Thehouseofleanv3 160208111244 PDF

Diunggah oleh

EstevaoasdJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Thehouseofleanv3 160208111244 PDF

Diunggah oleh

EstevaoasdHak Cipta:

Format Tersedia

Eduardo L. García. V3.

6 © 2016

linkedin.com/in/edulgg

CASH-FLOW – COST

SECURITY – LEAD TIME – QUALITY

ONE QCC Shijonka

KAIZEN-

Kaizen Soifuku ISHI- PDCA 8D 6σ ONE

AS IS KARA BLITZ

PIECE VSM JUNDATE ANDON JISHU- polyvalence

KAIKAKU

Idea from

OutOfLine KAWA Cycle

A3 POINT

FLOW

TO BE KURI KEN empowerment

PSP DMAIC LESSON

KAIZEN ·ASAKAY

5W+H 5

KJ

TAKT CYCLE SIPOC PUSH POKA Dayly-Huddle

JUNBIKI

PROGRESS

Chart/Table TEAM ·YUICHI VA/VE

(+2H) WHYS QFD FMEA METHOD

Time Time Diagram PULL YOKE MINDMAP

7

LT

WORK What BRAIN PPM

YAMA- SPS / STORM POTENTIAL

PM LTEfficiency

IF… PROBLEMS

LTStandard ZUMI KIT …

TPM

MIZU-

SUMASHI

4R

KAMI-

SHIBAI

JIT Gemba

3G

Genbutsu

Genjitsu

KAIZEN OJT/TWI

Hancho JIDOKA QRQC

QRKA

RCE

Root

Cause

MAP

PARETO &

Correlation

DandoriMan RULES CARDS & Q-Chart Analysis

ANALYSIS

TABLE

Moon- Pointing

(WASTES) The DESING FAULT

3A SMED 3P · IT’S &

5S PQC Spaghetti

Pika-Pika

Allocation

Amount

Article

Uchi-Soto

Dandori

Production

Preparation

shine

Concept

& Calling

A3/A2

MUDA Trimming · IT’S NOT

Technique · IN/OUT BOX

THINKING

TOOLS… Diagram

TREE

ANALYSIS

Diagram

Process

TIMWOOD RAMMPP

MVP TMA Production Bureaucracy LCA ICP CIA’s

KATAZUKE JUNJI 5ZEROs MURA TCP 6-Hats POKER ANDON

AKAFUDA INSPECTION POP theory

Minimum

Product

Therbligs

Motion 7 Wastes 6 Wastes Low Cost

Disney

LIST OF ESTIMATION BOARD

NEXT

Viable Analysis MURI Automation PCP PHOENIX

PRODUCTION

Burn-

down KANBAN KANBAN

BOARDs

SCRUM

SCALABLE HEIJUNKA

YAMA-

KUZUSHI

DAILY

INVENTORY

CHAKU

CHAKU

SEIRYUKA CELL

Chart DEVELOPMENT

SALES (Cells & Machinery easy to relocate)

PMP

BPMN STANDARDIZATION TQM STREAM Ji Koutei Handan- STABILIZATION PRODUCTION

MONTHLY

Production

COMITEE

2.0 ISO… Kanketsu kijun MEETING

3 3

PTSS PAB STM PCT OBC SWCT SWC SOS FLOW Machinery/Line

Production Forward Production Production Production

HEIJUNKA

PRODUCTION

Process Process Time Production

Skills Training

Process Operator Balance

Standardized

Standardized Standardized Control Control Control Plan Plan PRODUCTION

CONTROL*

WEEKLY

Matrix Work Combi-

DAY DAY 30 Days MEETING

Study Sheet Analysis Board

ILUO Matrix

Capability Table Chart

nation Table

Work Chart Operation Sheet DAY Weekly

1 2 3 4 5 6 7 8 5 4 3 2 1 2

KPI & Suggestion PRODUC- ILUO

BMC *VISUAL DAILY DAYLY Scheme KPI & Q KPI

KAIZEN QUALITY LCA RCE SAFETY

Business HOSHIN MONTHLY DAILY

TION

Root Matrix MONTHLY

SAFETY

CONTROL TARGET CONTROL Live Cycle

Model /ACTION COMITEE COMITEE Cause COMITEE

Canvas KANRI QCC MEETING MEETING

PLAN Assessment Analysis (STM) MEETING

5 6 Ø 5 4 4 2

LEAN Pointing (Safety 1st)

Start-Up &

Technics ENTERPRISE OPERATING SYSTEM (e-OS**) Calling ANZEN DAIICHI

All LONG MGMT.

3S

People’sPa TERM

rticipation VISION CS, ES, SS LEAN MANUFACTURING/MANAGEMENT MONTHLY

MEETING

MGMT.

COMETEE

1 1

This work is licensed under the Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License. To view a copy of this license, visit http://creativecommons.org/licenses/by-nc-nd/4.0/. (ELG 2016 ©)

Anda mungkin juga menyukai

- Legacycode SampleDokumen61 halamanLegacycode SampleMahendar SBelum ada peringkat

- Model B: Raspberry Pi 4 ComputerDokumen6 halamanModel B: Raspberry Pi 4 ComputerEstevaoasdBelum ada peringkat

- Power SupplyDokumen11 halamanPower SupplyEstevaoasdBelum ada peringkat

- Sample Bom JLCSMTDokumen2 halamanSample Bom JLCSMTEstevaoasdBelum ada peringkat

- Deploying RFID PDFDokumen16 halamanDeploying RFID PDFHagenPFBelum ada peringkat

- PidDokumen14 halamanPidarnisiBelum ada peringkat

- MAX7400/MAX7403/MAX7404/MAX7407Dokumen12 halamanMAX7400/MAX7403/MAX7404/MAX7407xyalfaxyzBelum ada peringkat

- 30V P-Channel MOSFET: Product Summary General DescriptionDokumen5 halaman30V P-Channel MOSFET: Product Summary General DescriptionAndrea CupelloBelum ada peringkat

- sn74hc86 DatasheetDokumen21 halamansn74hc86 DatasheetEstevaoasdBelum ada peringkat

- sn74hc86 DatasheetDokumen21 halamansn74hc86 DatasheetEstevaoasdBelum ada peringkat

- MAX7400/MAX7403/MAX7404/MAX7407Dokumen12 halamanMAX7400/MAX7403/MAX7404/MAX7407xyalfaxyzBelum ada peringkat

- Lora SX1272Dokumen129 halamanLora SX1272Shinichi KudoBelum ada peringkat

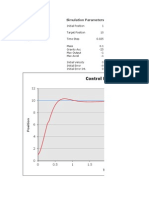

- Ziegler-Nichols Closed-Loop Tuning Method - Control NotesDokumen6 halamanZiegler-Nichols Closed-Loop Tuning Method - Control NotesEstevaoasd100% (1)

- LaTeX SymbolsDokumen22 halamanLaTeX SymbolstamgiangBelum ada peringkat

- sx1276 77 78 79 PDFDokumen132 halamansx1276 77 78 79 PDFSaikat MajumderBelum ada peringkat

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Cyclic Redundancy CheckDokumen12 halamanCyclic Redundancy Check40 Tanmay JadhavBelum ada peringkat

- ZTE LTE FDD Admission Control Feature Guide PDFDokumen82 halamanZTE LTE FDD Admission Control Feature Guide PDFAnonymous BfrEBpWBelum ada peringkat

- Veerachary CBCS JAVA III Sem-WatermarkDokumen198 halamanVeerachary CBCS JAVA III Sem-WatermarkShilesh RkBelum ada peringkat

- Ie BusDokumen92 halamanIe BusMino MaraBelum ada peringkat

- Introduction To Excel Cooling Load Calculations Using RTS MethodDokumen6 halamanIntroduction To Excel Cooling Load Calculations Using RTS MethodMelvyn Koa WingBelum ada peringkat

- Process Selection and Facility LayoutDokumen2 halamanProcess Selection and Facility LayoutMai SamalcaBelum ada peringkat

- Steel Frame Design Manual SAP2000 PDFDokumen197 halamanSteel Frame Design Manual SAP2000 PDFkarimBelum ada peringkat

- ABAP Class Upload-Download UtilitiesDokumen6 halamanABAP Class Upload-Download UtilitiesBrett HallBelum ada peringkat

- Munir AhmedDokumen1 halamanMunir AhmedXEN 220kV G/S NTDC KHUZDARBelum ada peringkat

- Soalan Projek PSPD LatestDokumen9 halamanSoalan Projek PSPD LatestAzlan AliBelum ada peringkat

- Introduction To Computing Exit Exam Model QuestionsDokumen28 halamanIntroduction To Computing Exit Exam Model QuestionsAbdulaziz TilahunBelum ada peringkat

- Bridging The Gap Between Theory and Practice in Maintenance: D.N.P. (Pra) MURTHYDokumen50 halamanBridging The Gap Between Theory and Practice in Maintenance: D.N.P. (Pra) MURTHYDinesh Kumar MaliBelum ada peringkat

- Mark FormDokumen2 halamanMark FormDiana Teresa Vargas AristaBelum ada peringkat

- OFDB-1 Installation ManualDokumen9 halamanOFDB-1 Installation ManualPuneet SharmaBelum ada peringkat

- EEDIDguide V1Dokumen18 halamanEEDIDguide V1giorgioviBelum ada peringkat

- CH 21 Managing Digital Communications Dr. A Haidar at FALL 17-18Dokumen63 halamanCH 21 Managing Digital Communications Dr. A Haidar at FALL 17-18AbdullahRafiqBelum ada peringkat

- NetPinger 2010 NamespaceDokumen1 halamanNetPinger 2010 NamespaceAmit Apollo BarmanBelum ada peringkat

- XK Epm1001a ManualDokumen20 halamanXK Epm1001a ManualCaleb OdagledBelum ada peringkat

- Mind Mapping and Its Applications in Vocabulary LearningDokumen6 halamanMind Mapping and Its Applications in Vocabulary LearningAdandedjan Alessandro BidossessiBelum ada peringkat

- Setup LogDokumen7 halamanSetup Logseuzehh11Belum ada peringkat

- Ch01 SolutionsDokumen7 halamanCh01 SolutionsАлекс БогдановBelum ada peringkat

- Database II Database Administration: Abbas Khan Department of Computer Science University of PeshawarDokumen24 halamanDatabase II Database Administration: Abbas Khan Department of Computer Science University of PeshawarIjaz SwateBelum ada peringkat

- Mateusz Grzesiukiewicz (Mateusz Grzesiukiewicz) - Hands-On Design Patterns With React Native-Packt Publishing (2018)Dokumen326 halamanMateusz Grzesiukiewicz (Mateusz Grzesiukiewicz) - Hands-On Design Patterns With React Native-Packt Publishing (2018)hashir mahboobBelum ada peringkat

- Productflyer - 978 3 319 18841 6Dokumen1 halamanProductflyer - 978 3 319 18841 6Jesse BurrisBelum ada peringkat

- नामांकन म / Enrollment No: 146Dokumen2 halamanनामांकन म / Enrollment No: 146Mukesh MistriBelum ada peringkat

- Python in 30 Minutes! : Fariz DarariDokumen64 halamanPython in 30 Minutes! : Fariz DarariJuan DominguezBelum ada peringkat

- NIMCET MCA Entrance 2008 Solved Question PaperDokumen14 halamanNIMCET MCA Entrance 2008 Solved Question PaperSharma Furniture JsrBelum ada peringkat

- Release Notes - Change Details R5B009 To R6A023 P1ADokumen14 halamanRelease Notes - Change Details R5B009 To R6A023 P1Aapi-3736768Belum ada peringkat

- SyokDokumen15 halamanSyokSuchye IhwanaBelum ada peringkat