Aluminum Design

Diunggah oleh

ksuscribdacct0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

52 tayangan17 halamanExcerpt from UBC97

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniExcerpt from UBC97

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

52 tayangan17 halamanAluminum Design

Diunggah oleh

ksuscribdacctExcerpt from UBC97

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF atau baca online dari Scribd

Anda di halaman 1dari 17

ter uneronm BuLoMa cove

van 26.01

Chaptor 20

LIGHTWEIGHT METALS

Division GENERAL

‘SECTION 2001 — MATERIAL STANDARDS AND Fie = testing yield engl win 1.0 inch (254 mm) of &

SvMBoLs veld, bs (Pa)

Fe = allovabl compressive stress ksi (MP).

2001.1 General. Te ili, ei bvicnon ad erection of

tluinum eed svt in bigs sdsracauses sal con

{lm othe requirements ts chp ther aplaer-

‘ements of his nde a Divison

Allowable sees ad din formu rove ath caper

shall be sed willows ses dlgn ond combinant

‘pecied in Soson 16123.

20012 Alloys. The of stomium aos and wapers tbr

than hose eoveedy thi cape and te lightweight meta a

lop ae lowe for aac! members ad asembles, poi

‘dae of perfomance oes han hse qe hi chap

tera nbd foe ait of he bling of.

‘When oj y te ullg oa cereton that he ays

el tcaper cle foron he plane bave been arsed shal Be

proved

20013 Symbols and Notations. The symbol a eaatoas

Seed chapter re dtited as flo

‘A rey, gute aces (a),

Ac = ste of compression element, squat laches (22)

(GempessonTnge pos one hid of tes f web be

fen emprosion flange an naa at)

tea of rss section ying within 1.0 ich of a weld

eat ines (a)

4 = shore dmension of ectngaar pal inches om).

3 = lange mension of eetangala pal ns om)

te = equivalent wid of cel pe, ches (=)

ane

boeing formula consans, wih following sobs:

‘compres 9 alms

‘peompresson eit plates

‘eampesson rowed bes

‘oending a voud bes

tenting in veel tars

‘ear at pier

width of sectons, nces

tridho-biclness mii of rezanglar element of «

‘ince from rental is to exteme et aches en)

damacer, ines (2).

ephofzion or ean, inches).

‘compressive modsler of elas, Rp per squat ch

Gs or.

_Mlowble ses (MP).

lowable compres rex fr member consiee a

nasil lated ol (MP),

1 = allowable compressive sts for member considered as

"beam, ti Ps).

Fy = bearing timate stength, kl (MPa).

‘Fae = bestng inate regi whi 1. inh (254m) of

srl Pa

‘iy = benting eld sheng, kl (MP).

Fe = comprstiv yield strength (MP).

Fos = compres eld sng serosa but wel (0.2

ott inch (254 mn) ge eg).

Fre = BEI wl, where islendemes ao for member

osiead aclu ening fi ine ple of Be

Spied Desdng moments kt (Ps

lowable sins for css econ 1.0 ich (25.4 mm) or

trem wl a ()

Fe = lowe seston os sco, prt of whos sea ies

‘within (2.4 mes) foch oa el A (MPa),

FF = allowable teat suse for members abject aly 12

toon ose st (MP)

Fay = shear lion strength kl (APS)

seni engi within 1. ch (25-4 me) of

elds ts).

Fy = shear yield reat, ks (MPa)

yu = shew yield seg within Lach (254m) of eg

‘si qua),

Fra = tne inte sng el (MP)

ese alm steagh across abut weld, hi (MP).

tes yieldstengh, ki (MP).

tent yell stength crs ul weld [0.2 pect f=

{Sti se (34m) ga length (ME

4, = cher Fy orf whichever le, a (MPa)

1 cabs tee, bi (MP).

4 = average comprstiv ses on css stton of member

rodced yeilcompree na, (MP).

(f= maximum tending tess Compressive) cased by

{Trevene kde oerd momen, (MPa)

ear ses cased by aon oF Waves ser, ks

iis.

modal of dsc in sb bi (MP),

‘Picing of ret orbol tle perpen diction

oud ates (em)

lear eight shear web, nes).

tmoment of eri, nck (2)

‘moment of eis tool stifee inches (a)

‘roment of bea of ante ilfener oe est

Dac, nes ei,

1 = moet of et beam aout as perpendicular

se inches!

Inches ee.

ye = momen fines af cmpresion ment about ais

purl veical web, nbs

4 = torsion conta nce).

iy © costcint or decriniog lenders iit forse

fiw for which te alowabe comprenive ase fe

aes onepping eng

fy = corfcen for deemining allowable compesive

‘Stee f stons with lenges ra above for

SHAR 20, ont

which he slowblecmptesive sess tse on

Shuibg eng

se = concent fr compreson ener.

fi = cutie oreo mente

1 ka mpi emi ean i of

‘spe or se engh fan conn

ep wae na oh rt eg cab

‘ed nck)

1 = eng of term betwee one wl the compresion

Shang s suppor gan! er movement enh

of antler beam fom een opin a whic the

tent inches ea

14 = tof engi of prion of ol ying within 1.0 ch

(254 im oa wed (exci weds at end ca

ms tha Suporte a heads) inches (am),

increased length oe ubstitedin corn oral o

determine slowaHe ses for welled cite, ces

tr.

Ur = seams ato fo columns

M » bendiag momen, inci Nn.

Mae

beating moments at wo ends of 2 beam, ic kips

Cony

Me = beating moms ot cee of son hing fom oppid

‘engl neeips avon nm

Mq * maxim bending omen in spn rshing fom

Applied bead lend, Gt),

1 eng oteaing at eset or rorentate onches

(rm.

rig = fico of sty on ppesrece of bucting

Ins = factor of sey on okie eng

ny = lacor o safety on eld seg

= tcl od cosenrtion on being tency, tips (8).

e «allowable action of concentrated aad per we, ips

an,

sllowsbe eit pr see es opting

ipsa,

2 = se ds of oad the or min onside aus

{eran oval it, nh (re).

y= dus of arate of wha amber, aces (sm),

2, = taniton rads, he rai ofan ofthe weld

ei,

3 au of gyration of caus, aches i).

‘1 = rads of yoo ip orb bol fae of Mange oe

‘hich ipa, nes aa).

45 rast gyration of enon eprom)

ie bal ue sd

teh flanges nee ian the compression fee)

eres iis

= sectgn modo of bam, compression sie, laches?

(oo)

Si © ses ao, tera of im es Yo axinum

seston meds of beam, etson ie, aches? cm),

be

‘ uirona BuiLoING cone

2 = spacing of transverse iene (es dsance between

stfenes fo eer costing of i treme

neon exc ea he we, celeste dane.

beeen steers consising of member on ote se of

‘he we col ints (mn) spacing et or al oly

parle cect fod, che (oa),

# thlkaes of ange, te, web of ibe, ches am).

(or tapered anges, ris the average knee)

V = shear freon web ttn lst, is (N)-

= a factor equal oui fora fee eosising of egal

‘embers thse ofthe wh aod cual fore

Silene costing a member on nee sly

0 ange between plan of we and plane of besing surface

(@'= 90) epee,

20014 Wentcalin. Aluminum fr src ements sa

al inst seed otherwise handed ine oeter's

lan othe ep alloy and tempest ove ent

Freda afte ompteton of esto sal be make iene

1y te slloy a temper. Such markings sal be aed

Senplete members and seis or obese bul shi

‘mens of melile eas poo shipncnt am the fats

plea

‘SECTION 2002 — ALLOWABLE STRESSES FOR

MEMBERS AND FASTENERS

20021 Allowable Uni Streses. Exp a8 mdi by Div

‘son allowable ui steer inaumine ly stuce] me

ters shal be eee in secorance wih he emul of Take

204-€ uiicng the sft actors Tale SUD, ad he

onsunls etd occas ned in Taber 20.-Es SOF an

OG. Wire wo fomulas ae given the sale of he rsh

Sroses sal be wed,

20022 Welded Sirucural Members. Allows ont seses

forsival menfers ws ee roca ss ie

{in inc (254 mm) fhe cen ine of 9b wel ef he elo

‘St wed sal be Gere by aso the formas Table

204-€ wlng he sptae lin expected ected

ropes for Welded semi alloys htt Divo It The

eset enh, Fy lb 0 pant fe Acc

Society of Mecancl Enter weld qealcnon test els of

altmte seg. Except at mosiied by Divison Mi cing

‘stants determined in ctrdane witht formes ies

2D-E and 2016 thal be eseled wing the conwsled we

‘ania ropes of the esptctve mina alloys

hess tha 15 perce ofthe ae ofa gen crs sein es

ha in (25. ot cenerin bt eld rea

fai wel te elo te wed my be neglected sed sn

‘he sess or oowelded satel memes may be ed.

Tee sea os sect th ex wi nck 254m)

eld ste 1 percent nd 10 percent of thal ae fe

{sos secion ie alowsble see all clue 9 he

Towing ermal

denne

WHERE:

A netares of ros Seton of eon mee or exson

‘ngs oa or goss aa ees secon scm

presion member campresion Mange ot team,

Sate inches (m=) (A team ange onside

ons of tat pton of he mente fare than 23

from the neal aie where te dance om he

sata asta he enone itr)

‘907 uronm SULDNG CODE

4c = wee sig iin A)

alain. 54 im) 08

fe © sant son co ena of hn eet

‘ini Sem oe

1 SeroeneSemetews ei

For columns a beams with side a eto ote hn t

‘heir appre eed tt farther om the supports ak GOS

{om the en) and for alee coma nd Single eb ams

‘itterene eon pete ene eat

‘inibe provisos af Dic

20023 Rivets and Bol. Allovoble ese in slminun vets

And ole shal bea et fort Table 20.

2A Filet Welds. Allowable shear stresses in filet welds

allbecrst fhe fable S040,

‘SECTION 2003 — DESIGN

20031 Combined Stee. Menbers abject 0 combi

Insane mesh he ves oF

20082 Light Gage Members. Whe he design of iat gage

facto ener vale, espe provisan of Dison

IS ppd.

2M8.3 Strctral Roofing and Siding. The lie load dee.

tio sactral olin and sling ad ome sheet hl nt

xced Tg the peng

‘nar 2, 0.1

20034 Connections. The design cf mechanical and welt

amectone sl be in acstane with he nthe poi

‘SECTION 2008 — FABRICATION AND ERECTION

20041 Cutting, Oxygen cating of sium aoys shal nt be

pried

20042 Fasteners. Bois sn ibe tenes tl be liu,

Stalls sel oc lumii, bodpgalvanized of cctogava™

zed sel. Doble eadmlunpsed AN sel asa as be

‘hed Stel etal tbe ed exp wher aluminam 0B

20043 Disinilr Mails, Wher slumioum allo pn are

‘ncontat with sa els oe han sis foie

‘orphaned wes or sb bling mater kly to be

fled or ater opr scordane wh isbn

20048 Painting. Except as pescred in Section 2004.3, pin

{ng or cotng ofan alloy prs Be reque ny when

‘Sed foron he plas

20045 Welding, Aluminum pn stall be welded with nine

‘is shee are or resiance welding pros. Nowell pro

{ss tht oques a eli shale aed allay cons

‘lng wih te equreeats of Dib I shall be wed

200446 Welder Quaifeation, Al vel of strstr members

Sal be prt by meee quedo coda wah te

‘pocedas ofr

20047 Erection, Duig crectog, sacl sluninum shall be

dequsely braced sad fastened ores ded wid a erection

Toes

‘7 FORM BULDG CODE : TaLe2eie

Division DESIGN STANDARD |

‘Seeed.on Specitaions for Aluminum Structures of The Aumioan Ae oeee

‘SECTION 2005 — scope

Ti sandud cores design of suninam alley lndcying

enters

SECTION 2006 —areniaLs

SECTION 2007 —Desian

esp al a secadce wth Dviton Ian eer pte

Provisions thi oe,

Proper of scion, such at crst-sectinel sre, momea of

neni section modal rads of gyaton acetal ae

lve by ecped met of

Sere omens see and ecco sais oes

‘ith aecptd piles of cane eral tee

SECTION 2008 — ALLOWABLE stresses

‘Allowable stress shal be determined in secrsce with he

‘ovine of Dison |

‘SECTION 2009 — SPECIAL DESIGN RULES

Bending. A mene sub-

‘Eso nal eompresion ua crying stand one iy

blero eet ads shall bs popoiened beers

‘he folowing tomas

2. Bending momest a emt equal oot peter tan 9 of

‘maxinun beeing mora span

hah

BY RyRy

2, Bending moment ener elo or et thi 0 of ms.

‘num beading moment sp

hehe

RRS!

3 ,eting moment center bewcen 05 sn 09 maximum

easing mostat in span

beak

Og

wuere:

Mc = bending moment at cme ofp,

‘My = maximum bending more inp

30082 ‘Torsion and Shear la Tes. Allowable shes sresse

{Mtpindor oral thes dae rson ov enavese shen at

be dkmined fom Speciation 2 Role Soe rie

‘replaced by ncpivalet hr given by hfs

Exuivsent 29(8)""(e)"

(

1997 UnFoRu au omg,

FOR aLUmnuM srRUcTURES

n (December, 1906)

WHERE:

1» leah be betvcer chef iene,

om) Egan (i) =a wean

Speciation 2014 abe 30.

20099 Conbied Shear, Compreson ned Bending,

20 combats often compretan ea ea A

ovals eam arn ort wallet sa ec

‘rom the allowing erat

hohe

RYE

nad

For sinple ecangl ps ving the same hicks te

{anges ne ase farmed set ostomy

equcmen con be cxpesied

no

WHERE:

ba, clea wid op, aces (mn.

Allowable sess fo Dnges wl liso babe meting he

20085 Horizontal Sutfener for Shear Webs. Is horizon

illness on ateam web, sab sed oe ea

t= aye [ (+B) Og seahos

For Ste ic =416231 mt

WHERE:

“AL es rs of eos eton of hers sient ie

Sect

© 1 fr siteer consisting of equ members on both

sides ofthe web

35 fosters consisting of member os oly oe side

ise = Bm)

1967 unIronu BURNS CODE 5

For Ste ich! = 416231 mt

Whena silfese compose of pairof memters one on cack

sige eth web te slener slag abe theses Stance

Between be paisa fen Whea 9 fener comport fs

‘ember on nt sie ola the we, th seme sata sll

‘ethe ditane bore ie ine ter cone nes

For sient composed of members feel ix 0 x sde

of te wed he mene ona ofthe sere sal Be com

ted bol th cet in oth web Fe siflene eomposed of

_Frumber on one sifecly ofthe web he monet finer of te

‘Eilers be ennpued abut th aca he web in coat

fro ye

15,000

i (

sens he dstnes sll awa be ken she ul lea eight

‘fie web epi of whee vn 3 hare iene

a

Sie shall exead fom ange to Mage bal ned not be

comet 1 ee ange,

Unless tower eo sine contact sien, ts

thickness alot elt ham one tcl he ear wh fe

cessing egy

‘Vert sifenes hal, were goss, be placed in pos at

sendberings an at pins of sup of conrad lod They

Shall be comectedo he webby enough ies or ter mea

anit thelone Sac fener salt ite form stand

‘lbentesrng pin th lend flange ues we dei

{uae tefl este roa, are proved ewes Hane

tod fene,

(aly th pro xfer cose section which es ouside the

‘et ote tage age shal considered scene a esig

“Bening seni stl oo be oie.

‘The moment of ine ofthe ering lens sl abe ess

“an ta gen by tn fatotng expression:

46 ried manele being siti cst

2 Spec

311 Appearance of bck. Fer eyo sections he ae

abe compres sess ena Speciation 915,16 18

Lg tT 6 may ale alec re

st aequte magn of sett povided agaist nas

[nye vere ony ppeatnc ol bing mt

te sowab sess for thin sertons hl a exsted

of Fe ves bythe flowing ormaae

Provsions for Thin Sections

are

ator

fa + the

aaa

fe > pare

coun. py 8

200912 Weighted aerae allowable compressive stress The

tres secon fs compression member maybe composed of

‘veal in lames whe llonable ree are clad

by Speciation 9.” 10 of Table 504-6 Toe flowable com

rete ses for ibe section as whole maybe cane ob

The weg avepe allowable stress orth nda lect

are te alonae ste french elements wighted stn

lice whe ae the res of he semen othe alates

Section The allovable compressive set forthe soon 23

‘nbd ised alma st at excel at piven by Specifics

Gon Tot abe 2c

Wejghed avenge allomble compesve sets for tea

‘anges maybe cleuled ee ae wa, where te awe

sess for idviual ements ae determine from Spectr

igs troup 1 of Tale 204. The ea ge mayb eon

‘Sled cena fang popes ene io be set

2000.73 Trapesidal formed sest bes. The weighed a9-

tne allowable comprenve ses for» pez oe shes

bar called acco to prapagh 2

Fa Full)

TE

Fog weighed average allowable componsve sree for

‘eo Mange,

Fig = allowable sess or pe rope base on Spin

Gol ble M.A

Fy = allowable see for webs bated on Spcifain 18 or

ot Table ae

‘The foregoing oma may aa be apd oe swale ee

sie ses taperoiafonmes shest beim the designe

‘wibesio uke fl advan of he eng ofthe ston lathe

‘se Fg Is the weighed average allows tes sues, Fy 6

‘terited rom Speen 3, Table 20.0 ae Fi sen

‘by Spienion fin Tbe 20-46

Inegons of pte bedig moment (or example Inet

suppor of mulpespe beams) the allowable ee ess

{teem flange fomed set teat all ot exceed he

Compete ures tat would be lowed ati same ge

‘we in conpresie

200974 et oc buekling on clams strength. An ad-

hon intaton mst be pardon ease ts Grey

‘Niewvalled column whos cot eto eungartae &

{ormed she shape auch ha te fnges cost of fat lesen.

‘ported bah ee th bi forte ange of ch cole

‘Sis than the vale ofS in Specification 9 of Tole 20. or

less than 0. ofthe maxi slenernens ra (cr) ote cl

‘nn, no sol recon In alowable nse eer

However fe maximo foe ages greater ae val

eof Spectenton So Tle 20-EC sas geste an

Uicot he ou andere ato forte clu tesla

thle coum Suess hal at kee the ae ten

A ae

= TP eI

WHERE:

Fre = reduced allowable sess on clu,

‘The allable es hal aboot exced the value gen by

speiteaton ol Table 0166

2008.75 Erect of lea buckling on Bem strong. The ale

icwabt compressive bending ses for single web es ws

Manges cont of thin i ements supa on one el hal

als be rede in th case where the ale of ote Range is

‘Bese tua vale of; fom Speicaion 13 of His PE

dao pese tha 16 Uist ashe sow oe

Ses al ou exceed

- ae

ETE eDHT

wuere;

Fig = reduc alomblecompresive bending ses in beam

fang

aly = Sendes rt for bea,

2009.6 iene width for caution of detec

see setts. Acted

hin

‘ain lint fare. This eal burlng may ese

‘0 deflects for ston cataaing tha lemcc ohn

le exceding 5.5, whee be vale Ss obese

meat in guesion fn Speciestions 913,16 Bed ot

‘the 201.6

ete deco t eign ads ita theefetv win

SEREER may be eto damien tectne secon shee

selection esti, The eens wich hoe taco

‘secede compression stesice

Uh > nk bee

WHERE;

% = elective wid oft plas lanes be eed in ee

‘once, ches

as = lowabe ses or emt fom Sesion gs

Ou

Ze sme exprsion maybe wed clue the fone

wish one compro ae eet ee ee

Frese bending tress deo heaped ae fe

20002. eb expping. For seul famed sheet sotng

tnd sing. lowe ineriar atone sa canes en ee

ae webs shal notexaed

rom ote (6+ onl

[14-onff) i] ee

and Pe = 1,500 EE + ("for ® > c,

2se(6 + 1)

Fie + oor ifia ~ aia

‘lowe co econ at at eer

lnwhionc, =

tnd Po 1 SODEEW + 3 (E) foe > op

fewtiche, = 125 + 1)

FB + 00eg)fur ~ ai

iene

4 deh vere pj che ny,

‘Fy = sinam copes i sng et

ersqa nh)

Pe = allowable action or concen lad er

oy.

= tend sat jane of fange and wed

secon, mead oie sae toa

Com),

1 = shes ches aces (am).

WY spe wid of web (ear hes pcing beeen

‘at of tape ston, ces ey

6 spl tween plane of web of wap etn ag

eo tang sarc (0.30, Segues

008 Fateue For po 10000 sper of maxima ve

ind ss ari

2029 Compression in Single-web Beams. The fcmsss of

Seeleation I of Table 2016 for sgn esas noes

5 ae tel on an approximation in sich the oes Ie

‘laces a more complicated expresion involving even! dent

‘ropes ofthe beam cs secon Beem Sie ae

‘on te formals ave very concrnive afr seein

on, sume for vals ally exceing shee a

_sbtions achat he beng omen Serine See

Sprifcaton Io Table 204.C may een see

15 ven by one of be folowing foouls

Bem srs subjected 1 end moment only ort tansverse

Jno apie tthe neta af fee

neh =254 mm,

Beams subjccted to ransrerse ad pido he tp obo

tom fangs (whee he ads eo moe aly wi obey

‘the eam sou bac)

Elective r, =

For St: 1 ach «25-4

‘The pls sig in ot fhe tom“. apis en ison

‘te btm Mang, he mis ii hele ison he op Mange,

Eteciver, = valu tbe sbi for in Speciation 1

orTae 301

‘The terms appesig in he be formals ae died in hs

Vio cea aoe

seas nesranen aon arena,

Sanna, ee

‘sie en tom er

Scogiames isch

course ous

4009.10 Compresin in Elataly Supported anges. A

onsite corpresve sees i hel soppore tages,

St compris fgg sa lr os

Sayed beam ded wih th to Ganges compre sal

etrmined fom Sztetn No wih ie lowing tne

ale ly sbstiatedin the ols for aoa ses

bo 47 JB

ce ff = 27 BE

tee = 27 gh

B= spring constant nese fre tn ips aplicd 1 2

‘och 2.4 ma length the mene a te compres

son Mage io cause 3 ech (234 mm) elon he

‘ange AP).

2010 — MECHANICAL CONNECTIONS

210.1 Rivted and Woted Connections. Aluminum sys

iets nd bos sal be hae ed Tale Nes

lac (64 obs a sar shal be 202.74 Nea ot

{ltr bos shall be aly 601-76 of 202.7. Fit

ll be Alclad 202-1 Spring lock wae shall te

JOIST. For impeowed case esis 8 0000 nck

G05) mii cos ol cology Sem a

HALL Allowable tnds, The slowable lads on rivets an

EA clculed wing ne allowable besing ses a

BAC with allomsbe se seria Tae DAT

esring ses depends on ihe of ge Usanc 0

el amet wise he og sane whe ios fom

oh va orb sete Sige uf sen arg ae

he prewar o eo bit is dee.

ig sree on bls py ce treads or

setae

ve diameter. Th tec dame of ves

the ol tft hl nl exceed tenet

fh vet by pret for cold ven eso

Bete nk The ce dane oft

minal dsm he bel

2010.13 Shear area The etesive ato rvt oe bel in aay

‘eae salle bed onthe etn mer ee he

bole with heads ned nh hear plas the cece shear

$e shall be based onthe roo lant

2010.14 Beacng area The eiecive besing ae of Hes or

bos sal be the fete glared ty te ngs is

ering except th couse et, al of ede othe

‘unter shall be eet fm he gt.

2010.18 Arrangements and strength of comsctions. Ister

3: poss, conecon sl be sranged so tate ait oe

Sine ofthe conection sl cone with hee neo

Seton ofthe load Where cca ext mbes md coe

‘eto sale popotoned olen syn nese

iy of adeg abe Convection

‘210.16 Net section, The net section ofa riveted or bolted tn.

‘Soa meri shal be determined ee um othe secon a

‘tscomonen prs The et section of ute pfs of ne

‘hikes oft pu males by ltt wth The et

‘dh fo tin holes enendig aero te a any tight

rbot in sale obtied by deat te pss wth

the sm ofthe disses fale ots nh ho Se ag

_2h reach gage pce ithe chain conection gant

'P)g, donee spacing parle des te oa ies)

‘of ny to secre Rls in the chin ince and ets

‘ng the spacing pepe otbeGeton of he a ee

Samet, ining mn

‘De tel ection of the part shal be blaine! fm hl cin

ch ges th feast vith: Te ble dame oe dedcred

Shall ete ac hol diameter for dled emer

the ole ame pas i074 mm prc ole

For anges he rs wd shal be these wd of he

legs eth teks. The age for oles epposte ey sel he

‘he samof be gags ome ck of he enghsiss he cen

x spice member, te hicks shal oth pao

thet fe mei hat a develope by es ol,

beyond the section cose

2010.7 Effective sections of anges. ifs dicootinous angle

(Gago pated) se tesson i conmeted oom sd as pe

Dl the eve net sector al tet etna cons

etd ley pas vendo the tecon the onstage wr

Is the oustanding ees connected bya hag spe eee

t,he eectve ne sin sal be he entre stn

gl. Teg angle sal bs designed to devel test ne al

the load inthe member aed sal Be conned ote mln

meer y a ast fener

For dsb angles ced back to back and conned obo

sides pst leh etecve nt etn sll ee

‘on the comet es pis two hd of thon to

sndg lg

Fo inemediejoins of omlauos angles be eect et

ste shall be the gros Seton se les datos Fer hoe.

2010.18 Grip af rivets and bois, te Bip Gta hikes of

‘mel ein ened) of sive Sl ean sta

‘reeds Oran oneal ines he mee aowsbe ad

inet obl tl be rece The eed alae a sll

5 th ora allowable fond vised by [s+ (9) wae

bth gip dD is te sonal tice o ever on TE

The ipo he vet exceeds nix times the damier special exe

salb keno ensue tt holes wl be ladon.

2010.19 Spacing of rvs ad bts. Misi dso of

cnr shal be he ties terol ie dame:

‘tm eance ol cates shal two ad ov alae

‘ominl bot amc, I bitop compression members, te

Bch in te deco fares sh We tsk ha eras

Soothe Indien one sheet ad stops sed or

ss hivig eg qual oe et ort ch eek oe

(planed ste The gg atv agesto hedtceanretaaes

Shull sch hatte allowabe teeta ote shes

ated om Speifeton 9 of Tie 204-e cece the asin

‘os niin the wih maybe een O84 whos

‘inches

2010.10 Sitch rivets and bots. Where twa oF mor webs

Bes ae i conn, there shall Be sie obo ne

them cin won compres member he pch ad ora

‘uch ries rol lb deemined as ling ae

{eersion member the maxinom ih org owe Se oy

‘os sal ot aces diane it aches cea fo Ga

‘whichis the tte fhe ote plas nchs (aa

2010.1 Edge dstanceof iets or bls. The dance from

{te cen of te orl under computed een he aoe

‘Geel ar shpe ward wc ie pes cued sha oso,

tbe nomial diameter af he vet er ole Whee nares igs

stance uid the allowable bearing wes as Slee

‘Bile 204.6 shal ‘be reduced by ihe mls see a

stance ice vt or belt ameter Te cope dase al Et

‘ss than 1.5 times the ve orb nets ished a

‘ied or pte ees,

2010.12 ind rivets, Binet maybe wed oly when he

Bip engi and veel lances sem recone tee

‘Sipcte manuocuses

2010.13 ollow-end vives If hoow-end res wit said

{Goi sections fora prion aie engi re we he seg

{hese rivets may bs ten equa de enh of scree ee

Se mse provided tat te boom fe cra ea ge

25 percent of the vive ameter tom the pee ose

an, fob proved that hey

ese in rans re iey wil nate sbjece open

Bie ee sess

2010.14 Lock bos, Lok oe maybe se when isle in

enforce with lek tot manlscuers esearch

osles an provied he ody diameter and being es es

he hed and rato tir quale, re ot es as

‘eave mi aa ol

7802 Thread Forming Capping) Seren and Metal Sich

ing tapes I joints crying xelated oe se obs ke

wih tad foming screws oF meal eich sowahe east

talus for thee cosecan shal be eid oe ene

‘peti scespabe es.

20103 Fasteners fr Siretorat Formed Shot Rooting a

‘Siang.

2003.1 Genera. Fastnes shal have lease an esl ane

Storage suena nesting tuk lone pl nena oe

strength ote conecdon Between ste Sad net

201032 Allowable ens for fsteners. Teall tease

Tes pr eaten sal

A, » (22)x(nisioum segs of conection beveen a

tenets

2003.3 Atowabl lads or specie faseners. The sllovable

loads fr te Spec asin led, eesed in mes

‘hull bused ules ier alowable ons ne non

‘ble ods or fsenr nt ted shal be bse te ane

(iii

‘7 ron sug

{es 2nd shal comply with he provisions of Scans

te 21033 sare r

1. No 14 sakes set alloy sepying screws,

pani pated wih compost mins

usin prion of which has micoont i

.stinc 137k adn me

4 Salles sel peopene water seiner

tue es minictdimenins of 038 nes see

2) hens td eh (16 nm) OD Ine

Fe 1h

Fars F356,

dia veya

P=,

Fors: Fasaaey

2 Sule sel allay welded ss, Sicha

tim) bast Yinchdametr (276 tan) seemed ia

‘eiitied Snagedtuminum op of rch Gs oa

Pero

FoeSt anasy

SECTION 2011 —FaBRICATION

2011 Laying Out. Hote centr maybe comer punched and

{uo ting ty be pune or stn. Cone anit a

Secbing shall ot be wed whee sath mars would en

A tmperatsrecozeton sal be spl where esr in

tte lyou fecal dnensons. The celle! of tec

Shale iken 5 0.00013 per “F (QOD00072 ps

29112 Cutting Material may be sheared, sawed, et with «

{ue or rut Aedes whch have ben Cty Sep,

‘Shale planed a move cge eke

ut igs sal be ne, mouth a fom excesive bus er

rapped beaks

Re-aial cus il be avoided wherever pose ast,

‘hey sal be ila by dling pra cag?

Orygen cating of mim oy al nt be permite,

20413 Heating. Sica mera stall ot be het

ig S07 (SH ter peo reg SS ses ee

tna bening Sahil ee caw oes

es ceeeearaatepmemer alse

20114 Punching, Ditiog and Reaming. Te following es

ex punching ling an ang shall cbeod

1. Rive orbalt eles may bir punched riled, Puce

lng stl nol bused the mel i sper ee

sf the hole. The smoone by whisk te dameles at

ub punched hte sks an ht fhe ned Soe ek

rast one ou th hikes fhe psc and a noc seh,

Ngalach (08 ma

2, The finshed dame of holes for cold ven sive salt

tbe mote ha percent peter than he nia ee

ie ren

‘87 uironM sunD%G CoO :

3. The ished diameter of bolt fart dives vet shall ot

‘ne more tan 7 pee greater than te bool Game of fe

4. The finshed dimer of bles fr bls hl og be mre

than inch (La) ager han th amt bo mete

5 Many hls mus be ealuged i adi he sets ols they

stale reamed: Por mato a sl be aus fore

tos, Holes sano be dred ia sucha mater ao dot he

etl All chips Idged between contact sures al ee

‘novel Store see

2OILS. Deven bead The ven best of shaun alloy #9-

ftesallbe of he Mato the con pit ype wth cers os

follows

1. Fat heads all have a mete ot es than 14 me he

ornare amie eda Belg wa es ha Oe tbe

fori ret came

2.Cone goin hens shall havea iter ot eth ies

the nominal iret dante ai heh othe ge fhe ca ot

Tes than 048 tines the nominal tvtime

glib ape fhe cone sl be pponitly 127 pees

20112 Hole fing, Rives sal il bole compel. Rivet

eal sal be concent with he rive ols sd al prope

ats with errs othe ace

20153 Detective ints, Dstcive ive sabe removed by

cn

ais Painting

BUG Genera. Smuts of he ays covered by thee

Sands are ot ord plc wi te excep of

BATS when exposed 10 cores cvionmens). Sues

be pained wher

4 Th lamin alley pars aria coma wth, oc a fasted

ie menor te esr matre

{2 Tsecures re be exposed io ene coetve cone

Bees ecu ogc Puig ada coved

Bie folowing patos and melodr of cleaing ad

peso ae fou Seton 301 (resto aad pling

Snctre in acordoce wi Unied Ses Miyy

liao MILT-T0t rato axepble)

Contact with disinite materials Whee al

ny pat we in cont wih rar ned to el

eo rote dsr mary he uminum hl Sept

Hse cot wih he lo te amr matt

elbysilyng he ot corpo inion tothe ine

spies Zine chrome puis te lowed oy ad

ous) before steal fe pare These sacs

BS in contac wih aun shall be pained with god

Big pain, sch vn chro pine macorance

a Speciation THP.645, flawed by ove cot af

bg of 2 pounds of sami pai pignon (ASTM,

96 ype 2, Clas 8) pe gon 0 of

ing Fede Speciation TESS Type oe

quvalet. Sunless eel or alumina, hotplate or

‘Sogalvaniaed el place incon wi smi ce a

be pines.

2 Wes lumii in scons! with woo, Seta oe

ee beak

For Ste

Fort:

The above fms asm hat th ete css ston win

(he length Ly, lect bye het af weg Irony see

Ss tn is 0 alse, he silat seer eske S

set ust oP he ota in Seon S005

20123 Weding Fabrication. Welding of sumiaum shal bein

‘sordance with pprovednaonlyneogaised seetoas

SECTION 2013 — TESTING

20131 Goma, Tesing stall be considered a9 scceplble

Inti fr ssa the design of alumina ser

‘887 uurow nung)

faming nemo. Tests tal be conducted by a nd

tein tostor ory a manus ay hc

ities ht may exist eben nomial se

ston popes

nd thes sed sean shall be codes

19 UNFORM BUONO CODE. 5 TOLEDO

‘ABLE LA MECHAMEAL PROPERTIES FOR ALUIANLA ALLOYS,

see Mave en Une ore e6

Tee Lee Pe

& a Ey

oe VSB!

To Tepeee ee nuees

oiaae i

ES ae i

= ae a

pee eeeeea 7

ie ela) a

ee #)3| oF

jena | fe |= [ole «|e

ome te ta fe pe tats

SEE SSESESeSSeesn sags meeeenaaen!

ae

a8

aoe soo

Beran | Rae

Enis 0 0500. a :

Re [eBhe. g |e

oe 4300.1.009 3 i

Lame | Semone | aR" a|3

eee Ts

BP |S ee

“War. 35, ‘Sheet and pe Toi-coOr =

Boo | Seem | piesa 5

a, ‘Rolled cod and tar | yp io 000 Bf at |

Le I ai gl?

| = zi g| 2

ao = ot

ues als apply Fesit aan

il mace pe act A 4 teat

i son eng meen

owe 5 2 ss ‘or Wa pan en

a ey

‘orci ratnmtanni koran went

"pone gr es

Sn eee ee aA

s [Ta Ta Teles Ea 3

| & a H & a

ea] 2 g

Le Bl st i i

lelel¢ f z

;eiael? 2 5

epee sr =

| & « i a 5

1 = tae

(ei esa ele] é

a ft

aia teeta co PCT scones

Pee ee ea ees ssa

«fe fete fs fw pe | vo la

ee ee oa w SHE ae

em Cs [ET cee eo | w aay

ee ae me ia

= aT Se aoe

(a TaTe Ta tatala seo noes

sey Fen on ao 2a mab

ssacTiv mini’ Gaotan sos sauneeta ets Shan

eronen 1009 oomne muon es

Anda mungkin juga menyukai

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- RAM Structural System TutorialDokumen234 halamanRAM Structural System Tutorialksuscribdacct100% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- SSMA Product Technical Guide 2014Dokumen72 halamanSSMA Product Technical Guide 2014Diego PovedaBelum ada peringkat

- Hollow Sections 2nd EdtDokumen240 halamanHollow Sections 2nd Edtksuscribdacct100% (2)

- Brokers Market Analysis and Strategy Report PDFDokumen6 halamanBrokers Market Analysis and Strategy Report PDFksuscribdacct100% (2)

- Ocean Network Conference ScheduleDokumen2 halamanOcean Network Conference ScheduleksuscribdacctBelum ada peringkat

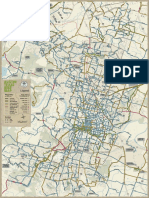

- COA Bike Map v12 FULL Web PDFDokumen1 halamanCOA Bike Map v12 FULL Web PDFksuscribdacctBelum ada peringkat

- Haydon Catalog 9-10 PDFDokumen148 halamanHaydon Catalog 9-10 PDFksuscribdacctBelum ada peringkat

- Pages From ManualDokumen1 halamanPages From ManualksuscribdacctBelum ada peringkat

- Rules Sparks Games 092013Dokumen17 halamanRules Sparks Games 092013ksuscribdacctBelum ada peringkat

- Page 16 From Unistrut Catalog 17Dokumen1 halamanPage 16 From Unistrut Catalog 17ksuscribdacctBelum ada peringkat

- Kanvinde - Shear Transfer in Exposed Column Base PlatesDokumen159 halamanKanvinde - Shear Transfer in Exposed Column Base PlatesksuscribdacctBelum ada peringkat