CFC 041 Vamp 265

Diunggah oleh

Uday SinghJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

CFC 041 Vamp 265

Diunggah oleh

Uday SinghHak Cipta:

Format Tersedia

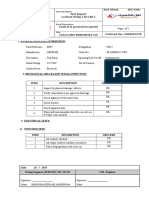

Suryansh Automation and Technology

Document Title: PROTECTION RELAY TEST REPORT Date: 01/03/2019

Client Name: Kubaisa Cement

Project Name: Wartsila Power plant testing and charging.

Location: Iraq

Document ID: SAT/KUBAISA/IRAQ/001

Report ID: SAT/KUBAISA/TEST/050

Technical Specifications :

Feeder Name : CFC041 (DG # 4 Control panel)

Feeder Location : Generator control room

Relay Make: VAMP I CT Ratio: 800/5 A

Relay Model: VAMP 265 I’ CT Ratio: 800/1A

Relay Sr.N.: 036735 VT Ratio: 11000/110 V

Prerequisites: During this checking, Engine should be stopped, Testing Kit earth point should be connected to earth.

Methodology: Each enabled protection of VAMP265 to be tested by means of Secondary injection method. Each protection should be

tested at setting values with considering the respective curve and measure the trip timing of relay trip contacts and Relay Pick-up time. Be

sure that no voltage or current will be transferred to any external circuit.

A. General Checks of Generator Protection Relay

Item Check Description Result Remark

1. Checks the Protection Relay technical specification and Aux. Checked Found OK

supply as per design and rating

2. Checks the CT,PT Scaling on Protection Relay as per system Checked Found OK

design and rating

3. Protection Relay protective earthing point, properly connected Checked Found OK

4. Checks the all set-points of each enabled protection as per system Checked as per last saved Found OK

designed configuration or any change settings

5. Protective Earthing of Testing kit should be connected to proper Done Found OK

earth

6. All connections to Protection Relay check for tightness, Carried out Found OK

marking/lugging, termination, clamping etc.

7. Star Point on Protection Relay for current measurement, check for checked Found OK

proper earth

8. Inspection & checking of Relay Front Panel {Display, Key pad, Carried out Found OK

LED Indicators, RS232 Communication Port }

8. Check the Relay function of Forced Control/ Simulation Checked Found OK

9. Check whether recording of events and faults value are stored or in Checked Found OK

event register and data can be read via Relay local display

10. Checks the Protection Relay Communication Profibus, RS232 Checked Found OK

Regd. Office: Work Shop:

23, Teachers Colony, Modinagar, 551, Sikhera Road Industrial Area,

Distt.: Ghaziabad, U.P. – 201204 Modinagar, Distt.: Ghaziabad - 201204

Website: www.suryanshtechnology.com

e-mail: info@suryanshtechnology.com, suryanshautomation@gmail.com

Suryansh Automation and Technology

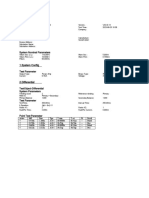

B. Testing of Generator Differential Protection

B.1 Differential Protection, Stage DI>

Settings:

Setting for Stage : 6% of In

Delay Type for Stage : Instantaneous

Trip Level Test DI> (IL1, IL2, IL3):

Inaccuracy % Remarks

Theoretical Pickup value : 0.23A ---

The Relay should not pick up before : 0.21A ---

The Relay should pick up before : 0.26A ---

Actual Pickup Level L1 : 0.22A 0.2 Found OK

Actual Pickup Level L2 : 0.23A 0.0 Found OK

Actual Pickup Level L3 : 0.22A 0.2 Found OK

Trip Level Test DI> (IL1’, IL2’, IL3’):

Inaccuracy % Remarks

Theoretical Pickup value : 0.00A ---

The Relay should not pickup before : -0.03A ---

The Relay should pickup before : 0.03A ---

Actual Pickup Level L1 : 0.02A 0.04 Found OK

Actual Pickup Level L2 : 0.03A 0.03 Found OK

Actual Pickup Level L3 : 0.02A 0.02 Found OK

Remarks: The Differential Protection Stage DI>, found healthy at pre-determined set values/settings.

B.2 Differential Protection, Stage DI>>

Settings:

Setting for Stage : 10% of In

Delay Type for Stage : Instantaneous

Trip Level Test DI> (IL1, IL2, IL3):

Inaccuracy % Remarks

Theoretical Pickup value : 0.38A ---

The Relay should not pick up before : 0.36A ---

The Relay should pick up before : 0.41A ---

Actual Pickup Level L1 : 0.37A 2.6 Found OK

Actual Pickup Level L2 : 0.38A 1.3 Found OK

Actual Pickup Level L3 : 0.37A 2.6 Found OK

Regd. Office: Work Shop:

23, Teachers Colony, Modinagar, 551, Sikhera Road Industrial Area,

Distt.: Ghaziabad, U.P. – 201204 Modinagar, Distt.: Ghaziabad - 201204

Website: www.suryanshtechnology.com

e-mail: info@suryanshtechnology.com, suryanshautomation@gmail.com

Suryansh Automation and Technology

Trip Level Test DI> (IL1’, IL2’, IL3’):

Inaccuracy % Remarks

Theoretical Pickup value : 0.00A ---

The Relay should not pickup before : -0.03A ---

The Relay should pickup before : 0.03A ---

Actual Pickup Level L1 : 0.03A 0.04 Found OK

Actual Pickup Level L2 : 0.02A 0.04 Found OK

Actual Pickup Level L3 : 0.02A 0.04 Found OK

Remarks: The Differential Protection Stage DI>>, found healthy at pre-determined set values/settings.

Test Performed by Witnessed by Witnessed by

Name : Uday Singh Kathait Name: Name:

Designation : Sr. Engineer Designation Designation

Signature & Date Signature & Date Signature & Date

Regd. Office: Work Shop:

23, Teachers Colony, Modinagar, 551, Sikhera Road Industrial Area,

Distt.: Ghaziabad, U.P. – 201204 Modinagar, Distt.: Ghaziabad - 201204

Website: www.suryanshtechnology.com

e-mail: info@suryanshtechnology.com, suryanshautomation@gmail.com

Anda mungkin juga menyukai

- Fault Code 428 Water-in-Fuel Indicator Sensor Circuit - Voltage Above Normal or Shorted To High SourceDokumen14 halamanFault Code 428 Water-in-Fuel Indicator Sensor Circuit - Voltage Above Normal or Shorted To High SourceAhmedmah100% (2)

- WAM ES Screw Conveyors Manual JECDokumen43 halamanWAM ES Screw Conveyors Manual JECabbas tawbiBelum ada peringkat

- T200A Single Phase Universal Test SetDokumen8 halamanT200A Single Phase Universal Test SetpiticelBelum ada peringkat

- PGDT c3 DiagnosticsDokumen14 halamanPGDT c3 DiagnosticsHushanjiBelum ada peringkat

- 546 MicomDokumen37 halaman546 MicomNambiBelum ada peringkat

- Emisipn Control SystemsDokumen4 halamanEmisipn Control SystemsArt Doe100% (1)

- High-Tech Range: MRR1 - Multifunctional Generator Rotor Protection RelayDokumen16 halamanHigh-Tech Range: MRR1 - Multifunctional Generator Rotor Protection RelayAnandSreeBelum ada peringkat

- DTC b0012 or b0013Dokumen15 halamanDTC b0012 or b0013Masmas MasBelum ada peringkat

- 6lb+r-Red 670Dokumen15 halaman6lb+r-Red 670Mohamed AwadBelum ada peringkat

- Bahria University Karachi Campus: Under / Over Current Monitoring Using Numerical RelayDokumen5 halamanBahria University Karachi Campus: Under / Over Current Monitoring Using Numerical Relaysaud aliBelum ada peringkat

- 6BB+BS - Req650Dokumen7 halaman6BB+BS - Req650Mohamed AwadBelum ada peringkat

- Smart Lighting Centralized Controller: Technical SpecificationDokumen9 halamanSmart Lighting Centralized Controller: Technical SpecificationSamar YoussefBelum ada peringkat

- Ohmega 402 OmicronDokumen27 halamanOhmega 402 OmicronhossamBelum ada peringkat

- RM 86Dokumen14 halamanRM 86ingen88888Belum ada peringkat

- Test Object - Device Settings: Substation/BayDokumen2 halamanTest Object - Device Settings: Substation/BayWaruna RasanjayaBelum ada peringkat

- Circuit: K01 11 KV Feeder Ocef Protection: 1. General Relay DataDokumen11 halamanCircuit: K01 11 KV Feeder Ocef Protection: 1. General Relay DataosmpotBelum ada peringkat

- HarmonicsDokumen37 halamanHarmonicsMelkin NPBelum ada peringkat

- OSM & RC Testing Summary 0260119070398 + VT 509190132Dokumen3 halamanOSM & RC Testing Summary 0260119070398 + VT 509190132Mohammed MaherBelum ada peringkat

- UntitledDokumen10 halamanUntitledKIRUBANESANBelum ada peringkat

- Spare Feeder P10Dokumen80 halamanSpare Feeder P10Yogesh JethwaBelum ada peringkat

- XK3118T1 Operation ManualDokumen10 halamanXK3118T1 Operation ManualGerardo RodriguezBelum ada peringkat

- Testobject: 1.system ConfigDokumen2 halamanTestobject: 1.system ConfigQuang Bình TrầnBelum ada peringkat

- Unit-1 10KV 10BBB01 P127Dokumen41 halamanUnit-1 10KV 10BBB01 P127MühâMméd SàhãdhBelum ada peringkat

- HZFD 400 Battery Charge and Discharge TesterDokumen17 halamanHZFD 400 Battery Charge and Discharge TesterMohammed A. AliBelum ada peringkat

- 2hss858 ManualDokumen25 halaman2hss858 ManualAbdusaid AbduraufovBelum ada peringkat

- Task Day 2 - Activity EV - V2.0Dokumen7 halamanTask Day 2 - Activity EV - V2.0047 Karunakaran MBelum ada peringkat

- CSPC MRR1 HDDokumen16 halamanCSPC MRR1 HDTarun PatelBelum ada peringkat

- User'S Manual: HT824 Multifunction Process CalibratorDokumen13 halamanUser'S Manual: HT824 Multifunction Process CalibratorBrayan Severiano RosasBelum ada peringkat

- Alarm Acknowledgment in The RTAC HMI - AG2014-35 - 20200807Dokumen12 halamanAlarm Acknowledgment in The RTAC HMI - AG2014-35 - 20200807teodorojrBelum ada peringkat

- Checking Monitor Status: 1Gr-Fe Engine Control System - Sfi SystemDokumen3 halamanChecking Monitor Status: 1Gr-Fe Engine Control System - Sfi Systemmike chenBelum ada peringkat

- FAULT CODE 1117 - Power Supply Lost With Ignition On - Data Erratic, Intermittent, or IncorrectDokumen8 halamanFAULT CODE 1117 - Power Supply Lost With Ignition On - Data Erratic, Intermittent, or IncorrectAli ArdinBelum ada peringkat

- Typical Protection Relay ReportDokumen49 halamanTypical Protection Relay Reporttafseerahmed86Belum ada peringkat

- FAULT CODE 144 (ISB/QSB Automotive and Industrial, ISC/QSC/ISL/QSL Automotive, Industrial, and Marine) Engine Coolant Temperature 1 Sensor Circuit - Voltage Above Normal or Shorted To High SourceDokumen16 halamanFAULT CODE 144 (ISB/QSB Automotive and Industrial, ISC/QSC/ISL/QSL Automotive, Industrial, and Marine) Engine Coolant Temperature 1 Sensor Circuit - Voltage Above Normal or Shorted To High SourceAhmedmahBelum ada peringkat

- Sle00131 PSRPT 2020-06-17 14.43.01 PDFDokumen8 halamanSle00131 PSRPT 2020-06-17 14.43.01 PDFMohammad MakhloufBelum ada peringkat

- Lor Ri 16-Rp 94f-2 6rp2Dokumen2 halamanLor Ri 16-Rp 94f-2 6rp2Humayun AhsanBelum ada peringkat

- Calibration Manual For PXIe-4139Dokumen24 halamanCalibration Manual For PXIe-4139Elaine Marie YosoresBelum ada peringkat

- 549287614.docx Multi-Function Tester (TC-V2.12k)Dokumen14 halaman549287614.docx Multi-Function Tester (TC-V2.12k)JoseLuisRuizBelum ada peringkat

- 6la+r - P546Dokumen8 halaman6la+r - P546Mohamed AwadBelum ada peringkat

- Accent P0030 HO2S Heater Control CircuitDokumen6 halamanAccent P0030 HO2S Heater Control Circuitflash_24014910Belum ada peringkat

- SOP Name SOP For Led Driver Quality Test (Refrigerator) DATE ISSUED 07.07.2020Dokumen7 halamanSOP Name SOP For Led Driver Quality Test (Refrigerator) DATE ISSUED 07.07.2020swapon kumar shill0% (1)

- I3500 TroubleshootingDokumen14 halamanI3500 TroubleshootingAdriana Velásquez100% (2)

- CL-NG-6460-002-085 Checklist For Relay & Control Panel Scheme Check and Function Test Rev01-1Dokumen6 halamanCL-NG-6460-002-085 Checklist For Relay & Control Panel Scheme Check and Function Test Rev01-1محمد عادلBelum ada peringkat

- Multi Function Tester tc1 v2.12kDokumen14 halamanMulti Function Tester tc1 v2.12kRoger100% (2)

- Testobject: 1.system ConfigDokumen2 halamanTestobject: 1.system ConfigQuang Bình TrầnBelum ada peringkat

- Non Dir. O/C Relay ARGUS - 7SR1102: 1. General Data & InformationDokumen6 halamanNon Dir. O/C Relay ARGUS - 7SR1102: 1. General Data & InformationAnonymous dH3DIEtzBelum ada peringkat

- Dynamic Test Report of DECR-S Excitation Devices: ExperimenterDokumen14 halamanDynamic Test Report of DECR-S Excitation Devices: ExperimenterSalmanEjazBelum ada peringkat

- Spare Feeder - P10 - 2Dokumen79 halamanSpare Feeder - P10 - 2Yogesh JethwaBelum ada peringkat

- +K01 FinalDokumen94 halaman+K01 FinalMERLYNBelum ada peringkat

- Manual Controlador Solar Srne SR LG 48 60Dokumen43 halamanManual Controlador Solar Srne SR LG 48 60dreamweaver i'm a believerBelum ada peringkat

- Site Test Report Date: 29/5/2018 Contractor's Name: HADI HAIDER Customer: Sec-Eoa Jubail Commercial Port 115/13.8Kv Ss-2 Tapcon 260 Avr RelayDokumen4 halamanSite Test Report Date: 29/5/2018 Contractor's Name: HADI HAIDER Customer: Sec-Eoa Jubail Commercial Port 115/13.8Kv Ss-2 Tapcon 260 Avr RelayMuhammad NasirBelum ada peringkat

- Alstom P642Dokumen37 halamanAlstom P642Vijaya KumarBelum ada peringkat

- VFD WarningsDokumen7 halamanVFD WarningsCiprian MariusBelum ada peringkat

- OSM & RC Testing Summary 0320120114973-OkDokumen2 halamanOSM & RC Testing Summary 0320120114973-OkMartin RodriguezBelum ada peringkat

- Transformer Protection Final Rev.01 PDFDokumen2 halamanTransformer Protection Final Rev.01 PDFNader Asgar Pangarungan MamarobaBelum ada peringkat

- Adecon India: Test Report of Bimetallic Overload RelayDokumen1 halamanAdecon India: Test Report of Bimetallic Overload Relay8085roBelum ada peringkat

- Inverter Non TechnicalDokumen9 halamanInverter Non TechnicalyosefBelum ada peringkat

- MiCom P546 Relay PDFDokumen39 halamanMiCom P546 Relay PDFshaunBelum ada peringkat

- The PIC Microcontroller: Your Personal Introductory CourseDari EverandThe PIC Microcontroller: Your Personal Introductory CoursePenilaian: 1 dari 5 bintang1/5 (2)

- Content Analysis of Studies On Cpec Coverage: A Comparative Study of Pakistani and Chinese NewspapersDokumen18 halamanContent Analysis of Studies On Cpec Coverage: A Comparative Study of Pakistani and Chinese NewspapersfarhanBelum ada peringkat

- ITP - Plaster WorkDokumen1 halamanITP - Plaster Workmahmoud ghanemBelum ada peringkat

- Business Logic Module 1Dokumen5 halamanBusiness Logic Module 1Cassandra VenecarioBelum ada peringkat

- Agenda - Meeting SLC (LT) - 27.06.2014 PDFDokumen27 halamanAgenda - Meeting SLC (LT) - 27.06.2014 PDFharshal1223Belum ada peringkat

- Feasibility and Optimization of Dissimilar Laser Welding ComponentsDokumen366 halamanFeasibility and Optimization of Dissimilar Laser Welding Componentskaliappan45490Belum ada peringkat

- Aspen Plus User ModelsDokumen339 halamanAspen Plus User Modelskiny81100% (1)

- A Guide To Sample Size For Animal-Based Studies (VetBooks - Ir)Dokumen292 halamanA Guide To Sample Size For Animal-Based Studies (VetBooks - Ir)Jonathan MannBelum ada peringkat

- Lecture 11 - Performance AppraisalsDokumen23 halamanLecture 11 - Performance AppraisalsCard CardBelum ada peringkat

- The Neuroscience of Helmholtz and The Theories of Johannes Muèller Part 2: Sensation and PerceptionDokumen22 halamanThe Neuroscience of Helmholtz and The Theories of Johannes Muèller Part 2: Sensation and PerceptionCrystal JenningsBelum ada peringkat

- Climatol GuideDokumen40 halamanClimatol GuideFressiaBelum ada peringkat

- Each Life Raft Must Contain A Few ItemsDokumen2 halamanEach Life Raft Must Contain A Few ItemsMar SundayBelum ada peringkat

- TOPIC: Movable and Immovable Property Under Section-3 of Transfer of Property ActDokumen10 halamanTOPIC: Movable and Immovable Property Under Section-3 of Transfer of Property ActRishAbh DaidBelum ada peringkat

- Demonstration of Preprocessing On Dataset Student - Arff Aim: This Experiment Illustrates Some of The Basic Data Preprocessing Operations That Can BeDokumen4 halamanDemonstration of Preprocessing On Dataset Student - Arff Aim: This Experiment Illustrates Some of The Basic Data Preprocessing Operations That Can BePavan Sankar KBelum ada peringkat

- FS-C8025MFP Release NotesDokumen22 halamanFS-C8025MFP Release NotesFirmware SM-SHBelum ada peringkat

- ADAMS/View Function Builder: Run-Time FunctionsDokumen185 halamanADAMS/View Function Builder: Run-Time FunctionsSrinivasarao YenigallaBelum ada peringkat

- 1974 - Roncaglia - The Reduction of Complex LabourDokumen12 halaman1974 - Roncaglia - The Reduction of Complex LabourRichardBelum ada peringkat

- IVISOR Mentor IVISOR Mentor QVGADokumen2 halamanIVISOR Mentor IVISOR Mentor QVGAwoulkanBelum ada peringkat

- Corometrics 170 Series BrochureDokumen3 halamanCorometrics 170 Series BrochureCesar MolanoBelum ada peringkat

- Catálogo StaubliDokumen8 halamanCatálogo StaubliJackson BravosBelum ada peringkat

- Changing Historical Perspectives On The Nazi DictatorshipDokumen9 halamanChanging Historical Perspectives On The Nazi Dictatorshipuploadimage666Belum ada peringkat

- AIF User Guide PDFDokumen631 halamanAIF User Guide PDFÖzgün Alkın ŞensoyBelum ada peringkat

- Integration Plan Grade 9 Mapeh SeptemberDokumen3 halamanIntegration Plan Grade 9 Mapeh Septemberbernie evaristo bacsaBelum ada peringkat

- Gr. 10 Persuasive EssayDokumen22 halamanGr. 10 Persuasive EssayZephania JandayanBelum ada peringkat

- APPSC GROUP 4 RESULTS 2012 - Khammam District Group 4 Merit ListDokumen824 halamanAPPSC GROUP 4 RESULTS 2012 - Khammam District Group 4 Merit ListReviewKeys.comBelum ada peringkat

- Group 2 - BSCE1 3 - Formal Lab Report#6 - CET 0122.1 11 2Dokumen5 halamanGroup 2 - BSCE1 3 - Formal Lab Report#6 - CET 0122.1 11 2John Eazer FranciscoBelum ada peringkat

- Logarithms Functions: Background Information Subject: Grade Band: DurationDokumen16 halamanLogarithms Functions: Background Information Subject: Grade Band: DurationJamaica PondaraBelum ada peringkat

- Excel Crash Course PDFDokumen2 halamanExcel Crash Course PDFmanoj_yadav735Belum ada peringkat

- Question BankDokumen3 halamanQuestion BankHimanshu SharmaBelum ada peringkat

- Tree Based Machine Learning Algorithms Decision Trees Random Forests and Boosting B0756FGJCPDokumen109 halamanTree Based Machine Learning Algorithms Decision Trees Random Forests and Boosting B0756FGJCPJulio Davalos Vasquez100% (1)