Bed Up Bar For Watertank

Diunggah oleh

E.PrasathJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Bed Up Bar For Watertank

Diunggah oleh

E.PrasathHak Cipta:

Format Tersedia

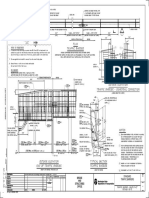

NO.

5 BARS

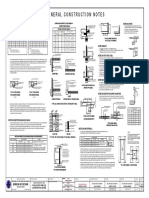

CONSTRUCTION NOTES

NO. 5 BARS NO. 5 BARS

(EPOXY COATED) (EPOXY COATED) FILL HEIGHTS OF LESS THAN 2'-0" 5 FILL HEIGHTS OF LESS THAN 2'-0" (EPOXY COATED) CONSTRUCT CULVERTS PER SPEC. 2412 EXCEPT AS NOTED.

NO. 5 BARS (EPOXY COATED)

@ 1'-0" SPACING @ 1'-0" SPACING REQUIRE A DISTRIBUTION SLAB REQUIRE A DISTRIBUTION SLAB @ 1'-0" SPACING

5 @ 1'-0" SPACING

REFER TO THE GENERAL PLAN AND ELEVATION SHEET FOR THE DISTANCE BETWEEN

BARRELS OF ADJACENT BOXES AND TO STANDARD FIGURE 5-395.115 FOR MATERIAL

6"

6"

DISTRIBUTION SLAB DISTRIBUTION SLAB REQUIREMENTS FOR FILL BETWEEN ADJACENT BOXES.

SELECT GRANULAR MATERIAL SELECT GRANULAR MATERIAL

PER SPEC. 3149.2.B.2 PER SPEC. 3149.2.B.2 PROVIDE WELDED WIRE REINFORCEMENT, SHEAR REINFORCEMENT AND REINFORCEMENT

CAST-IN-PLACE

3" MIN.FOR

6" MIN.FOR PRECAST

CAST-IN-PLACE

3" MIN.FOR

6" MIN.FOR PRECAST

BARS PER THE APPLICABLE REQUIREMENTS OF AASHTO M259.

DISTRIBUTION SLAB MAY

1•" MIN. AND 2" MAX. CONCRETE COVER ON ALL REINFORCEMENT, INCLUDING

END AT START OF RADIUS

SHEAR REINFORCEMENT, EXCEPT FOR TONGUE AND GROOVE DETAIL.

ANY OF THE FOLLOWING COMBINATIONS OF STEEL REINFORCEMENT MAY BE USED:

DISTRIBUTION SLAB SECTION DISTRIBUTION SLAB - LONGITUDINAL SECTION (a) 1 OR 2 LAYERS OF WELDED WIRE REINFORCEMENT OR

(b) 1 LAYER OF WELDED WIRE REINFORCEMENT AND 1 LAYER OF REINFORCEMENT

BARS OR

4'-0" MINIMUM (c) 1 LAYER OF REINFORCEMENT BARS.

M DEVELOP REINFORCEMENT IN ACCORDANCE WITH AASHTO "LRFD BRIDGE DESIGN

"X" SPECIFICATIONS". IF BAR REINFORCEMENT IS SUBSTITUTED FOR WELDED WIRE

As7 RADIUS (7" MIN., 1'-0" MAX.) OR 2" MAX. SEE BARREL INFORMATION TABLE 2" MAX.

CHAMFER (4" MIN., 7" MAX.)(TYP.) REINFORCEMENT, INCREASE THE AREA OF REINFORCEMENT BY 8%, AND SUBMIT DESIGN

FOR TRANSVERSE REINFORCEMENT

CALCULATIONS VERIFYING COMPLIANCE WITH AASHTO 5.7.3.4. "CONTROL OF

3" NO. 3 HAUNCH BARS @ 1'-0" MAX SPACING 3"

Tt

CRACKING BY DISTRIBUTION OF REINFORCEMENT".

4" 4" MAXIMUM SIZE OF REINFORCEMENT BARS IS NO. 6. THE MAXIMUM WELDED WIRE

REINFORCEMENT SIZE IS W23 PER LAYER (MAXIMUM OF 2 LAYERS).

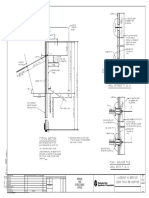

3 As6 As2

Tt

HAUNCH BAR LENGTH: SPACE CENTER TO CENTER OF TRANSVERSE WIRES NOT LESS THAN 2" NOR MORE

2 3 As5

31" FOR 8" WALL THICKNESS THAN 4". SPACE CENTER TO CENTER OF LONGITUDINAL WIRES NOT MORE THAN 8".

34" FOR 9" WALL THICKNESS NO. 3 BAR, CUT AS NECESSARY

RISE/2)- 6"

1

NO. 3 HAUNCH BARS 34" FOR 10" WALL AND 10" SLAB TO FIT TONGUE AT CORNERS WHEN USING As1, As7, AND As8 REINFORCEMENT AS ONE CONTINUOUS CAGE WITH

@ 1'-0" SPACING (TYP.) 36" FOR 10" WALL AND 11" SLAB SPLICES OCCURRING IN THE CENTER OF THE TOP AND BOTTOM OF THE BOX SECTION,

TIE HOLE

38" FOR 10" WALL AND 12" SLAB THE MIN. LAP LENGTH FOR THE As7 AND As8 IS 15".

38" FOR 11" WALL THICKNESS

RISE

As5 3 WELDING IS NOT PERMITTED ON REINFORCEMENT BARS OR WELDED WIRE

CUT OR BEND INSIDE REINFORCEMENT, EXCEPT THAT THE ORIGINAL WELDING REQUIRED TO MANUFACTURE

(

As6 3

REINFORCEMENT AS NECESSARY TO WIRE REINFORCEMENT IS ACCEPTABLE.

As4 As1 ACHIEVE COVER REQUIREMENTS

RISE

TONGUE AND REINFORCEMENT NOT WHEN REINFORCEMENT IS CUT, PLACE ADDITIONAL REINFORCEMENT ON BOTH SIDES

GROOVE SHOWN SHOWN FOR CLARITY 3 OF THE CUT MEMBER TO REPLACE OR EXCEED THE CUT STEEL.

LONGITUDINAL USE CONCRETE MIX NO. 3W82 WITH NO CALCIUM CHLORIDE ALLOWED.

4 1" CLEAR As1

REINFORCEMENT

As5 3

PROVIDE SHOP DRAWING APPROVAL PER SPEC. 3238.2.A.

As6 3 As3

NO. 3 BAR COMPACT THE FIRST 1.5' (LOOSE) OF FILL ABOVE THE BOX WITH LIGHT COMPACTION

NYLON BOOTS ON EVERY FOURTH

WIRE. PLASTIC SPACERS MAY BE EQUIPMENT SUCH AS PLATE COMPACTORS OR WALK BEHIND ROLLERS.

Tb

UTILIZED IN LIEU OF NYLON BOOTS

WHEN SPACED AT A MAXIMUM OF TRANSVERSE REINFORCEMENT IS PARALLEL TO THE CULVERT SPAN.

48 INCHES. LONGITUDINAL REINFORCEMENT IS PERPENDICULAR TO THE CULVERT SPAN.

As8

Ts SPAN Ts

Tb

TRANSVERSE 1 USE 1" DIAMETER CULVERT TIES. SEE STANDARD PLATE NO. 3145 FOR DETAILS.

REINFORCEMENT

CUT BARS AS NECESSARY TO FIT TONGUE AT CORNERS 2 USE 12" VERTICAL, 12" HORIZONTAL HAUNCHES ON ALL BOX SIZES.

SEE FORMING DETAIL

TRANSVERSE BARREL SECTION BOTTOM OF FORM 3 PLACE LONGITUDINAL REINFORCEMENT DENOTED AS As5 AND As6 IN ALL SLABS

AND WALLS WITH A MINIMUM OF 0.06 SQ. IN./FT.

BAR REINFORCEMENT OPTION SHOWN LONGITUDINAL BARREL SECTION

4 SEE STANDARD PLATE NO. 3007 FOR SHEAR REINFORCEMENT OPTIONS. THE MAXIMUM

PLAN BAR REINFORCEMENT OPTION SHOWN

1" CLEAR SHEAR REINFORCEMENT SPACING IN THE LONGITUDINAL DIRECTION IS 6".

SMALL RADIUS OR (TYPICAL)

LONGITUDINAL REINFORCEMENT 5 ROADWAY OR SHOULDER FILL HEIGHTS OF LESS THAN 2'-0" REQUIRE A

)

TYP.

BEVEL OPTIONAL NYLON BOOTS ON EVERY FOURTH

6" THICK DISTRIBUTION SLAB WITH CONCRETE MIX 3S52.

• "

As1, As7, As8 WIRE. PLASTIC SPACERS MAY BE

OUTSIDE FACE LAYER OF WELDED WIRE REINFORCEMENT

UTILIZED IN LIEU OF NYLON BOOTS

(

PLACE CAST-IN-PLACE DISTRIBUTION SLABS WITH 3" MIN. SELECT GRANULAR

WHEN SPACED AT A MAXIMUM OF

MATERIAL PER SPEC. 3149.2.B.2 BETWEEN BARREL AND DISTRIBUTION SLAB.

48 INCHES.

"T"

PRECAST DISTRIBUTION SLABS MAY BE USED FOR FILL HEIGHTS OVER 1'-0".

BOTTOM OF FORM LAYER OF WELDED WIRE REINFORCEMENT

PROVIDE 6" MINIMUM SELECT GRANULAR MATERIAL PER SPEC. 3149.2.B.2

STEEL FORM OR EQUAL BETWEEN BARREL AND SLAB.

REINFORCEMENT LAYER DETAIL

• "

3• "

As2, As3, As4 SECTION EXTEND THE WIDTH OF THE DISTRIBUTION SLAB TO THE OUTSIDE EDGES OF THE

INSIDE FACE 4" WHEN MORE THAN ONE LAYER OF WELDED WIRE REINFORCEMENT IS

ROADWAY SHOULDERS UNLESS DIRECTED BY THE ENGINEER.

USED TO OBTAIN THE REQUIRED REINFORCEMENT AREAS,

FORMING DETAIL PLACE THE WIRES OF THE WELDED WIRE REINFORCEMENT AS SHOWN

6 REDESIGN THE DISTRIBUTION SLAB PER THE MnDOT PAVEMENT DESIGN MANUAL

IF IT IS USED AS PAVEMENT SURFACE.

TONGUE AND GROOVE JOINT DETAIL

PAYMENT FOR THE DISTRIBUTION SLAB AND SELECT GRANULAR MATERIAL

BENEATH THE SLAB IS CONSIDERED INCIDENTAL.

6 REFER TO SPEC, 2412 FOR SEALANT REQUIREMENTS.

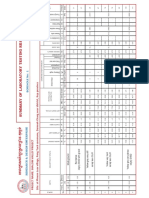

BARREL INFORMATION TABLE ***

WELDED WIRE REINFORCEMENT 4 SHEAR REINFORCEMENT

DISTRIBUTION RECESSED

OVERFILL DIMENSIONS

f'c SLAB TIE RODS WEIGHT As1 As2 As3 As4 As7 As8 TOP AND BOTTOM OF BARREL

LOCATION SIZE LIMITS

(P.S.I.) REQUIRED REQUIRED (LBS./FT.)

(FT.) SPAN RISE Tt Tb Ts AREA LENGTH M AREA LENGTH AREA LENGTH AREA LENGTH AREA LENGTH AREA LENGTH AREA MAX. SPG. X

* ** (FT.) (FT.) (IN.) (IN.) (IN.) (IN.!/FT.) (FT.) (FT.) (IN.!/FT.) (FT.) (IN.!/FT.) (FT.) (IN.!/FT.) (FT.) (IN.!/FT.) (FT.) (IN.!/FT.) (FT.) (IN.!/FT.) (IN.) (IN.)

YES NO

YES NO

* ALL CLASS 1 CULVERTS WITH FILL HEIGHTS OF LESS THAN 2'-0" REQUIRE A DISTRIBUTION SLAB.

IF A DISTRIBUTION SLAB IS NOT REQUIRED, INDICATE "NO" IN THIS BOX.

REVISION: FEBRUARY 22, 2018 STATE PROJ. NO - (T.H. ) STA. + . FIG. 5-395.101(B)

** FOR PEDESTRIAN CULVERT APPLICATIONS HIDE-AWAY OR RECESSED TIE CONNECTIONS ARE REQUIRED,

TITLE:

SEE STANDARD PLATE 3145. IF REQUIRED, INDICATE "YES" IN THIS BOX. CERTIFIED BY

DES: DR: APPROVED:

APPROVED: MARCH 24, 2011

PRECAST CONCRETE BRIDGE NO.

*** BOX CULVERTS WITH SPANS FROM 6 TO 14 FT. ARE DESIGNED FOR HL-93 LIVE LOADS (AASHTO LRFD 3.6.2.1)

LICENSED PROFESSIONAL ENGINEER DATE

BARREL DETAILS

CHK: CHK:

NOT INCLUDING THE DESIGN LANE LOAD. BOXES WITH SPANS OF 16 FT. ARE DESIGNED FOR HL-93 LIVE LOADS

STATE BRIDGE ENGINEER INCLUDING THE DESIGN LANE LOAD. NAME: LIC. NO. (SPECIAL DESIGN) SHEET NO. OF SHEETS

Anda mungkin juga menyukai

- End of Bridge Approach Slab Guardrail Connection DetailsDokumen1 halamanEnd of Bridge Approach Slab Guardrail Connection DetailsAdnan NajemBelum ada peringkat

- I61-07 - Typical DetailsDokumen1 halamanI61-07 - Typical DetailsTAHABelum ada peringkat

- General Construction NotesDokumen1 halamanGeneral Construction NoteschrisBelum ada peringkat

- Canopy assembly installation diagramDokumen1 halamanCanopy assembly installation diagramErnesto LopezBelum ada peringkat

- Detail 1: Roof Slope Plan 1/8" 1'-0"Dokumen1 halamanDetail 1: Roof Slope Plan 1/8" 1'-0"Shumaila ShaukatBelum ada peringkat

- R A S L I M S-02 Proposed 3-Storey Mix-Used Commercial BuildingDokumen1 halamanR A S L I M S-02 Proposed 3-Storey Mix-Used Commercial BuildingShariah MelonBelum ada peringkat

- Elevation: NotesDokumen1 halamanElevation: NotesErika Faye GutierrezBelum ada peringkat

- Package-9 joint groove detailsDokumen3 halamanPackage-9 joint groove detailsSoodi Nagendra PrasadBelum ada peringkat

- Confidential Client Not For Construction: 1301 Burlington Street SUITE 100 P 816.361.1177 N Kansas City, Mo 64116Dokumen1 halamanConfidential Client Not For Construction: 1301 Burlington Street SUITE 100 P 816.361.1177 N Kansas City, Mo 64116mirza.adeelBelum ada peringkat

- Bridge Engineeing Drawings 10.2 - A1 - 3Dokumen1 halamanBridge Engineeing Drawings 10.2 - A1 - 3Adnan NajemBelum ada peringkat

- Prokon Geek SLAB DETAILING 101 NotesDokumen1 halamanProkon Geek SLAB DETAILING 101 NotesProkon GeekBelum ada peringkat

- Notes:: Piping Standards CommitteeDokumen1 halamanNotes:: Piping Standards CommitteeMustapha SedikBelum ada peringkat

- Bridge Approach Slab and Traffic Barrier DetailsDokumen1 halamanBridge Approach Slab and Traffic Barrier DetailsAdnan NajemBelum ada peringkat

- Bridge Engineeing Drawings 10.2 - A6 - 3Dokumen1 halamanBridge Engineeing Drawings 10.2 - A6 - 3Adnan NajemBelum ada peringkat

- STDB 2 BDokumen1 halamanSTDB 2 BgarpheetBelum ada peringkat

- Standard D500connections To SteelDokumen1 halamanStandard D500connections To SteelMallesh NenkatBelum ada peringkat

- Beam I-36 Standart DetailDokumen2 halamanBeam I-36 Standart DetailAna Maria Nina EstrellaBelum ada peringkat

- Plan Traffic BarrierDokumen1 halamanPlan Traffic BarrierAdnan NajemBelum ada peringkat

- Covered Walkway Wall-AttachedDokumen1 halamanCovered Walkway Wall-AttachedErnesto LopezBelum ada peringkat

- Soldier Pile Steel & Timber LaggingDokumen1 halamanSoldier Pile Steel & Timber LaggingHendy WijayaBelum ada peringkat

- Hig Lower 38 WestDokumen4 halamanHig Lower 38 WestShivani SoniBelum ada peringkat

- Stonelite: 2400 Hwy 1431 West Marble Falls, TX 78654 800.328.6275Dokumen1 halamanStonelite: 2400 Hwy 1431 West Marble Falls, TX 78654 800.328.6275231Sondos Mahmoud AhmedBelum ada peringkat

- Plan Traffic BarrierDokumen1 halamanPlan Traffic BarrierAdnan NajemBelum ada peringkat

- 24 Plaza Corp.: Shoreline Development Review 700 Ne 24Th Street, Miami, Florida View Corridor DiagramDokumen3 halaman24 Plaza Corp.: Shoreline Development Review 700 Ne 24Th Street, Miami, Florida View Corridor DiagramNone None NoneBelum ada peringkat

- Notes 2Dokumen1 halamanNotes 2JOSHUA ALZAGABelum ada peringkat

- Soil Test ReportDokumen3 halamanSoil Test ReportPhanna MongBelum ada peringkat

- Revised Y-Axis Beams PDFDokumen28 halamanRevised Y-Axis Beams PDFPetreya UdtatBelum ada peringkat

- Plan Traffic BarrierDokumen1 halamanPlan Traffic BarrierAdnan NajemBelum ada peringkat

- Plan View Section A-A Scale: N.T.S.: NAUBU-1-8737-D-16605Dokumen1 halamanPlan View Section A-A Scale: N.T.S.: NAUBU-1-8737-D-16605GBelum ada peringkat

- Plate No.3 PlumbingDokumen1 halamanPlate No.3 PlumbingDawat JohnBelum ada peringkat

- Grease Trap Manhole Frame InstallationDokumen1 halamanGrease Trap Manhole Frame Installationbladeliger22Belum ada peringkat

- House 5 & 6 PlanDokumen1 halamanHouse 5 & 6 Planvinsonpeng26Belum ada peringkat

- 07 2007d PDFDokumen1 halaman07 2007d PDFpangit catcatBelum ada peringkat

- Plan - Soldier Pile Wall Without P. G. A.: Timber Lagging SizesDokumen1 halamanPlan - Soldier Pile Wall Without P. G. A.: Timber Lagging SizesgmkmalBelum ada peringkat

- Handrail DetailsDokumen2 halamanHandrail DetailsVivianBelum ada peringkat

- ABSPRINT1Dokumen1 halamanABSPRINT1Ruchita davaneBelum ada peringkat

- Issue For Construction: Typical Road Cross-Section (Access Road) Minimum Pipe CoveringDokumen1 halamanIssue For Construction: Typical Road Cross-Section (Access Road) Minimum Pipe CoveringCivil Design EngineerBelum ada peringkat

- PR-402 2021-578Dokumen1 halamanPR-402 2021-578Krishna SankarBelum ada peringkat

- Clarkson Kga+ Dn1200 Nps48 HC RDC 08.ADokumen1 halamanClarkson Kga+ Dn1200 Nps48 HC RDC 08.AAlejandro Pupunovich RodriguezBelum ada peringkat

- Anchorage and Splice Lengths of Tension Bars in Beams and SlabsDokumen1 halamanAnchorage and Splice Lengths of Tension Bars in Beams and SlabsHenriel HaoBelum ada peringkat

- Typical Footing Detail 1Dokumen1 halamanTypical Footing Detail 1Fritz NatividadBelum ada peringkat

- 59S-CS-518 - Steel Repair Details Sheet 2 of 5-Default - R3Dokumen1 halaman59S-CS-518 - Steel Repair Details Sheet 2 of 5-Default - R3anandkc55Belum ada peringkat

- General Structural/Construction Notes and Specifications: Proposed 4-Storey Residential Building W/FenceDokumen1 halamanGeneral Structural/Construction Notes and Specifications: Proposed 4-Storey Residential Building W/FenceWilbert ReuyanBelum ada peringkat

- Typical Isolated Footing Detail: SectionDokumen1 halamanTypical Isolated Footing Detail: SectionJohn Eric D. WongBelum ada peringkat

- Section "A": Beam Connection Joint 9Dokumen1 halamanSection "A": Beam Connection Joint 9Jhon SabinoBelum ada peringkat

- 5.05.23 WTP Structural Plans 1Dokumen3 halaman5.05.23 WTP Structural Plans 1Sir Enoch MoraBelum ada peringkat

- General Construction Notes: Bureau of DesignDokumen1 halamanGeneral Construction Notes: Bureau of DesignKevinBelum ada peringkat

- BD Ps12eDokumen1 halamanBD Ps12eLiran AnabyBelum ada peringkat

- Area of The Site Area of The Pro.G.F.Building Area of The Open SpaceDokumen1 halamanArea of The Site Area of The Pro.G.F.Building Area of The Open SpaceAsr FlowerBelum ada peringkat

- S3-0-0 - Typical Slab On Grade Details PDFDokumen1 halamanS3-0-0 - Typical Slab On Grade Details PDFVictor Miranda AcuñaBelum ada peringkat

- QP10 Q 1580 TypicalPipelineDitchForSingleAndTwinLineDokumen1 halamanQP10 Q 1580 TypicalPipelineDitchForSingleAndTwinLineMohammad HegazyBelum ada peringkat

- Bharat Ji - Footing Design & SectionsDokumen1 halamanBharat Ji - Footing Design & SectionsMukesh JangidBelum ada peringkat

- FOLDED PLATE-fINALDokumen1 halamanFOLDED PLATE-fINALVamshi BattleBelum ada peringkat

- 6" 6" As Per Site 6": Plan of Septic TankDokumen1 halaman6" 6" As Per Site 6": Plan of Septic TankHammad ZafarBelum ada peringkat

- Joint Detail Slab-On-Grade Construction: A B C D E FDokumen1 halamanJoint Detail Slab-On-Grade Construction: A B C D E FJaybert DumaranBelum ada peringkat

- Bridge Engineering Drawings 10.2 - A3 - 3Dokumen1 halamanBridge Engineering Drawings 10.2 - A3 - 3Adnan NajemBelum ada peringkat

- General Notes:: Bridge Deck Rehabilitation With Concrete OverlayDokumen1 halamanGeneral Notes:: Bridge Deck Rehabilitation With Concrete OverlaySolomon AhimbisibweBelum ada peringkat

- FOUNDATION DDokumen1 halamanFOUNDATION DMuhammad UsmanBelum ada peringkat

- Bridge Girder Reinforcement DetailsDokumen1 halamanBridge Girder Reinforcement DetailsJesús Rodríguez RodríguezBelum ada peringkat

- Design and Analysis of Isolated Footing Tiruppur Terzaghi Geotech RajaDokumen1 halamanDesign and Analysis of Isolated Footing Tiruppur Terzaghi Geotech RajaE.PrasathBelum ada peringkat

- Design of slender columnDokumen4 halamanDesign of slender columnE.PrasathBelum ada peringkat

- Design of isolated footingDokumen4 halamanDesign of isolated footingE.PrasathBelum ada peringkat

- Geology Book PDFDokumen54 halamanGeology Book PDFprimesamBelum ada peringkat

- Er - Kannan Sir Plan.8.7.19 PDFDokumen1 halamanEr - Kannan Sir Plan.8.7.19 PDFE.PrasathBelum ada peringkat

- Anchor Design ProcedureDokumen3 halamanAnchor Design ProcedureE.PrasathBelum ada peringkat

- Cat CatalystDokumen7 halamanCat Catalystkhaled fathyBelum ada peringkat

- Chengannur ReDokumen1.077 halamanChengannur ReArul RajanBelum ada peringkat

- 38352cable ListDokumen9 halaman38352cable ListsinamicsBelum ada peringkat

- ULTIMATE SERVICES COMPANYDokumen14 halamanULTIMATE SERVICES COMPANYAdmin UTSBelum ada peringkat

- Grating Weight DatasheetDokumen14 halamanGrating Weight Datasheetkiller shaBelum ada peringkat

- Unit+1 Some+Basic+Concepts+In+Chemistry PDFDokumen20 halamanUnit+1 Some+Basic+Concepts+In+Chemistry PDFParth GargBelum ada peringkat

- Tencate Semi PregDokumen6 halamanTencate Semi PregyigitilgazBelum ada peringkat

- Hydrogen Embrittlement in Power Plant Steels: Sadhana June 2003Dokumen22 halamanHydrogen Embrittlement in Power Plant Steels: Sadhana June 2003Rolando Nuñez MonrroyBelum ada peringkat

- Bostik NeverseezDokumen8 halamanBostik NeverseezginuxBelum ada peringkat

- EIL A6 Piping Vendor ListDokumen16 halamanEIL A6 Piping Vendor Listdhan210100% (2)

- Brochure GC Fuji IX GP EXTRA PDFDokumen20 halamanBrochure GC Fuji IX GP EXTRA PDFRifqie al harisBelum ada peringkat

- Potassium Carbonate: Product Data Sheet (PDS)Dokumen1 halamanPotassium Carbonate: Product Data Sheet (PDS)Iqbal batchaBelum ada peringkat

- 4014 03Dokumen7 halaman4014 03Carlos Romero Muñoz100% (2)

- Unit 6 - Chemical Reactions - Complete NotesDokumen57 halamanUnit 6 - Chemical Reactions - Complete Notesapi-508178584Belum ada peringkat

- bs4994 Case Study PDFDokumen4 halamanbs4994 Case Study PDFA.Subin DasBelum ada peringkat

- Crockmaster 680Dokumen2 halamanCrockmaster 680dyetex100% (1)

- GGFHJDokumen1 halamanGGFHJanon_791172439Belum ada peringkat

- Alkalno Silikatna ReakcijaDokumen24 halamanAlkalno Silikatna Reakcijajozica majdaBelum ada peringkat

- Stock Register - 2Dokumen6 halamanStock Register - 2gayan_sarindaBelum ada peringkat

- Cathodic Protection System For Tank Bottom Plate 1688916078Dokumen6 halamanCathodic Protection System For Tank Bottom Plate 1688916078youplai100% (1)

- Soyol Polyol FormulationsDokumen3 halamanSoyol Polyol FormulationsurethanBelum ada peringkat

- User's Guide: BondekDokumen8 halamanUser's Guide: BondekMing ChongBelum ada peringkat

- Lect - 3 - Earthquake - Design - Philosophy - Part 1Dokumen8 halamanLect - 3 - Earthquake - Design - Philosophy - Part 1jana ShmaysemBelum ada peringkat

- MOS of Thermoplastic PaintDokumen2 halamanMOS of Thermoplastic PaintL V Laxmipathi Rao100% (1)

- Water QualityDokumen34 halamanWater QualitySarim ChBelum ada peringkat

- CH 3.4 Law of Definite Proportions 11-12Dokumen14 halamanCH 3.4 Law of Definite Proportions 11-12Sumera SarwarBelum ada peringkat

- Rugged AC Magnetic Particle Inspection ProbeDokumen2 halamanRugged AC Magnetic Particle Inspection ProbeNubia BarreraBelum ada peringkat

- Building Construction Tools List With Images and Their UsesDokumen8 halamanBuilding Construction Tools List With Images and Their UsesunaisaliBelum ada peringkat

- Mytest Coba ChemistryDokumen3 halamanMytest Coba ChemistryDigilib Cambridge TazkiaBelum ada peringkat

- Mole Calculations Made EasyDokumen27 halamanMole Calculations Made EasyAmyBelum ada peringkat