Power Plant California Ex 1 Ans

Diunggah oleh

AbhiDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Power Plant California Ex 1 Ans

Diunggah oleh

AbhiHak Cipta:

Format Tersedia

A power plant in California uses coal at the rate of 100,000 pounds each day.

It also

uses MRO material at the rate of 1,000 pounds each day. The coal comes from

Wyomung and the MRO material comes from Chicago. Coal costs $0.01 per pound,

whereas MRO material costs $10 per pound, on average. Holding costs at the power

plant are 25 percent. Transportation choices available are as follows:

Train

Lead Time = 15 days

Carload (100,000 pounds) at $400 per carload

Full train (70 cars) at $15,000 per train

Truck

Lead time = 4 days

Minimum cost = $100

Upto 10,000 pounds at $0.08 per pound

Between 10,000 and 20,000 pounds at $0.07 per pound for entire load

Between 25,000 and 40,000 pounds at $0.06 per pound for entire load

Small TL (40,000 pounds) for $2,000

Large TL (60,000 pounds) for $2,600

Safety inventory of coal and MRO materials is kept at twice the consumption during

the lead time of supply. What mode of transport do you recommend for each of the

two products? Why?

Solution

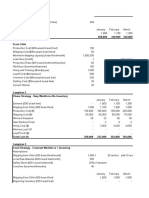

Train

Safety inventory for coal = 100,000*2*15 = 3,000,000

Safety inventory for MRO = 1000*2*15 = 30,000

Total holding cost

Coal = (3,000,000*0.01)*.25 = $7,500

MRO = (30000*10)* .25 = $75,000

Let ‘x’ car load be used

Total Cost of transportation for Coal = (365)*400 = 146,000

If the whole train is used, Cost for coal= (365/70)*15000 = 78214.

Total Cost of transportation for MRO = (365*1000)/(100,000)*400 = 1460

Coal

Optimal cost = $7,500+$78,214 = $85,714

MRO

Optimal cost = $75,000+$1,460 = $76,460

Truck

Safety inventory for coal = 100,000*2*4 = 800,000

Safety inventory for MRO = 1000*2*4 = 8,000

Total holding cost

Coal = (800,000*0.01)*.25 = $2,000

MRO = (8000*10)* .25 = $20,000

Option Coal MRO

Upto 10,000 pounds = =

(100,000*365/10,000)*10000*0.08 (1,000*365/10,000)*10000*0.08

= 2,920,000 = 29,200

10000 to 20000 pounds = =

(100,000*365/20,000)*20000*0.07 (1,000*365/10,000)*10000*0.07

= 2,555,000 = 25,550

25000 to 400000 = =

pounds (100,000*365/20,000)*20000*0.06 (1,000*365/10,000)*10000*0.06

= 2,190,000 = 21,900

40000 pounds = (100,000*365/40,000) *2000 = (1,000*365/40,000) *2000 =

=1,825,000 18250

60000 pounds = (100,000*365/60,000) *2600 = (1,000*365/60,000)

=1,581,667 *2600=15816.7

So, minimum cost for coal in this option is using 60000 pound truck

So, minimum cost for MRO in this option is using 60000 pound truck

So,

Coal

Optimal cost = $2,000+$1581667 = $1,583,667

MRO

Optimal cost = $20,000+$15,816.7 = $35,816.7

So, based on the comparison,

The total cost is minimum for coal while using full train load, cost = $85,714

The total cost is minimum for MRO while using 60000 pound truck, cost = $35,816.7

Anda mungkin juga menyukai

- Group 16 - CoolwipesDokumen13 halamanGroup 16 - Coolwipesabhikalp bhaskarBelum ada peringkat

- Designing Coolwipes' production networkDokumen16 halamanDesigning Coolwipes' production networkSherene Dharshinee100% (1)

- Cool Wipes: Q1. Annual Cost of Serving Entire Nation Using Existing Plant at ChicagoDokumen28 halamanCool Wipes: Q1. Annual Cost of Serving Entire Nation Using Existing Plant at ChicagoPankhuri Singhal0% (1)

- Designing The Distribution Network For Michaels HardwareDokumen6 halamanDesigning The Distribution Network For Michaels HardwareAhmed Bilal100% (1)

- Retailer Inventory Turns and CostsDokumen2 halamanRetailer Inventory Turns and CostsGhadeer Mohammed100% (1)

- Trade Offs When Selecting Transportation ModeDokumen2 halamanTrade Offs When Selecting Transportation ModeAmarnath DixitBelum ada peringkat

- Bloomex.ca Logistics Optimization Case SolutionDokumen7 halamanBloomex.ca Logistics Optimization Case SolutionRajneesh100% (1)

- Airline Cost and Revenue Comparison: Delta, Southwest, JetBlueDokumen7 halamanAirline Cost and Revenue Comparison: Delta, Southwest, JetBlueKumar AbhishekBelum ada peringkat

- Operations Research g1Dokumen7 halamanOperations Research g1AbhishekBelum ada peringkat

- Bloomex - Ca Logistics OptimizationDokumen2 halamanBloomex - Ca Logistics OptimizationDr EngineerBelum ada peringkat

- Formula SheetDokumen5 halamanFormula SheetTarek DarwishBelum ada peringkat

- Specialty Packaging Corporation Case StudyDokumen7 halamanSpecialty Packaging Corporation Case StudyDaud Jutt67% (3)

- Quarterly production plan forecastDokumen3 halamanQuarterly production plan forecastCristhian ValverdeBelum ada peringkat

- Ch13 Bradford Manufacturing2Dokumen3 halamanCh13 Bradford Manufacturing2Martha Pinet100% (1)

- Coolwipes CaseDokumen7 halamanCoolwipes CaseSherene Dharshinee67% (3)

- Cool Wipes - Case Summary: AssumptionsDokumen15 halamanCool Wipes - Case Summary: AssumptionsNeeraj SBelum ada peringkat

- Chapter 8 Answers To ExercisesDokumen12 halamanChapter 8 Answers To ExercisesSaroj Kumar RaiBelum ada peringkat

- Optimize Bloomex Logistics shipping network and costsDokumen7 halamanOptimize Bloomex Logistics shipping network and costsSaumya SahaBelum ada peringkat

- Exercise Solutions:: Chapter 8: Aggregate Planning in A Supply ChainDokumen6 halamanExercise Solutions:: Chapter 8: Aggregate Planning in A Supply ChainSkyeBelum ada peringkat

- This Spreadsheet Supports STUDENT Analysis of The Case "Bloomex - Ca Logistics Optimization" (UVA-QA-0760)Dokumen4 halamanThis Spreadsheet Supports STUDENT Analysis of The Case "Bloomex - Ca Logistics Optimization" (UVA-QA-0760)shishirBelum ada peringkat

- Management Accounting: Case:-Dakota Office ProductsDokumen13 halamanManagement Accounting: Case:-Dakota Office ProductsVishnu Sharma100% (1)

- Bloomex LogisticsDokumen3 halamanBloomex LogisticsdodgekpBelum ada peringkat

- CII SCM EXE Mock ExaminationDokumen17 halamanCII SCM EXE Mock ExaminationShraddha Tembhurne100% (4)

- Comparing Timbuk2's Messenger Bag and New Laptop Bag Supply ChainsDokumen4 halamanComparing Timbuk2's Messenger Bag and New Laptop Bag Supply Chainskankris18100% (1)

- Starbucks Simulation Analyzes Employee LevelsDokumen23 halamanStarbucks Simulation Analyzes Employee Levelsjayshah1991Belum ada peringkat

- OM WordDokumen3 halamanOM WordpulakitBelum ada peringkat

- Group2 BloomexDokumen9 halamanGroup2 BloomexRajneesh100% (1)

- Case-Aggregate Planning at Green MillsDokumen6 halamanCase-Aggregate Planning at Green MillsRIDHIMA MAHAJAN33% (3)

- Operations Research - 2013Dokumen106 halamanOperations Research - 2013vinit557% (7)

- Case 3.1 Auto AssemblyDokumen11 halamanCase 3.1 Auto AssemblySC24100% (1)

- Case Studies - Operations Research and ManagementDokumen12 halamanCase Studies - Operations Research and ManagementVineet NairBelum ada peringkat

- Gartland Steel Maximizes Profits Within EPA LimitsDokumen11 halamanGartland Steel Maximizes Profits Within EPA Limitsshama vidyarthyBelum ada peringkat

- Assignment - Inventory ManagementDokumen3 halamanAssignment - Inventory ManagementKaushal ShresthaBelum ada peringkat

- Mridula Icecream Case !Dokumen1 halamanMridula Icecream Case !Preetam JogaBelum ada peringkat

- Bloomex.CA logistics optimization and cost dataDokumen3 halamanBloomex.CA logistics optimization and cost dataTrinity JordanBelum ada peringkat

- FormulationDokumen40 halamanFormulationNitin KumarBelum ada peringkat

- Karnataka Engineering CaseDokumen5 halamanKarnataka Engineering CaseJSBelum ada peringkat

- A-CAT Corp. MRP SolnDokumen13 halamanA-CAT Corp. MRP SolnAbhishta SharmaBelum ada peringkat

- Ch19 Bradford ManufacturingDokumen6 halamanCh19 Bradford Manufacturingnurul_azizah0120% (5)

- CEC Guesstimates 2Dokumen3 halamanCEC Guesstimates 2Aditya ChaudharyBelum ada peringkat

- Scientific Glass Inc - Inventory ManagementDokumen11 halamanScientific Glass Inc - Inventory ManagementdathanBelum ada peringkat

- Green MillsDokumen8 halamanGreen MillsFlorenciano Johanes25% (4)

- Master scheduling and aggregate planning optimize productionDokumen26 halamanMaster scheduling and aggregate planning optimize productionMithun Muraleekrishna0% (1)

- Cochin MarineDokumen4 halamanCochin MarineSivasaravanan A TBelum ada peringkat

- Cool WipesDokumen8 halamanCool WipesRohit SinhaBelum ada peringkat

- What Do You Think of The Discounting Scheme That KAR Had Used Historically? Do You Think It Was Justified Given The Circumstances?Dokumen3 halamanWhat Do You Think of The Discounting Scheme That KAR Had Used Historically? Do You Think It Was Justified Given The Circumstances?Lohith Kumar100% (1)

- DocxDokumen5 halamanDocxSelinnur GöklerBelum ada peringkat

- DocxDokumen8 halamanDocxMburu J. Irungu100% (1)

- Amazon Supply Chain Case StudyDokumen2 halamanAmazon Supply Chain Case Studyknadmk100% (2)

- Operations@FlipkartDokumen9 halamanOperations@FlipkartAseem Rohatgi100% (1)

- Solman 12 Second EdDokumen23 halamanSolman 12 Second Edferozesheriff50% (2)

- California Power Plant: Analysis of Transportation Option For Coal MaterialDokumen9 halamanCalifornia Power Plant: Analysis of Transportation Option For Coal Materialadelina zianBelum ada peringkat

- Chapter 14 Examples - 1 Thru 4Dokumen14 halamanChapter 14 Examples - 1 Thru 4shivamBelum ada peringkat

- QUOTATIONDokumen1 halamanQUOTATIONderrick andivaBelum ada peringkat

- Refaa 1Dokumen5 halamanRefaa 1Refáä JallaqBelum ada peringkat

- Lecture 4 Weight EstimationDokumen35 halamanLecture 4 Weight Estimationraman palBelum ada peringkat

- Land transportation appendix with conversion tables and ratesDokumen6 halamanLand transportation appendix with conversion tables and ratesEwch WangBelum ada peringkat

- Calculate transport service costsDokumen3 halamanCalculate transport service costsChisenga MambweBelum ada peringkat

- Energy Technology List Claim Values September 2016Dokumen40 halamanEnergy Technology List Claim Values September 2016Christian MerchanBelum ada peringkat

- TGS - Aerodinamika - Desain Pesawat Dengan 3 PenumpangDokumen11 halamanTGS - Aerodinamika - Desain Pesawat Dengan 3 PenumpangAbdullah Azyam Dhiyaa UlhaqBelum ada peringkat

- FoldriteDokumen6 halamanFoldriteAbhiBelum ada peringkat

- Channel DecisionsDokumen63 halamanChannel DecisionsAbhiBelum ada peringkat

- Decomposition of A Time SeriesDokumen7 halamanDecomposition of A Time SeriesAbhiBelum ada peringkat

- Exponential SmoothingDokumen3 halamanExponential SmoothingAbhiBelum ada peringkat

- Sourcing Strategy ExerciseDokumen2 halamanSourcing Strategy ExerciseAbhiBelum ada peringkat

- sbr1 DMDokumen3 halamansbr1 DMAbhiBelum ada peringkat

- IOE 202: Operations Modeling: Module 5: Supply Chain Network DesignDokumen34 halamanIOE 202: Operations Modeling: Module 5: Supply Chain Network DesignAbhiBelum ada peringkat

- Renalut CaseDokumen26 halamanRenalut CaseAbhiBelum ada peringkat

- Sorcing PricingDokumen1 halamanSorcing PricingAbhiBelum ada peringkat

- Burton Hospital Summary of Time Taken TemplateDokumen1 halamanBurton Hospital Summary of Time Taken TemplateAbhiBelum ada peringkat

- VSM HealthcareDokumen26 halamanVSM HealthcareAmitesh Prasad0% (1)

- Total Cost of Ownership ExerciseDokumen3 halamanTotal Cost of Ownership ExerciseAbhiBelum ada peringkat

- Planning To Meet A Surge in DemandDokumen19 halamanPlanning To Meet A Surge in DemandAbhi0% (1)

- GMBA Sep 2019 Group AssignmentDokumen3 halamanGMBA Sep 2019 Group AssignmentAbhiBelum ada peringkat

- Intangible Assets Slides - FinalDokumen28 halamanIntangible Assets Slides - FinalAbhiBelum ada peringkat

- Communicating ValueDokumen32 halamanCommunicating ValueAbhiBelum ada peringkat

- EthicsDokumen11 halamanEthicsAbhiBelum ada peringkat

- Sorcing PricingDokumen1 halamanSorcing PricingAbhiBelum ada peringkat

- Advantages of Supplier Scorecard at MetalcraftDokumen4 halamanAdvantages of Supplier Scorecard at MetalcraftAbhi100% (1)

- Maersk Line CaseDokumen1 halamanMaersk Line CaseAbhiBelum ada peringkat

- Sourcing Strategy & Portfolio AnalysisDokumen16 halamanSourcing Strategy & Portfolio AnalysisAbhiBelum ada peringkat

- Company LawDokumen49 halamanCompany LawAbhiBelum ada peringkat

- Business Law NotesDokumen29 halamanBusiness Law NotesAbhiBelum ada peringkat

- 3pl Vs 4plDokumen16 halaman3pl Vs 4plAbhiBelum ada peringkat

- Burton Hospital Summary of Time Taken TemplateDokumen1 halamanBurton Hospital Summary of Time Taken TemplateAbhiBelum ada peringkat

- FMS MetricsDokumen2 halamanFMS MetricsAbhiBelum ada peringkat

- Nurifer SolutionDokumen2 halamanNurifer SolutionAbhiBelum ada peringkat

- Winners and Losers From Trump's New Tariffs On Aluminium and SteelDokumen7 halamanWinners and Losers From Trump's New Tariffs On Aluminium and SteelAbhiBelum ada peringkat

- Nokia IndiaDokumen8 halamanNokia IndiaAbhiBelum ada peringkat

- Case 1 1 Starbucks Going Global FastDokumen2 halamanCase 1 1 Starbucks Going Global FastBoycie TarcaBelum ada peringkat

- What Is Inventory Management?Dokumen31 halamanWhat Is Inventory Management?Naina SobtiBelum ada peringkat

- Contract To Sell LansanganDokumen2 halamanContract To Sell LansanganTet BuanBelum ada peringkat

- Assignment 2: Lesson Plan Analysis, Revision and Justification - Kaitlin Rose TrojkoDokumen9 halamanAssignment 2: Lesson Plan Analysis, Revision and Justification - Kaitlin Rose Trojkoapi-408336810Belum ada peringkat

- John PFTDokumen231 halamanJohn PFTAlexander Santiago ParelBelum ada peringkat

- 8086 Microprocessor: J Srinivasa Rao Govt Polytechnic Kothagudem KhammamDokumen129 halaman8086 Microprocessor: J Srinivasa Rao Govt Polytechnic Kothagudem KhammamAnonymous J32rzNf6OBelum ada peringkat

- Destroyed Inventory Deduction ProceduresDokumen7 halamanDestroyed Inventory Deduction ProceduresCliff DaquioagBelum ada peringkat

- DJDokumen907 halamanDJDeepak BhawsarBelum ada peringkat

- Module 7 - Assessment of Learning 1 CoursepackDokumen7 halamanModule 7 - Assessment of Learning 1 CoursepackZel FerrelBelum ada peringkat

- BWT Septron Line 31-61 Rev01!08!05-18 Opm enDokumen56 halamanBWT Septron Line 31-61 Rev01!08!05-18 Opm enDavide Grioni100% (1)

- Yardi Commercial SuiteDokumen52 halamanYardi Commercial SuiteSpicyBelum ada peringkat

- Theatre Arts I 9 - 12 Grade Beginning Theatre Students: TH THDokumen18 halamanTheatre Arts I 9 - 12 Grade Beginning Theatre Students: TH THAppleSamsonBelum ada peringkat

- Case Study - Help DocumentDokumen2 halamanCase Study - Help DocumentRahBelum ada peringkat

- Plumbing Arithmetic RefresherDokumen80 halamanPlumbing Arithmetic RefresherGigi AguasBelum ada peringkat

- Project Final Report: Crop BreedingDokumen16 halamanProject Final Report: Crop BreedingAniket PatilBelum ada peringkat

- Nysc Editorial ManifestoDokumen2 halamanNysc Editorial ManifestoSolomon Samuel AdetokunboBelum ada peringkat

- Performance of a Pelton WheelDokumen17 halamanPerformance of a Pelton Wheellimakupang_matBelum ada peringkat

- Describing An Object - PPTDokumen17 halamanDescribing An Object - PPThanzqanif azqaBelum ada peringkat

- B+V ELEVATOR SIDE DOOR Collar Type VS09 A4Dokumen19 halamanB+V ELEVATOR SIDE DOOR Collar Type VS09 A4Игорь ШиренинBelum ada peringkat

- KG ResearchDokumen257 halamanKG ResearchMuhammad HusseinBelum ada peringkat

- FIDIC delay and disruption standardsDokumen7 halamanFIDIC delay and disruption standardsMohammad FayazBelum ada peringkat

- Lesson Plan 12 Climate ChangeDokumen5 halamanLesson Plan 12 Climate ChangeRey Bello MalicayBelum ada peringkat

- Arcelor Mittal - Bridges PDFDokumen52 halamanArcelor Mittal - Bridges PDFShamaBelum ada peringkat

- Pic Attack1Dokumen13 halamanPic Attack1celiaescaBelum ada peringkat

- Appendix B, Profitability AnalysisDokumen97 halamanAppendix B, Profitability AnalysisIlya Yasnorina IlyasBelum ada peringkat

- Gujarat Technological University: Aeronautical EngineeringDokumen16 halamanGujarat Technological University: Aeronautical EngineeringumodiBelum ada peringkat

- Ejemplo FFT Con ArduinoDokumen2 halamanEjemplo FFT Con ArduinoAns Shel Cardenas YllanesBelum ada peringkat

- APTARE IT Analytics: Presenter NameDokumen16 halamanAPTARE IT Analytics: Presenter NameCCIE DetectBelum ada peringkat

- Mercury QCDokumen23 halamanMercury QCMarcus MeyerBelum ada peringkat

- ĐỀ CƯƠNG ANH 9 - CK2 (23-24)Dokumen7 halamanĐỀ CƯƠNG ANH 9 - CK2 (23-24)thuyhagl2710Belum ada peringkat