Attachments Drawings

Diunggah oleh

MOHNISHKUMARJHAHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Attachments Drawings

Diunggah oleh

MOHNISHKUMARJHAHak Cipta:

Format Tersedia

B.

Auto Air Relief Valve自动排气阀

C. Pressure Gauge 压力表

D. Pressure Relief Valve 泄压阀

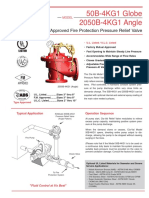

MODEL

50B-4KG-1

Fire Protection Pressure Relief Valve

• U.L. Listed / U.L.C. Listed

LLED B

LAB Y

ULC

U N D E R W RIT

CANADA

OF

R

• Factory Mutual Approved

S

S E

LAB RI

O R AT O

• Fast Opening to Maintain Steady Line Pressure

• Accommodates Wide Range of Flow Rates

• Closes Gradually for Surge-Free Operation

• Adjustable Pressure Settings, Not Affected by

Pressure At Valve Discharge

The Cla-Val Model 50B-4KG-1 Globe / 2050B-4KG Angle

Pressure Relief Valve is designed specifically to automati-

cally relieve excess pressure in fire protection pumping sys-

tems. Pilot controlled, it maintains constant system pres-

sure at the pump discharge within very close limits as

demands change.

U.L. Listed...............Sizes 3" thru 8"

F.M. Approved.........Sizes 3" thru 8"

U.L.C. Listed............Sizes 2” thru 10”

2050B-4KG1 (Angle)

Typical Application Model 2050B-4KG-1 Operation Sequence

Pressure Relief Valve

(Angle Pattern) At pump start, Cla-Val Relief Valve modulates to relieve

excess pump capacity, maintaining positive system pres-

sure at the pump discharge.

When fire demand slows or ceases, Cla-Val Model

50B-4KG-1 opens, diverting entire pump output to dis-

charge, allowing fire pump to be stopped without causing

Fire Pump surging in the lines.

(Please note that if the Model 50B-4KG-1 is to be used on

a continuous duty basis to maintain fire-system pressure,

suitable back pressure must be provided on the valve to

prevent cavitation damage. Consult the factory for details.)

Check Valve

"Fluid Control at It's Best"

To Fire

Protection System

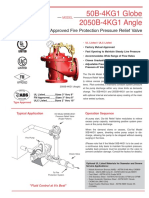

Specifications Dimensions

B

Sizes Globe: 2" - 12" flanged

Angle: 2" - 12" flanged

End Details 150 and 300 ANSI B16.42

Pressure Ratings class - 175 psi Max. G

class - 300 psi Max

Water, to 180°F Max.

Model 50B-4KG-1 Globe Model 2050B-4KG-1 Angle

Materials Main Valve Body & Cover

Ductile Iron ASTM A-536 A H E

Naval Bronze ASTM B61

Other Material Available

Standard Main Valve Trim:

C

Bronze Seat, Teflon Coated

C

Stainless Steel Stem, Delrin Sleeved

Standard Pilot Control System:

Cast Bronze with

Stainless Steel trim D F

Adjustment Range Available in the following relief

pressure ranges: We recommend providing adequate space around valve for maintenance work.

20-200 psi (150 Class)

Valve Size (inches) 2" 2 1/2" 3" 4" 6" 8" 10" 12"

100-300 psi (300 Class)

Threaded Ends 9.38 11.00 12.50 -- -- -- -- --

Optional Protective epoxy resin coating

A 150 Flanged 9.38 11.00 12.00 15.00 20.00 25.38 29.75 34.00

of wetted surfaces of main

valve cast iron components 300 Flanged 10.00 11.62 13.25 15.62 21.00 26.38 31.12 35.50

(UL listed HNFX EX2855) 300 x 150 12.88 15.31 20.56 25.88 30.44 34.75

B 3.31 4.00 4.56 5.75 7.88 10.00 11.81 14.00

Purchase Specifications C 12.00 12.25 12.50 13.00 14.31 16.31 18.00 20.56

The Fire Pump Pressure Relief Valve shall modulate to relieve excess D 1.50 1.69 2.56 3.19 4.31 5.31 9.25 10.75

pressure in a fire protection system. It shall maintain constant pressure Threaded Ends 4.75 5.50 6.25 -- -- -- -- --

in the system regardless of demand changes. It shall be pilot controlled E 150 Flanged 4.75 5.50 6.00 7.50 10.00 12.75 14.88 17.00

and back pressure shall not affect its set point. It shall be actuated by 300 Flanged 5.00 5.88 6.38 7.88 10.50 13.25 15.56 17.75

line pressure through a pilot control system and open fast in order to

Threaded Ends 3.25 4.00 4.50 -- -- -- -- --

maintain steady system pressure as system demand decreases. It shall

F 150 Flanged 3.25 4.00 4.00 5.00 6.00 8.00 8.62 13.75

close gradually to control surges and shall re-seat drip-tight within 5% of

its pressure setting. The main valve shall be of the hydraulically-operat- 300 Flanged 3.50 4.31 4.38 5.31 6.50 8.50 9.31 14.50

ed, pilot-controlled, diaphragm-type, globe or angle valve. It shall have G&H 6.00 6.69 7.75 7.88 8.50 9.75 13.25 14.25

a single, removable, teflon-coated seat, a grooved stem guided at both

ends, and a resilient disc with a rectangular cross section, being con-

tained on 3 1/2 sides. No external packing glands shall be permitted and Valve Size (mm) 50 65 80 100 150 200 250 300

the diaphragm shall not be used as a seating surface. The pilot control Threaded Ends 238 279 318 -- -- -- -- --

shall be a direct-acting, adjustable, spring-loaded, diaphragm-type valve A 150 Flanged 238 279 305 381 508 645 756 864

designed for modulating service to permit flow when controlling pressure 300 Flanged 254 295 337 397 533 670 790 902

exceeds spring setting. This valve shall be UL Listed and Factory Mutual 300 x 150 -- -- 327 389 522 657 773 883

approved. It shall be the Model 50B-4KG-1 (globe) or Model 2050B- B 84 102 116 146 200 254 300 356

4KG-1 (angle) Pressure Relief Valve as manufactured by Cla-Val

C 305 311 318 330 363 414 457 522

Newport Beach, California.

*Special Note: D 38 43 65 81 109 135 235 273

The Model 50B-4KG-1 Pressure Relief Valve is available with 300# ANSI Threaded Ends 121 140 159 -- -- -- -- --

inlet flange and 150# ANSI outlet flange. This valve is used on higher E 150 Flanged 121 140 152 191 254 324 378 432

pressure systems where 300# flange connections are required, and 300 Flanged 127 149 162 200 267 337 395 451

allows for adapting of a discharge cone (generally supplied with 150# Threaded Ends 83 102 114 -- -- -- -- --

flange) to accommodate "atmospheric break" at relief valve discharge.

F 150 Flanged 83 102 102 127 152 203 219 349

This relief valve, with 300# / 150# flanges is available on special order,

300 Flanged 89 109 111 135 165 216 236 368

and is UNDERWRITERS LABORATORIES LISTED AND FACTORY

MUTUAL APPROVED. G&H 152 170 197 200 216 248 337 362

Specifications Seawater Service Option Valve Capacity

Sizes Globe: 2" - 10" flanged Valve Sizes in Inches: 2" 2 1/2" 3" 4" 6" 8" 10" 12"

Angle: 2" - 10" flanged

Consult factory for materials and flange ratings. NFPA 20 Maximum

Recommended GPM 208 300 500 1000 2500 5000 11000 16000

CLA-VAL Represented By:

PO Box 1325 Newport Beach CA 92659-0325 Phone: 949-722-4800

Fax: 949-548-5441 Web Site: cla-val.com E-mail: claval@cla-val.com

CLA-VAL CANADA CLA-VAL EUROPE CLA-VAL UK

4687 Christie Drive Chemin des M sanges 1 Dainton House, Goods Station Road

Beamsville, Ontario CH-1032 Romanel/ GB - Tunbridge Wells

Canada LOR 1B4 Lausanne, Switzerland Kent TN1 2 DH England

Phone: 905-563-4963 Phone: 41-21-643-15-55 Phone: 44-1892-514-400

Fax: 905-563-4040 Fax: 41-21-643-15-50 Fax: 44-1892-543-423

E-Mail: sales@cla-val.ca E-Mail: cla-val@cla-val.ch E-Mail: info@cla-val.co.uk

'COPYRIGHT CLA-VAL 2002 Printed in USA Specifications subject to change without notice.

E-50B-4KG-1 (R-11/06)

E. Enclosed Waste Cone 排水视窗

F. Muffler 消音器

Engine Exhaust Silencers — Model “JI” Series

Industrial Grade

End Inlet/End Outlet Side Inlet/End Outlet

C

D

A B

A B

E

Part Number A B D WT Part Number A B C E F WT

JIE-02-300060 2 6 24 12 JIS-02-400090 2 6 22 5.5 3.0 12

JIE-25-300061 2.5 8 24 18 JIS-25-400091 2.5 8 22 6.5 3.7 18

JIE-03-300062 3 8 25 20 JIS-03-400092 3 8 22 7 4.2 20

JIE-35-300063 3.5 10 31 30 JIS-35-400093 3.5 10 29 8 5 30

JIE-04-300064 4 10 32 31 JIS-04-400094 4 10 29.5 8.5 5.5 31

JIE-05-300065 5 12 44 45 JIS-05-400095 5 12 41.6 10 7.6 50

JIE-06-300066 6 12 44 50 JIS-06-400096 6 12 41.6 10 7.6 50

JIE-08-300067 8 18 56 120 JIS-08-400097 8 18 54.5 13 10.5 120

JIE-10-300068 10 22 72 180 JIS-10-400098 10 22 69 15 15 180

JIE-12-300069 12 26 72 250 JIS-12-400099 12 26 69.5 17 17 250

JIE-14-300070 14 30 84 375 JIS-14-400100 14 30 82 19 20 375

JIE-16-300071 16 36 100 470 JIS-16-400101 16 36 97 22 23 470

JIE-18-300072 18 42 104 1155 JIS-18-400102 18 42 101 25 26.5 1155

JIE-20-300073 20 48 103 1360 JIS-20-400103 20 48 101.5 28 26 1360

Note: 3.5-inch and smaller standard with male NPT connections; 4.0-inch and larger standard with 150 # ANSI drilled plate flange connections.

Dimensions in inches, weights in pounds. Dimensions and weights are nominal and may vary slightly with production models.

30

25

Representative Attenuation Curve

ATTENUATION (dB)

20

for “JI” Series Silencers

15 • Typical reduction = 12 – 18 dB

10 • Aluminized/carbon steel construction

• Stainless steel construction available

5

• Contact factory for custom fit applications

0

63 1252 50 500 1000 2000 4000 8000

OCTAVE BAND CENTER FREQUENCY (Hz)

Phillips & Temro Industries • EM Products® Division • Prior Lake, MN 55372 • phone (952) 440-9200 • fax (952) 440-3400 • www.phillipsandtemro.com

Page 6

Anda mungkin juga menyukai

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGDari EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGBelum ada peringkat

- Cla-Val: Fire Protection Pressure Relief ValveDokumen2 halamanCla-Val: Fire Protection Pressure Relief ValveShoaib AhmedBelum ada peringkat

- Claval Pressure Relief Valve (UL&FM)Dokumen2 halamanClaval Pressure Relief Valve (UL&FM)engineering projectBelum ada peringkat

- Cal Val Refile ValveDokumen1 halamanCal Val Refile Valvesourav samadderBelum ada peringkat

- E 50B 4KG1 - Fire PDFDokumen2 halamanE 50B 4KG1 - Fire PDFPatricia J Ángeles100% (1)

- 7.5. Cla-Val E-650-01Dokumen4 halaman7.5. Cla-Val E-650-01sigithvacBelum ada peringkat

- E55L60.pdf Relief ValveDokumen2 halamanE55L60.pdf Relief ValveYasser ShehataBelum ada peringkat

- 90 01KO Data Sheet USDokumen4 halaman90 01KO Data Sheet USAngga ArdanaBelum ada peringkat

- 50B-4KG1 Globe 2050B-4KG1 Angle: Listed/Approved Fire Protection Pressure Relief ValveDokumen2 halaman50B-4KG1 Globe 2050B-4KG1 Angle: Listed/Approved Fire Protection Pressure Relief ValveNazrul IslamBelum ada peringkat

- Pressure Relief Valve/ Pump Casing Relief Valve: ModelDokumen2 halamanPressure Relief Valve/ Pump Casing Relief Valve: ModelJosé ArgüelloBelum ada peringkat

- E69001 PRV ClavalDokumen4 halamanE69001 PRV ClavalPlanner CyberBelum ada peringkat

- Pressure Relief & Pressure Sustaining Valve: ModelDokumen4 halamanPressure Relief & Pressure Sustaining Valve: ModelKevin E JodiBelum ada peringkat

- Valvula de Alivio 55LDokumen2 halamanValvula de Alivio 55LRobinzonJVilcchezzBelum ada peringkat

- Alarm check valve features and specificationsDokumen3 halamanAlarm check valve features and specificationsLIJINBelum ada peringkat

- Pressure Reducing Valve: ModelDokumen4 halamanPressure Reducing Valve: ModelTiam Yee YongBelum ada peringkat

- Seawater Service Solenoid Operated Deluge Valve: ModelDokumen2 halamanSeawater Service Solenoid Operated Deluge Valve: ModelJesus RodriguezBelum ada peringkat

- 50B-4KG1 Globe 2050B-4KG1 Angle: Fire Protection Pressure Relief ValveDokumen2 halaman50B-4KG1 Globe 2050B-4KG1 Angle: Fire Protection Pressure Relief ValveAlbeiro LeivaBelum ada peringkat

- Pressure Reducing Valve: ModelDokumen4 halamanPressure Reducing Valve: ModelSaad KhBelum ada peringkat

- E4036Dokumen2 halamanE4036Pablo Cardenas SandovalBelum ada peringkat

- Pressure Reducing Valve: ModelDokumen4 halamanPressure Reducing Valve: ModeltorqueuBelum ada peringkat

- KVS PRESSURE REDUCING VALVEDokumen3 halamanKVS PRESSURE REDUCING VALVEThúy VyBelum ada peringkat

- 50B-4KG1 Globe 2050B-4KG1 Angle: Fire Protection Pressure Relief ValveDokumen2 halaman50B-4KG1 Globe 2050B-4KG1 Angle: Fire Protection Pressure Relief ValveArdhana ArdhanaBelum ada peringkat

- ISZ3000ILDokumen4 halamanISZ3000ILDiana V. RosalesBelum ada peringkat

- Pressure Relief Valve/ Pump Casing Relief Valve: ModelDokumen2 halamanPressure Relief Valve/ Pump Casing Relief Valve: ModelEng Salah RamadanBelum ada peringkat

- Válvula Reductora de Presión PDFDokumen4 halamanVálvula Reductora de Presión PDFPaola LopezBelum ada peringkat

- CLA-VAL Reguladora de Presion 90-01 BlueDokumen4 halamanCLA-VAL Reguladora de Presion 90-01 BlueSergio HoyosBelum ada peringkat

- Accurate and Reliable Pressure Control: Qualitrol 070/351Dokumen4 halamanAccurate and Reliable Pressure Control: Qualitrol 070/351setiyawanBelum ada peringkat

- FT - E55l60 - v. AlivioDokumen2 halamanFT - E55l60 - v. AlivioLuiggy Garcia SuarezBelum ada peringkat

- Pressure Reducing Valve: ModelDokumen4 halamanPressure Reducing Valve: Modelguangyu LuBelum ada peringkat

- Gco Ecp FRB Ppu Doc PRV BrochureDokumen2 halamanGco Ecp FRB Ppu Doc PRV BrochureRafael AguilarBelum ada peringkat

- Seawater Service Pressure Relief Valve: ModelDokumen2 halamanSeawater Service Pressure Relief Valve: ModelHemant RasamBelum ada peringkat

- Regulators 63egDokumen20 halamanRegulators 63egAlberto CastellanosBelum ada peringkat

- Brosur Tyco-Acv-rc-wma (002) (Alarm Check Valve)Dokumen10 halamanBrosur Tyco-Acv-rc-wma (002) (Alarm Check Valve)Akhmad Syukri100% (1)

- Pressure Reducing Valve CatalogueDokumen4 halamanPressure Reducing Valve CatalogueSteveBelum ada peringkat

- 200-FPS 2378Dokumen2 halaman200-FPS 2378Green MichaelsBelum ada peringkat

- Air SpringDokumen28 halamanAir SpringKanchan PrasadBelum ada peringkat

- Rate of Flow Non-Surge Check Valve: ModelDokumen2 halamanRate of Flow Non-Surge Check Valve: ModelAndrzej BąkałaBelum ada peringkat

- Plug Valve CatalogeDokumen20 halamanPlug Valve CatalogenguyenmainamBelum ada peringkat

- Series 600: Globe Style Sizes 3 Through 42 InchesDokumen8 halamanSeries 600: Globe Style Sizes 3 Through 42 InchesSergio Veliz RBelum ada peringkat

- wp-contentuploads202302B-FP Commercial Services Brochure PDFDokumen8 halamanwp-contentuploads202302B-FP Commercial Services Brochure PDFAhmad AbdalhayBelum ada peringkat

- Model RV-1 Pressure Relief Valve 2 To 8 Inch (DN50 To DN200), 250 Psi (17,2 Bar) Pilot-Operated, Globe and Angle Body Styles General DescriptionDokumen8 halamanModel RV-1 Pressure Relief Valve 2 To 8 Inch (DN50 To DN200), 250 Psi (17,2 Bar) Pilot-Operated, Globe and Angle Body Styles General DescriptionmarioBelum ada peringkat

- Enerpac GP GF Series CatalogDokumen2 halamanEnerpac GP GF Series CatalogTitanplyBelum ada peringkat

- Crankcase Pressure RegulatingDokumen8 halamanCrankcase Pressure RegulatingSubramanian gokulBelum ada peringkat

- Expansion Devices: TXV in ControlDokumen2 halamanExpansion Devices: TXV in ControlRajat JunejaBelum ada peringkat

- E Series Proportional Pressure Controls: Pilot Relief / Relief / Reducing and RelievingDokumen30 halamanE Series Proportional Pressure Controls: Pilot Relief / Relief / Reducing and RelievinghaggBelum ada peringkat

- Modulating Float Valve: ModelDokumen4 halamanModulating Float Valve: ModelGus HdezBelum ada peringkat

- Differential Pressure Valve E-250-01Dokumen3 halamanDifferential Pressure Valve E-250-01Navin RamnauthBelum ada peringkat

- Rate of Flow and Fuel Shut Off Valve: ModelDokumen2 halamanRate of Flow and Fuel Shut Off Valve: Modelanon_867776278Belum ada peringkat

- PR/ UL: Pressure ReducingDokumen6 halamanPR/ UL: Pressure ReducingTatiana RomeroBelum ada peringkat

- Valvula Axial Sub Est. GasDokumen8 halamanValvula Axial Sub Est. GasdanielaBelum ada peringkat

- Catalog SoclaDokumen15 halamanCatalog SoclaJhonBelum ada peringkat

- " - 12" Circuit Balancing Valves: File No.: Date: Supersedes: DateDokumen8 halaman" - 12" Circuit Balancing Valves: File No.: Date: Supersedes: DateNorman GarduñoBelum ada peringkat

- General Service. Bulletin RTAA-SB - 4. Lit TRANE - SL Ide Valve Operat Ion and Troubleshoot I Ng. SuDokumen6 halamanGeneral Service. Bulletin RTAA-SB - 4. Lit TRANE - SL Ide Valve Operat Ion and Troubleshoot I Ng. Suahmed gamalBelum ada peringkat

- Motion control valvesDokumen1 halamanMotion control valvesSLK Amg55Belum ada peringkat

- Proportional Relief Valves - 170825Dokumen10 halamanProportional Relief Valves - 170825BrunoBelum ada peringkat

- Anderson Greenwood LCP SeriesDokumen6 halamanAnderson Greenwood LCP SeriesHafziBelum ada peringkat

- DelugeDokumen12 halamanDelugeHaitham MohammadBelum ada peringkat

- Anderson Greenwood Series Series 60 and 80Dokumen59 halamanAnderson Greenwood Series Series 60 and 80Hafzi100% (3)

- How To Do ItDokumen1 halamanHow To Do ItMOHNISHKUMARJHABelum ada peringkat

- Crispy Honey Orange Glazed Salmon - Cafe DelitesDokumen1 halamanCrispy Honey Orange Glazed Salmon - Cafe DelitesMOHNISHKUMARJHABelum ada peringkat

- TestingishDokumen1 halamanTestingishMOHNISHKUMARJHABelum ada peringkat

- This Here Is A Tutorial On How To Write Tutorial - H - K - R - TDokumen1 halamanThis Here Is A Tutorial On How To Write Tutorial - H - K - R - TMOHNISHKUMARJHABelum ada peringkat

- Coating and Painting Work.Dokumen9 halamanCoating and Painting Work.MOHNISHKUMARJHABelum ada peringkat

- Technical problem solving and leadership in challenging situationsDokumen4 halamanTechnical problem solving and leadership in challenging situationsMOHNISHKUMARJHABelum ada peringkat

- ReadmeDokumen1 halamanReadmephnghi24Belum ada peringkat

- Reoxidation of sponge iron is an exothermic processDokumen15 halamanReoxidation of sponge iron is an exothermic processMOHNISHKUMARJHA100% (1)

- WinRAR User ManualDokumen29 halamanWinRAR User ManualMcSwitch01Belum ada peringkat

- Storage & Transportation of Radioactive SourcesDokumen10 halamanStorage & Transportation of Radioactive SourcesVarunSharmaBelum ada peringkat

- Engines For Fire PumpDokumen39 halamanEngines For Fire PumpMOHNISHKUMARJHABelum ada peringkat

- Deluge ValveDokumen8 halamanDeluge ValveMOHNISHKUMARJHABelum ada peringkat

- ReadmeDokumen1 halamanReadmephnghi24Belum ada peringkat

- ISO 45001 Internal Audit Checklist for OH&S Management SystemsDokumen4 halamanISO 45001 Internal Audit Checklist for OH&S Management SystemsMOHNISHKUMARJHABelum ada peringkat

- FM Certisfication认证证书Dokumen15 halamanFM Certisfication认证证书MOHNISHKUMARJHABelum ada peringkat

- Portsaid Tunnels Project: Date Project Supervisor LocationDokumen8 halamanPortsaid Tunnels Project: Date Project Supervisor LocationMOHNISHKUMARJHABelum ada peringkat

- Crane Training Book-Rev. 2014Dokumen338 halamanCrane Training Book-Rev. 2014arjun100% (1)

- FTA550F: Limited Option Jockeyxg Pump ControllerDokumen8 halamanFTA550F: Limited Option Jockeyxg Pump ControllerMOHNISHKUMARJHABelum ada peringkat

- Emergency PlanDokumen34 halamanEmergency PlanMOHNISHKUMARJHABelum ada peringkat

- Job Safety Analysis FM TradesDokumen83 halamanJob Safety Analysis FM TradesFarrahxviiiBelum ada peringkat

- Radioactive Contamination of Material Naturally and DecontaminationDokumen13 halamanRadioactive Contamination of Material Naturally and DecontaminationMOHNISHKUMARJHABelum ada peringkat

- Radioactive Contamination of Material Naturally and DecontaminationDokumen13 halamanRadioactive Contamination of Material Naturally and DecontaminationMOHNISHKUMARJHABelum ada peringkat

- Ebook - Ransomware - A Survival GuideDokumen29 halamanEbook - Ransomware - A Survival GuideMOHNISHKUMARJHABelum ada peringkat

- Coating and Painting Work.Dokumen9 halamanCoating and Painting Work.MOHNISHKUMARJHABelum ada peringkat

- Coating and Painting Work.Dokumen9 halamanCoating and Painting Work.MOHNISHKUMARJHABelum ada peringkat

- I00250 1655279-1Dokumen10 halamanI00250 1655279-1mustafaBelum ada peringkat

- Dust Masks and RespiratorsDokumen1 halamanDust Masks and RespiratorsMOHNISHKUMARJHABelum ada peringkat

- Female Genital Mutilation Kurds Iraq Report SummaryDokumen4 halamanFemale Genital Mutilation Kurds Iraq Report SummaryMOHNISHKUMARJHABelum ada peringkat

- Nationalism and Feminism Case of KurdistanDokumen6 halamanNationalism and Feminism Case of KurdistanMOHNISHKUMARJHABelum ada peringkat

- 10.0 Troubleshooting Gas Dehydration Operational Problems: F P C C ADokumen7 halaman10.0 Troubleshooting Gas Dehydration Operational Problems: F P C C AHiep LeBelum ada peringkat

- VD 1233 330 Dig 001 1Dokumen12 halamanVD 1233 330 Dig 001 1Reza AranBelum ada peringkat

- Distributor-Catalogue 2012 1edition enDokumen140 halamanDistributor-Catalogue 2012 1edition enJose Diegozeta NuntonBelum ada peringkat

- BRT-100 User ManualDokumen2 halamanBRT-100 User ManualEricBelum ada peringkat

- Ratio Pressure Reducing ValvesDokumen4 halamanRatio Pressure Reducing Valveskanem1Belum ada peringkat

- Technical Data Sheet: Art. NR: PR-030601-0121 Version: 041020Dokumen8 halamanTechnical Data Sheet: Art. NR: PR-030601-0121 Version: 041020bharukBelum ada peringkat

- Hydraulic and Pneumatic Power SystemsDokumen57 halamanHydraulic and Pneumatic Power SystemsManic Chillfax100% (2)

- Mk1a 77x8 Csa ManDokumen21 halamanMk1a 77x8 Csa ManalessgionBelum ada peringkat

- Giddings & Lewis Sect08 HydDokumen24 halamanGiddings & Lewis Sect08 HydAngel AdautaBelum ada peringkat

- Domestic Water Booster Test ProcedureDokumen6 halamanDomestic Water Booster Test ProcedureEduardo ChvaBelum ada peringkat

- Cylinder Assy Parts List and DiagramsDokumen36 halamanCylinder Assy Parts List and DiagramsNelson Cortes0% (1)

- PRESSURE SAFETY VALVES: CONSTRUCTION AND WORKINGDokumen68 halamanPRESSURE SAFETY VALVES: CONSTRUCTION AND WORKINGAdil JelaniBelum ada peringkat

- Moatti SparesDokumen708 halamanMoatti Sparesdavid_891517609100% (2)

- Schroedahl ArvDokumen19 halamanSchroedahl ArvfadzilharmanBelum ada peringkat

- Design CriteriaDokumen6 halamanDesign CriteriaAllyssa Jane ErcillaBelum ada peringkat

- Manual Del Propietario Motor Honda GX200Dokumen54 halamanManual Del Propietario Motor Honda GX200Aprender20Belum ada peringkat

- LiveStar 2014Dokumen1 halamanLiveStar 2014kztro066Belum ada peringkat

- Valve Machining and Testing Technology: Made in GermanyDokumen48 halamanValve Machining and Testing Technology: Made in GermanyraulBelum ada peringkat

- Códigos de Diagnóstico Mack MixersDokumen110 halamanCódigos de Diagnóstico Mack Mixersdaniilo agudeloBelum ada peringkat

- Flowserve User Instructions (Pump)Dokumen68 halamanFlowserve User Instructions (Pump)Marco Antonio Hernandez MotaBelum ada peringkat

- Anhydrous Ammonia:: Managing The RisksDokumen16 halamanAnhydrous Ammonia:: Managing The RisksRASHEED YUSUFBelum ada peringkat

- Datasheet For Level TransmitterDokumen11 halamanDatasheet For Level TransmitterEliyanto E BudiartoBelum ada peringkat

- Z-16-319 R4 CB20SG Accessories.S+EDokumen14 halamanZ-16-319 R4 CB20SG Accessories.S+EBashir AliBelum ada peringkat

- Operating Manual PAT-Drill 301T - 301TPDokumen23 halamanOperating Manual PAT-Drill 301T - 301TPvano0100% (3)

- Control Ad or Neumatico de Nivel Fisher 2502Dokumen16 halamanControl Ad or Neumatico de Nivel Fisher 2502mizor82Belum ada peringkat

- Low Noise Solutions For Turbine Bypass To Air-Cooled CondensersDokumen10 halamanLow Noise Solutions For Turbine Bypass To Air-Cooled CondensersElavarasan Ramalingam100% (1)

- 2-Latest EIC-E-1002-0 (DSG-03 Series Solenoid Operated Directional Valves)Dokumen12 halaman2-Latest EIC-E-1002-0 (DSG-03 Series Solenoid Operated Directional Valves)SivaBelum ada peringkat

- F BV PDFDokumen28 halamanF BV PDFDaren NeradBelum ada peringkat

- Apf239664 enDokumen64 halamanApf239664 enSoe Thit HtunBelum ada peringkat

- 1884 0x0 TALIS Your Partner For Water and Sewage EN 02 2012 PDFDokumen36 halaman1884 0x0 TALIS Your Partner For Water and Sewage EN 02 2012 PDFkad-7Belum ada peringkat