Piping Interview Questionnaire PDF

Diunggah oleh

sushilJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Piping Interview Questionnaire PDF

Diunggah oleh

sushilHak Cipta:

Format Tersedia

lOMoARcPSD|3353238

Piping Interview Questionnaire

Design Of Mechanical Systems (University of Mumbai)

StuDocu is not sponsored or endorsed by any college or university

Downloaded by Sushil Wadiye (sushil.wadiye@gmail.com)

lOMoARcPSD|3353238

PIPING INTERVIEW QUESTIONNAIRE

COMPRESSORS

1. What are the types of compressors?

Ans : Positive Displacement, Centrifugal and Axial, rotary screw, rotary

vane, rotary lobe, dynamic, liquid ring compressors.

2. What are types of compressor drives?

Ans : Electric motor, gas turbine, steam turbine and gas engine.

3. How Centrifugal compressors work ?

Ans : Highspeed impellers increase the kinetic energy of the gas, converting this energy into higher

pressures in a divergent outlet passage called a diffuser. Large volume of gas at moderate pressure.

4. What are types of steam turbine and why are they popular?

Ans : Condensing and non-condensing, Popular because can convert large amounts of heat energy

into mechanical work very efficiently.

5. Where gas turbine drive is used ?

Ans : Desserts and offshore platforms where gas is available, for gas transmission, gas lift, liquid

pumping, gas re-injection and process compressors.

6. What are the auxillary equipments of compressor?

Ans : Lube oil consoles, Seal oil consoles, Surface condensers,

Condensate pump, Air blowers, Inlet air filters, Wast heat system,

compressor suction drum, knock out pot, Pulsation dampner, volume

bottles, Inter and after coolers.

7. What are the types of seal oil system?

Ans : Gravity and pressurized.

8. What factors to be considered while designing compressor housing?

Ans : Operation, Maintenance, Climate conditions, Safety, Economics.

9. What are the compressor housing design points?

Ans : Floor elevation, building width, building elevation, hook centreline elevation.

10. What are the types of compressor cases?

Ans : Horizontal split case, Vertical split case.

11. What are compressor suction line requirements ?

Ans : Minimum 3D straight pipe between elbow and inlet nozzle,

increases based on inlet piping layout. 4D

Downloaded by Sushil Wadiye (sushil.wadiye@gmail.com)

lOMoARcPSD|3353238

12. What are necessary parts of inlet line of compressor?

Ans : Block Valve, Strainer, Break out flanges in both inlet and outlet to

remove casing covers, Straightening vane in inlet line if not enough

straight piece in inlet line available, PSV in interstage line and in

discharge line before block valve.

13. What points to be considered for reciprocating compressor piping

layout?

Ans : High pulsation, simple line as low to grade as possible for supporting, analog study, all branches

close to line support and on top, Isolate line support from adjacent compressor or building

foundations

14. What are the types of compressor shelters?

Ans : On ground with no shelter, Open sided structure with a roof,

Curtain wall structure (Temperate climates), Open elevated installation,

Elevated multicompressor structure.

DRUMS

15. What are drum internals?

Ans : Demister pads, Baffles, Vortex breakers, Distribution piping.

16. What are drum elevation requirements?

Ans : NPSH, minimum clearance, common platforming, maintenance,

operator access.

17. What are drum supports?

Ans : Skirt for large drums, legs, lugs, saddles for horizontal drums.

18. What are necessary nozzles for non-pressure vessel?

Ans : Inlet, outlet, vent, manhole, drain, overflow, agitator, temperature

element, level instrument, and steamout connection.

19. What are necessary nozzles for pressure vessel?

Ans : Inlet, outlet, manhole, drain, pressure relief, agitator, level guage,

pressure gauge, temperature element, vent and for steamout.

Downloaded by Sushil Wadiye (sushil.wadiye@gmail.com)

lOMoARcPSD|3353238

20. What is preferred location for level instrument nozzles?

Ans : Away from the turbulence at the liquid outlet nozzle, although the

vessel is provided with a vortex breaker, instrument should be set in the

quiet zone of the vessel for example on the opposite side of the weir or

baffle or near the vapor outlet end.

21. What is preferred location for process nozzles on drum?

Ans : Minimum from the tangent line.

22. What is preferred location for steam out nozzle on drum?

Ans : At the end opposite to the maintenance access.

23. What is preferred location for vent ?

Ans : AT the top section of drum at the end opposite the steam out

connecton.

24. What is preferred location for pressure instrument nozzle on drum?

Ans : Must be anywhere in the vapor space, preferable at the top section

of drum

25. What is preferred location for temperature instrument?

Ans : Must be in liquid space, preferably on the bottom section of drum.

26. What is preferred location for drain?

Ans : Must be located at the bottom section of drum.

PIPING INTERVIEW QUESTIONNAIRE

valves

1. What are the steps in selection of valve?

Ans : What to handle, liquid, gas or powder, fluid nature, function,

construction material, disc type, stem type, how to operate, bonnet type,

body ends, delivery time, cost, warranty.

2. What are functions of valves?

Ans : Isolation, regulation, non-return and special purposes.

Downloaded by Sushil Wadiye (sushil.wadiye@gmail.com)

lOMoARcPSD|3353238

3. What are isolating valves?

Ans : Gate, ball, plug, piston, diaphragm, butterfly, pinch.

4. What are regulation valves?

Ans : Globe, needle, butterfly, diaphragm, piston, pinch.

5. What are non-return valves?

Ans : check valve,

6. What are special valves?

Ans : multi-port, flush bottom, float, foot, pressure relief, breather.

7. What materials are used for construction of valves?

Ans : Cast iron, bronze, gun metal, carbon steel, stainless steel, alloy

carbon steel, polypropylene and other plastics, special alloys.

8. What is trim?

Ans : Trim is composed of stem, seat surfaces, back seat bushing and

other small internal parts that normally contact the surface fluid.

9. Which standard specifies trim numbers for valve ?

Ans : API 600.

10. What are wetted parts of valve?

Ans : All parts that come in contact with surface fluid are called wetted

parts.

11. What is wire drawing?

Ans : This term is used to indicate the premature erosion of the valve

seat caused by excessive velocity between seat and seat disc, when valve

is not closed tightly.

12. What is straight through valve?

Ans : Valve in which the closing operation of valve is achieved by

90degrees turn of the closing element.

13. What pressure tests are carried out on valves?

Ans : Shell-hydrostatic, seat-hydrostatic, seat-pneumatic

Downloaded by Sushil Wadiye (sushil.wadiye@gmail.com)

lOMoARcPSD|3353238

14. What are available valve operators?

Ans : Handlever, handwheel, chain operator, gear operator, powered

operator likes electric motor, solenoid, pneumatic and hydraulic

operators, Quick acting operators for non-rotary valves (handle lift).

15. What are two types of ball valve?

Ans : Full port design and regular port design, according to type of seat,

soft seat and metal seat.

16. What are ball valve body types?

Ans : Single piece, double piece, three piece, the short pattern, long

pattern, sandwitch and flush bottom design.

17. Why ball valves are normally flanged?

Ans : Because of soft seat PTFE which can damage during welding.

18. What are butterfly valve types?

Ans : Double flange type, wafer lug type and wafer type.

19. What are types of check valve?

Ans : Lift check valves and swing check valves.

20. What are non-slam check valves?

Ans : Swing check valve, conventional check valve, wafer check valve,

tilting disc check valve, piston check valve, stop check valve, ball check

valve.

21. Where stop check valve is used ?

Ans : In stem generation by multiple boilers, where a valve is inserted

between each boiler and the main steam header. It can be optionally

closed automatically or normally.

22. Where diaphragm valves are used ?

Ans : Used for low pressure corrosive services as shut off valves.

23. What is Barstock Valve?

Ans: Any valve having a body machined from solid metal (barstock).

Usually needle or globe type.

24. What is BIBB Valve?

Ans: A small valve with turned down end, like a faucet.

Downloaded by Sushil Wadiye (sushil.wadiye@gmail.com)

lOMoARcPSD|3353238

25. What is Bleed Valve?

Ans: Small valve provided for drawing off liquid.

26. What is BlowDown Valve?

Ans Refers to a plug type disc globe valve used for removing sludge and

sedimentary matter from the bottom of boiler drums, vessels, driplegs etc.

27. What is Breather Valve?

Ans: A special self acting valve installed on storage tanks etc. to release vapour or gas on slight

increase of internal pressure ( in the region of ½ to 3 ounces per square inch).

28. What is Drip Valve?

Ans: A drain valve fitted to the bottom of a driplet to permit blowdown.

29. What is Flap Valve?

Ans: A non return valve having a hinged disc or rubber or leather flap

used for low pressure lines.

30. What is Hose Valve?

Ans: A gate or globe valve having one of its ends externally threaded to

one of the hose thread standards in use in the USA. These valves are

used for vehicular and firewater connections.

31. What is Paper-Stock Valve?

Ans: A single disc single seat gate valve (Slide gate) with knife edged or

notched disc used to regulate flow of paper slurry or other fibrous slurry.

32. What is Root Valve?

Ans: A valve used to isolate a pressure element or instrument from a line

or vessel, or a valve placed at the beginning of a branch form the

header.

33. What is Slurry valve?

Ans: A knife edge valve used to control flow of non-abrasive slurries.

34. What is Spiral sock valve?

Ans: A valve used to control flow of powders by means of a twistable

fabric tube or sock.

35. What is Throttling valve?

Ans: Any valve used to closely regulate flow in the just-open position.

Downloaded by Sushil Wadiye (sushil.wadiye@gmail.com)

lOMoARcPSD|3353238

36. What is Vacuum breaker?

Ans: A special self-acting valve or nay valve suitable for vacuum service,

operated manually or automatically, installed to admit gas (usually

atmospheric air) into a vacuum or low-pressure space. Such valves are

installed on high points of piping or vessels to permit draining and

sometimes to prevent siphoning.

37. What is Quick acting valve ?

Ans: Any on/off valve rapidly operable, either by manual lever, spring or

by piston, solenoid or lever with heat-fusible link releasing a weight which

in falling operates the valve. Quick acting valves are desirable in lines

conveying flammable liquids. Unsuitable for water or for liquid service in

general without a cushioning device to protect piping from shock.

38. What is diverting valve ?

Ans : This valve switch flow from one main line to two different outlets.

WYE type and pneumatic control type with no moving part.

39. What is sampling valve?

Ans : Usually of needle or globe pattern, placed in branch line for the

purpose of drawing all samples of process material thru the branch.

40. What are blow off valve?

Ans : It is a variety of globe valve confirming with boiler code

requirements and specially designed for boiler blowoff service. WYE

pattern and angle type, used to remove air and other gases from boilers

etc.

41. What is relief valve?

Ans : Valve to relieve excess pressure in liquids in situations where full

flow discharge is not required, when release of small volume of liquid

would rapidly lower pressure.

42. What is safety valve?

Ans : Rapid opening(popping action) full flow valve for air and other gases.

Downloaded by Sushil Wadiye (sushil.wadiye@gmail.com)

lOMoARcPSD|3353238

43. What is foot valve?

Ans : Valve used to maintain a head of water on the suction side of sump pump, basically a lift check

valve with integrated strainer.

44. What is float valve?

Ans : Used to control liquid level in tanks, operated by float, which rises with liquid level and opens

the valve to control water level. It can also remove air from system, in which case, air flows out of

system in valve open condition, but when water reaches valve, float inside valve raises to close the

valve and stop flow of water. Used in drip legs.

45. What are flush bottom valves?

Ans : Special type of valves used to drain out the piping, reactors and

vessels, attached on pad type nozzles.

46. What are types of flush bottom valves?

Ans : Valves with discs opening into the tank and valves with disks into

the valve.

47. What are the uses of three-way valve?

Ans : Alternate connection of the two supply lines to a common delivery

vise versa, isolating one safety valve, division of flow with isolation

facility.

48. What are uses of four way valve?

Ans : Reversal of pump suction and delivery, By pass of strainer or

meter, reversal of flow through filter, heat exchanger or dryer.

49. What is metal seated lubricated plug valve?

Ans : A plug valve with no plastic material, where grease is applied to

contacting surfaces for easy operation.

50. What are three patterns of plug valve design?

Ans : Regular pattern, short pattern and ventury pattern.

51. What is regular pattern plug valve?

Ans : Rectangular port, area almost equal to pipe bore, smooth transition

from round body to rectangular port, for minimum pressure loss.

52. What are short pattern plug valve?

Ans : Valves with face to face dimension of gate valve, as a alternative to gate valve.

Downloaded by Sushil Wadiye (sushil.wadiye@gmail.com)

lOMoARcPSD|3353238

53. What are ventury pattern plug valve?

Ans : Change of section through the body throat so graded to have

ventury effect, minimum pressure loss.

54. What are inverted plug design valve?

A s : Plug al e ith taper portio up of plug. For 8 a d higher size.

55. What is pressure balanced plug valve?

Ans : With holes in port top and bottom connecting two chambers on top

and bottom of plug, to reduce turning effort.

56. What are Teflon sleeved plug valve?

Ans : PTFE sleeve between plug and body of valve, low turning effort,

minimum friction, temperature limitation, anti static design possible.

57. What are permasil plug valve?

Ans : Plug valves with Teflon seat instead of sleeves, for on off

applications, can handle clean viscous and corrosive liqiuids, Graphite seat

for high temperature applications. Drip tight shut off not possible.

58. What are eccentric plug valve?

Ans : Off center plug, corrosive and abrasive service, on off action,

moves into and away from seat eliminating abrasive wear.

59. What is dimensional standard for plug valve?

Ans : API 599.

60. What is pinch valve?

Ans : Similar to diaphragm valve, with sleeves of rubber or PTFE, which

get sqeezed to control or stop the flow, Cast iron body, for very low

service pressures like isolation of hose connections, manufacture

standard.

61. What is needle valve?

Ans :Full pyramid disc, same design as globe valve, smaller sizes, sw or threaded, flow control, disc

can be integral with stem, inside screw, borged or barstock body and bonnet, manufacturers

standard.

62. How to install a globe valve ?

Ans : Globe valve should be installed such that the flow is from the

underside of the disk, Usually flow direction is marked on the globe valve.

Downloaded by Sushil Wadiye (sushil.wadiye@gmail.com)

lOMoARcPSD|3353238

63. What are globe valve port types?

Ans : Full port: More than 85% of bore size, Reducer port: One size less

than the connected pipe.

64. What are globe valve disk types?

Ans :Flat faced type for positive shutoff, loose plug type for plug renewalor needle type for finer

control.

65. What are characteristics of globe valve stem?

Ans : Always rising design, with disk nut at the lower end and handwheel

at upper end.

66. What are types of globe valve?

Ans : Angle globe valve, plug type disc globe valve, wye-body globe

valve, composite disc globe valve, double disc globe valve.

67. What is angle globe valve?

Ans : Ends at 90 degree to save elbow, higher pressure drop.

68. Where plug type disc globe valve is used?

Ans : For severe regulating service with gritty liquids such as boiler

feedwater and for blow off service.

69. Where WYE body globe valve is used ?

Ans : In line ports with stem emerging at 45 degree, for erosive fluids

due to smoother flow pattern.

70. What is double disc globe valve ?

Ans : Has two discs bearing on separate seats spaced apart, on a single

shaft, for low torque, used for control valves.

71. What are port types for gate valves?

Ans : Full port and reduced port. Default is reduced bore. Full port has to

be specified in bom.

72. How to close a gate valve ?

Ans :Turn the handwheel in clockwise direction.

73. What is lantern ring?

A s : It’s a olle tio poi t to drai off a hazardous seepages or as a

point where lubricant can be injected, it is in the middle of packing rings.

Downloaded by Sushil Wadiye (sushil.wadiye@gmail.com)

lOMoARcPSD|3353238

74. What are types of gate valves?

Ans : Solid plane wedge, solid flexible wedge, split wedge, double disc parallel seats, double disc

wedge, single disc single seat gate or slide, single disc parallel seats, plug gate valve.

75. What are the types of bonnets?

Ans : Bolted bonnet, bellow sealed bonnet, screwed on bonnet, union

bonnets, A U-bolt and clamp type bonnet, breechlock bonnet, pressure

seal bonnet.

76. Can you explain in detail three or more major differences between code ANSI B31.1 and code

ANSI B31.3?

Answer: There is only one major difference between the two, B31.1 is for Power Piping and B31.3 is

for Refinery/Chemical Plant Piping.

77. There is a power plant inside a Process refinery. Where exactly the ANSI B31.1 & ANSI B31.3

scope break occurs?

Answer: Based on my experience there were two cases. Case #1, B31.1 stopped at the Power Plant

Unit block valves. Thus all piping inside the Power Plant was B31.1. Case #2, B31.1 stopped at the

equipment (Boiler) isolation block valves and then all other piping was B31.3. This is normally the

choice of the owner/operator/client.

78. Which of the following piping system is more health hazardous. A) Fuel oil piping b) Process

piping with Caustic c) process piping with HF acid d) Sulphuric acid piping.

Answer: c) process piping with HF acid

79. There is a steam piping with low pocket but without steam trap. What will be worst consequence

of this layout?

Answer: There will be a build up of condensate to the point that a slug will be pushed by the steam

flow. This slug of condensate will ause ater ha er a d ould rip the pipi g apart.

80. In what circumstance, the reducer of a pump suction piping will be in bottom flat position.

Explain why the reducer should be so.

Answer: When reducers are placed in pipe Rack they are generally bottom side flat to maintain BOP

to facilitate supporting. (Answer Credit: Samir Kumar)

81. A P&ID shows a spec break (at Flange) between carbon steel & stainless steel specification. What

additional arrangements you have to make for that dissimilar material flange joint?

Answer: Use the Gasket and bolts from the SS spec.

82. A stainless steel piping specification mentions Galvanized carbons steel bolts. What is your first

reaction to this and how do you rectify it?

Answer: If that is what the Spec call for then that is what I am supposed to use. But, I would ask the

Piping Material Engineer (PME) why he/she specified galvanized bolts.

Downloaded by Sushil Wadiye (sushil.wadiye@gmail.com)

lOMoARcPSD|3353238

83. How many types of piping specialty items do you know? Why it is called a piping special? Why

not we include them in standard piping specification.

Answer: I could possibly count 50 or more depending on the PME and how the piping material specs

were developed. They are called them SP items because they are NOT written into the normal Piping

Material (Line Class) Specifications. They are not included because they are normally of limited use,

purchased from a limited product line vendor and are often after thoughts.

84. Draw a typical steam trap station layout and explain why the existence of a by-pass line around

the trap is not a good idea, when the condensate is returning to a condensate header?

Answer: (No drawing) It is not advisable to have a bypass around a steam trap because the block

valve could be left open and defeat the purpose of the trap.

85. E plai hat is a Dou le lo k & Bleed al e? Wh e eed a leed al e? Whe do e use

this?

A s er: The pri ar purpose of a Dou le Blo k & Bleed is Safet . Ho e er it is ot fail safe. The

next better Safet set-up would be Double Block Valve with a Spec Blind between the valves. The

higher level of safety would be double block valves with a removable spool for absolute isolation.

86. In a typical tie-in where should the spectacle blind be inserted? a) after block valve and towards

existing plant b) before block valve and towards new plant. Explain why.

Answer: The Spec Blind shall be placed on the Unit side of the Unit Block valves. This placement

allows for the closing of the Unit isolation block valve, the unit side is depressured and drained. Then

the spec blind can be installed for isolation of the unit.

87. Stress i te sifi atio fa tor SIF Where do e use this? E plai this ter . Ho a t pes of

these SIF’s e ist?

Answer: Stress Intensification Factor (SIF) is a multiplier on nominal stress for typically bend and

intersection components so that the effect of geometry and welding can be considered in a beam

analysis. Stress Intensification Factors form the basis of most stress analysis of piping systems. As for

the quantity, ask a Stress Engineer.

88. When all design parameters are same, whose thermal expansion is higher among the following?

A) Carbon steel b) Stainless steel c) Duplex steel d) Cast Iron e) Galvanized Carbon steel.

Answer: b) Stainless steel

89. In a hose station the hose couplings used for water, air & steam should be different type. Do you

agree? Explain your view.

Answer: I agree. If they are all the same then the hoses can be connected to the wrong services and

could result in the injury of an operator (i.e.: thinking the hose is connected to water when it is

connected to steam).

90. What is your view on the usage of Metallic expansion joints? When they become necessary and

when they could be avoided?

Answer: I do everything I can as a piping designer to avoid the use of all types of expansion joints.

Expansion joints are always the weakest point in any system where they are used.

Downloaded by Sushil Wadiye (sushil.wadiye@gmail.com)

lOMoARcPSD|3353238

91. A water cooler heat exchanger, located on a 20 m high structural platform. Water header is

located u/g. What precaution do you take, in case of Pressure loss in cooling water header?

Answer: I do not understand this question it does not appear to be a piping issue. I would assume

that the cooling water system has a (loss of) pressure sensor and the plant shut-down alarms and

sequence would be activated.

92. In what order do you arrange the pipes in the Pipe rack and why? How much % of area should be

reserved for Future expansion? Specify a range.

Answer: The largest hottest lines on the outside edge of the pipe rack working in with cooler lines in

towards the middle of the rack. This allows the longer loop legs as you lay the loops back over the

other lines to the other side of the rack and back. The lower temperature loops ould e ested

inside the larger, hotter loops.

Future ra k spa e is or all at the dire tio of the Clie t. It a e a thi g fro 0% to as u h

as 25%.

93. When a utility line (like condensate or water etc) is connected permanently to a process piping

what precaution we have to take to avoid cross contamination?

Answer: Option #1, double block valve with a drop-out spool.

Option #2, Double block valve with a spec blind.

Option #3, double block valves with a bleed valve.

94. A air fin cooler (2 air coolers with each having 2 inlet nozzles) needs a Typical piping

arrangement. How many types of piping arrangement is possible.

Answer: There are a number of ways to pipe a Fin-Fan cooler depending on what the P&ID call for?

Downloaded by Sushil Wadiye (sushil.wadiye@gmail.com)

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Summery of Changes ASME DIV 1Dokumen8 halamanSummery of Changes ASME DIV 1sushilBelum ada peringkat

- Bins and Elevated TanksDokumen10 halamanBins and Elevated TankssushilBelum ada peringkat

- Chapter 3 Design Methodology: 3.1 IntroductionDokumen10 halamanChapter 3 Design Methodology: 3.1 Introductionsushil100% (1)

- Wind Desgin As Per Ubc-97Dokumen2 halamanWind Desgin As Per Ubc-97sushilBelum ada peringkat

- Hydraulic Cylinder Side LoadDokumen8 halamanHydraulic Cylinder Side LoadsushilBelum ada peringkat

- Design of TrunionDokumen3 halamanDesign of TrunionsushilBelum ada peringkat

- Davits DesignDokumen5 halamanDavits DesignsushilBelum ada peringkat

- Design of Vessels With Refractory LiningsDokumen7 halamanDesign of Vessels With Refractory LiningssushilBelum ada peringkat

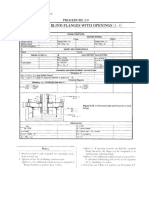

- Blind Flanges With OpeningsDokumen1 halamanBlind Flanges With OpeningssushilBelum ada peringkat

- Combined Function Hydraulic OperationDokumen4 halamanCombined Function Hydraulic OperationPutra Jawa100% (2)

- RWC UK P&H Product Guide February 2023Dokumen47 halamanRWC UK P&H Product Guide February 2023Xe CohBelum ada peringkat

- Wagi Valve Asia Pacific SDN - BHD.: Delivery RecordsDokumen7 halamanWagi Valve Asia Pacific SDN - BHD.: Delivery Recordsunnamed90Belum ada peringkat

- Compressed Gas Regulators v2 0Dokumen12 halamanCompressed Gas Regulators v2 0RajanbabuBelum ada peringkat

- Brochure Bettis Pressurematic Pneumatic Hydraulic High Low Pressure Pilots en 83954Dokumen6 halamanBrochure Bettis Pressurematic Pneumatic Hydraulic High Low Pressure Pilots en 83954jo4ubvBelum ada peringkat

- LADWER API 510 - API RP 576 - April 2017Dokumen8 halamanLADWER API 510 - API RP 576 - April 2017Luthfi ArdiansyahBelum ada peringkat

- 8 Hydrograph AnalysisDokumen26 halaman8 Hydrograph AnalysisMiera SaidBelum ada peringkat

- Basic Hydraulic: Hands-On TrainingDokumen25 halamanBasic Hydraulic: Hands-On TrainingX800XL100% (1)

- 5.6 Execution 5.4 5.5: Ball ValvesDokumen2 halaman5.6 Execution 5.4 5.5: Ball ValvesMajid DixonBelum ada peringkat

- Stg-1 TDBFP Isolation NormalisationDokumen4 halamanStg-1 TDBFP Isolation Normalisationnetygen1Belum ada peringkat

- Models 106-PR / 206-PR Pressure Reducing Valve: Key FeaturesDokumen3 halamanModels 106-PR / 206-PR Pressure Reducing Valve: Key FeaturesLouie SerranoBelum ada peringkat

- 3483 - Sterling W Series Technical Brochure SPA021 LR 01 18 PDFDokumen44 halaman3483 - Sterling W Series Technical Brochure SPA021 LR 01 18 PDFYizhar Dwi GogaBelum ada peringkat

- PowerpackDokumen39 halamanPowerpackESRABelum ada peringkat

- 5 Series E-Lite Control ModuleDokumen1 halaman5 Series E-Lite Control ModuleDuy ThaiBelum ada peringkat

- PCDokumen45 halamanPCKrishna ChaitanyaBelum ada peringkat

- 0 - Mains Water Pipe SizingDokumen4 halaman0 - Mains Water Pipe SizingstarykltBelum ada peringkat

- Coiled Tubing Operation Safety StandardDokumen23 halamanCoiled Tubing Operation Safety Standardahmed elsanhoryBelum ada peringkat

- Load Sensing Control Block SB12 PDFDokumen40 halamanLoad Sensing Control Block SB12 PDFAlaa saidBelum ada peringkat

- FireDos Stationaer EDokumen12 halamanFireDos Stationaer ERicardo CardosoBelum ada peringkat

- Priority of Procurement - Rev.20180924Dokumen17 halamanPriority of Procurement - Rev.20180924Jahangir AlamBelum ada peringkat

- Catalogo Componentes Hidraulicos ElectronicosDokumen149 halamanCatalogo Componentes Hidraulicos ElectronicosSympatyagaBelum ada peringkat

- Hawa Engineers Valves Product CatalogueDokumen88 halamanHawa Engineers Valves Product CatalogueMusef ShaikhBelum ada peringkat

- SDHI18 - Komparativna Analiza Primene Vodostana I Sinhronih Regulatora TurbinaDokumen13 halamanSDHI18 - Komparativna Analiza Primene Vodostana I Sinhronih Regulatora TurbinaAleksandar PetkovicBelum ada peringkat

- ZOLOTO Price ListDokumen10 halamanZOLOTO Price Listjafarptr0% (1)

- LESSON PLAN CEW442 SEP 15-JAN 16 New PODokumen3 halamanLESSON PLAN CEW442 SEP 15-JAN 16 New POImran37AfiqBelum ada peringkat

- 216, 226, 232, 242, 236, 246, 252 and 262 Hydraulic System Skid Steer LoaderDokumen2 halaman216, 226, 232, 242, 236, 246, 252 and 262 Hydraulic System Skid Steer LoaderHector CharreBelum ada peringkat

- Valve Definitions: N2 - CL150 RFFE, CS, Trim 8Dokumen5 halamanValve Definitions: N2 - CL150 RFFE, CS, Trim 8Chirag ShahBelum ada peringkat

- Fig.101-102 Bronze & Brass Gate ValveDokumen1 halamanFig.101-102 Bronze & Brass Gate ValveDỰ ÁN TD SCHOOL TDMEBelum ada peringkat

- WelcomeDokumen80 halamanWelcomeAhemad100% (1)

- Design A Safe, In-Compliance Relief ValveDokumen5 halamanDesign A Safe, In-Compliance Relief Valvehans nijmeijerBelum ada peringkat