GC 70 Ul

Diunggah oleh

Anonymous VNu3ODGavJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

GC 70 Ul

Diunggah oleh

Anonymous VNu3ODGavHak Cipta:

Format Tersedia

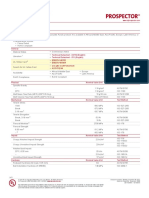

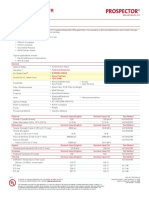

Technical Data Sheet

Gordon Composites™ GC-70-UL

Advanced Composites

Key Characteristics

Product Description

A continuous unidirectional "E" fiberglass/epoxy laminate that has high strength and stiffness along the longitudinal (0) axis.

GC-70-UL is manufactured with a proprietary pulforming process in which all glass fibers are pretensioned and aligned during

the impregnation and curing process.

General

Material Status • Commercial: Active

Regional Availability • North America

Filler / Reinforcement • Glass Fiber, 70% Filler by Weight

• Industrial Applications • Prosthetics

Uses • Marine Applications • Sporting Goods • Structural Parts

• Metal Replacement • Springs

Appearance

• Black • Brown • Red

• Blue • Colorless • White

Forms • Sheet 1 • Unidirectional 2

Processing Method • Machining

Technical Properties 3

Physical Typical Value (English) Typical Value (SI) Test Method

Density 1.88 g/cm³ 1.88 g/cm³ ASTM D1505

Mechanical Typical Value (English) Typical Value (SI) Test Method

Tensile Modulus ASTM D3039

-- 4 6.00E+6 psi 41400 MPa

5 1.50E+6 psi 10300 MPa

--

Tensile Strength ASTM D3039

4 152000 psi 1050 MPa

--

-- 5 6800 psi 46.9 MPa

4 2.5 % 2.5 % ASTM D3039

Tensile Strain (Break)

Flexural Modulus 5.80E+6 psi 40000 MPa ASTM D790

Flexural Strength 6 208000 psi 1430 MPa ASTM D790

Compressive Modulus ASTM D3410

-- 5 1.80E+6 psi 12400 MPa

-- 4 6.00E+6 psi 41400 MPa

Compressive Strength ASTM D3410

-- 4 111000 psi 765 MPa

-- 5 21200 psi 146 MPa

Shear Modulus ASTM D5379

-- 7 490000 psi 3380 MPa

-- 8 650000 psi 4480 MPa

Shear Strength

-- 8 7400 psi 51.0 MPa ASTM D5397

-- 7 4900 psi 33.8 MPa ASTM D5379

9 0.29 0.29 ASTM D3410

Poisson's Ratio

Copyright ©, 2017 PolyOne Corporation. PolyOne makes no representations, guarantees, or warranties of any kind with respect to the Information contained in this document about its

accuracy, suitability for particular applications, or the results obtained or obtainable using the information. Some of the Information arises from laboratory work with small-scale equipment which

may not provide a reliable indication of performance or properties obtained or obtainable on larger-scale equipment. Values reported as “typical” or stated without a range do not state minimum

or maximum properties; consult your sales representative for property ranges and min/max specifications. Processing conditions can cause material properties to shift from the values stated in

the Information. PolyOne makes no warranties or guarantees respecting suitability of either PolyOne’s products or the Information for your process or end-use application. You have the

responsibility to conduct full-scale end-product performance testing to determine suitability in your application, and you assume all risk and liability arising from your use of the Information

and/or use or handling of any product. POLYONE MAKES NO WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, either with respect to the Information or products reflected by the Information. This data sheet shall NOT operate as

permission, recommendation, or inducement to practice any patented invention without permission of the patent owner.

Rev: 2017-02-21 Page: 1 of 2

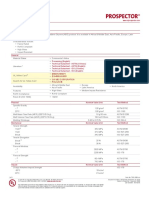

Gordon Composites™ GC-70-UL Technical Data Sheet

Thermal Typical Value (English) Typical Value (SI) Test Method

Glass Transition Temperature 250 °F 121 °C ASTM D3418

Notes

1

Width: .1.50" to 18.00"

Thickness: .018" to .080"

Length: 6" to 120" strips

2

Also available in roll form with lengths up to 250 ft.

3

Typical values are not to be construed as specifications.

4

0 degree orientation

5

90 degree orientation

6

Strength Values developed from ASTM D790 are dependent on thickness. As thickness increased flex strength decreased.

The test data above is based on a test thickness of .060"

7

Inter-laminar, 2,3 direction

8

In-plane, 1,2 direction

9

nu12 (0/90), valid both tensile and compression

CONTACT INFORMATION

Americas Asia Europe

United States - Avon Lake China - Guangzhou Germany - Gaggenau

+1 440 930 1000 +86 20 8732 7260 +49 7225 6802 0

United States - McHenry China - Shenzhen Spain - Barbastro (Huesca)

+1 815 385 8500 +86 755 2969 2888 +34 974 310 314

China - Suzhou

+86 512 6823 24 38

China - Suzhou

+86 512 6265 2600

Hong Kong -

+852 2690 5332 Beyond Polymers.

Taiwan - Yonghe City,

+886 9396 99740, +886 2929 1849 SM

Better Business Solutions.

www.polyone.com

PolyOne Americas PolyOne Asia PolyOne Europe

33587 Walker Road No. 88 Guoshoujing Road 6 Giällewee

Avon Lake, Ohio 44012 Z.J Hi-tech Park, Pudong +352 269 050 35

United States Shanghai, 201203, China

+1 440 930 1000 +86 21 5080 1188

+1 866 POLYONE

Copyright ©, 2017 PolyOne Corporation. PolyOne makes no representations, guarantees, or warranties of any kind with respect to the Information contained in this document about its

accuracy, suitability for particular applications, or the results obtained or obtainable using the information. Some of the Information arises from laboratory work with small-scale equipment which

may not provide a reliable indication of performance or properties obtained or obtainable on larger-scale equipment. Values reported as “typical” or stated without a range do not state minimum

or maximum properties; consult your sales representative for property ranges and min/max specifications. Processing conditions can cause material properties to shift from the values stated in

the Information. PolyOne makes no warranties or guarantees respecting suitability of either PolyOne’s products or the Information for your process or end-use application. You have the

responsibility to conduct full-scale end-product performance testing to determine suitability in your application, and you assume all risk and liability arising from your use of the Information

and/or use or handling of any product. POLYONE MAKES NO WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, either with respect to the Information or products reflected by the Information. This data sheet shall NOT operate as

permission, recommendation, or inducement to practice any patented invention without permission of the patent owner.

Rev: 2017-02-21 Page: 2 of 2

Anda mungkin juga menyukai

- Starex SD 0150Dokumen5 halamanStarex SD 0150claudiaBelum ada peringkat

- Datenblatt Rohstoff Torlon 4301Dokumen4 halamanDatenblatt Rohstoff Torlon 4301DarkedgeBelum ada peringkat

- Wonderlite® PC-110Dokumen3 halamanWonderlite® PC-110Rhekron PlasticsBelum ada peringkat

- Polylac® Pa-747Dokumen3 halamanPolylac® Pa-747vicenteBelum ada peringkat

- Kumho ABS 750SWDokumen3 halamanKumho ABS 750SWVu TranBelum ada peringkat

- RTPU Isoplast 101 LGF40 IdesDokumen1 halamanRTPU Isoplast 101 LGF40 IdescountzeroaslBelum ada peringkat

- Ryton R-4-200NA: Polyphenylene SulfideDokumen3 halamanRyton R-4-200NA: Polyphenylene SulfideMatteo BaldiniBelum ada peringkat

- PEI Ultem 2310R 30%GLDokumen4 halamanPEI Ultem 2310R 30%GLcountzeroaslBelum ada peringkat

- ABS Sabic Cycolac MG94 Cust.cDokumen5 halamanABS Sabic Cycolac MG94 Cust.cMurillo AraujoBelum ada peringkat

- PC Lexan 3412R 20% GL - IdesDokumen5 halamanPC Lexan 3412R 20% GL - IdescountzeroaslBelum ada peringkat

- ALLEN 8300FR Technical Data SheetDokumen2 halamanALLEN 8300FR Technical Data SheetRachit RanjanBelum ada peringkat

- POLYLAC® PA-765: Chi Mei CorporationDokumen3 halamanPOLYLAC® PA-765: Chi Mei CorporationagungBelum ada peringkat

- TDS - Acrylic V825 - From PolyOneDokumen2 halamanTDS - Acrylic V825 - From PolyOneVio Amariei0% (1)

- LS Nylon 11 DatasheetDokumen1 halamanLS Nylon 11 DatasheetkeeblerkhanBelum ada peringkat

- Tenac 4013ADokumen3 halamanTenac 4013APhung LucBelum ada peringkat

- ACRYREX® CM-211: Chi Mei CorporationDokumen3 halamanACRYREX® CM-211: Chi Mei CorporationPhuoc Thinh TruongBelum ada peringkat

- Lexan 925u ResinDokumen2 halamanLexan 925u ResinAndrBelum ada peringkat

- Abs Ex58f - AsiaDokumen4 halamanAbs Ex58f - AsiaGiang CaoBelum ada peringkat

- PBT Valox 865 30% GLDokumen4 halamanPBT Valox 865 30% GLcountzeroaslBelum ada peringkat

- Pmma Plexigals Hfi7-101Dokumen4 halamanPmma Plexigals Hfi7-101countzeroaslBelum ada peringkat

- ACRYLITE® Satinice df21 8NDokumen3 halamanACRYLITE® Satinice df21 8NEnriqueBelum ada peringkat

- CALIBRE™ MEGARAD™ 2081-15: Polycarbonate ResinDokumen3 halamanCALIBRE™ MEGARAD™ 2081-15: Polycarbonate ResinmikeybhabaBelum ada peringkat

- PPS Ryton R-4-230Dokumen3 halamanPPS Ryton R-4-230thegeneral2040Belum ada peringkat

- TPU Estane 2103-55DDokumen1 halamanTPU Estane 2103-55DcountzeroaslBelum ada peringkat

- ABS CHIMEI Pa-757Dokumen3 halamanABS CHIMEI Pa-757Muslim N FBelum ada peringkat

- PC Calibre Technical DataDokumen4 halamanPC Calibre Technical DataMitja GorseBelum ada peringkat

- Technical Data Sheet MarlexDokumen2 halamanTechnical Data Sheet MarlexWilly NursalimBelum ada peringkat

- Sabic® PP 38MK10RDokumen2 halamanSabic® PP 38MK10RGiang CaoBelum ada peringkat

- Kumho ABS 750Dokumen2 halamanKumho ABS 750Murundu EstudioBelum ada peringkat

- Exceed™ XP 8346CB: Performance PolymerDokumen2 halamanExceed™ XP 8346CB: Performance PolymerMaram YasserBelum ada peringkat

- Mitsubishi Chemical Advanced Materials Nylatron ® GSM Nylon, Cast Mos2 Filled Type 6 (Astm Product Data Sheet)Dokumen2 halamanMitsubishi Chemical Advanced Materials Nylatron ® GSM Nylon, Cast Mos2 Filled Type 6 (Astm Product Data Sheet)Irwan SaputraBelum ada peringkat

- Exceed™ XP 6056ML: Performance PolymerDokumen2 halamanExceed™ XP 6056ML: Performance PolymerkjmontilBelum ada peringkat

- Marpol LL6F 801: Linear Low Density PolyethyleneDokumen1 halamanMarpol LL6F 801: Linear Low Density PolyethylenedianaBelum ada peringkat

- Tenac C 4520Dokumen2 halamanTenac C 4520Phung LucBelum ada peringkat

- Esd 800 HBDokumen3 halamanEsd 800 HBsrinivasaBelum ada peringkat

- PermaStat 600 UVDokumen2 halamanPermaStat 600 UVPhung LucBelum ada peringkat

- Tristar® PC-05GFRDokumen3 halamanTristar® PC-05GFRRhekron PlasticsBelum ada peringkat

- Kopla Pa6 KNG1015Dokumen3 halamanKopla Pa6 KNG1015agungBelum ada peringkat

- Infino SC-1220R: Lotte Advanced Materials Co., Ltd. - PolycarbonateDokumen2 halamanInfino SC-1220R: Lotte Advanced Materials Co., Ltd. - PolycarbonateVenkatesan ManikandanBelum ada peringkat

- Product PDF 181Dokumen2 halamanProduct PDF 181RicardoBelum ada peringkat

- HP 3D High Reusability PA 12: Strong, Lowest Cost, 1 Quality PartsDokumen2 halamanHP 3D High Reusability PA 12: Strong, Lowest Cost, 1 Quality Partsnon sono ioBelum ada peringkat

- DoW LDPE 2685GDokumen4 halamanDoW LDPE 2685Gtariquekhan143Belum ada peringkat

- Exceed 3518PA Cast PDFDokumen2 halamanExceed 3518PA Cast PDFchinchotarngBelum ada peringkat

- Exceed™ XP 8346PA: Performance PolymerDokumen2 halamanExceed™ XP 8346PA: Performance PolymerMaram YasserBelum ada peringkat

- Exxonmobil™ Lldpe LL 3001.63: Linear Low Density Polyethylene ResinDokumen2 halamanExxonmobil™ Lldpe LL 3001.63: Linear Low Density Polyethylene ResinLeductoan LeBelum ada peringkat

- LS PEKK CF HT23 Material Datasheet 201705Dokumen1 halamanLS PEKK CF HT23 Material Datasheet 201705Angel LagrañaBelum ada peringkat

- Enable™ 4009MC Blown: Performance PolymerDokumen2 halamanEnable™ 4009MC Blown: Performance PolymerCristian RodriguezBelum ada peringkat

- Exceed™ XP 6026 Series: Performance PolymerDokumen2 halamanExceed™ XP 6026 Series: Performance PolymerMaram YasserBelum ada peringkat

- Product PDF 244478Dokumen3 halamanProduct PDF 244478lorejaz84071127Belum ada peringkat

- Acrylic Sheet Fabrication GuideDokumen44 halamanAcrylic Sheet Fabrication GuideBa BagymkyzyBelum ada peringkat

- Exceed XP 8784 SeriesDokumen2 halamanExceed XP 8784 SeriesAli RazuBelum ada peringkat

- SABIC® PC Resin PC0703R - AsiaDokumen4 halamanSABIC® PC Resin PC0703R - AsiaLong Trịnh ĐìnhBelum ada peringkat

- Exceed™ XP 8656ML: Performance PolymerDokumen2 halamanExceed™ XP 8656ML: Performance PolymerCristian RodriguezBelum ada peringkat

- PP ARPP200-1 Black 14 Melt HomoDokumen1 halamanPP ARPP200-1 Black 14 Melt HomocountzeroaslBelum ada peringkat

- PC-Transparent 144RDokumen5 halamanPC-Transparent 144Rsantosh.bhattBelum ada peringkat

- Starex GR-4020: Lotte Advanced Materials Co., LTDDokumen5 halamanStarex GR-4020: Lotte Advanced Materials Co., LTDsivalingabeastboy2002Belum ada peringkat

- PP R200P 2Dokumen1 halamanPP R200P 2quangga10091986Belum ada peringkat

- TPU Estane 2102-80ADokumen1 halamanTPU Estane 2102-80AcountzeroaslBelum ada peringkat

- Composite Frac Tree System PsDokumen1 halamanComposite Frac Tree System PsAnonymous VNu3ODGavBelum ada peringkat

- Octoparse V8.1 Release NotesDokumen1 halamanOctoparse V8.1 Release NotesAnonymous VNu3ODGavBelum ada peringkat

- SPE 110805 Use of Advanced Optimization Techniques To Manage A Complex Drilling ScheduleDokumen9 halamanSPE 110805 Use of Advanced Optimization Techniques To Manage A Complex Drilling ScheduleAnonymous VNu3ODGavBelum ada peringkat

- Photon Resin SettingDokumen4 halamanPhoton Resin SettingAnonymous VNu3ODGav57% (7)

- Si047data Sheetgate Valve 1051100619 PDFDokumen2 halamanSi047data Sheetgate Valve 1051100619 PDFAnonymous VNu3ODGavBelum ada peringkat

- Responsibilities of Rig Superintendent StudyDokumen7 halamanResponsibilities of Rig Superintendent StudyAnonymous VNu3ODGavBelum ada peringkat

- Medium Voltage Cable Inspection Digital PDFDokumen4 halamanMedium Voltage Cable Inspection Digital PDFAnonymous VNu3ODGavBelum ada peringkat

- Woodhouse Stock Jan 2019Dokumen720 halamanWoodhouse Stock Jan 2019Anonymous VNu3ODGav100% (2)

- 4 Week Project Timeline: Week 1 Week 2 Week 3 Week 4Dokumen1 halaman4 Week Project Timeline: Week 1 Week 2 Week 3 Week 4Mile VasilicBelum ada peringkat

- Activity Report Workshop eDokumen5 halamanActivity Report Workshop eAnonymous VNu3ODGavBelum ada peringkat

- Dittrich Et Al Supplementary MaterialDokumen5 halamanDittrich Et Al Supplementary MaterialAnonymous VNu3ODGavBelum ada peringkat

- Im 862Dokumen54 halamanIm 862Anonymous VNu3ODGavBelum ada peringkat

- Activity Report Workshop eDokumen5 halamanActivity Report Workshop eAnonymous VNu3ODGavBelum ada peringkat

- Ensco 80Dokumen1 halamanEnsco 80Anonymous VNu3ODGavBelum ada peringkat

- ProHeat 35 TC Calibration Verification Procedure 232169BDokumen3 halamanProHeat 35 TC Calibration Verification Procedure 232169BAnonymous VNu3ODGavBelum ada peringkat

- Woodhouse Stock Jan 2019Dokumen720 halamanWoodhouse Stock Jan 2019Anonymous VNu3ODGav100% (2)

- 4 Week Project Timeline: Week 1 Week 2 Week 3 Week 4Dokumen1 halaman4 Week Project Timeline: Week 1 Week 2 Week 3 Week 4Mile VasilicBelum ada peringkat

- Arc Welding Equipment Monthly ChecklistDokumen1 halamanArc Welding Equipment Monthly ChecklistAnonymous VNu3ODGav40% (5)

- Welding Electrode Classifications 123Dokumen2 halamanWelding Electrode Classifications 123Unnikrishnan RajanBelum ada peringkat

- Engineering Standards Manual - Welding Standards Manual - Volume 3 Welding Procedure SpecificationsDokumen3 halamanEngineering Standards Manual - Welding Standards Manual - Volume 3 Welding Procedure SpecificationsjacquesmayolBelum ada peringkat

- Fleet 234-ChinookDokumen2 halamanFleet 234-ChinookAnonymous VNu3ODGavBelum ada peringkat

- Weld Cracking PDFDokumen5 halamanWeld Cracking PDFjuanBelum ada peringkat

- Vantage 500 Code 11467 Ingles PDFDokumen76 halamanVantage 500 Code 11467 Ingles PDFamerica1591100% (1)

- Weiss TR Ringindexeertafel Handleiding EN 2016 PDFDokumen84 halamanWeiss TR Ringindexeertafel Handleiding EN 2016 PDFMai Văn ĐịnhBelum ada peringkat

- Calibration ValidationDokumen12 halamanCalibration Validationelmira100% (2)

- Landmark - Drilling and Completions Portfolio PDFDokumen1 halamanLandmark - Drilling and Completions Portfolio PDFAnonymous VNu3ODGavBelum ada peringkat

- Im 805Dokumen51 halamanIm 805Anonymous VNu3ODGavBelum ada peringkat

- IC Asset Tracking 8566 V3Dokumen4 halamanIC Asset Tracking 8566 V3juharieBelum ada peringkat

- 3512B Engine-Maintenance IntervalsDokumen56 halaman3512B Engine-Maintenance IntervalsAnonymous VNu3ODGavBelum ada peringkat

- Fleet - CH 47d ChinookDokumen2 halamanFleet - CH 47d ChinookAnonymous VNu3ODGavBelum ada peringkat

- Flare Piping PDFDokumen1 halamanFlare Piping PDFNilesh GohelBelum ada peringkat

- 104 - Vacuum DryingDokumen2 halaman104 - Vacuum DryingJeisson PerezBelum ada peringkat

- Thermal Performance Analysis On Staggered Finned Absorber Solar Air HeaterDokumen12 halamanThermal Performance Analysis On Staggered Finned Absorber Solar Air HeaterTJPRC PublicationsBelum ada peringkat

- Materials Testing and Characterization TechniquesDokumen1 halamanMaterials Testing and Characterization TechniquesdsathiyaBelum ada peringkat

- Structural Controls For Climate Responsive Design (For Cooling Purpose)Dokumen31 halamanStructural Controls For Climate Responsive Design (For Cooling Purpose)mehtabhumikaaBelum ada peringkat

- 2020 Assemblies TOCDokumen9 halaman2020 Assemblies TOCTobyBelum ada peringkat

- Buy Affordable Residential Flats in Zirakpur at Escon ArenaDokumen26 halamanBuy Affordable Residential Flats in Zirakpur at Escon ArenaEscon ArenaBelum ada peringkat

- AB Die Casting EngDokumen24 halamanAB Die Casting Engkaniappan sakthivelBelum ada peringkat

- Structural SteelDokumen17 halamanStructural SteelliBelum ada peringkat

- Protastructure Suite 2024 Whats NewDokumen79 halamanProtastructure Suite 2024 Whats NewJuan RestrepoBelum ada peringkat

- Stauff Surface Cable ClampsDokumen54 halamanStauff Surface Cable ClampsOliver HermosaBelum ada peringkat

- Stress Analysis - Creo-Simulate-220813Dokumen35 halamanStress Analysis - Creo-Simulate-220813saad HussainBelum ada peringkat

- Type-61 ElastomerSeatedButterflyValves 10 28 2022Dokumen10 halamanType-61 ElastomerSeatedButterflyValves 10 28 2022viksursBelum ada peringkat

- Compressive Strength Test On Concrete CylindersDokumen9 halamanCompressive Strength Test On Concrete CylindersSyrille Lubigan AlarconBelum ada peringkat

- Design - Sheet - For Self Supported Stack-2Dokumen4 halamanDesign - Sheet - For Self Supported Stack-2Sabir NasimBelum ada peringkat

- PBT - Lanxess Pocan B3235 000000Dokumen3 halamanPBT - Lanxess Pocan B3235 000000armandoBelum ada peringkat

- Arcelor Mittal CRGODokumen4 halamanArcelor Mittal CRGOGes SyBelum ada peringkat

- Repair and Rehabilitation of Structures Two Mark Questions With AnswerDokumen13 halamanRepair and Rehabilitation of Structures Two Mark Questions With AnswerSony Sundar33% (3)

- AUTOMOTIVE Lightning EDokumen15 halamanAUTOMOTIVE Lightning EShivamBelum ada peringkat

- Acb TroubleshootingDokumen3 halamanAcb TroubleshootingSomu JaganathanBelum ada peringkat

- Maz 10 Ym - Mip Ea 151 - 02 - RNCCDokumen62 halamanMaz 10 Ym - Mip Ea 151 - 02 - RNCCFilipe Areas100% (1)

- Specification For Sprinkler LPC - FSD Circular 2006 - 03Dokumen46 halamanSpecification For Sprinkler LPC - FSD Circular 2006 - 03James Li100% (1)

- GST-250 PSI Vertical Storage Tanks: 1500 Gallons Through 20,000 GallonsDokumen33 halamanGST-250 PSI Vertical Storage Tanks: 1500 Gallons Through 20,000 GallonsPham LanphuongBelum ada peringkat

- Aws C 5.4 Stud Welding PracticesDokumen7 halamanAws C 5.4 Stud Welding PracticesJose Aciano Hernandez0% (1)

- Momentive Silicon Data Sheet - MPMtsf451-50e - EDokumen4 halamanMomentive Silicon Data Sheet - MPMtsf451-50e - EMutharasan VishnuBelum ada peringkat

- Ficha Tecnica - DuraliteDokumen2 halamanFicha Tecnica - DuraliteedocducBelum ada peringkat

- Closed Coupled Pumps NMDokumen11 halamanClosed Coupled Pumps NMwpt_meBelum ada peringkat

- Engine Cooling Specifications PDFDokumen2 halamanEngine Cooling Specifications PDFMichael HernandezBelum ada peringkat

- Cellecta Sound Proofing Solutions GuideDokumen24 halamanCellecta Sound Proofing Solutions Guidejamiecellecta2012Belum ada peringkat

- 50HJ 007 540Dokumen15 halaman50HJ 007 540free73Belum ada peringkat

- A Place of My Own: The Architecture of DaydreamsDari EverandA Place of My Own: The Architecture of DaydreamsPenilaian: 4 dari 5 bintang4/5 (242)

- Building Construction Technology: A Useful Guide - Part 1Dari EverandBuilding Construction Technology: A Useful Guide - Part 1Penilaian: 4 dari 5 bintang4/5 (3)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedDari EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedPenilaian: 5 dari 5 bintang5/5 (1)

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionDari EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionPenilaian: 4.5 dari 5 bintang4.5/5 (2)

- Nuclear Energy in the 21st Century: World Nuclear University PressDari EverandNuclear Energy in the 21st Century: World Nuclear University PressPenilaian: 4.5 dari 5 bintang4.5/5 (3)

- The Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseDari EverandThe Complete Guide to Building Your Own Home and Saving Thousands on Your New HousePenilaian: 5 dari 5 bintang5/5 (3)

- THE PROPTECH GUIDE: EVERYTHING YOU NEED TO KNOW ABOUT THE FUTURE OF REAL ESTATEDari EverandTHE PROPTECH GUIDE: EVERYTHING YOU NEED TO KNOW ABOUT THE FUTURE OF REAL ESTATEPenilaian: 4 dari 5 bintang4/5 (1)

- Building Construction Technology: A Useful Guide - Part 2Dari EverandBuilding Construction Technology: A Useful Guide - Part 2Penilaian: 5 dari 5 bintang5/5 (1)

- Field Guide for Construction Management: Management by Walking AroundDari EverandField Guide for Construction Management: Management by Walking AroundPenilaian: 4.5 dari 5 bintang4.5/5 (3)

- Welding for Beginners in Fabrication: The Essentials of the Welding CraftDari EverandWelding for Beginners in Fabrication: The Essentials of the Welding CraftPenilaian: 5 dari 5 bintang5/5 (5)

- How to Build a Tiny Portable House: With Plans and InstructionsDari EverandHow to Build a Tiny Portable House: With Plans and InstructionsPenilaian: 4 dari 5 bintang4/5 (1)

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideDari Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuidePenilaian: 3.5 dari 5 bintang3.5/5 (7)

- The Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsDari EverandThe Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsBelum ada peringkat

- Civil Engineer's Handbook of Professional PracticeDari EverandCivil Engineer's Handbook of Professional PracticePenilaian: 4.5 dari 5 bintang4.5/5 (2)

- Estimating With Microsoft ExcelDari EverandEstimating With Microsoft ExcelPenilaian: 4.5 dari 5 bintang4.5/5 (3)

- Markup & Profit: A Contractor's Guide, RevisitedDari EverandMarkup & Profit: A Contractor's Guide, RevisitedPenilaian: 5 dari 5 bintang5/5 (11)

- The Everything Woodworking Book: A Beginner's Guide To Creating Great Projects From Start To FinishDari EverandThe Everything Woodworking Book: A Beginner's Guide To Creating Great Projects From Start To FinishPenilaian: 4 dari 5 bintang4/5 (3)

- Practical Power Distribution for IndustryDari EverandPractical Power Distribution for IndustryPenilaian: 2.5 dari 5 bintang2.5/5 (2)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ADari EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ABelum ada peringkat

- Building Construction and DrawingDari EverandBuilding Construction and DrawingPenilaian: 2.5 dari 5 bintang2.5/5 (3)

- Green Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsDari EverandGreen Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsBelum ada peringkat

- Shipping Container Homes: How to build a shipping container home, including plans, cool ideas, and more!Dari EverandShipping Container Homes: How to build a shipping container home, including plans, cool ideas, and more!Belum ada peringkat