Ckyfukulyfl

Diunggah oleh

TarunJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Ckyfukulyfl

Diunggah oleh

TarunHak Cipta:

Format Tersedia

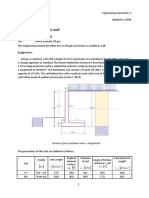

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

DESIGN DATA FOR SUPERSTRUCTURE(73 M BRIDGE)

Span of bridge 73 m

Nos. of panels 11 nos

Length of intermediate panels 6.636 m 3.318

Length of end panels 6.636 m

Spacing of intermediate girders 6.636 m

Spacing of end girders 6.636 m

Width of slab 4.68 m

Panel length of slab 4.68 m

Panel width of slab 6.636 m

Thickness of deck slab 0.008 m

Width of carriageway 4.25 m

Av. Thickness of wearing coat 0 m

Density of concrete(slab) 2.5 t/m3

Density of wearing coat 2.5 t/m3

Height of truss 7.5 m

Height of kerb 0.275 m

Width of kerb 0.215 m

Impact factor (for steel members) 1.154

Length of cross girder 4.68 m

Width of member 0.4 m

Effective width of bridge 5.104 m

Width of footpath 0 m

Overall width 5.50 m

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

DESIGN OF DECK SLAB :

A)Dead load calculation :

Dead load intensity of deck : 0.008 * 7.85 = 0.0628 t/m2

dead loadintensity of wearing: 0 * 2.5 = 0 t/m2

total 0.0628 t/m2

Say 0.23 t/m2

Use M25 grade of concrete and spanning transversely between the cross girder . Influence

co-efficient are taken from "Steel Table" by Prof. Ramamrutham.

Deck slab is design like a continuous beam.

B.M. due to dead load :

a. + Ve B.M. at 0.5L in the end

= 0.078 x 0.23 * 6.636 * 6.636

= 0.790101322 t-m/m

b. -Ve B.M.at penultimate support

= 0.105 x 0.23 * 6.636 * 6.636

= 1.063597934 t-m/m

c. -Ve B.M. at inner support

= 0.079 x 0.23 * 6.636 * 6.636

= 0.800230826 t-m/m

d. +Ve B.M.at 0.5L in inner span

= 0.046 0.23 * 6.636 * 6.636

= 0.46595719 t-m/m

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Live load calculation :

CLASS A LOAD

Length of load : 0.25 m

Total load : 11.4 t

Width of track : 0.5 m

Width overall track : 2.3 m

Clearence : 0.3 m

Dispersed width of load in longitudinal direction :

= 0.25 + 2 *( 0 + 0.008 )

= 0.266 m 11.4 11.4

Dispersed width of load in transverse direction : 1.22 2.708 m

Be = Alpha * x ( 1 - x/l) + Bw 6.636 m

l = 6.636 m

x = 2.708 m

Length of slab / Width of slab = 4.68 / 6.636

= 0.70520548

So Alpha = 2.48 ( As per IRC-21 cl -305.16.2 for continuous slab)

Bw = 0.5 + 2 * 0

= 0.5 m

Be = 2.48 * 2.708 ( 1 - 0.4080822 ) + 0.5

= 3.9755 + 0.5

= 4.475 m > 1.8 m

So there is overlapping.

1.8 m

4.475

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

So Be = 4.475 + 1.8 = 6.2754922 m

Intensity of load :

Impact factor : 50 % as per IRC-6-2000

= 11.4 * 1.5 / ( 6.2754922 * 1 )

= 2.724885869 t/m

Total intensity of load = 2.7248859 t/m

= 4.1 t/m

B.M. due to live load :

a. + Ve B.M. at 0.5L in the end

= 4.1 * 2.7081818 - 4.1 * 2.70818 * 3.9282 / 6.6364

= 11.10354545 - 6.5723863

= 4.531159166 tm/m

b. -Ve B.M.at penultimate support

= 6.572386289

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Total B.M.

1. Max . -Ve B.M. : 1.063597934 + 6.57238629 = 7.635984 tm

2. Max. + Ve B.M. : 0.790101322 + 4.53115917 = 5.32126 tm

Check for depth of deck slab :

Depth reqd. : SQRT( M / R b)

Use M35 Grade Concrete

Here Permissible compressive stress of concrete: 11.5 N/mm2

Permissible tensile stress of steel : 240 N/mm2

For bridge m : 10

k = 11.5 * 10 / 11.5 * 10

= 115 / 355 + 240

= 0.323943662

j = 1 - 0.3239437 / 3

= 0.892018779

R = 0.5 * 11.5 * 0.3239437 * 0.89202

= 1.661542022

Check for depth of deckslab :

d reqd = SQRT 76359842.23 / 1.66154202 * 1000

= 214.3763372 mm

Provided depth of deck slab = 8 mm

Provided clear cover = 40 mm

Dia. of reinforcement = 12 mm

Effective depth of deck slab = 8 - 40 - 6

= -38 mm > 214.3763 mm

O.K.

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Main reinforcement :

1. Top reinforcement :

Ast = 76359842.23 / ( 240 * 0.8920188 * -38 )

= -9386.33795 mm2/m

Provided 16 dia bar @ 130 mm c/c. Area provided = 1547 mm2

Hence OK

2.Bottom reinforcement :

Ast = 53212604.88 / 240 * 0.8920188 * -38

= -6541.02311 mm2/m

Provided 12 dia bar @ 150 mm c/c. Area provided = 754 mm2

Hence OK

Distribution reinforcement :

Ast = 0.12 * 1000 * 8 / 100

= 9.6 mm2/m

OR Ast = 0.3 * -9386.3379 = -2815.9 mm2

Provided 10 dia bar @ 200 mm c/c. Area provided = 392.7 mm2

Check for shear :

Shear force = 0.23 * 6.63636364 / 2 * + 4.1 +

at support 4.1 * 5.41636364 / 6.636364

= 0.763181818 + 7.44627397

= 8.209455791 t

Depth (d) = -38 mm

Width (b) = 1000 mm

Due to Dead Load X 0.23 t/m

0.008 m 6.6363636 m

B

A

X

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

X

Reaction on Support : 0.23 *6.63636364 / 2 + 4.1 +

4.1 * 5.4163636 / 6.63636

= 0.7631818 + 4.1 + 3.34627

= 8.2094558 ton

Force at section X-X : 8.209455791 - 0.23 * 0.008

= 8.207615791 t

Shear stress = 82076.15791 / ( -38 * 1000 )

= -2.15989889 N/mm2

% of Tensile steel : 100 * 1546.6302

-38 * 1000

; -4.07008

Permissible shear stress : -0.683118 N/mm2 -4.07008 0.75 1.00

Hence OK -0.59402 0.37 0.42

As per Cl. 304.7.1.3.3 of IRC : 21 : 2000

The shear stress shall be increased by 15 %

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

DESIGN OF INTERMEDIATE CROSS GIRDER:

Crossgirder is design as a composite section.Composite section is consist of deck slab

and steelsection.

Ec = 290000 kg/cm2

Es = 2110000 kg/cm2

Section Properties ( Permanent Loads)

m = 15 ( For Bridge)

Effective flange width ( As per IRC 21 -2000-cl-305.15.2)

be = bw + l/ 5

13.35 + 468 / 5

= 106.95 cm

beff = 106.95 / 15 Properties ISMB 400

Area 78.46 cm2

= 7.13 cm C.G. 20.00 cm

I 20458.4 cm4

Depth 40.00 cm

Section properties for dead loads :

Item size(cm) Area (cm2) Yt(cm) A * Yt(cm3) A*Yt2(cm4Ixo(cm4)

B(cm) t(cm)

Slab 7.13000 0.8 5.704 0.4 2.2816 0.9 0.30421

ISMB 400 14 0.89 78.46 20.8 1631.968 33945 20458.4

Plate 33 0 0 40 0 0 0

Total 84.164 61.2 1634.2496 33946 20458.7

Ycg = 1634.2496 / 84.164 = 19.417442 cm

Ixx = 20458.70421 + 33945.847 - 19.417442 * 19.4174

* 84.164

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

= 22671.60421 cm4

Ztt = 22671.60421 / 19.417442

= 1167.589637 cm3 400 ISMB 400 400

Zbb = 22671.60421 / 21.382558

= 1060.284946 cm3

Section Properties ( Transient Loads)

m = 7.5 ( For Bridge)

Effective flange width ( As per IRC 21 -2000-cl-305.15.2)

be = bw + l/ 5

6.675 + 468 / 5

= 100.275 cm

beff = 100.275 / 7.5 Properties ISMB 400

Area 78.46 cm2

= 13.37 cm C.G. 20.00 cm

I 20458.4 cm4

Depth 40.00 cm

Section properties :

Item size(cm) Area (cm2) Yt(cm) A * Yt(cm3) A*Yt2(cm4Ixo(cm4)

B(cm) t(cm)

Slab 13.37 0.8 10.696 0.4 4.2784 1.7 0.57045

ISMB 400 14 0.89 78.46 20.8 1631.968 33945 20458.4

Plate 33 0 0 40 0 0 0

Total 89.156 61.2 1636.2464 33947 20459

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Ycg = 1636.2464 / 89.156 = 18.352622 cm

Ixx = 20458.97045 + 33946.646 - 18.352622 * 18.3526

* 89.156

= 24376.20393 cm4

Ztt = 24376.20393 / 18.352622

= 1328.213671 cm3 400 ISMB 400 400

Zbb = 24376.20393 / 22.447378

= 1085.926576 cm3

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

LOAD CALCULATION :

1) Dead load :

Load due to deck slab : 0.23 * 6.6363636 = 1.53 t/m

Load due to crossgirder : 0.06 t/m

Total UDL : 1.59 t/m

1.59

A 5.104 m

B

4.05 t 4.05 t

Max. SF at end = 1.59 * 5.104 / 2

= 4.05 t

Max. B.M. at mid = 4.05 * 2.552 - 1.59 * 5.104

* 5.104 / 8

= 5.17 t-m

Live load analysis for Crossgirder :

Load of each wheel with impact: 5.7 * 1.48 = 8.436 t

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

8.436 t 8.436 t

1.22 m

6.636 m 6.636 t

Max. reaction at central support : 8.436 + 8.436 * 5.41636 / 6.6364

: 8.436 + 6.8851627

= 15.321163 ton

Max. B.M. :

1.652 15.32 t 15.32 t 1.652

1.8

1.035

A 5.104 m B

15.32 15.32

B.M. : 15.32 * 2.552 - 15.32 * 0.9

= 25.31

= 25.31 tm

Max. S.F. : 15.32 t 15.32 t

0.212 0.325 1.8 2.455

0.40

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

5.104

A B

S.F. : ( 15.32 * 4.255 + 15.32 * 2.455 )

/ 5.104

+

= 102.805002 / 5.104

= 20.14204584

= 20.14204584 t

Total B.M. : 5.17 + 25.31 = 30.48 t-m

Total S.F. : 4.05 + 20.14 = 24.19 t

Check for compressive and tensile stress :

Max. compressive stress in concrete : 517093.958 / 1167.59 * 15

due to dead load = 29.5248686 kg/cm2 < 116.7 kg/cm2

Hence OK

Max . Tensile stress in steel : 517093.958 / 1060.285

due to dead load = 487.693389 kg/cm2 < 1550 kg/cm2

Hence OK

Max. compressive stress in concrete : 2531056.08 / 1328.214 * 7.5

due to live load = 254.081216 kg/cm2 > 116.7 kg/cm2

Revise

Max . Tensile stress in steel : 2531056.08 / 1085.927

due to dead load = 2330.78013 kg/cm2 > 1550 kg/cm2

Revise

Total compressive stress in concrete = 283.606085 Kg/cm2 < 116.7 Kg/cm2

Total tensile stress in steel = 2818.47352 Kg/cm2 < 1550 Kg/cm2

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Shear stress = 24194.5063 / ( 0.89 * 35 )

= 776.709674 Kg/cm2 < 950 Kg/cm2

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Connection of Plate and angle :

Maximum shear = 24.19450633 t

Horizental shear per 1 cm length = F * Ay

I

= 24194.50633 * 12.46 * 18.972442 + #REF! * 16.387

22671.60421

= 1.067172226 * ( 236.39663 + #REF! )

= #REF! kg

Provide staggere pitch

Dia of rivet = 1.6 cm

Shear strength of rivet = 3.14* 1.75 * 1.75 * #REF!

/ 4

= #REF! kg

Bearing strenght = 1 * 7.5 * 2250

= 16875 kg

Spacing = #REF! = #REF! cm

#REF!

Provided 10.68 cm spacing c/c ( Not exceed 12t)

Connection of Web Plate and angle :

Maximum shear = 24.19450633 t

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Horizental shear per 1 cm length = F * Ay

I

= 24194.50633 * 6.675 * 14.777442 + #REF! * 16.387

22671.60421

= 1.067172226 * ( 98.639426 + #REF! )

= #REF! kg

Provide staggere pitch

Dia of rivet = 1.6 cm

Shear strength of rivet = 3.14* 1.75 * 1.75 * #REF!

/ 4

= #REF! kg

Bearing strenght = 1 * 7.5 * 2250

= 16875 kg

Spacing = #REF! = #REF! cm

#REF!

Provided 9.6 cm spacing c/c ( Not exceed 12t)

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

DESIGN OF END CROSS GIRDER:

Properties ISA 100 100 8

Area 15.39 cm2

C.G. 2.76 cm

I 145.1 cm4

Depth cm

Section properties : Design as a symmetical section

Item size(cm) Area (cm2) Yt(cm) A * Yt(cm3) A*Yt2(cm4Ixo(cm4) Nos

B(cm) t(cm)

PL 45 1.8 81 0.9 72.9 65.6 21.87 1

PL 35 1.6 56 2.6 145.6 378.6 11.9467 1

ISA 100 100 10 0.8 30.78 6.16 189.6048 1168.0 290.2 2 nos

Web PL 33.6 1.6 53.76 21.20 1139.712 24161.9 5057.74 1

Web PL 31.6 1.2 75.84 21.20 1607.808 34085.5 6310.9 2

ISA 100 100 10 0.8 30.78 36.24 1115.4672 40424.5 290.2 2

PL 35 1.6 56 39.8 2228.8 88706.2 11.9467 1

PL 45 1.8 81 41.5 3361.5 139502.3 21.87 1

Total 465.16 9861.392 328492.6 12016.7

Ycg = 9861.392 / 465.16 = 21.2 cm

Ixx = 12016.67333 + 328492.58 - 21.2 * 21.2

* 465.16

= 131447.7438 cm4

350 * 16

ISA 100 100 8

Web PL 316 * 12

356.0 mm 424

Ztt = 131447.7438 / 21.2 Web PL 336.0 * 16 mm

= 6200.365275 cm3

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Zbb = 131447.7438 / 21.2

= 6200.365275 cm3 450 * 18 mm

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Stress check for Jackup Condition :

47.5 t 47.5 t

-1.198 m -1.198

7.5 m

A B

Reaction on each support A : 47.45 t

B.M. at Support A : 47.5 * -1.198

= -56.8451 t-m

S.F. at support A : 47.5

= 47.5 t

B.M. at centre : 47.45 * 2.552 - 47.5 * 3.8

= -56.8451 t-m

S.F. at centre : 0

Bending stress : -56.8451 * 100000 / 6200.365

= -916.802438 kg/cm2 < 1650kg/cm2

Shear stress : 47.45 * 1000 / 4 * 42.4

= 279.7759434 kg/cm2 < 950 kg/cm2

Combined Stress : SQRT -916.8024 * -916.8024 + 3 * 279.78

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

* 279.78

= 1036.991054 kg/cm2 < 2300kg/cm2

OK

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

CONNECTION BETWEEN CROSSGIRDER AND BOTTOM CHORD :(Intermediate Girder)

Max. S.F. : 24.194506 t

Use 2 nos ISA 150* 150* 12 as a cleat angle

Depth : 35.00 cm

Thick : 1.2 cm

Shear stress : 24194.506 / ( 35 * 0.89 )

= 776.70967 kg/cm2 < 950 kg/cm2 ( 0.38fy)

O.K.

Design of nos. bolt :

1.Connection between crossgirder and cleat angle :(Intermediate Girder)

Force : 24194.506 kg

Min thick 0.89 cm

HSFG Bolt :

Provide 22 dia 8 G Bolts

As per table 1 of SP:6(4)-1989

Proof Load = 18180 Kg

Shear per Bolt = 0.45 * 18180 * N / 1.4

= 5843.57 N Kg

N=2 Nos. of effective interfaces

Shear per Bolt = 5843.5714 * 2

= 11687.143 Kg

Nos. of Bolts reqd. = 24194.506 / 11687.14 * 1.05

= 2.1736905

Provided 6 Nos Bolt

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

2.Connection between bottomchord and cleat angle :(Intermediate Girder)

Force : 24194.506 kg

Min thick 0.76 cm

Dia of Bolt: 2.2 cm

Gross dia : 2.35 cm

Bolt value 5843.5714 Kg

Nos. of bolts reqd : 24194.506 * 1.05 / 5843.57

= 4.347381 nos

Provided 3 nos bolt on each side

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

CONNECTION BETWEEN CROSSGIRDER AND BOTTOM CHORD :(End Girder)

Max. S.F. : 47.5 t

Use 2 nos ISA 200* 200* 16 as a cleat angle and 10mm plate both side

Depth : 33.6 cm

Thick : 2.6 cm

Shear stress : 47450 / 2 * 33.6 * 2.6

= 271.57738 kg/cm2 < 950 kg/cm2

O.K.

Design of nos. of rivet :

1.Connection between crossgirder and cleat angle :(End Girder)

Force : 47450 kg

Min thick 2.6 cm

Dia of rivet: 2.4 cm

Gross dia : 2.55 cm

Permissible shear strss : 950 kg/cm2

Permissible bearing strss : 2250 kg/cm2

We provided the cleat angle on both side of web of cross girder. So double shear will be

acted.

Use 22 mm dia power driven rivet.

Shear strength of rivet = 2 * 3.14* 2.55 * 2.55 * 950

/ 4

= 9698.48 kg

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Bearing strength = 4 * 2.55 * 2250

= 22950 kg

Rivet value : 9698.4788 kg

Nos. of rivets reqd : 47450 * 1.2 / 9698.48

= 5.8710238 nos b

Provided 20 nos of rivet

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

2.Connection between bottomchord and cleat angle :(End Girder)

Force : 47450 kg

Min thick 1.6 cm

Dia of rivet: 2.4 cm

Gross dia : 2.55

Permissible shear strss : 950 kg/cm2

Permissible bearing strss : 2250 kg/cm2

Use 24 mm dia power driven rivet.

Shear strength of rivet = 3.14* 2.55 * 2.55 * 950

/ 4

= 4849.24 kg

Bearing strength = 1.6 * 2.55 * 2250

= 9180 kg

Rivet value : 4849.2394 kg

Nos. of rivets reqd : 47450 * 1.2 / 4849.24

= 11.742048 nos

Provided 20 nos of rivet on each side

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

DESIGN OF SHEAR CONNECTORS :

The longitudinal shear per unit length at the interface of prefebricated section and cast-

in-situ shall be evaluated from the following expression.

VL = V * Ac * Ycg / I

VL = Longitudinal shear per unit length.

V = Vertical shear due to SIDL and live load with impact = 20870.8 kg

Ac = Area of transform section on one side of interface = 0 cm2

Ycg = Distance of the centriod of the area under consideration from the neutral axis

of the composite section. ( 23.0136867 - 0.4 )

= 22.6137 cm

I = Moment of inertia of the composite section = 22671.6 cm4

VL = 20870.80415 * 0 * 22.613687 / 22671.6

= 0 kg/cm

= 0 N/mm

Use ISA 75*75*8 as a shear connectors with 10 dia bar and grade of concrete is M35

For the angle connector made with mild steel (As per IRC-21-cl-611-4-1-3-1)

Q = 3.32 * ( h + 0.5 t) L * SQRT fck

10mm dia bar

100mm

150mm

ISA75*75*8 40mm

crossgirder

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Q = The safe shear resistance in Newton's of one shear connector

h = Mimimum thickness of flange = 8 mm

t = Mimimum thickness of web = 8 mm

L = Length of shear connector = 140 - 2 * 20 = 100 mm

SQRTfck : SQRT 35 = 5.9160798

Q = 3.32 * ( 75 + 0.5 * 8 ) * 100 * 5.91607978

= 3.32 * 79 * 100 * 5.91608

= 155166.9406 N

Spacing of shear connectors :

P = Q / VL

= 155166.9406 / 0

= #DIV/0! mm

But P < 600 mm OR 4 * Height of connector = 600mm

So We provided ISA 75*75*8 @ 200 mm C/C

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

0.9955 t

1.6 m

Design of Footpath Beam :

1.7 m

Intensity of live load : ( P' - 260 + 4800 ) ( 16.5 - W )

73 15

: 400.00- 260 + 65.753425 ) ( 16.5 - 0 )

15

: 205.75 * 1.1

: 226.32877 kg/m2

Dead load due to deck slab : 0.15 * 6.6363636 * 2.5 = 2.4886 t/m

Load duee to live load : 0.226 * 6.6363636 = 1.502 t/m

Total = 3.9906 t/m

Point load due to railing and railing post : 0.15 * 6.636 = 0.9955 t

B.M. : 3.990636364 * 1.7 * 1.7 / 2 +

0.995455 * 1.6

= 5.766469545 + 1.5927273

= 7.359196818 t-m

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

S.F. : 3.990636364 * 1.7 + 0.9954545 = 7.77954 t

Provided ISMB 200 as a footpath beam

A : 32.33 cm2

Ixx : 2235.4 cm4

Zxx : 223.5 cm3

Zyy : 30 cm3

Depth : 20 cm

Thickness 0.57 cm

Bending stress : 7.359196818 * 100000 / 223.5

= 3292.705511 kg/cm2 < 1550kg/cm2

Shear stress : 7.779536364 * 1000 / 20 * 0.57

= 682.4154705 kg/cm2

Combined Stress : SQRT 3292.7055 * 3292.7055 + 3 * 682.42

* 682.42

= 3498.425676 kg/cm2 < 2300kg/cm2

OK

DESIGN OF FOOTPATH SLAB :

Dead load of footpath Slab : 0.15 * 2.5 = 0.375 t/m2

Use M35 grade of concrete and spanning transversely between the cross girder . Influence

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

co-efficient are taken from "Steel Table" by Prof. Ramamrutham.

Deck slab is design like a continuous beam.

B.M. due to dead load :

a. + Ve B.M. at 0.5L in the end

= 0.078 * 0.375 * 6.63636364 * 6.636364

= 1.288208678 t-m/m

b. -Ve B.M.at penultimate support

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

= 0.105 * 0.375 * 6.63636364 * 6.636364

= 1.734127066 t-m/m

c. -Ve B.M. at inner support

= 0.079 * 0.375 * 6.63636364 * 6.636364

= 1.304724174 t-m/m

d. +Ve B.M.at 0.5L in inner span

= 0.046 * 0.375 * 6.63636364 * 6.636364

= 0.75971281 t-m/m

B.M. Due to live load :

1. +Ve B.M. at 0.5L in the end span :

= 0.1 * 0.2263288 * 6.6363636 * 6.63636

= 0.996781818 t- m/m

2. -Ve B.M. atpenultimate support :

= 0.116 * 0.2263288 * 6.6363636 * 6.63636

= 1.156266909 t- m/m

3. -Ve B.M. at inner support :

= 0.107 * 0.2263288 * 6.6363636 * 6.63636

= 1.066556545 t- m/m

4. +Ve B.M. at 0.5L in inner support :

= 0.086 * 0.2263288 * 6.6363636 * 6.63636

= 0.857232364 t- m/m

Total B.M.

1. Max . -Ve B.M. : 1.734127066 + 1.15626691 = 2.890394 t- m/m

2. Max. + Ve B.M. : 1.288208678 + 0.99678182 = 2.28499 t- m/m

Check for depth of deck slab :

Depth reqd. : SQRT( M / R b)

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Here Permissible compressive stress of concrete: 11.5 N/mm2

Permissible tensile stress of steel : 200 N/mm2

For bridge m : 10

k = 11.5 * 10 / 11.5 * 10

= 115 / 315 + 200

= 0.365079365

j = 1 - 0.3650794 / 3

= 0.878306878

R = 0.5 * 11.5 * 0.3650794 * 0.87831

= 1.843747375

Check for depth of deckslab :

d reqd = SQRT 28903939.75 / 1.84374738 * 1000

= 125.2067706 mm

Provided depth of footpath slab = 150 mm

Provided clear cover = 40 mm

Dia. Of reinforcement = 16 mm

Width of footpath beam = 125 mm

Effective depth of deck slab = 150 - 40 - 8

= 102 mm > 125.2068 mm

O.K.

Main reinforcement :

1. Top reinforcement :

Ast = 28903939.75 / 200 * 0.8783069 * 102

= 1613.171691 mm2

Provided 10 dia bar @ 220 mm c/c. Area provided = 357 mm2

Revise

2.Bottom reinforcement :

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Ast = 22849905 / 200 * 0.8783069 * 102

= 1275.287041 mm2

Provided 10 dia bar @ 250 mm c/c. Area provided = 314.16 mm2

Revise

Distribution reinforcement :

Ast = 0.12 * 1000 * 150 / 100

= 180 mm2

Provided 8 dia bar @ 250 mm c/c. Area provided = 201.06 mm2

Hence OK

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Check for shear :

Shear force = ( 0.375 + 0.22632877 ) * 6.636364 / 2

= 1.995318182 t/m

Depth (d) = 102 mm

Width (b) = 1000 mm

X 1.99531818 t/m

0.2125 m 6.6363636 m

B

A

X

Reaction on each Support : 1.9953182 *6.63636364 / 2

= 6.6208285 t

Force at section X-X : 6.620828512 - 1.99531818 * 0.2125

= 6.196823399 t

Shear stress = 61968.23399 / 102 * 1000

= 0.607531706 N/mm2

% of Tensile steel : 100 * 356.99917

102 * 1000

; 0.3499992

Permissible shear stress : 0.2399998 N/mm2 0.35 0.75 1.00

Revise 0.24 0.32 0.37

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

CONNECTION BETWEEN FOOTPATH BEAM AND BOTTOM CHORD :

Check for shear stress :

Moment : 7.36 t-m

Max. S.F.: 7.779536364 t

Moment resisted by equal forces in angles , forming a couple of magnitude equal to end moment.

Pull on angles : Moment = 735.919682 = 36.796 t

Depth section 20

This pull will cause shear in both connecting angles to the section.

Use 2 ISA 150 150 12 as cleat angles

Thickness of web : 0.57 cm

Depth : 15 cm

Shear stress : 36795.98409 / 0.57 * 15 * 2

= 2151.811935 kg/cm2< 1075 kg/cm2

O.K.

Design of nos. of rivet :

1.Connection between beam and cleat angle :

Force : 36795.98409 kg

Min thick : 0.57 cm

Dia of rivet: 2.2 cm

Gross dia : 2.35 cm

Permissible shear strss : 950 kg/cm2

Permissible bearing strss : 2250 kg/cm2

We provided the cleat angle on both side of web of cross girder. So double shear will be

acted.

Use 20mm dia power driven rivet.

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Shear strength of rivet = 2 * 3.14* 2.35 * 2.35 * 950

/ 4

= 8236.8088 kg

Bearing strength = 0.57 * 2.35 * 2250

= 3013.875 kg

Rivet value : 3013.875 kg

Nos. of rivets reqd : 36795.98409 * 1.2 / 3013.875

= 14.65063445 nos

Provided 6 nos of rivet .

2.Connection between bottomchord and cleat angle :

Force : 36795.98409 kg

Min thick : 1.2 cm

Dia of rivet: 2.2 cm

Gross dia : 2.35 cm

Permissible shear strss : 950 kg/cm2

Permissible bearing strss : 2250 kg/cm2

Use 20mm dia power driven rivet.

Shear strength of rivet = 3.14* 2.35 * 2.35 * 950

/ 4

= 4118.4044 kg

Bearing strength = 1.2 * 2.35 * 2250

= 6345 kg

Rivet value : 4118.404375 kg

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Nos. of rivets reqd : 36795.98409 * 1.2 / 4118.404

= 10.7214292 nos

Provided 6 nos rivet on each side.

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

CALCULATION OF MULTIPLYING FACTORS :

1. Class A Loading (single lane) :

Half width of member : 0.2 m

Width of kerb : 0.227 m

Clearence : 0.15 m

Half Width of overall width of load 0.9 m

P(unit load)

0.2 0.227 0.9 3.377 m

0.40

5.104 m

Multiplying factor with impact :

= 3.377 * 1.154 / 5.104

= 0.763530172

Axle Load 2.7 t with multipication factor = 2.0615315 ton

Axle Load 11.4 t with multipication factor = 8.704244 ton

Axle Load 6.8 with multiplication factor = 5.1920052 ton

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

2. Class 24 R Track Loading ( Singla Lane ) :

Half width of member : 0.2 m

Width of kerb : 0.227 m

Clearence : 0.3 m

Half Width of overall width of load 1.22 m

P(unit load)

0.2 0.337 1.22 3.157 m

1.937

0.30

5.104 m

Multiplying factor with impact :

= 3.157 * 1.1 / 5.104

= 0.680387931

Track Load 25 t with multipication factor = 17.009698 ton

= 17 ton ( Say )

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Total Wt. of Structral Steel = 150 ton

Dead load of deck slab : 73 * 4.68 * 0 * 2.5

= 0 t

Dead load of W.C : 73 * 4.25 * 0 * 2.4

= 0 t

Wt of kerb : 0.215 * 0.275 * 73 * 2.5 * 2

= 21.580625 t

Railing = 0.1 * 73 * 2 = 14.6 t

Total Dead load : 186.180625 t

Load per truss : 93.0903125 t

UDL on Truss : 93.0903125 / 73

= 1.27520976 t/m

Say : 1.3 t/m 189.8 t

Snow load = 25 cm

Total load of snow on the bridge = 0.25 * 4.68 * 73 * 0.9

= 76.869 ton

Load on each truss = 76.869 /2

= 38.4345 ton

= 38.4345 / 73

= 0.5265 ton/m

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Bearing Load Calculations

Braking force is considered 20 % of live load coming on the span for the first train and 10% for the succeeding train as per

cl. 214.2 of IRC :6.

0

Non Seismic Case

Horizontal force at bearing level :

I Normal Case Live Load Max.

Total braking force = 82.6 kN

Horizontal force at free end DL LL rc. at free end wind load

mR = 0.03 x ( 474.50 + 300.00 + 178.20 + 0)

= 0.03 x 952.70 = 28.5811 kN

Horizontal force = 28.581111 + 82.6 = 69.8811 kN

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

at fixed end 2

Max. Vertical load = 952.70 KN

Governing Longitudnal force at Fixed End = 69.8811 kn

Governing Longitudinal force at Free End = 28.5811 KN

Non Seismic Case

Horizontal force at bearing level :

II Normal Case Live Load Min.

Total braking force = 82.6 kN

Horizontal force at free end DL LL rc. at free end

mR = 0.03 x ( 474.50 + 0.00 - 178.20 )

= 0.03 x 296.30 = 8.88889 kN

Horizontal force = 8.8888891 + 82.6 = 50.1889 kN

at fixed end = 2 82.6 - 8.8888891

= 73.7111 KN

Max. Vertical Load = 296.30 KN

Governing Longitudnal force at Fixed End = 73.7111 kN

Governing Longitudinal force at Free End = 8.88889 KN

ii Seismic Case Live Load Max.

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Seismic Coefficient = 0.15

Braking force due to live load = 41.3 kN

Total braking force in normal case = 41.3 KN

Fh due to seismic = 0.150 x ( 984.5875 ) = 147.688 kN

Total Fh in Seismic Case = 147.6881 + 41.3 = 188.98813 kN

Fh - mR = 188.988 - 33.0044 = 156 kN

Fh/2 mR = 188.988 + 33.0044 = 127.5 kN

2

Total Vertical load = 474.50 + 0.075 * 475 + 150.0

= 660.09 KN

Governing Longitudnal force at Fixed End = 155.984 kN

Governing Horizontal force at Free End = 33.004 KN

ii Seismic Case Live Load Min.

Seismic Coefficient = 0.15

Braking force due to live load = 41.3 kN

Total braking force in normal case = 41.3 KN

Fh due to seismic = 0.150 x ( 684.59 ) = 102.688 kN

Total Fh in Seismic Case = 102.6881 + 41.3 = 143.98813 kN

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

h

Fh - mR = 143.988 - 21.9456 = 122 kN

Fh/2 mR =143.988 + 21.9456 = 93.94 kN

2

Total Vertical load = 474.50 - 0.075 * 475 + 0.00

= 438.91 KN

Governing Longitudnal force at Fixed End = 122.043 kN

Governing Horizontal force at Free End = 21.946 KN

BEARING LOADS FOR 73 M SPAN STEEL BRIDGE OVER INDUS RIVER

Type of superstructure = Steel truss ( Through type)

Distribution plate = Reqd.

Grade of concrete for pedestal = M35

Fixed Bearing

Non Seismic Case

Max. Vertical Load = 952.7037 KN

Min. Vertical load = 296.2963 KN

Hor. Force ( Max. load) = 69.881111 KN

Hor. Force ( Min. Load) = 73.711111 KN

Movement Long. = 0 mm

Movement Trans = 0 mm

Rotation = 0.01 radians

Seismic Case

Max. Vertical Load = 660.0875 KN

Min. Vertical load = 438.9125 KN

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Hor. Force ( Max. load) = 155.98375 KN

Hor. Force (Min. Load) = 122.0425 KN

Movement Long. = 0 mm

Movement Trans = 0 mm

Rotation = 0.01 radians

Guide L Bearing

Non Seismic Case

Max. Vertical Load = 952.7037 KN

Min. Vertical Load = 296.2963 KN

Horizontal force ( Max. load ) = 28.581111 KN

Horizontal force ( Min. Load ) = 8.8888891 KN

Movement Long. = +/- 40 mm

Movement trans. = +/- 4.0 mm

Rotation = 0.01 radians

Seismic Case

Max. Vertical Load = 660.0875 KN

Min. Vertical Load = 438.9125 KN

Max. Horizontal force = 33.004375 KN

Min. Horizontal force = 21.945625 KN

Movement Long. = +/- 40 mm

Movement trans. = +/- 2.5 mm

Rotation = 0.01 radians

Guide T Bearing

Non Seismic Case

Max. Vertical Load = 952.7037 KN

Min. Vertical Load = 296.2963 KN

Max. Horizontal force = 69.881111 KN

Min. Horizontal force = 73.711111 KN

Movement Long. = +/- 4.0 mm

Movement trans. = +/-12.5 mm

Rotation = 0.01 radians

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Seismic Case

Max. Vertical Load = 660.0875 KN

Min. Vertical Load = 438.9125 KN

Max. Horizontal force = 155.98375 KN

Min. Horizontal force = 122.0425 KN

Movement Long. = +/-4.0 mm

Movement trans. = +/- 12.5 mm

Rotation = 0.01 radians

Free Float Bearing

Non Seismic Case

Max. Vertical Load = 952.7037 KN

Min. Vertical Load = 296.2963 KN

Horizontal force ( Max. Lo = 28.581111 KN

Horizontal force ( Min. Lo = 8.8888891 KN

Movement Long. = +/- 40 mm

Movement trans. = +/-12.5 mm

Rotation = 0.01 radians

Seismic Case

Max. Vertical Load = 660.0875 KN

Min. Vertical Load = 438.9125 KN

Horizontal force ( Max. Lo = 33.004375 KN

Horizontal force ( Min. Lo = 21.945625 KN

Movement Long. = +/- 40 mm

Movement trans. = +/- 12.5 mm

Rotation = 0.01 radians

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

BEARING LOADS FOR 73 M SPAN STEEL BRIDGE OVER INDUS RIVER

Type of superstructure = Steel truss ( Through type)

Distribution plate = Reqd.

Grade of concrete for pedestal = M35

Fixed Bearing

No. of bearing = 2

Non Seismic Case

Max. Vertical Load = 970 KN

Min. Vertical load = 290 KN

Hor. Force ( Max Load ) = 70 KN

Hor. Force (Min. load ) = 75 KN

Movement Long. = 0 mm

Movement Trans = 0 mm

Rotation = 0.01 radians

Seismic Case

Max. Vertical Load = 670 KN

Min. Vertical load = 430 KN

Hor. Force ( Max. Load ) = 160 KN

Hor. Force ( Min. Load ) = 125 KN

Movement Long. = 0 mm

Movement Trans = 0 mm

Rotation = 0.01 radians

Guide L Bearing

No. of bearing = 2

Non Seismic Case

Max. Vertical Load = 970 KN

Min. Vertical Load = 290 KN

Max. Horizontal force = 30 KN

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Min. Horizontal force = 10 KN

Movement Long. = +/- 40 mm

Movement trans. = +/- 2.5 mm

Rotation = 0.01 radians

Seismic Case

Max. Vertical Load = 670 KN

Min. Vertical Load = 430 KN

Max. Horizontal force = 35 KN

Min. Horizontal forcee = 25 KN

Movement Long. = +/- 40 mm

Movement trans. = +/- 2.5 mm

Rotation = 0.01 radians

Guide T Bearing

No. of bearing = 1

Non Seismic Case

Max. Vertical Load = 970 KN

Min. Vertical Load = 290 KN

Max. Horizontal force = 70 KN

Min. Vertical force = 75 KN

Movement Long. = +/- 2.5 mm

Movement trans. = +/-15.0 mm

Rotation = 0.01 radians

Seismic Case

Max. Vertical Load = 670 KN

Min. Vertical Load = 430 KN

Max. Horizontal force = 160 KN

Min. Vertical force = 125 KN

Movement Long. = +/-2.5 mm

Movement trans. = +/- 15.0 mm

Rotation = 0.01 radians

Free Float Bearing

No. of bearing = 1

Non Seismic Case

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Max. Vertical Load = 970 KN

Min. Vertical Load = 290 KN

Max. Horizontal force = 170 KN

Min. Vertical force = 114 KN

Movement Long. = +/- 40 mm

Movement trans. = +/-15.0 mm

Rotation = 0.01 radians

Seismic Case

Max. Vertical Load = 670 KN

Min. Vertical Load = 430 KN

Max. Horizontal force = 35 KN

Min. Vertical force = 25 KN

Movement Long. = +/- 40 mm

Movement trans. = +/-15.0 mm

Rotation = 0.01 radians

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

WIND LOAD ANALYSIS ( IRC-6-2000)

Member Length Depth

Ttop chord member : 6.636364 m 0.4 m

Bottom member : 6.636364 m 0.45 m

Vertical member : 7.5 m 0.25 m

Secondary vertical member : 3.75 m 0.16 m

diogonal member : 8.20124 m 0.25 m

Case 1. For Unloaded Bridge :

Intensity of wind pressure : 2.4 KN/m2

I.Exposed area per panel ( for top chord)

Member Windward Truss Leeward Truss

Top Chord 2.654545 1.33

Vertical member 1.875 0.94

Diagonal member 2.05031 1.03

1 Gusset 1*1.5 1.5 0.75

Total 8.079855 4.04

Average Ht. Of Ground Level = 8m

P = 82 Kg/m2 = 0.8 KN/m2 (As per Table 4 of IRC : 6:2000)

Total Exposed area = 8.08 + 4.04 = 12.12 m2

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Wind force on top chord P1 : 12.12 * 2.4 / 6.63636 = 4.3830448 KN/m

Governing wind force on top chord top chord P1 = 4.38304 KN/m being greater than 2.25 KN/m as

minimum as per cl- 212-6-IRC-6

II.Exposed area per panel ( for bottom chord)

Member Windward Truss Leeward Truss

Bottom chord 6.636 * 0.683 4.53 2.27

+ ST + Deck +

WC + Kerb

Vertical 1.88 0.94

Diagonal 2.05 1.03

Short vertical 0.00 0.00

Short diogonal 0.00 0.00

1 Gusset 1.50 0.75

Total 9.96 4.98

Total Exposed area = 9.96 + 4.98 = 14.94 m2

Wind force on bpttom chord P2 : 14.94 * 2.4 / 6.63636 = 5.4018448 KN/m

Governing wind force on bottom chord P2 = 5.40184 KN/m being greater than 4.5 KN/m as

minimum as per cl- 212-6-IRC-6

Total wind force on the two truss : 4.38304 * 59.7273 + 5.40184 * 73

= 656.122 KN

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

For loaded Bridge :

Length of live load : 18.84 m ( total length of train )

Height of live load : 3m

Wind load per panel on top chord /m : 0.8 * 14.94 / 6.63636

= 1.80061 KN/m < 2.25 KN/m

Live load area per panel : 18.84 * 3 * 6.636 / 73

= 5.138182 m2

18.84m length of load train

3m height of load train

Total exposed area bottom chord : 14.94 + 5.13818 = 20.08 m2

wind load on bottom chord /m : 20.08 * 0.8 / 6.63636 = 2.4200122 KN/m

< 4.5 KN/m

Governing wind pressure on bridge at loaded condition as follows

1. Wind force on unloaded at top chord : 2.25 KN/m

2. Wind force on loaded bottomchord : 4.5 KN/m

3. Wind force on moving load : 3 KN/m

Total wind load : 2.25 * 59.727 + 4.5 * 73 +

3* 18.84

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

= 519.4064 KN

III. Overturning Effect :

Taking the worst case in loaded condition .

wind force on top chord P1: 2.25 KN/m

Wind load on moving load : 3 KN/m acting at a height of 1.5 m above deck

Overturning moment about the CG of the loaded truss

Moment : 2.25 * 7.5 + 1.733 * 18.84 * 3 / 73

= 18.22 KN-m/m

top

Overturning Effect on worst loaded case : 18.217 * 6.6364 / 5.104

= 23.686 KN on each panel point

= 23.686 / 6.6364

= 3.5691 KN/m

= 3.5691 / 13

= 0.2745 * 100

= 27.455 % of dead load

Overturning moment on in unloaded condition : 4.383 * 7.5 = 32.8728 KN-m/m

Overturning effect on panel point : 32.873 * 6.6364 / 5.104

= 42.742 KN on each panel point

= 42.742 / 6.6364

= 6.4406 KN/m

= 6.4406 / 13

= 0.4954 * 100

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

= 49.543 % of dead load

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

LOAD ON MEMBER DUE TO SEISMIC :

For design of superstructure as per IS-1893 and IRC-6 . Seismic force shall be considered

only on 25% 0f LL + DL in transverse direction and only 50 % LL shall be considered for load analysis

during earthquake.

As per Ramchandra

Dead load of the bridge : 1898 KN

In critical condition for one train of Class B loading : 1 * 332

= 332 KN

Dead load on top chord / panel : 18.98 KN/panel

( Assuming Dead load of top chord be about 10 % of total weight of bridge )

DL + 0.25 LL on the bottom chord : 1898 - 18.98 * 10 +

0.25 * 332

= 1791.2 KN

Seismic force in Unloaded case :

On top chord : 0.12 * 18.98 = 2.2776 KN/panel

On bottom chord : 0.12 * 1791.2 = 214.94 KN

Load on bottom chord/panel : 214.944 / 11 = 19.5404 KN/panel

Load on top chord per metre : 2.2776 / 6.64 = 0.3432 KN/m

Load on bottom chord per metre : 19.5404 / 6.64 = 2.94444 KN/m

Overturning moment about cg of bottom chord member

Moment : 2.2776 * 7.5 + 19.5404 * 1.733

= 17.082 + 33.8635

= 50.9454502 KN/panel

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Overturning effect on panel point : 50.9455 / 5.104

= 9.98148 KN

= 9.98148 / 6.64

= 1.50406 KN/m

= 1.50406 / 13.00

= 0.1157 * 100.00

= 11.5697 % of dead load

Load of 1 Train of Loading = 55.4 ton

Braking force = 0.2 * 55.4 + 0.1 * 55.4

= 16.62 ton

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

SUMMARY OF FORCES

Normal case Wind load case Seismic case Nature

Member Dead load Class A Pedestrian Snow Braking Total wind loa Total seismic Total Governing

in tonne Load Load Load in ton in ton 1.15 % alload 1.25%

L0L1 20.04 21.93 7.71 14.14 8.31 72.13 10.22 52.09 2.40 65.79 72.13 Tensile

L1L2 54.39 57.32 20.92 14.14 8.31 155.08 27.74 139.45 6.53 146.02 155.08 Tensile

L2L3 81.11 80.75 31.20 24.56 8.31 225.93 41.37 203.85 9.73 213.48 225.93 Tensile

L3L4 100.19 96.57 38.53 32.00 8.31 275.60 51.10 249.04 12.02 260.93 275.60 Tensile

L4L5 111.64 101.52 42.94 36.46 8.31 300.87 56.94 272.20 13.40 285.76 300.87 Tensile

L5L5 115.46 97.49 44.41 36.46 8.31 302.13 58.88 274.99 13.86 288.31 302.13 Tensile

U1U2 38.57 40.98 14.83 23.81 118.19 19.67 99.18 4.63 110.13 118.19 Comp

U2U3 68.7 70.65 26.42 31.25 197.02 35.04 174.62 8.24 185.35 197.02 Comp

U3U4 91.61 89.58 35.23 35.72 252.14 46.72 228.82 10.99 238.70 252.14 Comp

U4U5 106.87 100.67 41.10 37.21 285.85 54.50 263.61 12.82 271.83 285.85 Comp

U5U6 114.51 100.07 44.04 37.21 295.83 58.40 275.67 13.74 282.89 295.83 Comp

L0U1 49.53 52.4 19.05 20.66 141.64 25.26 127.17 5.94 133.31 141.64 Comp

U1L1 49.53 48.04 19.05 15.22 131.84 25.26 123.37 5.94 125.47 131.84 Tensile

L1U2 40.09 43.32 15.42 10.87 109.70 20.45 103.72 4.81 103.94 109.70 Comp

U2L2 35.38 40.01 13.61 6.52 95.52 18.04 93.08 4.25 90.70 95.52 Tensile

L2U3 30.66 35.28 11.79 2.17 79.90 15.64 81.19 3.68 76.30 81.19 Comp.

U3L3 25.94 31.93 9.98 2.17 70.02 13.23 70.50 3.11 66.49 70.50 Tensile

L3U4 21.23 27.54 8.17 2.17 59.11 10.83 58.92 2.55 55.85 59.11 Comp

U4L4 16.51 24.77 6.35 2.17 49.80 8.42 48.74 1.98 46.50 49.80 Tensile

L4U5 11.79 21.1 4.53 2.17 39.59 6.01 37.77 1.41 36.44 39.59 Comp.

U5L5 7.08 19.06 2.72 2.17 31.03 3.61 28.24 0.85 27.68 31.03 Tensile

L5U6 2.36 16.66 0.91 2.17 22.10 1.20 18.38 0.28 18.63 22.10 Comp.

U1M1 4.31 14.9 1.66 3.17 24.04 2.20 20.06 0.52 20.97 24.04 Tensile

U2M2 4.31 13.82 1.66 7.93 27.72 2.20 19.12 0.52 23.91 27.72 Tensile

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

U3M3 4.31 13.77 1.66 4.76 24.50 2.20 19.07 0.52 21.34 24.50 Tensile

U4M4 4.31 13.77 1.66 1.58 21.32 2.20 19.07 0.52 18.79 21.32 Tensile

U5M5 4.31 13.76 1.66 2.16 21.88 2.20 19.07 0.52 19.25 21.88 Tensile

U6M6 4.31 13.77 1.66 2.16 21.89 2.20 19.07 0.52 19.25 21.89 Tensile

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

DESIGN OF MEMBERS :

Design of Tensile members :

Member : L0L1

Force : 72.13 t ( tension )

A net reqd = 72.1276923 * 1000 / 1500 = 48.0851 cm2

400

Provided area

Plate Width(cm) Thk Area Nos Total(cm2)

2 Plate 43 0.8 2 68.8

450 ISA 100 *100*8

ISA 100 *100*8 0.8 15.39 4 61.56 Plate 430 * 8

Total 130.36

Dia of bolt 2.2 cm

Nos. of bolt in one rows 5 nos

Deduction for hole : p

= 2 * 1.6 * 5 * 2.35 = 37.6 cm2

Net Area provided = 92.76 cm2 > 48.0851 cm2 OK

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Design of Connection :

Total area of web = 43 * 0.8 * 2+ 10 * 0.8 * 4

= 100.8 cm2

Area of gusset and splice plate required = 100.8 * 1.05

= 105.84 cm2

Provide 12 mm gusset plate on each side

Area of gusset plate provided = 45 * 1.2 * 2

= 108 cm2

Area of flange = 10 * 0.8 * 4

= 32 cm2

Area of cover plates required = 32 * 1.05

= 33.6 cm2

Provide 400 * 8 mm thick cover plate at top and bottom

Area of cover plate provided = 40 * 0.8 * 2

= 64 cm2

Nos. of 22 dia HSFG Bolts required

In Web = 105.84 * 1500 / 5843

= 27.171

Provide 13.59 Nos. bolt on each face ( In Single Shear)

6.79 Nos bolt on each face ( In double shear)

In flange = 33.6 * 1500 / 5843

= 8.6257

Provide 4.313 on each face

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Member : L1L2

Force = 155.1 ton

A net reqd = 155.1 * 1000 / 1500 = 103.386 cm2

Provided area 400

Plate Width(cm) Thk Area Nos Total(cm2)

2 Plate 43 0.8 2 68.8

450 ISA 100 * 100*8

ISA 100 * 100*8 0.8 15.39 4 61.56 Plate 430 * 8

Total 130.36

=

Dia of bolt 2.2 cm

Nos. of bolt in one rows 5 nos

Deduction for hole :

= 2 * 1.6 * 2 * 2.35

+ 3* 0.8 * 2* 2.35

= 26.32 cm2

Area provided : 104.04 cm2 Hence OK

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Design of Connection :

Total area of web = 43 * 0.8 * 2+ 10 * 0.8 * 4

= 100.8 cm2

Area of gusset and splice plate required = 100.8 * 1.05

= 105.84 cm2

Provide 12 mm gusset plate on each side

Area of gusset plate provided = 45 * 1.2 * 2

= 108 cm2

Area of flange = 10 * 0.8 * 4

= 32 cm2

Area of cover plates required = 32 * 1.05

= 33.6 cm2

Provide 400 * 8 mm thick cover plate at top and bottom

Area of cover plate provided = 40 * 0.8 * 2

= 64 cm2

Nos. of 22 dia HSFG Bolts required

In Web = 105.84 * 1500 / 5843

= 27.171

Provide 13.5854869 Nos. bolt on each face ( In Single Shear)

6.79274345 Nos bolt on each face ( In double shear)

In flange = 33.6 * 1500 / 5843

= 8.6257

Provide 4.31285299 on each face

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Member : L2L3

Force : 225.93 t ( tension )

A net reqd = 225.926154 * 1000 / 1500 = 150.617 cm2

400

Provided area

Plate Width(cm) Thk Area Nos Total(cm2)

PL 43 1.2 2 103.2

450 ISA 100*100*8

ISA 100*100*8 0.8 15.39 4 61.56 Plate 430 * 12

Total 164.76

Dia of bolt 2.2 cm

Nos. of bolt in one rows 5 nos

Deduction for hole :

= 2 * 2 * 2 * 2.35

+ 2* 1.2 * 3* 2.35

= 35.72 cm2

Provide 2 No.extra plate 230 * 8 mm on inner face at joint location

Area of extra plate provided = 36.8 cm2

Area provided : 165.84 cm2 Hence OK

at joint

Design of Connection :

Total area of web = 43 * 1.2 * 2+ 10 * 0.8 * 4

= 135.2 cm2

Area of gusset and splice plate required = 135.2 * 1.05

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

= 141.96 cm2

Provide 16 mm gusset plate on each side

Area of gusset plate provided = 45 * 1.6 * 2

= 144 cm2

Area of flange = 10 * 0.8 * 4

= 32 cm2

Area of cover plates required = 32 * 1.05

= 33.6 cm2

Provide 400 * 8 mm thick cover plate at top and bottom

Area of cover plate provided = 40 * 0.8 * 2

= 64 cm2

Nos. of 22 dia HSFG Bolts required

In Web = 141.96 * 1500 / 5843

= 36.444

Provide 18.22 Nos. bolt on each face ( In Single Shear)

9.11 Nos bolt on each face ( In double shear)

In flange = 33.6 * 1500 / 5843

= 8.6257

Provide 4.313 on each face

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Member : L3L4

Force : 275.60 t ( tension )

A net reqd = 275.604615 * 1000 / 1500 = 183.736 cm2

400

Provided area

Plate Width(cm) Thk Nos Total(cm2)

PL 43 1.6 2 137.6

450 ISA 100*100*8

ISA 100*100*8 0.8 15.39 4 61.56 Plate 430*16

Total 199.16

=

Dia of bolt 2.2 cm

Nos. of bolt in one rows 5 nos

Deduction for hole :

= 2 * 2.4 * 2 * 2.35

+ 2* 1.6 * 3* 2.35

= 45.12 cm2

Provide 2 No.extra plate 230 * 8 mm on inner face at joint location

Area of extra plate provided = 36.8 cm2

Area provided : 190.84 cm2 Hence OK

at joint

Design of Connection :

Total area of web = 43 * 1.6 * 2+ 10 * 0.8 * 4

= 169.6 cm2

Area of gusset and splice plate required = 169.6 * 1.05

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

= 178.08 cm2

Provide 12 mm gusset plate on each side and 10 mm splice plate on inner face.

Area of gusset plate provided = 45 * 1.2 * 2+ 42 * 1*2

= 192 cm2

Area of flange = 10 * 0.8 * 4

= 32 cm2

Area of cover plates required = 32 * 1.05

= 33.6 cm2

Provide 400 * 8 mm thick cover plate at top and bottom

Area of cover plate provided = 40 * 0.8 * 2

= 64 cm2

Nos. of 22 dia HSFG Bolts required

In Web = 178.08 * 1500 / 5843

= 45.716

Provide 22.86 Nos. bolt on each face ( In Single Shear)

11.43 Nos bolt on each face ( In double shear)

In flange = 33.6 * 1500 / 5843

= 8.63

Provide 4.31 on each face

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Member : L4L5, L5L5

Force : 302.13 t ( tension )

A net reqd = 302.127692 * 1000 / 1500 = 201.418 cm2

400

Provided area

Plate Width(cm) Thk Area Nos Total(cm2)

PL 43 1.6 2 137.6

450 ISA 100*100*10

ISA 100*100*10 1 19.03 4 76.12 Plate 430*16

Total 213.72

=

Dia of bolt 2.2 cm

Nos. of bolt in one rows 5 nos

Deduction for hole :

= 2 * 2.6 * 2 * 2.35

+ 2* 1.6 * 3* 1.6

= 39.8 cm2

Provide 2 No.extra plate 230 * 10 mm on inner face at joint location

Area of extra plate provided = 46 cm2

Area provided : 219.92 cm2 Hence OK

at joint

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Design of Connection :

Total area of web = 43 * 1.6 * 2+ 10 * 1* 4

= 177.6 cm2

Area of gusset and splice plate required = 177.6 * 1.05

= 186.48 cm2

Provide 12 mm gusset plate on each side and 420 * 10 mm splice plates on inner face.

Area of gusset plate provided = 45 * 1.2 * 2+ 42 * 1*2

= 192 cm2

Area of flange = 10 * 0.8 * 4

= 32 cm2

Area of cover plates required = 32 * 1.05

= 33.6 cm2

Provide 400 * 8 mm thick cover plate at top and bottom

Area of cover plate provided = 40 * 0.8 * 2

= 64 cm2

Nos. of 22 dia HSFG Bolts required

In Web = 186.48 * 1500 / 5843

= 47.873

Provide 23.94 Nos. bolt on each face ( In Single Shear)

11.97 Nos bolt on each face ( In double shear)

In flange = 33.6 * 1500 / 5843

= 8.63

Provide 4.31 on each face

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Member : L5L6

Force : #REF! t ( tension )

A net reqd = #REF! * 1000 / 1500 = #REF! cm2

Provided area 400

Plate Width(cm) Thk Area Nos Total(cm2)

PL 43 2.8 2 240.8

ISA 100*100*10 1 19.03 4 76.12 450 ISA 100*100*10

Total 316.92 Plate 430*28

Dia of bolt 2.2 cm =

Nos. of bolt in one rows 3 nos

Deduction for hole :

= 2 * 3.8 * 3 * 2.35 = 53.58 cm2

Provide 2 No.extra plate 230 * 12 mm on inner face at joint location p\

Area of extra plate provided = 55.2 cm2

Area provided : 318.54 cm2 Hence OK

at joint

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

TOP CHORD MEMBER

Member U1U2

Plate 340*8

Force 118.19 t ( compression ) 400

400 ISMC 400

Properties ISMC 400

Area 62.93 cm2

C.G. 2.83 cm

Ixx 15082.8 cm4

Iyy 504.8 cm4

Moment of inertia considered in X-X direction

Item Size Area (cm2Yt(cm) A * Yt(cmA*Yt2(c Ixo(cm4)

B(cm) t(cm) Area Nos

Top PL 34 0.8 1 27.2 0.400 10.88 4.352 2.83333

ISMC 400 62.93 2 125.86 20.8 2617.89 54452 30165.6

Total 153.06 2628.77 54456 30168

Ycg = 2628.768 / 153.06 = 17.1748 cm

Ixx = 30168.4333 + 54456.4 - 153.06 * 17.1748

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

* 17.1748

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

= 39476.4094 cm4

r min = SQRT 39476.41 / 153.06

= SQRT 257.9146

16.0597199 cm

Moment of inertia considered in Y-Y direction

Item Size Area (cm2Yt(cm) A * Yt(cmA*Yt2(c Ixo(cm4)

B(cm) t(cm) Area Nos

Top PL 34 0.8 1 27.2 20.000 544 10880 2620.27

ISMC 400 62.93 1 62.93 2.83 178.092 504 504.8

ISMC 400 62.93 1 62.93 37.17 2339.11 86945 504.8

Total 153.06 3061.2 98329 3629.87

Ycg = 3061.2 / 153.06 = 20 cm

Ixx = 3629.86667 + 98328.6 - 153.06 * 20

* 20

= 40734.5148 cm4

r min = SQRT 40734.51 / 153.06

= SQRT 266.1343

16.3136229 cm

S.R = 0.85 * 663.636 / 16.0597 35.1246 30 40

= 35.1245795 1419.25 1450 1390

Permissible stress : 1419.253 kg/cm2

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Axial Stress : 118.1946 * 1000 / 153.06

= 772.211 kg/cm2 < 1419.25 kg/cm2

Hence OK

Design of connection :

Total area of web = 40 * 0.84 * 2+ 10 * 0.8 * 0

= 67.2 cm2 *

Area of gusset and splice plate required = 67.2 * 1.05

= 70.56 cm2

Provide 12 mm gusset plate on each side and 420 * 0 mm splice plate on each face

Area of gusset plate provided = 40 * 1.2 * 2+ 42 * 0* 2

= 96 cm2

Area of flange at top = 10 * 1.53 * 2+ 34 * 0.8 * 1

= 57.8 cm2

Area of cover plates required = 57.8 * 1.05

= 60.69 cm2

Provide 400 * 12 mm thick cover plate at top

Area of cover plate provided = 40 * 1.2 * 1

= 48 cm2

Area of flange at bottom = 10 * 1.53 * 2

= 30.6 cm2

Area of cover plates required = 30.6 * 1.05

= 32.13 cm2

Provide 400 * 8 mm thick cover plate bottom

Area of cover plate provided = 40 * 0.8 * 1

= 32 cm2

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Nos. of 22 dia HSFG Bolts required

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

In Web = 70.56 * 1500 / 5843

= 18.114

Provide 9.05699127 Nos. bolt on each face ( In Single Shear)

4.52849564 Nos bolt on each face ( In double shear)

In flange at top = 60.69 * 1500 / 5843

= 15.58

Provide 7.79 on each face

In flange at bottom = 32.13 * 1500 / 5843

= 8.25

Provide 4.12 on each face

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

TOP CHORD MEMBER

MEMBER U1U2, U2U3

Force 197.02 t ( compression )

Plate 340 * 8

400

Properties ISA 100*100*8 400 ISA 100*100*8

Area 15.39 cm2 Plate 380 * 8

C.G. 2.76 cm

I 145.1 cm4

=

Moment of inertia considered in X-X direction

Item Size Area (cm2Yt(cm) A * Yt(cmA*Yt2(c Ixo(cm4)

B(cm) t(cm) Area Nos

Top PL 34 0.8 1 27.2 0.400 10.88 4.352 2.83333

ISA 100*100*8 15.39 2 30.78 3.56 109.577 390.09 290.2

ISA 100*100*8 15.39 2 30.78 38.04 1170.87 44540 290.2

2 Plate 38 0.8 2 60.8 20.8 1264.64 26305 7316.27

Total 149.56 2556 71239 7899.5

Ycg = 2555.968 / 149.56 = 17.0899 cm

Ixx = 7899.5 + 71238.9 - 149.56 * 17.0899

* 17.0899

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

= 35457.1167 cm4

r min = SQRT 35457.12 / 149.56

= SQRT 237.0762

15.397279 cm

S.R = 0.85 * 663.636 / 15.3973 36.6358 30 40

= 36.6357529 1410.19 1450 1390

Permissible stress : 1410.185 kg/cm2

Axial Stress : 197.0231 * 1000 / 149.56

= 1317.351 kg/cm2 < 1410.19 kg/cm2

Hence OK

Design of connection :

Total area of web = 38 * 0.8 * 2+ 10 * 0.8 * 4

= 92.8 cm2 *

Area of gusset and splice plate required = 92.8 * 1.05

= 97.44 cm2

Provide 12 mm gusset plate on each side and 420 * 0 mm splice plate on each face

Area of gusset plate provided = 40 * 1.2 * 2+ 42 * 0* 2

= 96 cm2

Area of flange at top = 10 * 0.8 * 2+ 34 * 0.8 * 1

= 43.2 cm2

Area of cover plates required = 43.2 * 1.05

= 45.36 cm2

Provide 400 * 12 mm thick cover plate at top

Area of cover plate provided = 40 * 1.2 * 1

= 48 cm2

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Area of flange at bottom = 10 * 0.8 * 2

= 16 cm2

Area of cover plates required = 16 * 1.05

= 16.8 cm2

Provide 400 * 8 mm thick cover plate bottom

Area of cover plate provided = 40 * 0.8 * 1

= 32 cm2

Nos. of 22 dia HSFG Bolts required

In Web = 97.44 * 1500 / 5843

= 25.015

Provide 12.51 Nos. bolt on each face ( In Single Shear)

6.25 Nos bolt on each face ( In double shear)

In flange at top = 45.36 * 1500 / 5843

= 11.645

In flange at bottom = 16.8 * 1500 / 5843

= 4.31

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

MEMBER U3U4

Force 252.14 t ( compression )

Plate 340 * 8

400

Properties ISA 100*100*8

Area 15.39 cm2

C.G. 2.76 cm 400 ISA 100*100*8

I 145.1 cm4 Plate 380 * 12

Moment of inertia considered in X-X direction

Item Size Area (cm2Yt(cm) A * Yt(cmA*Yt2(c Ixo(cm4)

B(cm) t(cm) Area Nos

Top PL 34 0.8 1 27.2 0.400 10.88 4.352 2.83333

ISA 100*100*8 15.39 2 30.78 3.56 109.577 390.09 290.2

ISA 100*100*8 15.39 2 30.78 38.04 1170.87 44540 290.2

2 Plate 38 1.2 2 91.2 20.8 1896.96 39457 10974.4

Total 179.96 3188.29 84391 11558

Ycg = 3188.288 / 179.96 = 17.7166 cm

Ixx = 11557.6333 + 84391.2 - 179.96 * 17.7166

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

* 17.7166

= 39463.0105 cm4

r min = SQRT 39463.01 / 179.96

= SQRT 219.2877

14.8083651 cm

S.R = 0.85 * 663.636 / 14.8084 38.0927 30 40

= 38.0927202 1401.44 1450 1390

Permissible stress : 1401.444 kg/cm2

Axial Stress : 252.1446 * 1000 / 179.96

= 1401.115 kg/cm2 < 1401.44 kg/cm2

Hence OK

Design of connection :

Total area of web = 38 * 1.2 * 2+ 10 * 0.8 * 4

= 123.2 cm2 *

Area of gusset and splice plate required = 123.2 * 1.05

= 129.36 cm2

Provide 12 mm gusset plate on each side and 360 *8 mm splice plate on each face

Area of gusset plate provided = 40 * 1.2 * 2+ 36 * 0.8 * 2

= 153.6 cm2

Area of flange at top = 10 * 0.8 * 2+ 34 * 0.8 * 1

= 43.2 cm2

Area of cover plates required = 43.2 * 1.05

= 45.36 cm2

Provide 400 * 12 mm thick cover plate at top

Area of cover plate provided = 40 * 1.2 * 1

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

= 48 cm2

Area of flange at bottom = 10 * 0.8 * 2

= 16 cm2

Area of cover plates required = 16 * 1.05

= 16.8 cm2

Provide 400 * 8 mm thick cover plate bottom

Area of cover plate provided = 40 * 0.8 * 1

= 32 cm2

Nos. of 22 dia HSFG Bolts required

In Web = 129.36 * 1500 / 5843

= 33.209

Provide 16.60 Nos. bolt on each face ( In Single Shear)

8.30 Nos bolt on each face ( In double shear)

In flange at top = 45.36 * 1500 / 5843

= 11.645

In flange at bottom = 16.8 * 1500 / 5843

= 4.31

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Member U4U5

Force 285.85 t ( compression ) Plate 340 * 8

400

400 ISA 100*100*8

Plate 380 * 16

Properties ISA 100*100*8

Area 15.39 cm2

C.G. 2.76 cm

I 145.1 cm4

Moment of inertia considered in X-X direction

Item Size Area (cm2Yt(cm) A * Yt(cmA*Yt2(c Ixo(cm4)

B(cm) t(cm) Area Nos

Top PL 34 0.8 1 27.2 0.400 10.88 4.352 2.83333

ISA 100*100*8 15.39 2 30.78 3.56 109.577 390.09 290.2

ISA 100*100*8 15.39 2 30.78 38.04 1170.87 44540 290.2

2 Plate 38 1.6 2 121.6 20.8 2529.28 52609 14633

Total 210.36 3820.61 97543 15216

Ycg = 3820.608 / 210.36 = 18.1622 cm

Ixx = 15215.7667 + 97543.4 - 210.36 * 18.1622

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

* 18.1622

= 43368.3917 cm4

r min = SQRT 43368.39 / 210.36

= SQRT 206.1627

14.3583679 cm

S.R = 0.85 * 663.636 / 14.3584 39.2866 30 40

= 39.2865618 1394.28 1450 1390

Permissible stress : 1394.281 kg/cm2

Axial Stress : 285.8538 * 1000 / 210.36

= 1358.879 kg/cm2 < 1394.28 kg/cm2

Hence OK

Design of connection :

Total area of web = 38 * 1.6 * 2+ 10 * 0.8 * 4

= 153.6 cm2 *

Area of gusset and splice plate required = 153.6 * 1.05

= 161.28 cm2

Provide 12 mm gusset plate on each side and 360 *10 mm splice plate on each face

Area of gusset plate provided = 40 * 1.2 * 2+ 36 * 1* 2

= 168 cm2

Area of flange at top = 10 * 0.8 * 2+ 34 * 0.8 * 1

= 43.2 cm2

Area of cover plates required = 43.2 * 1.05

= 45.36 cm2

Provide 400 * 12 mm thick cover plate at top

Area of cover plate provided = 40 * 1.2 * 1

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

= 48 cm2

Area of flange at bottom = 10 * 0.8 * 2

= 16 cm2

Area of cover plates required = 16 * 1.05

= 16.8 cm2

Provide 400 * 8 mm thick cover plate bottom

Area of cover plate provided = 40 * 0.8 * 1

= 32 cm2

Nos. of 22 dia HSFG Bolts required

In Web = 161.28 * 1500 / 5843

= 41.403

Provide 20.7016943 Nos. bolt on each face ( In Single Shear)

10.3508472 Nos bolt on each face ( In double shear)

In flange at top = 45.36 * 1500 / 5843

= 11.645

Provide 5.82235153 on each face

In flange at bottom = 16.8 * 1500 / 5843

= 4.3129

Provide 2.15642649 on each face

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Member U5U6

Force 295.83 t ( compression )

Plate 340*12

400

Properties ISA 100*100*8 400 ISA 100*100*8

Area 15.39 cm2 Plate 380*20

C.G. 2.76 cm

I 145.1 cm4

Moment of inertia considered in X-X direction

Item Size Area (cm2Yt(cm) A * Yt(cmA*Yt2(c Ixo(cm4)

B(cm) t(cm) Area Nos

Top PL 34 0.8 1 27.2 0.400 10.88 4.352 2.83333

ISA 100*100*8 15.39 2 30.78 3.56 109.577 390.09 290.2

ISA 100*100*8 15.39 2 30.78 38.04 1170.87 44540 290.2

2 Plate 38 2 2 152 20.8 3161.6 65761 18291

Total 240.76 4452.93 110696 18873.9

Ycg = 4452.928 / 240.76 = 18.4953 cm

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Ixx = 18873.9 + 110696 - 240.76 * 18.4953

* 18.4953

= 47211.3345 cm4

r min = SQRT 47211.33 / 240.76

= SQRT 196.0929

14.0033186 cm

S.R = 0.85 * 663.636 / 14.0033 40.2827 40 50

= 40.282659 1388 1390 1320

Permissible stress : 1388.021 kg/cm2

Axial Stress : 295.8323 * 1000 / 240.76

= 1228.744 kg/cm2 < 1388 kg/cm2

Hence OK

Design of connection :

Total area of web = 38 * 2* 2+ 10 * 0.8 * 4

= 184 cm2 *

Area of gusset and splice plate required = 184 * 1.05

= 193.2 cm2

Provide 12 mm gusset plate on each side and 360 *16 mm splice plate on each face

Area of gusset plate provided = 40 * 1.2 * 2+ 36 * 1.6 * 2

= 211.2 cm2

Area of flange at top = 10 * 0.8 * 2+ 34 * 0.8 * 1

= 43.2 cm2

Area of cover plates required = 43.2 * 1.05

= 45.36 cm2

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Provide 400 * 12 mm thick cover plate at top

Area of cover plate provided = 40 * 1.2 * 1

= 48 cm2

Area of flange at bottom = 10 * 0.8 * 2

= 16 cm2

Area of cover plates required = 16 * 1.05

= 16.8 cm2

Provide 400 * 8 mm thick cover plate bottom

Area of cover plate provided = 40 * 0.8 * 1

= 32 cm2

Nos. of 22 dia HSFG Bolts required

In Web = 193.2 * 1500 / 5843

= 49.598

Provide 24.7989047 Nos. bolt on each face ( In Single Shear)

12.3994523 Nos bolt on each face ( In double shear)

In flange at top = 45.36 * 1500 / 5843

= 11.645

Provide 5.82235153 on each face

In flange at bottom = 16.8 * 1500 / 5843

= 4.3129

Provide 2.15642649 on each face

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Diagonal Member :

Member L0U1

Force 141.64 + 19.77 ( Thrust at Portal Bracing )

= 161.410199 ( compression )

Plate 340 * 8

400

Properties ISA 100*100*8

Area 15.39 cm2

C.G. 2.76 cm 400 ISA 100*100*8

I 145.1 cm4 Plate 380 * 8

Moment of inertia considered in X-X direction

Item Size Area (cm2Yt(cm) A * Yt(cmA*Yt2(c Ixo(cm4)

B(cm) t(cm) Area Nos

Top PL 34 0.8 1 27.2 0.400 10.88 4.352 2.83333

ISA 100*100*8 15.39 2 30.78 3.56 109.577 390.09 290.2

ISA 100*100*8 15.39 2 30.78 38.04 1170.87 44540 290.2

2 Plate 38 0.8 30.4 2 60.8 20.8 1264.64 26305 7316.27

Total 149.56 2556 71239 7899.5

Ycg = 2555.968 / 149.56 = 17.0899 cm

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Ixx = 7899.5 + 71238.9 - 149.56 * 17.0899

* 17.0899

= 35457.1167 cm4

r min = SQRT 35457.12 / 149.56

= SQRT 237.0762

15.397279 cm

S.R = 0.85 * 820.124 / 15.3973 45.2746 60 70

= 45.2745815 1367.25 1220 1120

Permissible stress : 1367.254 kg/cm2

Axial Stress : 141.64 * 1000 / 149.56

= 947.0447 kg/cm2 < 1367.25 kg/cm2

Hence OK

Nos. of 22 dia bolts reqd. = 161.41 * 1000 / 5843

= 27.625

Provide 13.812271 Nos. On each side

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Member : U1L1

Force : 131.84 t ( tension )

A net reqd = 131.84 * 1000 / 1500 = 87.8933 cm2

Plate 270*12

Plate 376*10

Plate 270*12

Item Size Area (cm2x(cm) A*x A*x2 Ixo(cm4)

B(cm) t(cm) Area Nos

2 plate 27 1.2 32.4 2 64.8 13.5 874.8 11809.8 3936.6

Plate 37.6 1 37.6 1 37.6 13.5 507.6 6852.6 3.13333

Total 102.4 1382.4 18662 3939.73

Ycg = 1382.4 / 102.4 = 13.5 cm

Ixx = 3939.73333 + 18662.4 - 102.4 * 13.5

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

* 13.5

= 3939.73333 cm4

r min = SQRT 3939.733 / 102.4

= SQRT 38.47396

6.20273797 cm

S.R = 0.85 * 820.124 / 6.20274

= 112.386718 < 300 OK

Permissible stress : 1500 kg/cm2

Dia of bolt 2.2 cm

Nos. of bolt in one rows 2 nos

Deduction for hole :

= 2 * 1.2 * 2.35 * 2 = 11.28 cm2

=

Net area provided 102.4 - 11.28 = 91.12 cm2

Hence OK

Nos. of 22 dia bolts reqd. = 131.84 * 1000 / 5843

= 22.564

Provide 11.2818757 Nos. On each side

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Member : U2L2

Force : 95.52 t ( tension )

A net reqd = 95.52 * 1000 / 1500 = 63.6785 cm2

Plate 200*10

Plate 380*10

Plate 200*10

Item Size Area (cm2x(cm) A*x A*x2 Ixo(cm4)

B(cm) t(cm) Area Nos

2 plate 20 1 20 2 40 10 400 4000 1333.33

Plate 38 1 38 1 38 10 380 3800 3.16667

Total 78 780 7800 1336.5

Ycg = 780 / 78 = 10 cm

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Ixx = 1336.5 + 7800 - 78 * 10

* 10

= 1336.5 cm4

r min = SQRT 1336.5 / 78

= SQRT 17.13462

4.13939795 cm

S.R = 0.85 * 820.124 / 4.1394

= 168.407428 < 300 OK

Permissible stress : 1500 kg/cm2

Dia of bolt 2.2 cm

Nos. of bolt in one rows 2 nos

Deduction for hole :

= 2 * 1 * 2.35 * 2 = 9.4 cm2

=

Net area provided 78 - 9.4 = 68.6 cm2

OK

Nos. of 22 dia bolts reqd. = 95.52 * 1000 / 5843

= 16.347

Provide 8.174 Nos. On each side

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Member : U3L3

Force : 70.50 t ( tension )

A net reqd = 70.5011505 * 1000 / 1500 = 47.0008 cm2

Plate 180*8

Plate 384*8

Plate 180*8

Item Size Area (cm2x(cm) A*x A*x2 Ixo(cm4)

B(cm) t(cm) Area Nos

2 plate 18 0.8 14.4 2 28.8 9 259.2 2332.8 777.6

Plate 38.4 0.8 30.72 1 30.72 9 276.48 2488.3 1.6384

Total 59.52 535.68 4821.1 779.238

Ycg = 535.68 / 59.52 = 9 cm

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Ixx = 779.2384 + 4821.12 - 59.52 * 9

* 9

= 779.2384 cm4

r min = SQRT 779.2384 / 59.52

= SQRT 13.09204

3.61829283 cm

S.R = 0.85 * 820.124 / 3.61829

= 192.6614 < 300 OK

Permissible stress : 1500 kg/cm2

Dia of bolt 2.2 cm

Nos. of bolt in one rows 2 nos

Deduction for hole :

= 2 * 0.8 * 2.35 * 2 = 7.52 cm2

=

Net area provided 59.52 - 7.52 = 52 cm2

OK

Nos. of 22 dia bolts reqd. = 70.50 * 1000 / 5843

= 12.066

Provide 6.03295828 Nos. On each side

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Member : U4L4,U5 L5,

Force : 49.80 t ( tension )

A net reqd = 49.8 * 1000 / 1500 = 33.2 cm2

Plate 180*8

Plate 384*8

Plate 180*8

Item Size Area (cm2x(cm) A*x A*x2 Ixo(cm4)

B(cm) t(cm) Area Nos

2 plate 18 0.8 14.4 2 28.8 9 259.2 2332.8 777.6

Plate 38.4 0.8 30.72 1 30.72 9 276.48 2488.3 1.6384

Total 59.52 535.68 4821.1 779.238

Ycg = 535.68 / 59.52 = 9 cm

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Ixx = 779.2384 + 4821.12 - 59.52 * 9

* 9

= 779.2384 cm4

r min = SQRT 779.2384 / 59.52

= SQRT 13.09204

3.61829283 cm

S.R = 0.85 * 820.124 / 3.61829

= 192.6614 < 300 OK

Permissible stress : 1500 kg/cm2

Dia of bolt 2.2 cm

Nos. of bolt in one rows 2 nos

Deduction for hole :

= 2 * 0.8 * 2.35 * 2 = 7.52 cm2

=

Net area provided 59.52 - 7.52 = 52 cm2

OK

Nos. of 22 dia bolts reqd. = 49.80 * 1000 / 5843

= 8.523

Provide 4.26 Nos. On each side

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

450

Provided area

Plate Width(cm) Thk Area Nos Total(cm2)

PL 43 1.2 2 103.2

450 PL 430 * 12.0

4ISA100*100*10 19.03 4 76.12

Total 179.32

=

4ISA100*100*10

Dia of bolt #REF! cm

Nos. of bolt in one rows 4 nos

Deduction for hole :

= #REF! * 1.2 * 4 * 2 = #REF! cm2

=

Net area provided 179.32 - #REF! = #REF! cm2

#REF!

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Member : U2L2

Force : 95.52 t ( tension )

A net reqd = 95.5176923 * 1000 / 1500 = 63.6785 cm2

210

400

Properties ISA 100*100*8

Area 15.39 cm2

C.G. 2.76 cm

I 145.1 cm4

ISA 100*100*8

Item Size Area (cm2Yt(cm) A * Yt(cmA*Yt2(c Ixo(cm4)

B(cm) t(cm) Area Nos

ISA 100*100*8 10 1 15.39 2 30.78 7.24 222.847 1613.4 290.2

ISA 100*100*8 10 1 15.39 2 30.78 13.76 423.533 5827.8 290.2

Plate 38 0 0 1 0 10 0 0 0

Total 61.56 646.38 7441.2 580.4

Ycg = 646.38 / 61.56 = 10.5 cm

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Ixx = 580.4 + 7441.23 - 61.56 * 10.5

* 10.5

= 1234.63506 cm4

r min = SQRT 1234.635 / 61.56

= SQRT 20.0558

4.47837025 cm

S.R = 0.85 * 820.124 / 4.47837

= 155.660502 < 300 OK

Permissible stress : 1500 kg/cm2

Dia of bolt 2.2 cm

Nos. of bolt in one rows 2 nos

Deduction for hole :

= 2 * 1 * 2.35 * 2 = 9.4 cm2

=

Net area provided 61.56 - 9.4 = 52.16 cm2

Hence OK

Nos. of 22 dia bolts reqd. = 95.52 * 1000 / 5843

= 16.347

Provide 8.1736858 Nos. On each side

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

450

Provided area

Plate Width(cm) Thk Area Nos Total(cm2)

PL 43 0.8 2 68.8

450 PL 430 * 8.0

4ISA100*100*10 19.03 4 76.12

Total 144.92

=

4ISA100*100*10

Dia of bolt #REF! cm

Nos. of bolt in one rows 4 nos

Deduction for hole :

= #REF! * 0.8 * 4 * 2 = #REF! cm2

=

Net area provided 144.92 - #REF! = #REF! cm2

#REF!

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Member : U2L2

Force : 95.52 t ( tension )

A net reqd = 95.5176923 * 1000 / 1500 = 63.6785 cm2

208

400

Properties ISA 100*100*10

Area 19.03 cm2

C.G. 2.84 cm

I 176 cm4

ISA 100*100*10

Item Size Area (cm2Yt(cm) A * Yt(cmA*Yt2(c Ixo(cm4)

B(cm) t(cm) Area Nos

ISA 100*100*10 10 1 19.03 2 38.06 7.16 272.51 1951.2 352

ISA 100*100*10 10 1 19.03 2 38.06 13.64 519.138 7081 352

Plate 38 0 0 0 0 10 0 0 0

Total 76.12 791.648 9032.2 704

Ycg = 791.648 / 76.12 = 10.4 cm

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Ixx = 704 + 9032.22 - 76.12 * 10.4

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

* 10.4

= 1503.07731 cm4

r min = SQRT 1503.077 / 76.12

= SQRT 19.74615

4.44366458 cm

S.R = 0.85 * 820.124 / 4.44366

= 156.876234 < 300 OK

Permissible stress : 1500 kg/cm2

Dia of bolt 2.2 cm

Nos. of bolt in one rows 2 nos

Deduction for hole :

= 2 * 1 * 2.35 * 2 = 9.4 cm2

=

Net area provided 76.12 - 9.4 = 66.72 cm2

Hence OK

Nos. of 22 dia bolts reqd. = 95.52 * 1000 / 5843

= 16.347

Provide 8.1736858 Nos. On each side

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

210

Provided area

Plate Width(cm) Thk Area Nos Total(cm2)

Pl. 380 * 8 38 0.8 30.4 1 24.32

400 Plate 380 * 8.0

4ISA100*100*8 10 1 15.32 4 61.28

Total 85.6

=

4ISA100*100*8

Dia of bolt 2.2 cm

Nos. of bolt in one rows 2 nos

Deduction for hole :

= 2 * 1 * 2.35 * 2 = 9.4 cm2

=

Net area provided 85.6 - 9.4 = 76.2 cm2

Hence OK

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

450

Provided area

Plate Width(cm) Thk Area Nos Total(cm2)

PL 43 0.8 2 68.8

450 PL 430 * 8.0

4ISA75*75*8 11.38 4 45.52

Total 114.32

=

4ISA75*75*8

Dia of bolt #REF! cm

Nos. of bolt in one rows 4 nos

Deduction for hole :

= #REF! * 0.8 * 4 * 2 = #REF! cm2

=

Net area provided 114.32 - #REF! = #REF! cm2

#REF!

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Member : U3L3

Force : 70.50 t ( tension )

A net reqd = 70.5011505 * 1000 / 1500 = 47.0008 cm2

208

400

Properties ISA 100*100*8

Area 15.39 cm2

C.G. 2.76 cm

I 145.1 cm4

ISA 100*100*8

Item Size Area (cm2Yt(cm) A * Yt(cmA*Yt2(c Ixo(cm4)

B(cm) t(cm) Area Nos

ISA 100*100*8 10 0.8 15.39 2 30.78 7.24 222.847 1613.4 290.2

ISA 100*100*8 10 0.8 15.39 2 30.78 13.56 417.377 5659.6 290.2

Plate 38 0 0 1 0 10 0 0 0

Total 61.56 640.224 7273 580.4

Ycg = 640.224 / 61.56 = 10.4 cm

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

Ixx = 580.4 + 7273.04 - 61.56 * 10.4

* 10.4

= 1195.113536 cm4

r min = SQRT 1195.114 / 61.56

= SQRT 19.4138

4.40610941 cm

S.R = 0.85 * 820.124 / 4.40611

= 158.213358 < 300 OK

Permissible stress : 1500 kg/cm2

Dia of bolt 2.2 cm

Nos. of bolt in one rows 2 nos

Deduction for hole :

= 2 * 0.8 * 2.35 * 2 = 7.52 cm2

=

Net area provided 61.56 - 7.52 = 54.04 cm2

Hence OK

Nos. of 22 dia bolts reqd. = 70.50 * 1000 / 5843

= 12.066

Provide 6.03295828 Nos. On each side

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

210

Provided area

Plate Width(cm) Thk Area Nos Total(cm2)

400

4ISA 100*100*8 10 0.8 15.39 4 61.56

Total 61.56

=

4ISA 100*100*8

Dia of bolt 2.2 cm

Nos. of bolt in one rows 2 nos

Deduction for hole :

= 2 * 0.8 * 2.35 * 2 = 7.52 cm2

=

Net area provided 61.56 - 7.52 = 54.04 cm2

Hence OK

SATVIR GUPTA FABRICATOR

DESIGN OF STEEL BRIDGE OVER INDUS 73 M SPAN

210

Provided area