Solder Paste

Diunggah oleh

Edgar DauzonJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Solder Paste

Diunggah oleh

Edgar DauzonHak Cipta:

Format Tersedia

SMDLTLFP15T4

Datasheet revision 1.1 www.chipquik.com

Solder Paste No-Clean Sn42/Bi57.6/Ag0.4 15g T4 Mesh

Two Part Mix™ [PATENT PENDING]

Product Highlights

2 year shelf life unrefrigerated before mixed

Printing speeds up to 100mm/sec

Long stencil life

Wide process window

Clear residue

Low voiding

Excellent wetting compatibility on most board finishes

RoHS II and REACH compliant

Specifications

Alloy: Sn42/Bi57.6/Ag0.4

Mesh Size: T4

Micron (µm) Range: 20-38

Flux Type: Synthetic No-Clean

Flux Classification: REL0

Metal Load: 87% Metal by Weight

Melting Point: 138°C (281°F)

Packaging: 2 compartment bag, includes Jar for after mixed storage, 15g

Shelf Life: Before Mixed: Refrigerated >24 months, Unrefrigerated >24 months

After Mixed: Refrigerated >6 months, Unrefrigerated >2 months

How to Mix the Two Parts

This product MUST BE MIXED within its bag before use. To mix, squeeze the flux pocket towards the solder powder pocket

and the seal between the two compartments will break open, creating a single pocket bag. Then knead the mixture back and

forth for 2-3 minutes, or until a uniform consistency is achieved.

Printer Operation

Print Speed: 25-100mm/sec

Squeegee Pressure: 70-250g/cm of blade

Under Stencil Wipe: Once every 10-25 prints, or as necessary

Stencil Life

>8 hours @ 20-50% RH 22-28°C (72-82°F)

>4 hours @ 50-70% RH 22-28°C (72-82°F)

Stencil Cleaning

Automated stencil cleaning systems for both stencil and misprinted boards. Manual cleaning using isopropyl alcohol (IPA).

Storage and Handling

Before Mixed: Store refrigerated or at room temperature 3-25°C (37-77°F). Do not freeze.

After Mixed: Refrigerate at 3-8°C (37-46°F). Do not freeze. Allow 4 hours for solder paste to reach an operating temperature

of 20-25°C (68-77°F) before use. Once mixed, the solder paste can be dispensed by cutting a small corner off the bag. It

can be resealed with a piece of Scotch® tape, or it can be stored by dispensing the entire bag into the provided empty jar.

1 © 1994-2015 Chip Quik® Inc.

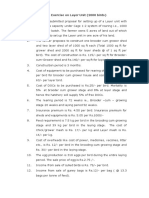

Recommended Profile

Reflow profile for Sn42/Bi57.6/Ag0.4 solder assembly, designed as a starting point for process optimization.

165°C (329°F)

138°C (281°F)

130°C (266°F)

Temperature

90°C (194°F)

25°C (77°F)

0sec 90sec 180sec 210sec 240sec 270sec

Time

Test Results

Test J-STD-004 or other Test Requirement Result

requirements as stated

Copper Mirror IPC-TM-650: 2.3.32 L: No breakthrough

Corrosion IPC-TM-650: 2.6.15 L: No corrosion

Quantitative Halides IPC-TM-650: 2.3.28.1 L: <0.5%

Electrochemical Migration IPC-TM-650: 2.6.14.1 L: <1 decade drop (No-clean)

Surface Insulation Resistance 85°C, IPC-TM-650: 2.6.3.7 L: ≥100MΩ (No-clean)

85% RH @ 168 Hours

Tack Value IPC-TM-650: 2.4.44 48g

Viscosity – Malcom @ 10 RPM/25°C IPC-TM-650: 2.4.34.4 Print: 125-180, Dispense: 90-130

(x103mPa/s)

Visual IPC-TM-650: 3.4.2.5 Clear and free from precipitation

Conflict Minerals Compliance Electronic Industry Citizenship Compliant

Coalition (EICC)

REACH Compliance Articles 33 and 67 of Regulation (EC) Contains no substance >0.1% w/w that

No 1907/2006 is listed as a SVHC or restricted for

use in solder materials

Conforms to the following Industry Standards:

J-STD-004B, Amendment 1 (Solder Fluxes): Yes

J-STD-005A (Solder Pastes): Yes

J-STD-006C, Amendments 1 & 2 (Solder Alloys and Fluxed/Non-Fluxed Solders): Yes

RoHS 2 Directive 2011/65/EU: Yes

2 © 1994-2015 Chip Quik® Inc.

Anda mungkin juga menyukai

- Drake Family - Work SampleDokumen1 halamanDrake Family - Work Sampleapi-248366250Belum ada peringkat

- Tefabloc Tosi 431 65a PDFDokumen5 halamanTefabloc Tosi 431 65a PDFAdriana UceanuBelum ada peringkat

- Toshiba Power MOSFETsDokumen34 halamanToshiba Power MOSFETsEdgar DauzonBelum ada peringkat

- AluminumPresentationIEEE (CompatibilityMode)Dokumen31 halamanAluminumPresentationIEEE (CompatibilityMode)A. HassanBelum ada peringkat

- 3048421Dokumen2 halaman3048421Philippe VelhaBelum ada peringkat

- SMD291AX50T3Dokumen2 halamanSMD291AX50T3Jonatan SmithBelum ada peringkat

- 3289310Dokumen2 halaman3289310Philippe VelhaBelum ada peringkat

- Ultradur® B 6550 LN en SI - Product DatasheetDokumen2 halamanUltradur® B 6550 LN en SI - Product Datasheetnoto.sugiartoBelum ada peringkat

- Rma 223Dokumen2 halamanRma 223Sergio ChicBelum ada peringkat

- SMD29130CCDokumen1 halamanSMD29130CCzokiBelum ada peringkat

- SP-2888 RG PDSDokumen5 halamanSP-2888 RG PDSreza ashtariBelum ada peringkat

- TDS Castrol Perfecto XPG - Power VersionDokumen2 halamanTDS Castrol Perfecto XPG - Power VersionTeguh SBelum ada peringkat

- Transaqua - HT2 TDSDokumen6 halamanTransaqua - HT2 TDSFerri AguswanBelum ada peringkat

- Technical Data Sheet: Page 1 of 6 HCD-10307 (Rev. 2011-11-03 2:00 PM)Dokumen6 halamanTechnical Data Sheet: Page 1 of 6 HCD-10307 (Rev. 2011-11-03 2:00 PM)Pedro NavarroBelum ada peringkat

- Product Data Energol THB: DescriptionDokumen2 halamanProduct Data Energol THB: Descriptionkarim karimBelum ada peringkat

- ET-3528W-1B1W: Cool WhiteDokumen22 halamanET-3528W-1B1W: Cool Whitesonyfrancis1970Belum ada peringkat

- NC257 SN100C: Lead-Free Solder Paste FeaturesDokumen3 halamanNC257 SN100C: Lead-Free Solder Paste Featureshuynh thi y viBelum ada peringkat

- ALPHA OM 338 PT Solder Paste EN 22oct21 TBDokumen7 halamanALPHA OM 338 PT Solder Paste EN 22oct21 TBEdison SpolaorBelum ada peringkat

- Alpha Ef 2100 Technical Data SheetDokumen4 halamanAlpha Ef 2100 Technical Data SheetYounes Ben TaherBelum ada peringkat

- TDS Polidan TA HF V 1.0 June 2017Dokumen3 halamanTDS Polidan TA HF V 1.0 June 2017valdecirnasatoBelum ada peringkat

- Shielded Power Inductors - LPS6225: Halogen FreeDokumen3 halamanShielded Power Inductors - LPS6225: Halogen Freedecaedron decaedrumBelum ada peringkat

- De400001 SM-6Dokumen3 halamanDe400001 SM-6seve1Belum ada peringkat

- ABS Terlux 2802 TR - Fiche Technique enDokumen2 halamanABS Terlux 2802 TR - Fiche Technique endamien_roule5728Belum ada peringkat

- TDS Yd535lv - TH7253 - 8Dokumen5 halamanTDS Yd535lv - TH7253 - 8polypolyy100% (2)

- More Production: in Less TimeDokumen2 halamanMore Production: in Less TimeDaniel GarciaBelum ada peringkat

- Technical Datasheet LITEN BB 85 F - EngDokumen2 halamanTechnical Datasheet LITEN BB 85 F - EngTo RaBelum ada peringkat

- Ultradur: Product InformationDokumen3 halamanUltradur: Product InformationirisBelum ada peringkat

- Enersyn RC-S RangeDokumen2 halamanEnersyn RC-S RangecarmaBelum ada peringkat

- H70SDokumen1 halamanH70SJustin SantiagoBelum ada peringkat

- Polystyrene CRYSTAL 1160: DescriptionDokumen2 halamanPolystyrene CRYSTAL 1160: DescriptionlyesBelum ada peringkat

- PDS - SP 8888 - High Temperature Novolac Pipeline Coating - 2017 03 13 PDFDokumen3 halamanPDS - SP 8888 - High Temperature Novolac Pipeline Coating - 2017 03 13 PDFMohamed NouzerBelum ada peringkat

- Interbond 808: Epoxy AnticorrosiveDokumen4 halamanInterbond 808: Epoxy AnticorrosivedcsamaraweeraBelum ada peringkat

- Ultradur B2520Dokumen2 halamanUltradur B2520Phung LucBelum ada peringkat

- SP-9888® Tank Lining: Selection & Specification DataDokumen4 halamanSP-9888® Tank Lining: Selection & Specification DataSatees KrishnanBelum ada peringkat

- Colpoly 736 WAT TDSDokumen2 halamanColpoly 736 WAT TDSKristjan PosavecBelum ada peringkat

- Sikafloor®-263 SLDokumen6 halamanSikafloor®-263 SLHalit Baris SertbakanBelum ada peringkat

- Resist 65: Technical Data SheetDokumen5 halamanResist 65: Technical Data Sheetchristian210789Belum ada peringkat

- Technical Datasheet LITEN FB 75 - EngDokumen2 halamanTechnical Datasheet LITEN FB 75 - EngTo RaBelum ada peringkat

- Resist 86: Technical Data SheetDokumen5 halamanResist 86: Technical Data SheetantonyfmBelum ada peringkat

- Thwi Tds (JK r2 0315) EnglishDokumen2 halamanThwi Tds (JK r2 0315) EnglishMasood KhanBelum ada peringkat

- Alpha Om-338 Teknisk DatabladDokumen3 halamanAlpha Om-338 Teknisk Databladnormans00Belum ada peringkat

- PDS Stopaq Wrappingband CZH V8 enDokumen2 halamanPDS Stopaq Wrappingband CZH V8 enMajid SattarBelum ada peringkat

- Power Oil Data SheetDokumen1 halamanPower Oil Data SheetSreeram PanigrahiBelum ada peringkat

- TDS - MT 950 - enDokumen2 halamanTDS - MT 950 - enTo RaBelum ada peringkat

- Brayco Micronic™ SV/B: DescriptionDokumen5 halamanBrayco Micronic™ SV/B: DescriptionAlfonsus W.M.Belum ada peringkat

- Enhanced P L A P: Olyimide Aminate ND RepregDokumen4 halamanEnhanced P L A P: Olyimide Aminate ND Repregoutra_pessoaBelum ada peringkat

- Alpha Om-338-T CNP TB SM871-20 English 20190604Dokumen6 halamanAlpha Om-338-T CNP TB SM871-20 English 20190604Красимир КостадиновBelum ada peringkat

- Comprit 185H 0 6Dokumen1 halamanComprit 185H 0 6Ahmed AbdelhamidBelum ada peringkat

- Colpoly 7331 LV TDSDokumen2 halamanColpoly 7331 LV TDSKristjan PosavecBelum ada peringkat

- Ultramid A205fDokumen3 halamanUltramid A205fSATHISH KUMAR SBelum ada peringkat

- Elix Pc-Abs 5130Dokumen4 halamanElix Pc-Abs 5130DiegoTierradentroBelum ada peringkat

- Latigloss 66 H2 G 50 F2 PDFDokumen4 halamanLatigloss 66 H2 G 50 F2 PDFBadis ChemaliBelum ada peringkat

- PCRS9309-QT TDSDokumen5 halamanPCRS9309-QT TDSDaniele CatacchioBelum ada peringkat

- Alpha CVP390 PDFDokumen7 halamanAlpha CVP390 PDFSergio MoyaBelum ada peringkat

- OsiSense XM - XMLB070D2S11Dokumen6 halamanOsiSense XM - XMLB070D2S11Hamed YazidiBelum ada peringkat

- TDS - Resist 65Dokumen5 halamanTDS - Resist 65Teknik produksi wikonBelum ada peringkat

- Agip OSO: Characteristics (Typical Figures)Dokumen2 halamanAgip OSO: Characteristics (Typical Figures)Luis Carlos Lagos SalinasBelum ada peringkat

- DR Fike Axius SCDokumen3 halamanDR Fike Axius SCCamilaBelum ada peringkat

- Shielded Power Inductors - MOS6020Dokumen2 halamanShielded Power Inductors - MOS6020mauricio alfonsoBelum ada peringkat

- TDS - Jotamastic 80 PrimerDokumen6 halamanTDS - Jotamastic 80 PrimershahoorhussainBelum ada peringkat

- Alpha Om-338-T CNP TB SM871 EnglishDokumen4 halamanAlpha Om-338-T CNP TB SM871 Englishachref jebaliBelum ada peringkat

- Transistor Electronics: Use of Semiconductor Components in Switching OperationsDari EverandTransistor Electronics: Use of Semiconductor Components in Switching OperationsPenilaian: 1 dari 5 bintang1/5 (1)

- 24aa08 - 24lc08 Eeprom PDFDokumen40 halaman24aa08 - 24lc08 Eeprom PDFEdgar DauzonBelum ada peringkat

- R2A LM4040-n V-RefDokumen71 halamanR2A LM4040-n V-RefEdgar DauzonBelum ada peringkat

- 43B-LM431SB-Prog Shunt RegDokumen13 halaman43B-LM431SB-Prog Shunt RegEdgar DauzonBelum ada peringkat

- LD7576GS PWM CTRLR PDFDokumen20 halamanLD7576GS PWM CTRLR PDFEdgar DauzonBelum ada peringkat

- Rubycon Al Eectrolytics DatasheetDokumen2 halamanRubycon Al Eectrolytics DatasheetEdgar DauzonBelum ada peringkat

- Tda4887 Video PreamplifierDokumen68 halamanTda4887 Video PreamplifierEdgar DauzonBelum ada peringkat

- Flyback Transformer Specification: Code: First Issue DateDokumen21 halamanFlyback Transformer Specification: Code: First Issue Datefrancisco navarroBelum ada peringkat

- Bridge Rectifier: FeaturesDokumen3 halamanBridge Rectifier: FeaturesEdgar DauzonBelum ada peringkat

- MC34163-D Switching RegulatorDokumen16 halamanMC34163-D Switching RegulatorEdgar DauzonBelum ada peringkat

- Defibrillator Monitors Comparison ChartsDokumen2 halamanDefibrillator Monitors Comparison ChartsEdgar DauzonBelum ada peringkat

- RCMaDokumen18 halamanRCMaAnonymous ffje1rpaBelum ada peringkat

- DTC P1602 Deterioration of Battery: DescriptionDokumen5 halamanDTC P1602 Deterioration of Battery: DescriptionEdy SudarsonoBelum ada peringkat

- Case Exercise On Layer Unit (2000 Birds)Dokumen2 halamanCase Exercise On Layer Unit (2000 Birds)Priya KalraBelum ada peringkat

- Industrial Visit ReportDokumen8 halamanIndustrial Visit ReportAnuragBoraBelum ada peringkat

- Intraocular Pressure and Aqueous Humor DynamicsDokumen36 halamanIntraocular Pressure and Aqueous Humor DynamicsIntan EkarulitaBelum ada peringkat

- Content Map PE & Health 12Dokumen12 halamanContent Map PE & Health 12RIZZA MEA DOLOSOBelum ada peringkat

- OBESITY - Cayce Health DatabaseDokumen4 halamanOBESITY - Cayce Health Databasewcwjr55Belum ada peringkat

- 2 - Pizeo Electric SensorDokumen33 halaman2 - Pizeo Electric SensorNesamaniBelum ada peringkat

- Learning Activity Sheet MAPEH 10 (P.E.) : First Quarter/Week 1Dokumen4 halamanLearning Activity Sheet MAPEH 10 (P.E.) : First Quarter/Week 1Catherine DubalBelum ada peringkat

- Bee Keeping-KVK MorenaDokumen6 halamanBee Keeping-KVK MorenaAsh1Scribd100% (1)

- طبى 145Dokumen2 halamanطبى 145Yazan AbuFarhaBelum ada peringkat

- Ural Evelopment: 9 9 Rural DevelopmentDokumen17 halamanUral Evelopment: 9 9 Rural DevelopmentDivyanshu BaraiyaBelum ada peringkat

- Laboratory Medicine Internship BookletDokumen95 halamanLaboratory Medicine Internship BookletMuhammad Attique100% (1)

- Class 7 Work Book Answers Acid Bases and SaltsDokumen2 halamanClass 7 Work Book Answers Acid Bases and SaltsGaurav SethiBelum ada peringkat

- 224 Chinese Healing ExercisesDokumen4 halaman224 Chinese Healing ExercisesKiné Therapeut-manuelle Masseur GabiBelum ada peringkat

- Supercritical Carbon DioxideDokumen3 halamanSupercritical Carbon DioxideRawda SeragBelum ada peringkat

- ATRT66Dokumen10 halamanATRT66luunhauyen.pisaBelum ada peringkat

- Exam Questions: Exam Title: Chapter MEK 8Dokumen4 halamanExam Questions: Exam Title: Chapter MEK 8vishnu sharmaBelum ada peringkat

- Pearls and Pitfalls in Emergency Radiology Variants and Other Difficult Diagnoses 2013Dokumen389 halamanPearls and Pitfalls in Emergency Radiology Variants and Other Difficult Diagnoses 2013mmbire@gmail.comBelum ada peringkat

- 1Manuscript-BSN-3y2-1A-CEDILLO-222 11111Dokumen32 halaman1Manuscript-BSN-3y2-1A-CEDILLO-222 11111SHARMAINE ANNE POLICIOSBelum ada peringkat

- Foundation Engineering. 02 Soil CompressibilityDokumen63 halamanFoundation Engineering. 02 Soil Compressibilitysammy lopezBelum ada peringkat

- 5000mah Mi Power Bank 2 - PDFDokumen6 halaman5000mah Mi Power Bank 2 - PDFManuel Jesús Fernández lavadoBelum ada peringkat

- Uppercut MagazineDokumen12 halamanUppercut MagazineChris Finn100% (1)

- EBANX Beyond Borders 2020Dokumen71 halamanEBANX Beyond Borders 2020Fernanda MelloBelum ada peringkat

- Photosynthesis PastPaper QuestionsDokumen24 halamanPhotosynthesis PastPaper QuestionsEva SugarBelum ada peringkat

- Dif Stan 3-11-3Dokumen31 halamanDif Stan 3-11-3Tariq RamzanBelum ada peringkat

- NT PotentialMiningDevelopmentsDokumen13 halamanNT PotentialMiningDevelopmentsho100hoBelum ada peringkat

- Teleperformance Global Services Private Limited: Full and Final Settlement - December 2023Dokumen3 halamanTeleperformance Global Services Private Limited: Full and Final Settlement - December 2023vishal.upadhyay9279Belum ada peringkat