- Characteristics and Types of ValvesDokumen5 halamanCharacteristics and Types of ValvesCELSHIA MARY P URK18BT005Belum ada peringkat

- Unit 3Dokumen6 halamanUnit 3hariharanbookBelum ada peringkat

- Basics of Valves Interview Questions & Answers: Directional Control ValveDokumen7 halamanBasics of Valves Interview Questions & Answers: Directional Control ValveJêmš NavikBelum ada peringkat

- Directional Control ValveDokumen12 halamanDirectional Control ValveManojkumar ThilagamBelum ada peringkat

- Control Valve ActuatorsDokumen31 halamanControl Valve ActuatorsMuhammad ImtiazBelum ada peringkat

- Control Valves in Process PlantDokumen8 halamanControl Valves in Process Plantmukramah.yusufBelum ada peringkat

- Chapter 8Dokumen60 halamanChapter 8ryan williamBelum ada peringkat

- Basics of Directional-Control ValvesDokumen11 halamanBasics of Directional-Control ValvesJosh LeBlancBelum ada peringkat

- Lab 9Dokumen5 halamanLab 9Fazail BangashBelum ada peringkat

- Discrete Control ElementsDokumen44 halamanDiscrete Control ElementswaqasahmadzBelum ada peringkat

- Fluid MDokumen17 halamanFluid MSafeer MBelum ada peringkat

- Lab 8Dokumen4 halamanLab 8Fazail BangashBelum ada peringkat

- Concepts of Instrumentation Module: ValvesDokumen23 halamanConcepts of Instrumentation Module: ValvesSnehashis BoseBelum ada peringkat

- Industrial Hydraulic CircuitsDokumen43 halamanIndustrial Hydraulic CircuitsFidel Garcia GarciaBelum ada peringkat

- 4 TH Unit ValvesDokumen43 halaman4 TH Unit ValvesBahaa EmadBelum ada peringkat

- Prevention of Actuator Emissions in the Oil and Gas IndustryDari EverandPrevention of Actuator Emissions in the Oil and Gas IndustryBelum ada peringkat

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGDari EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGBelum ada peringkat

- 4 - PDFsam - Designing Fillet Welds For Skewed T-Jointsâ - Part 1 - The James F ...Dokumen1 halaman4 - PDFsam - Designing Fillet Welds For Skewed T-Jointsâ - Part 1 - The James F ...mechfreeBelum ada peringkat

- Templates: To Check The Inside Diameter Made Out of 3-4Mm Thickness Plates D/4 To D/8 TemplatesDokumen1 halamanTemplates: To Check The Inside Diameter Made Out of 3-4Mm Thickness Plates D/4 To D/8 TemplatesmechfreeBelum ada peringkat

- 1 - PDFsam - Designing Fillet Welds For Skewed T-Jointsâ - Part 1 - The James F ...Dokumen1 halaman1 - PDFsam - Designing Fillet Welds For Skewed T-Jointsâ - Part 1 - The James F ...mechfreeBelum ada peringkat

- Logitech MX Vertical DatasheetDokumen2 halamanLogitech MX Vertical DatasheetmechfreeBelum ada peringkat

- 5 - PDFsam - Designing Fillet Welds For Skewed T-Jointsâ - Part 1 - The James F ...Dokumen1 halaman5 - PDFsam - Designing Fillet Welds For Skewed T-Jointsâ - Part 1 - The James F ...mechfreeBelum ada peringkat

- 18 PDFsam Shellrollingprocedure 131019050223 Phpapp01Dokumen1 halaman18 PDFsam Shellrollingprocedure 131019050223 Phpapp01mechfreeBelum ada peringkat

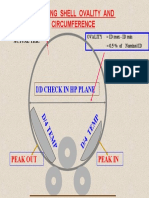

- Peak in / Peak Out: Over / Under Bending During Edge Breaking OperationDokumen1 halamanPeak in / Peak Out: Over / Under Bending During Edge Breaking OperationmechfreeBelum ada peringkat

- Tolerances On Circ. of Shells, D'Ends, Cones & BellowsDokumen1 halamanTolerances On Circ. of Shells, D'Ends, Cones & BellowsmechfreeBelum ada peringkat

- 14 PDFsam Shellrollingprocedure 131019050223 Phpapp01Dokumen1 halaman14 PDFsam Shellrollingprocedure 131019050223 Phpapp01mechfreeBelum ada peringkat

- 21 PDFsam Shellrollingprocedure 131019050223 Phpapp01Dokumen1 halaman21 PDFsam Shellrollingprocedure 131019050223 Phpapp01mechfreeBelum ada peringkat

- 7 PDFsam Shellrollingprocedure 131019050223 Phpapp01Dokumen1 halaman7 PDFsam Shellrollingprocedure 131019050223 Phpapp01mechfreeBelum ada peringkat

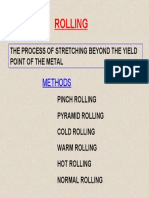

- Good Engineering Practices (For Rolling)Dokumen1 halamanGood Engineering Practices (For Rolling)mechfreeBelum ada peringkat

- Checking Shell Ovality and Circumference: I/D Check in HP PlaneDokumen1 halamanChecking Shell Ovality and Circumference: I/D Check in HP PlanemechfreeBelum ada peringkat

- 6 PDFsam Shellrollingprocedure 131019050223 Phpapp01Dokumen1 halaman6 PDFsam Shellrollingprocedure 131019050223 Phpapp01mechfreeBelum ada peringkat

- Procedure For Marking, Cutting and Checking of Shell PlatesDokumen1 halamanProcedure For Marking, Cutting and Checking of Shell PlatesmechfreeBelum ada peringkat

- 20 PDFsam Shellrollingprocedure 131019050223 Phpapp01Dokumen1 halaman20 PDFsam Shellrollingprocedure 131019050223 Phpapp01mechfreeBelum ada peringkat

- Rolling Depends: Provide Necessary Allowance (1.5 To 2 Times The Thickness)Dokumen1 halamanRolling Depends: Provide Necessary Allowance (1.5 To 2 Times The Thickness)mechfreeBelum ada peringkat

- 13 PDFsam Shellrollingprocedure 131019050223 Phpapp01Dokumen1 halaman13 PDFsam Shellrollingprocedure 131019050223 Phpapp01mechfreeBelum ada peringkat

- Cold Rolling: Rolling at Normal Room TemperatureDokumen1 halamanCold Rolling: Rolling at Normal Room TemperaturemechfreeBelum ada peringkat

- Good Engineering Practices (For Rolling)Dokumen1 halamanGood Engineering Practices (For Rolling)mechfreeBelum ada peringkat

- 11 PDFsam 875 C PDFDokumen1 halaman11 PDFsam 875 C PDFmechfreeBelum ada peringkat

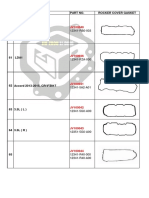

- Honda: No. Car Info. Part No. Rocker Cover GasketDokumen1 halamanHonda: No. Car Info. Part No. Rocker Cover GasketmechfreeBelum ada peringkat

- 8 - PDFsam - Johor Bahru - Travel Guide at WikivoyageDokumen1 halaman8 - PDFsam - Johor Bahru - Travel Guide at WikivoyagemechfreeBelum ada peringkat

- 19 PDFsam Shellrollingprocedure 131019050223 Phpapp01Dokumen1 halaman19 PDFsam Shellrollingprocedure 131019050223 Phpapp01mechfreeBelum ada peringkat

- 22 PDFsam Shellrollingprocedure 131019050223 Phpapp01Dokumen1 halaman22 PDFsam Shellrollingprocedure 131019050223 Phpapp01mechfreeBelum ada peringkat

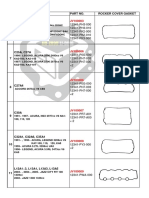

- Honda: No. Car Info. Part No. Rocker Cover Gasket EW1, EW3, EW4Dokumen1 halamanHonda: No. Car Info. Part No. Rocker Cover Gasket EW1, EW3, EW4mechfreeBelum ada peringkat

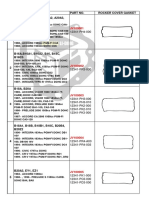

- Honda: No. Car Info. Part No. Rocker Cover GasketDokumen1 halamanHonda: No. Car Info. Part No. Rocker Cover GasketmechfreeBelum ada peringkat

- 1 PDFsam 875 C PDFDokumen1 halaman1 PDFsam 875 C PDFmechfreeBelum ada peringkat

- 15 - PDFsam - Johor Bahru - Travel Guide at WikivoyageDokumen1 halaman15 - PDFsam - Johor Bahru - Travel Guide at WikivoyagemechfreeBelum ada peringkat

- Honda: No. Car Info. Part No. Rocker Cover GasketDokumen1 halamanHonda: No. Car Info. Part No. Rocker Cover GasketmechfreeBelum ada peringkat

- Gas CompressorDokumen70 halamanGas CompressorMaulik DaveBelum ada peringkat

- CXHAXAN - Full - en - Metric - Letter BorbetDokumen2 halamanCXHAXAN - Full - en - Metric - Letter BorbetRonaldBelum ada peringkat

- EU125-40MCC Cooling TowerDokumen3 halamanEU125-40MCC Cooling TowerIndra BRBelum ada peringkat

- Anggaran Pembaikkan Bekalan Air Sistem Graviti KG Tuntul Papar, Sabah. Mukim Gana / KaiduanDokumen3 halamanAnggaran Pembaikkan Bekalan Air Sistem Graviti KG Tuntul Papar, Sabah. Mukim Gana / Kaiduansk kota kliasBelum ada peringkat

- 1st ICE Part B Paper I - 2june2010Dokumen4 halaman1st ICE Part B Paper I - 2june2010ImanAisyMuqrizBelum ada peringkat

- Process Calculations & Fan Audit Module in Cement IndustryDokumen99 halamanProcess Calculations & Fan Audit Module in Cement IndustryNITITN ASNANIBelum ada peringkat

- Ansi Fci70-2Dokumen3 halamanAnsi Fci70-2RafaelBelum ada peringkat

- Case Study - Hot Tap, Stopple and By-PassDokumen2 halamanCase Study - Hot Tap, Stopple and By-Passowenh796Belum ada peringkat

- Condensed Product CatalogueDokumen20 halamanCondensed Product CatalogueMateo Jaramillo EcheverriBelum ada peringkat

- Practical Rotordynamics For Centrifugal PumpsDokumen52 halamanPractical Rotordynamics For Centrifugal PumpsEric21Belum ada peringkat

- Cross Flow Heat Exchanger (Radiator-Fan)Dokumen9 halamanCross Flow Heat Exchanger (Radiator-Fan)Talha NasirBelum ada peringkat

- BR KU Product-Range-ValvesDokumen15 halamanBR KU Product-Range-ValvesBrion Bara IndonesiaBelum ada peringkat

- HYDAC High Pressure Ball ValvesDokumen8 halamanHYDAC High Pressure Ball ValvesOscar Andrés Aponte MurciaBelum ada peringkat

- Operators Manual: Artificial LiftDokumen25 halamanOperators Manual: Artificial LiftSam RugeBelum ada peringkat

- ch-3 Part-IDokumen29 halamanch-3 Part-ILamiBelum ada peringkat

- LMI Series AA-B-C-E-J-P Metering Pumps ManualDokumen44 halamanLMI Series AA-B-C-E-J-P Metering Pumps ManualShesharam ChouhanBelum ada peringkat

- BOMBA WILDEN P1500 PlasticDokumen24 halamanBOMBA WILDEN P1500 PlasticHiroaki HamadaBelum ada peringkat

- Calidra Comfort 24,28 CF-FFDokumen16 halamanCalidra Comfort 24,28 CF-FFFlorin BocanetBelum ada peringkat

- Debre Markos University Technology College Mechanical Engineering DepartmentDokumen4 halamanDebre Markos University Technology College Mechanical Engineering DepartmentAddisu DagneBelum ada peringkat

- 1.1 The Mechanical Energy EquationDokumen30 halaman1.1 The Mechanical Energy EquationDante ZayasBelum ada peringkat

- Compressor Surge ControlDokumen4 halamanCompressor Surge Controlerwan_exeBelum ada peringkat

- Module 5: Activity No. 2: P D D Q 150 GPM P PDokumen4 halamanModule 5: Activity No. 2: P D D Q 150 GPM P PLeyzer MalumayBelum ada peringkat

- Easy Control Valve SelectionDokumen5 halamanEasy Control Valve SelectionhrtoroBelum ada peringkat

- Com S 13 en - 09012000Dokumen4 halamanCom S 13 en - 09012000Mahmoud MahmoudBelum ada peringkat

- 3-FAMCO Hydraulic System Open CircuitDokumen59 halaman3-FAMCO Hydraulic System Open CircuitSulyman KemalBelum ada peringkat

- Compressed Air and Water SystemsDokumen10 halamanCompressed Air and Water SystemsChristian CazeñasBelum ada peringkat

- CBV BrochureDokumen8 halamanCBV BrochureHenry SuarezBelum ada peringkat

- Bomba de Alta Presion Denso Hp0pdfDokumen4 halamanBomba de Alta Presion Denso Hp0pdfMarcelo DieselBelum ada peringkat