Comparison of Counter Flow and Cross Flow Cooling

Diunggah oleh

Durjoy ChakrabortyHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Comparison of Counter Flow and Cross Flow Cooling

Diunggah oleh

Durjoy ChakrabortyHak Cipta:

Format Tersedia

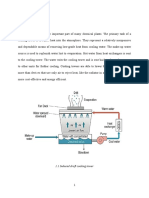

G) COMPARISON OF COUNTER FLOW AND CROSS FLOW COOLING

TOWERS.

SL. COUNTER FLOW

CRITERIA CROSS FLOW

NO.

1 Principle The airflow is vertically upwards, The air flows horizontally and

counter current with the hot water the water falling downwards

falling downwards. meets the air at different

The coldest water comes in contact temperatures. Therefore the

with the coolest and most dry air, heat transfer is not always

optimising the heat transfer and optimised.

obtaining maximum performance.

2 Area The tower area required is The area required is larger due

comparatively much smaller. The air to its constructional features

water contact is more due to the like the larger plenum

efficiency and arrangement of the fill chamber. Also the arrangement

pack. The plenum chamber area for and material of the pack is

hot air in this tower is smaller. different and requires a higher

area.

3 Air Flow * Since the air – water contact time is Since the air – water contact

higher; the quantity of air required is time is lesser; more air is

lesser. required to effect heat transfer.

4 Distribution The distribution is done through The distribution is done

System channel with lateral pipes, fitted with through open trough

splash cum spray nozzles. Growth of systems on the fan deck, fitted

algae is highly restricted as the lateral with nozzles.

pipes are a closed unit and not Distribution may not be as

located in direct sunlight. uniform as the counter flow

type and is easily attacked by

algae, causing problems like

scaling and clogging of

openings.

5 Recirculation The problem of Recirculation is much Since the air intake area

less in this case as the air intake is at extends from the bottom to the

the bottom of the tower and the deck level, the flume discharge

discharge is at a much higher level. is very close to the air intake

Further the side walls of the tower are area at the top. This creates the

closed till the top of the air intake effect of Recirculation wherein

area the discharged air reenters

the tower through the air intake

at the top. This creates a

significant reduction in

performance.

SL. COUNTER FLOW

CRITERIA CROSS FLOW

NO.

6 Fill Pack The fill pack can be splash type Only splash type fill used in

plastic fill for very bad quality of cross flow cooling towers.

water and film fill for better quality of Usually splash fill will be V

water. bar or timber laths.

7 Power The Fan Power consumption is low as The Fan Power consumption is

Consumption. the required air quantity is higher as the airflow required

& Pumping comparatively lower. is higher. The pumping

Head The pumping head is also lower as head is also higher since the

the inlet header is located below the distribution is located at the

fan deck area. fan deck level.

8 Maintenance Maintenance for counter flow towers Maintenance for cross flow

is much easier than cross flow towers. towers is time consuming and

The simplicity of structure and usually requires more skilled

comfortable sizing allow for technicians on the job as the

quick and exhaustive maintenance. movement of material is more

difficult.

Anda mungkin juga menyukai

- Cooling TowerDokumen52 halamanCooling TowerMuhammad AhmedBelum ada peringkat

- 05-Lecture (September 03)Dokumen20 halaman05-Lecture (September 03)Goura Sundar TripathyBelum ada peringkat

- Cooling Tower NotesDokumen19 halamanCooling Tower NotesAnonymous FWlt8YBelum ada peringkat

- Cooling Tower Word RefrenceDokumen17 halamanCooling Tower Word RefrenceKiran PatilBelum ada peringkat

- Coil Capacity EfficiencyDokumen3 halamanCoil Capacity EfficiencyChínhÂuBelum ada peringkat

- External InfluencesDokumen8 halamanExternal InfluencesmohamadBelum ada peringkat

- Cooling Tower Calculation DESIGNDokumen6 halamanCooling Tower Calculation DESIGNThakur Chandra Partap singh100% (1)

- Industrial Plant Cooling EquipmentDokumen15 halamanIndustrial Plant Cooling EquipmentkennnBelum ada peringkat

- What Is A Cooling Tower - Manufacturers of Cooling Towers & Systems - Delta Cooling Towers, IncDokumen9 halamanWhat Is A Cooling Tower - Manufacturers of Cooling Towers & Systems - Delta Cooling Towers, Incprabhanshu241991Belum ada peringkat

- Types of Cooling Tower: Mass Transfer Operations-2Dokumen27 halamanTypes of Cooling Tower: Mass Transfer Operations-2Chintan ModiBelum ada peringkat

- Experiment 7 Cooling TowerDokumen9 halamanExperiment 7 Cooling TowerRicky Jay0% (1)

- The Use of Air Cooled Heat Exchangers in Mechanical Seal Piping Plans - SnyderDokumen7 halamanThe Use of Air Cooled Heat Exchangers in Mechanical Seal Piping Plans - SnyderJaime Ocampo SalgadoBelum ada peringkat

- Comparison of Crossflow VS Counterflow Cooling TowerDokumen2 halamanComparison of Crossflow VS Counterflow Cooling TowerShahab Z Ahmed100% (1)

- Condenser S and Cooling Towers: By, Prof. M.B. GohilDokumen55 halamanCondenser S and Cooling Towers: By, Prof. M.B. Gohilanilm130484meBelum ada peringkat

- Cooling Water System Optimization: Figure 1. Cross Section of Counter and Cross Flow TowersDokumen4 halamanCooling Water System Optimization: Figure 1. Cross Section of Counter and Cross Flow TowersLeo PunongbayanBelum ada peringkat

- Cooling Tower: Refrigeration and Air Conditioning LabDokumen40 halamanCooling Tower: Refrigeration and Air Conditioning LabEngr Saad Bin SarfrazBelum ada peringkat

- Chapter SixDokumen25 halamanChapter SixADEFRIS BELACHEWBelum ada peringkat

- Cooling Tower SeminarDokumen67 halamanCooling Tower SeminarRupesh Desai100% (1)

- Cooling by Underground Earth Tubes PDFDokumen4 halamanCooling by Underground Earth Tubes PDFtrola666910Belum ada peringkat

- Cooling Tower 1Dokumen16 halamanCooling Tower 1Prasanna kumar subudhi100% (1)

- Cooling Tower FillDokumen14 halamanCooling Tower FillIrfan Shaikh100% (1)

- What Is A Cooling Tower?Dokumen11 halamanWhat Is A Cooling Tower?Pradeep Kumar PrakashBelum ada peringkat

- CHAPTER 7 - COOLING TOWER Edit MOSH 211220Dokumen25 halamanCHAPTER 7 - COOLING TOWER Edit MOSH 211220subash1111111Belum ada peringkat

- Cooling Towers (Excellent Collection)Dokumen55 halamanCooling Towers (Excellent Collection)moh khBelum ada peringkat

- Cooling TowerDokumen7 halamanCooling TowerpedpixBelum ada peringkat

- Cooling Tower DesignDokumen11 halamanCooling Tower DesignSmrutiBelum ada peringkat

- Stage 2Dokumen28 halamanStage 2Riya VermaBelum ada peringkat

- Cooling Tower and Cooling Water System: A Brief Presentation: Part-1 of 3Dokumen16 halamanCooling Tower and Cooling Water System: A Brief Presentation: Part-1 of 3Syed ImranBelum ada peringkat

- Chapter 10 - Cooling TowerDokumen24 halamanChapter 10 - Cooling TowerAsyraf Sabri100% (1)

- BUILDING UTILITIES 2 - MODULE FinalsDokumen22 halamanBUILDING UTILITIES 2 - MODULE Finals20-07677Belum ada peringkat

- Design Philosophy of Cooling TowerDokumen34 halamanDesign Philosophy of Cooling Towerdinesh100% (2)

- Energy Conservation in Cooling TowersDokumen13 halamanEnergy Conservation in Cooling TowersMohamad ChaudhariBelum ada peringkat

- Lecture 10 - Steam Condensers - Direct TypeDokumen4 halamanLecture 10 - Steam Condensers - Direct TypeHussain AbbasBelum ada peringkat

- C C T T T T: Ooling Ooling Owers Owers Owers OwersDokumen19 halamanC C T T T T: Ooling Ooling Owers Owers Owers OwersVitthal s kandeBelum ada peringkat

- Cooling Tower REPORTDokumen25 halamanCooling Tower REPORTSaroj KumarBelum ada peringkat

- Cooling TowerDokumen47 halamanCooling TowerVenkitaraj K P100% (1)

- CT PrsentationDokumen47 halamanCT PrsentationArvind ABelum ada peringkat

- Cooling Towers: Learning OutcomeDokumen26 halamanCooling Towers: Learning OutcomeMandeep MalikBelum ada peringkat

- ColngDokumen17 halamanColngadBelum ada peringkat

- Improve and Maintain Cooling Tower EfficiencyDokumen5 halamanImprove and Maintain Cooling Tower EfficiencyMTOLBelum ada peringkat

- AC - Duct Work SweatDokumen3 halamanAC - Duct Work SweatNidas SameeraBelum ada peringkat

- 04-Lecture (August 31)Dokumen16 halaman04-Lecture (August 31)Goura Sundar TripathyBelum ada peringkat

- E & I in Air Conditioning Units, Lubrication System, Belt ConveyorDokumen15 halamanE & I in Air Conditioning Units, Lubrication System, Belt ConveyorKailash NathBelum ada peringkat

- Air Flow Around Buildings PDFDokumen10 halamanAir Flow Around Buildings PDFsurya yogiBelum ada peringkat

- Variable Flow Cooling Tower-FlyerDokumen2 halamanVariable Flow Cooling Tower-FlyerManik Singh100% (1)

- Cooling Tower BasicDokumen6 halamanCooling Tower Basicsininarayanan50% (2)

- SC CoilCleaningGuide Ebook FNL1019Dokumen16 halamanSC CoilCleaningGuide Ebook FNL1019jeremy_chan_35Belum ada peringkat

- ÁdasDokumen10 halamanÁdasDũng LêBelum ada peringkat

- Plant Layout - Cooling Water TowersDokumen7 halamanPlant Layout - Cooling Water TowersSouparna DuttaBelum ada peringkat

- Rubble Trench Foundation3Dokumen6 halamanRubble Trench Foundation3Vicces P. EstradaBelum ada peringkat

- CFD SimulationDokumen39 halamanCFD SimulationSambhav JainBelum ada peringkat

- Sch1302 Mass Transfer - Ii Unit 1 Humidfication Prepared By: Dr.S.SathishDokumen20 halamanSch1302 Mass Transfer - Ii Unit 1 Humidfication Prepared By: Dr.S.SathishRamakrishna ReddyBelum ada peringkat

- Cooling TowersDokumen40 halamanCooling Towers1000 Subscribers Without a Video100% (2)

- Airto Air Heat ExchangerDokumen4 halamanAirto Air Heat Exchangerpauldurai kanagarajBelum ada peringkat

- By: Meet Shah & Arpit ThumarDokumen27 halamanBy: Meet Shah & Arpit ThumarArpit ThumarBelum ada peringkat

- Climatology: - Ar. Akshay GuptaDokumen43 halamanClimatology: - Ar. Akshay GuptaYogendra SinghBelum ada peringkat

- Air Washers: A New Look at A Vintage Technology: October 2003Dokumen6 halamanAir Washers: A New Look at A Vintage Technology: October 2003Sameer ShrivastavaBelum ada peringkat

- AirWashers AlookatvintagetechnologyEl Morsietal.2003Dokumen6 halamanAirWashers AlookatvintagetechnologyEl Morsietal.2003Rahul DuttaBelum ada peringkat

- Chimneys & Fireplaces: They Contribute to the Health Comfort and Happiness of the Farm Family - How to Build ThemDari EverandChimneys & Fireplaces: They Contribute to the Health Comfort and Happiness of the Farm Family - How to Build ThemBelum ada peringkat

- H2 KoreanDokumen3 halamanH2 KoreanDurjoy ChakrabortyBelum ada peringkat

- TG SynchronizationDokumen7 halamanTG SynchronizationDurjoy ChakrabortyBelum ada peringkat

- Glass Fibre Reinforced Products PDFDokumen16 halamanGlass Fibre Reinforced Products PDFDurjoy ChakrabortyBelum ada peringkat

- FAD Calculation For CompressorDokumen2 halamanFAD Calculation For CompressorDurjoy ChakrabortyBelum ada peringkat

- Coal FLowDokumen28 halamanCoal FLowDurjoy ChakrabortyBelum ada peringkat

- Restriction Orifice Diamater CalculationDokumen1 halamanRestriction Orifice Diamater CalculationDurjoy ChakrabortyBelum ada peringkat

- Waste Heat Recovery in Cement Plant IJERTV3IS051014 PDFDokumen5 halamanWaste Heat Recovery in Cement Plant IJERTV3IS051014 PDFDurjoy ChakrabortyBelum ada peringkat

- Gas TurbineInlet Air CoolingDokumen41 halamanGas TurbineInlet Air CoolingDurjoy ChakrabortyBelum ada peringkat

- Waste To Energy Plant in SuratDokumen18 halamanWaste To Energy Plant in SuratDurjoy ChakrabortyBelum ada peringkat

- 1811 Reclaiming SystemsDokumen4 halaman1811 Reclaiming SystemsDurjoy ChakrabortyBelum ada peringkat

- Ship Recognition Manual TOSDokumen138 halamanShip Recognition Manual TOSCody Lees94% (17)

- Progressive Muscle Relaxation ExerciseDokumen2 halamanProgressive Muscle Relaxation Exerciseraghu2362704100% (1)

- With You: Full-Line CatalogDokumen68 halamanWith You: Full-Line CatalogCOMIBelum ada peringkat

- Car Parking DesignDokumen6 halamanCar Parking Designcharler kinyuajBelum ada peringkat

- Energy BodiesDokumen1 halamanEnergy BodiesannoyingsporeBelum ada peringkat

- ToiletsDokumen9 halamanToiletsAnonymous ncBe0B9bBelum ada peringkat

- EXPERIMENT 1 - Bendo Marjorie P.Dokumen5 halamanEXPERIMENT 1 - Bendo Marjorie P.Bendo Marjorie P.100% (1)

- Admission: North South University (NSU) Question Bank Summer 2019Dokumen10 halamanAdmission: North South University (NSU) Question Bank Summer 2019Mahmoud Hasan100% (7)

- TransistorDokumen3 halamanTransistorAndres Vejar Cerda0% (1)

- Practice Test - Math As A Language - MATHEMATICS IN THE MODERN WORLDDokumen8 halamanPractice Test - Math As A Language - MATHEMATICS IN THE MODERN WORLDMarc Stanley YaoBelum ada peringkat

- A Presentation On-: E-Paper TechnologyDokumen19 halamanA Presentation On-: E-Paper TechnologyRevanth Kumar TalluruBelum ada peringkat

- Electronic Parts Catalog - Option Detail Option Group Graphic Film Card DateDokumen2 halamanElectronic Parts Catalog - Option Detail Option Group Graphic Film Card DatenurdinzaiBelum ada peringkat

- Ib Psychology - Perfect Saq Examination Answers PDFDokumen2 halamanIb Psychology - Perfect Saq Examination Answers PDFzeelaf siraj0% (2)

- ResumeDokumen3 halamanResumeAstig Kuging63% (8)

- PCM 2.4l Turbo 5 de 5Dokumen2 halamanPCM 2.4l Turbo 5 de 5Felix VelasquezBelum ada peringkat

- Emcee Script For Recognition DayDokumen3 halamanEmcee Script For Recognition DayRomeo Jr. LaguardiaBelum ada peringkat

- Bilateral Transfer of LearningDokumen18 halamanBilateral Transfer of Learningts2200419Belum ada peringkat

- En DAY4 David Chen Building The AI Computing Platform For Pervasive Intelligence enDokumen8 halamanEn DAY4 David Chen Building The AI Computing Platform For Pervasive Intelligence endieuwrignBelum ada peringkat

- TOEFL-Reading Question Type Definitions and ExplanationDokumen5 halamanTOEFL-Reading Question Type Definitions and ExplanationSamara SampaioBelum ada peringkat

- CadburyDokumen21 halamanCadburyramyarayeeBelum ada peringkat

- InterviewDokumen8 halamanInterviewswapnadip kumbharBelum ada peringkat

- Tecsun Pl310et PDFDokumen30 halamanTecsun Pl310et PDFAxel BodemannBelum ada peringkat

- CE-23113-SP-902-R01-00 Asset SpecificationDokumen14 halamanCE-23113-SP-902-R01-00 Asset SpecificationСветлана ФайберBelum ada peringkat

- Mathematics4 q4 Week4 v4Dokumen11 halamanMathematics4 q4 Week4 v4Morales JinxBelum ada peringkat

- Bamboo People - An Interdisciplinary Unit For High SchoolDokumen6 halamanBamboo People - An Interdisciplinary Unit For High SchoolChipo Jean MarundaBelum ada peringkat

- William Ury Power of A Positive No Bantam - 2007Dokumen227 halamanWilliam Ury Power of A Positive No Bantam - 2007Tam Jeopardy100% (1)

- Code of Federal RegulationsDokumen14 halamanCode of Federal RegulationsdiwolfieBelum ada peringkat

- Drsent PT Practice Sba OspfDokumen10 halamanDrsent PT Practice Sba OspfEnergyfellowBelum ada peringkat

- Solutions of Inverse Geodetic Problem in Navigational Applications PDFDokumen5 halamanSolutions of Inverse Geodetic Problem in Navigational Applications PDFLacci123Belum ada peringkat