Moment Connection: Supporting Column UC254X254X89 Supported Beam UC203X203X71

Diunggah oleh

massive85Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Moment Connection: Supporting Column UC254X254X89 Supported Beam UC203X203X71

Diunggah oleh

massive85Hak Cipta:

Format Tersedia

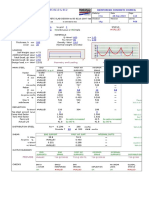

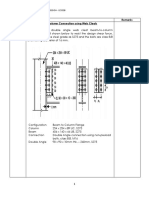

MOMENT CONNECTION

Case (i) Axial Fa1 = 34.98 kN Shear Fv1 = 48.3 kN

Moment(Mz1) = 47.39 kNm Shear Fh1 = 1.14 kN

Case (ii) Moment(Mz2) = 131.8 kNm (60 % capacity) Shear Fv2 = 91.5 kN

NOTES :

All bolts are M20, Grade 8.8

All main steel and fitting are grade S275

SECTION PROPERTIES :

Supporting Column = UC254X254X89 Supported Beam = UC203X203X71

Column Depth (Dc) = 260.3 mm Beam Depth (Db1) = 215.8 mm

Flange Width (W c) = 256.3 mm Flange Width (W b1) = 206.4 mm

Web thickness (tc) = 10.3 mm Web thickness (tb1) = 10 mm

Flange Thickness (Tc) = 17.3 mm Flange Thickness (Tb1) = 17.3 mm

Root Radius (rc) = 12.7 mm Root Radius (rb1) = 10.2 mm

Area of section (Ac) = 113 cm2 Area of section (Ab1) = 90.4 cm2

Sectional modulous (Sxx) = 799 cm3

MATERIAL PROPERTIES :

(A) Design yield Strength of S275 = 275 N/mm2

material up to & including 40 thk.

(B) Design yield Strength of S275 = 275 N/mm2

material beyond 40 thk.

(C) Tensile Strength of S275 material= Fu = 275 N/mm2

(D) Design Strength of fillet weld = 220 N/mm2

( For 42 class electrode & S275 steel grade, Refer clause 6.8.5 &Table 37, BS5950-1:2000 )

CHECK FOR BOLT :

Bolt dia. (d) = 20 mm Thickness of plate tp= 16 mm

Dia. of hole (dh)= 22 mm Width of plate wp= 220 mm

No. of bolt rows (nr) = 4 Gage g = g1= 60 mm

No. of columns of bolt (nc) = 2 Top of beam to 1st bolt = 60 mm

Total number of bolts (n) = 8 Dist between 1st & 2nd bolt = 60 mm

No. of Bolts near to Ten/com flg = 2 Nos Dist between 2nd & 3rd bolt = 60 mm

Dist between 3rd & 4th bolt = 100 mm

Reduced shear capacity of bolt (Fvb) = 36.76 kN

Allowable tension capacity of bolt (Ftb)= 109.8 kN

Total depth of section = 215.8 mm

CHECK FOR SHEAR :

Vertical shear per bolt (Case i) fvb1 = Fv1 / n fvb1 = 6.038 kN

(Case ii) fvb2 = Fv2 / n fvb2 = 11.44 kN

Fvb(36.7564)kN > fvb1 and fvb2 Therefore O.K.

CHECK FOR TENSION :

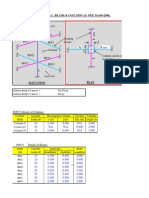

Calculation of tension in each bolt due to moment :

Distance of bolt (Li) from centre of rotation

Dist of 1st bolt and compression flange L1 = 267 mm

Dist of 2nd bolt and compression flange L2 = 207 mm

Dist of 3rd bolt and compression flange L3 = 147 mm

Dist of 4th bolt and compression flange L4 = 47.2 mm

Total moment @ major axis

Mz = Ti*Li = k* ∑ Li*li

In our case, Li i.e. lever arm of bolts is equal to distance from center of rotation i.e. li.

Therefore, k = M / ∑ Li*li

k = 47.39 * 1000 / 2 / ( 267.15^2 + 207.15^2 + 147.15^2 + )

= 0.17

Bolt tension due to moment @ major axis;

Tension in 1st bolt = 46.6 kN

Tension in 2nd bolt = 36.1 kN

Tension in 3rd bolt = 25.7 kN

Bolt tension due to moment and axial force in combination:

Tension per bolt due to axial force =Fa1/n + 2*Fa*sin60/n = 17.49 kN

Tension in 1st bolt T1 = 64 kN

Tension in 2nd bolt T2 = 54 kN

Tension in 3rd bolt T3 = 43 kN

Ftb(109.779kN) > ftb Therefore O.K.

Tension Ft2 = T1 = 64 kN

CHECK FOR COMBINED SHEAR AND TENSION:

fvb2

Shear stress per bolt fv = fv = 19.22 N/mm2

(p.d2/4)

Allowable tensile stress for bolt w.r.t.

shear stress = ft = ( 44 Ksi )2 - 4.39 fv2 Ft = 300.7 N/mm2

Allowable tension per bolt w.r.t.

shear stress Ftb1= ft x (p.d2 / 4) Ftb1= 94.47 kN

Ftb1 (94.47kN) > ftb (64.06kN) Therefore O.K.

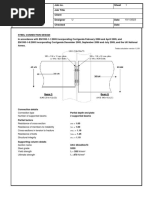

CHECK FOR END PLATE

Thickness of end plate required by first row of bolt:

Distance of bolt from flange = 42.7 mm

Flange length supporting tension in bolt = 98.2 mm

Distance of bolt from web = 25 mm

Web length supporting tension in bolt = 72.7 mm

Force shared by flange = 53.6 * (42.7 / 98.2) / (42.7 / 98.2 + 25 / 72.7 )

= 35.77 kN

Force shared by web = 53.6 - 35.77

= 28.29 kN

Moment due to tension in flange = 35.77 * 42.7 / 1000

= 1.527 kNm

Thickness of end plate required = ( 4 * 1.53 * 10^6 / ( 265 * 98.2 ) ) ^0.5

= 15.32 mm

Moment due to tension in web = 28.29 * 25 / 1000

= 0.707 kNm

Thickness of end plate required = ( 4 * 0.71 * 10^6 / ( 265 * 72.7 ) )^0.5

= 12.12 mm

Minimum thickness of end plate reqd. = 15.32 mm < 16 mm Hence OK

CHECK FOR WELD:

Weld between End plate and beam web Size of weld S = 6 mm

Load carrying Tw = 0.707 x S x ( Db1 - 2 x Tb1 ) x 2 x Fy265 Tw = 338 kN

capacity of Weld

Tw (338kN) > Fv2 (91.5kN) Therefore O.K.

Provide 6mm thk. Weld between End plate to web of beam

Weld between End plate and beam flange Size of weld S = 6 mm

Load carrying = 0.707 x S x Lw x 2 x Fy265 = 375.9 kN

capacity of Weld

Tw (375.91kN) > Ft2 (64.06kN) Therefore O.K

Anda mungkin juga menyukai

- Design of Base Plate 3Dokumen2 halamanDesign of Base Plate 3Andro RebuyasBelum ada peringkat

- Moment Connection Design BS CODEDokumen5 halamanMoment Connection Design BS CODEALPHYL BALASABASBelum ada peringkat

- Connection DesignDokumen14 halamanConnection DesignarjunBelum ada peringkat

- Client: Reem General Contracting Est. Al Jubail, Dammam, Commercial Street Kingdom of Saudi Arabia Al KhobarDokumen3 halamanClient: Reem General Contracting Est. Al Jubail, Dammam, Commercial Street Kingdom of Saudi Arabia Al KhobarUday UdmaleBelum ada peringkat

- Moment ConnectionDokumen30 halamanMoment ConnectionpandyatusharBelum ada peringkat

- Sloped FootingDokumen19 halamanSloped FootingBala ChandarBelum ada peringkat

- Combined Isolated FootingDokumen65 halamanCombined Isolated Footingarif_rubinBelum ada peringkat

- 1-Way Solid Concrete Slab Design To Bs 81101997 Table 3.12Dokumen7 halaman1-Way Solid Concrete Slab Design To Bs 81101997 Table 3.12asuncionBelum ada peringkat

- Base Plate Design1Dokumen24 halamanBase Plate Design1John Paul UmaliBelum ada peringkat

- Base Plate +and Foundation Bolt Design +connection Design 30-08-2021Dokumen9 halamanBase Plate +and Foundation Bolt Design +connection Design 30-08-2021Deepanshu GargBelum ada peringkat

- 2way Slab DesignDokumen10 halaman2way Slab DesignHari Amudhan IlanchezhianBelum ada peringkat

- Design of Flush Extended End Plate ConnectionsDokumen3 halamanDesign of Flush Extended End Plate ConnectionsMai CBelum ada peringkat

- Brace Load CalculationDokumen14 halamanBrace Load CalculationmaheshbandhamBelum ada peringkat

- Beam-Column Using Double Angle CleatDokumen7 halamanBeam-Column Using Double Angle CleatNur Syahira100% (1)

- Slab DesignDokumen87 halamanSlab Designshamen amarasekaraBelum ada peringkat

- Corbel DesignDokumen3 halamanCorbel DesignLim EcBelum ada peringkat

- 2 ConnectionDokumen18 halaman2 Connectionssikha100% (1)

- Rigid Connection DesignDokumen215 halamanRigid Connection DesignUmer AziqBelum ada peringkat

- Combined Footing DesignDokumen3 halamanCombined Footing Designkvamshi_1971Belum ada peringkat

- Column Base Plate (Hinge Type)Dokumen14 halamanColumn Base Plate (Hinge Type)Tengku Nizarul AslamiBelum ada peringkat

- Computation of Effective LengthDokumen6 halamanComputation of Effective LengthdsanandaBelum ada peringkat

- Shear Conn - Inside Fin PlateDokumen30 halamanShear Conn - Inside Fin PlatekalpanaadhiBelum ada peringkat

- Steel Plate Gate DesignDokumen5 halamanSteel Plate Gate DesignvsnsfbBelum ada peringkat

- Strap FootingDokumen26 halamanStrap Footingkabutar_royal70450% (1)

- Reinforcement Calculation - Cf1 (1000Mm THK) (Results From Staad) Min My For Load Case 120Dokumen3 halamanReinforcement Calculation - Cf1 (1000Mm THK) (Results From Staad) Min My For Load Case 120ARUNKUMAR KBelum ada peringkat

- 09) UB356x171x51TOUB610X305X149-B2CW - MC-1Dokumen126 halaman09) UB356x171x51TOUB610X305X149-B2CW - MC-1Asaru DeenBelum ada peringkat

- Column Beam Seismic ConnectionDokumen8 halamanColumn Beam Seismic ConnectionPrakash Singh RawalBelum ada peringkat

- Base Plate DesignDokumen4 halamanBase Plate DesignCHANDI KHANRABelum ada peringkat

- Structural Steelwork ConnectionsDokumen4 halamanStructural Steelwork Connectionstheunknown076Belum ada peringkat

- Design of Composite BeamDokumen7 halamanDesign of Composite BeamMohammed SumerBelum ada peringkat

- Isolated Footing Design: Foundation Type: IFDokumen7 halamanIsolated Footing Design: Foundation Type: IFBhuwan JoshiBelum ada peringkat

- Foundation Design For Pinned Support NewDokumen14 halamanFoundation Design For Pinned Support NewAwais HameedBelum ada peringkat

- Purlin SheetDokumen5 halamanPurlin SheetSher AfganBelum ada peringkat

- Axially Loaded FTNG DSNDokumen12 halamanAxially Loaded FTNG DSNKanaiyalal N. ShethBelum ada peringkat

- Steelwork Design Guide To BS 5950 Vol 1 Part B1 Dimensions & PropertiesDokumen56 halamanSteelwork Design Guide To BS 5950 Vol 1 Part B1 Dimensions & PropertiessubamanivelBelum ada peringkat

- Steel I Beam Web Shear CapacityDokumen1 halamanSteel I Beam Web Shear CapacityArjun RajaBelum ada peringkat

- Section CapcityDokumen16 halamanSection CapcityAnanthakrishna NageshBelum ada peringkat

- Isolated Footing Design: Forces DetailsDokumen7 halamanIsolated Footing Design: Forces DetailsMukhlish AkhatarBelum ada peringkat

- Beam To Column Connection ExampleDokumen9 halamanBeam To Column Connection ExampleLuqman ZolkibliBelum ada peringkat

- Typical Hea No Shear LugDokumen6 halamanTypical Hea No Shear Lugwaweng22Belum ada peringkat

- Slab Design Full Report: Material and Design DataDokumen22 halamanSlab Design Full Report: Material and Design DataazwanBelum ada peringkat

- Engineering Calculation Sheet Consulting EngineersDokumen27 halamanEngineering Calculation Sheet Consulting Engineersazhar ahmadBelum ada peringkat

- Beam DesignDokumen7 halamanBeam DesignKasi ViswanathanBelum ada peringkat

- DG Consulting Engineers: Job NoDokumen52 halamanDG Consulting Engineers: Job NosthakshyBelum ada peringkat

- Flat Slab Design by FemDokumen7 halamanFlat Slab Design by FemBathrudeen IshakBelum ada peringkat

- Knee ConnectionsDokumen13 halamanKnee ConnectionsNag RajBelum ada peringkat

- Beam Design SpreadsheetDokumen5 halamanBeam Design Spreadsheetewanz89100% (1)

- BeamDokumen7 halamanBeamsomumallidiBelum ada peringkat

- Counter Fort Retaining WallDokumen3 halamanCounter Fort Retaining WalljosefBelum ada peringkat

- Steeltek ConnectionDokumen5 halamanSteeltek ConnectioncadsultanBelum ada peringkat

- Bolted Connection Angle Brace TensionDokumen2 halamanBolted Connection Angle Brace TensionRajib MaharjanBelum ada peringkat

- Splice 03Dokumen15 halamanSplice 03LexBelum ada peringkat

- R.C.C Designs As Per Is 456-2000Dokumen188 halamanR.C.C Designs As Per Is 456-2000Umesh ChamaraBelum ada peringkat

- Design of BracingDokumen4 halamanDesign of Bracingankkeshmundra1Belum ada peringkat

- Wind Loads Calculation BS6399 PDFDokumen3 halamanWind Loads Calculation BS6399 PDFEmmanuel OtooBelum ada peringkat

- Steel Connection - IS CodeDokumen4 halamanSteel Connection - IS CodeAmit Ghosh75% (4)

- Pinned Base Plate-ECPLUS Design-ExampleDokumen4 halamanPinned Base Plate-ECPLUS Design-ExampleNivarBelum ada peringkat

- Fixed Base Plate Design-ECPLUS Design-ExampleDokumen4 halamanFixed Base Plate Design-ECPLUS Design-ExampleNivarBelum ada peringkat

- Vent Calculation API STD 2000Dokumen2 halamanVent Calculation API STD 2000massive85Belum ada peringkat

- Equivalent British Section Tables A PDFDokumen2 halamanEquivalent British Section Tables A PDFPrabhuBelum ada peringkat

- Roof Drain-Tank DesignDokumen3 halamanRoof Drain-Tank Designmassive85Belum ada peringkat

- Tank Shell & SE HeadDokumen1 halamanTank Shell & SE Headmassive85Belum ada peringkat

- Notes:: Supporting Beam Supported ColumnDokumen2 halamanNotes:: Supporting Beam Supported Columnmassive85Belum ada peringkat

- Pipeline Anchor Force CalculationDokumen1 halamanPipeline Anchor Force Calculationmassive85Belum ada peringkat

- Dybamic Design Analysis of Foundtison Wiell Help Us To Do All Things For Stuff and Help Peoples Fndna N Dnajjhaja IncludingDokumen1 halamanDybamic Design Analysis of Foundtison Wiell Help Us To Do All Things For Stuff and Help Peoples Fndna N Dnajjhaja Includingmassive85Belum ada peringkat

- Crack Width As Per ACI 318 - SpreadsheetDokumen2 halamanCrack Width As Per ACI 318 - Spreadsheetmassive8590% (10)

- Retaining Wall CalculationDokumen7 halamanRetaining Wall Calculationmassive85Belum ada peringkat

- Vertical Equation Foundation-Spread Sheet PDFDokumen6 halamanVertical Equation Foundation-Spread Sheet PDFmassive85Belum ada peringkat

- Rod DesignDokumen5 halamanRod Designmassive85Belum ada peringkat

- Anchor Bolt DesignDokumen2 halamanAnchor Bolt Designmassive85Belum ada peringkat

- Early Thermal Cracking CalculationsDokumen1 halamanEarly Thermal Cracking Calculationsmassive85Belum ada peringkat

- Culvert Design ManualDokumen54 halamanCulvert Design ManualMahmoud Al NoussBelum ada peringkat

- Vertical BraceDokumen2 halamanVertical Bracemassive85Belum ada peringkat

- Ejercicio de Soldadura AISC 2005Dokumen11 halamanEjercicio de Soldadura AISC 2005APBBelum ada peringkat

- Design Calculation: Base Pressure OkayDokumen2 halamanDesign Calculation: Base Pressure Okaymassive85Belum ada peringkat

- FOUNDATION Design Calculations Check ListDokumen1 halamanFOUNDATION Design Calculations Check Listmassive85Belum ada peringkat

- Structural Steel Design ChecklistDokumen2 halamanStructural Steel Design Checklistmassive85100% (3)

- Vertical BraceDokumen2 halamanVertical Bracemassive85Belum ada peringkat

- List of Civil PIP CodesDokumen1 halamanList of Civil PIP Codesmassive85100% (1)

- Bolt Design For Steel Connections As Per AISCDokumen24 halamanBolt Design For Steel Connections As Per AISCJayachandra PelluruBelum ada peringkat

- WeldDokumen7 halamanWeldsolver_dimecBelum ada peringkat

- Expansion Joint - Technical Paper 2Dokumen4 halamanExpansion Joint - Technical Paper 2Charles Orebola OresanwoBelum ada peringkat

- Structural Shapes Database v15.0Dokumen3 halamanStructural Shapes Database v15.0massive85Belum ada peringkat

- Anchor Block - Updated FileDokumen3 halamanAnchor Block - Updated Filemassive85Belum ada peringkat

- CPI Site-Activities PDFDokumen30 halamanCPI Site-Activities PDFmassive85Belum ada peringkat

- Aisc Shapes Database v15.0Dokumen14 halamanAisc Shapes Database v15.0ErickSimonBelum ada peringkat

- List of Civil PIP CodesDokumen1 halamanList of Civil PIP Codesmassive85100% (1)

- Five Essentials of Gel Refrigerant Design and Specification PDFDokumen10 halamanFive Essentials of Gel Refrigerant Design and Specification PDFtantibaBelum ada peringkat

- Atomic Absorption SpectrometryDokumen64 halamanAtomic Absorption Spectrometryanilrockzzz786Belum ada peringkat

- Livros de Mecanica Do ContinuoDokumen3 halamanLivros de Mecanica Do ContinuomdfdfdBelum ada peringkat

- Equivalence Between Iso Standards and National StandardsDokumen7 halamanEquivalence Between Iso Standards and National StandardsSelva KumarBelum ada peringkat

- Case Study - Single-Plane Rotor Balancing On A Disk RotorDokumen11 halamanCase Study - Single-Plane Rotor Balancing On A Disk RotorMotionicsBelum ada peringkat

- 7 MultiphaseFreeSurfaceFilmDokumen25 halaman7 MultiphaseFreeSurfaceFilmJesthyn VC100% (1)

- Turboden ORC Brochure PDFDokumen13 halamanTurboden ORC Brochure PDFSandeep TrichalBelum ada peringkat

- Beam Powered PropulsionDokumen19 halamanBeam Powered PropulsionSai Sushma100% (1)

- Chapter 2 ATMOSPHERIC PRESSUREDokumen8 halamanChapter 2 ATMOSPHERIC PRESSUREahmet gürbüzBelum ada peringkat

- Well Testing Schlumberger GlossaryDokumen18 halamanWell Testing Schlumberger GlossaryDiana La Cruz100% (1)

- WWW - Dgcaquestionpapers.In: Dgca Module 15 Gas Turbine EngineDokumen4 halamanWWW - Dgcaquestionpapers.In: Dgca Module 15 Gas Turbine Enginejontis jasoliyaBelum ada peringkat

- TsunamiDokumen13 halamanTsunamiVageesha Shantha Veerabhadra SwamyBelum ada peringkat

- Applanation TonometerDokumen15 halamanApplanation TonometerMuhammed AbdulmajeedBelum ada peringkat

- Fiberglass Vs Synthetic Air Filtration MediaDokumen13 halamanFiberglass Vs Synthetic Air Filtration MediaSridhar VA100% (1)

- Chapter 4 Single-Phase SystemDokumen38 halamanChapter 4 Single-Phase SystemRenu SekaranBelum ada peringkat

- Ps 00000 1165 0004 E - Rev 0 - Piping Material SpecificationDokumen877 halamanPs 00000 1165 0004 E - Rev 0 - Piping Material SpecificationThirunavukkarasu ParthasarathyBelum ada peringkat

- ISO 10110 Optical Drawing StandardsDokumen17 halamanISO 10110 Optical Drawing Standardskalvino314Belum ada peringkat

- Vibration Absorbers: Scan This QR CodeDokumen4 halamanVibration Absorbers: Scan This QR CodeThanhBelum ada peringkat

- The Aluminum-Silicon Phase Diagram and Eutectic ModificationsDokumen1 halamanThe Aluminum-Silicon Phase Diagram and Eutectic ModificationsBalaBelum ada peringkat

- Solutions Manual For College Physics 11e (Volume 2) Raymond Serway Chris VuilleDokumen70 halamanSolutions Manual For College Physics 11e (Volume 2) Raymond Serway Chris Vuillesobiakhan52292Belum ada peringkat

- Chapter 26 TEST BANKDokumen8 halamanChapter 26 TEST BANKAli AlhammadiBelum ada peringkat

- JNTU ANATHAPUR B.TECH Mechanical Engineering R09 SyllabusDokumen147 halamanJNTU ANATHAPUR B.TECH Mechanical Engineering R09 Syllabuspavankumar72Belum ada peringkat

- Gen Sci ReviewerDokumen2 halamanGen Sci ReviewerBerlin AlonzoBelum ada peringkat

- Four Types of Climate in The PhilippinesDokumen2 halamanFour Types of Climate in The PhilippinesAnonymous P1iMibBelum ada peringkat

- Overall Heat Transfer CoefficientDokumen3 halamanOverall Heat Transfer CoefficientcordobaluisfBelum ada peringkat

- Mechanical Properties and Surface Characteristics of Three Archwire AlloysDokumen7 halamanMechanical Properties and Surface Characteristics of Three Archwire AlloysYeraldin EspañaBelum ada peringkat

- Experiment 6 Performance of Centrifugal Compressor: A. ObjectiveDokumen6 halamanExperiment 6 Performance of Centrifugal Compressor: A. ObjectiveSurjit DuttaBelum ada peringkat

- Aote Aviation BrochureDokumen4 halamanAote Aviation BrochureSaurabh UttamBelum ada peringkat

- Six Common Types of Cracks in Your ConcreteDokumen5 halamanSix Common Types of Cracks in Your ConcreteNidDouBelum ada peringkat

- Fatigue of Materials Solved Problems UnlockedDokumen20 halamanFatigue of Materials Solved Problems UnlockedMAT-LIONBelum ada peringkat