Hydraulic Systems and Controls

Diunggah oleh

Jonna Mae PullanJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Hydraulic Systems and Controls

Diunggah oleh

Jonna Mae PullanHak Cipta:

Format Tersedia

12

HYDRAULIC

SYSTEMS AND

CONTROLS

This chapter discusses hydraulic systems, their control systems, and some of

the principles of tractor hitches.

Hydraulic Component Symbols

Hydraulic systems have become so complicated that it is much easier to use

symbols to describe them. This language, Graphic Symbols for Fluid Power Dia-

grams, must necessarily be learned before proceeding to a discussion of hy-

draulic systems.

The symbols are shown in Appendix B along with some examples of their

use. Some advantages of using symbols are:

1. Their use simplifies communication and saves drawing time.

2. Symbols can be used to convey the functional requirements of a com-

ponent, or an assembly of components. Thus, a designer's concept of the

component will not be biased by seeing a drawing or model of the com-

ponent being designed or redesigned.

Symbolic representation of hydraulic circuits does not take the place of

drawings for manufacturing purposes.

Hydraulic Components

A hydraulic system consists of part or all of the following components:

1. Pump

2. Motor

314

J. B. Liljedahl et al., Tractors and their Power Units

© Van Nostrand Reinhold 1989

MOTOR PERFORMANCE 315

FIGURE 12-1 Schematic diagram of

double-acting cylinder.

3. Valves

4. Lines and connections

5. Heat exchanger

6. Sump (supply tank)

7. Accumulator (stored energy)

8. Controls (manual or automatic)

9. Fluid

10. Actuators

11. Filters

Pumps and motors are often quite similar and can sometimes be inter-

changed in their purpose. The simplest type of pump or motor is a hydraulic

cylinder (fig. 12-1). When hydraulic cylinders are arranged axially, as shown

in figure 12-2, the rate of flow through the pump can be regulated by con-

trolling the angle between the piston block and the swash plate, a common

method of control on a hydrostatic transmission.

Radial piston pumps (fig. 12-3) can also be used as motors. The displace-

ment of a radial piston pump can be controlled by allowing the pressure to

lift the pistons off the eccentric. By this method the pump unloads and does

not do any work except when the pressure drops sufficiently to force the

pistons back onto the eccentric.

A spur-gear pump is shown in figure 12-4. It is normally used on tractor

hydraulic systems of lower pressure.

The spur-gear, the internal-gear pump (fig. 12-5), the gerotor-gear pump

(fig. 12-6), and the vane-type pump (fig. 12-7) are all used on tractor hydraulic

systems where lower pressures are used.

Motor Performance*

Because efficiencies are often high, very accurate instrumentation is required

if the motor is externally loaded because a small error in measurement of

*This section also applies to pumps. Equations I and 2 should be inverted when used for pumps.

Anda mungkin juga menyukai

- Velammal Engineering College, Chennai - 600066.: Department of Mechanical Engineering University Question BankDokumen6 halamanVelammal Engineering College, Chennai - 600066.: Department of Mechanical Engineering University Question BankmurugesanvBelum ada peringkat

- Unit 1: Basics of Fluid Power and Pumps: Q. No. Description MarksDokumen1 halamanUnit 1: Basics of Fluid Power and Pumps: Q. No. Description MarksShivanand TalwarBelum ada peringkat

- HP Unit 1QBDokumen1 halamanHP Unit 1QBShivanand TalwarBelum ada peringkat

- ME080 Section 2 - Types of Hydraulic CircuitsDokumen55 halamanME080 Section 2 - Types of Hydraulic CircuitsAhmed FaragBelum ada peringkat

- Constructive-Functional Analysis of Single-Rod Double-Acting Hydraulic CylindersDokumen7 halamanConstructive-Functional Analysis of Single-Rod Double-Acting Hydraulic CylindersALEXSANDROBelum ada peringkat

- Automation and Robotics LabDokumen38 halamanAutomation and Robotics LabRanjit KumarBelum ada peringkat

- Mechatronics Lab ManualDokumen54 halamanMechatronics Lab ManualAjay Chacko100% (1)

- Fluid Power PDFDokumen13 halamanFluid Power PDFtony0% (1)

- Fluid Power DME 6TH SEMDokumen58 halamanFluid Power DME 6TH SEMAman Ahmed MokamiBelum ada peringkat

- Centre For Research and Industrial Staff PerformanceDokumen5 halamanCentre For Research and Industrial Staff PerformanceSourabh KhandelwalBelum ada peringkat

- Atm1122 Hydraulics Module 1Dokumen20 halamanAtm1122 Hydraulics Module 1Masood AlamBelum ada peringkat

- OHP Assignment 19122016 060442AMDokumen3 halamanOHP Assignment 19122016 060442AMPARMAR MAHENDRABelum ada peringkat

- Automationof DrillingmachinesDokumen7 halamanAutomationof Drillingmachinesdevang mishraBelum ada peringkat

- MEM 341 - Chapter 9 Hydraulic CircuitDokumen22 halamanMEM 341 - Chapter 9 Hydraulic CircuitMuhammad AbdullahBelum ada peringkat

- Doe-Hdbk-1016!1!93 Fluid Power PidDokumen13 halamanDoe-Hdbk-1016!1!93 Fluid Power PidmeirangongBelum ada peringkat

- Mechanical Equipment: Nuclear Training Course 23001 (NEIT 230.1)Dokumen59 halamanMechanical Equipment: Nuclear Training Course 23001 (NEIT 230.1)abuhurairaqaziBelum ada peringkat

- Steady State Performance Analysis of Hydrostatic Transmission System (HST)Dokumen4 halamanSteady State Performance Analysis of Hydrostatic Transmission System (HST)polat035Belum ada peringkat

- National Institute of TransportDokumen12 halamanNational Institute of TransportROYALNEWSSBelum ada peringkat

- Pe-4030 CH 4 Pneumatic and Hydraulic Actuation System Oct 29Dokumen99 halamanPe-4030 CH 4 Pneumatic and Hydraulic Actuation System Oct 29Charlton S.InaoBelum ada peringkat

- I IremosDokumen11 halamanI IremosWilliamBelum ada peringkat

- Aerospace Actuators 1: Needs, Reliability and Hydraulic Power SolutionsDari EverandAerospace Actuators 1: Needs, Reliability and Hydraulic Power SolutionsBelum ada peringkat

- Oil Hydraulics and Pneumatics IMP Question BankDokumen3 halamanOil Hydraulics and Pneumatics IMP Question Bankkishan mauryaBelum ada peringkat

- Basic Hydraulics and PneumaticsDokumen36 halamanBasic Hydraulics and PneumaticsKush Dilwal100% (1)

- Multi-Functional Loader Steering Hydraulic System Model Construction and Simulation Based On Power Bond GraphsDokumen7 halamanMulti-Functional Loader Steering Hydraulic System Model Construction and Simulation Based On Power Bond GraphsDeniezRamadhanBelum ada peringkat

- PT18PCMTL5 - Applied Hydraulics & Pneumatics LabDokumen37 halamanPT18PCMTL5 - Applied Hydraulics & Pneumatics LabvamshimohanBelum ada peringkat

- Ahp 2013 Imp PDFDokumen3 halamanAhp 2013 Imp PDFganeshkumarBelum ada peringkat

- Hydraulic System: Operación de SistemasDokumen5 halamanHydraulic System: Operación de Sistemasmiguel_catBelum ada peringkat

- Chapter 1. Introduction To Hydraulic & Pneumatic SystemsDokumen25 halamanChapter 1. Introduction To Hydraulic & Pneumatic SystemsHiphop OpBelum ada peringkat

- Department of Mechanical Engineering Question Bank Sub. Code/Name: ME1305 Applied Hydraulics and Pneumatics Year/Sem: III/VDokumen8 halamanDepartment of Mechanical Engineering Question Bank Sub. Code/Name: ME1305 Applied Hydraulics and Pneumatics Year/Sem: III/VVVCET - MechBelum ada peringkat

- Hydraulic SystemDokumen38 halamanHydraulic SystemTrường NguyenBelum ada peringkat

- BMT7L1-Fluid Power Automation LabDokumen37 halamanBMT7L1-Fluid Power Automation LabvamshimohanBelum ada peringkat

- Hydraulic System Design of Combined Harvester HeadDokumen7 halamanHydraulic System Design of Combined Harvester HeadEmma OkurutBelum ada peringkat

- Hydraulic CKT Colour CodeDokumen10 halamanHydraulic CKT Colour CodepawargdBelum ada peringkat

- Circuitos Hcos.Dokumen23 halamanCircuitos Hcos.Ramon PeyegrinBelum ada peringkat

- Applied Hydraulics and PneumaticsDokumen18 halamanApplied Hydraulics and PneumaticsJeba ChristoBelum ada peringkat

- HgaDokumen24 halamanHgaJenner Volnney Quispe ChataBelum ada peringkat

- ME 2305 Applied Hydraulics and Pneumatics: Dhanalakshmi Srinivasan Instuitute of Research and TechnologyDokumen10 halamanME 2305 Applied Hydraulics and Pneumatics: Dhanalakshmi Srinivasan Instuitute of Research and TechnologyAnonymous p8bHAAxBelum ada peringkat

- Ia Ha 2Dokumen4 halamanIa Ha 2Er Shubham RaksheBelum ada peringkat

- XL4100II - Technical Manual - 5-11Dokumen424 halamanXL4100II - Technical Manual - 5-11BarryBelum ada peringkat

- c4 - Components in Hydraulic SystemDokumen65 halamanc4 - Components in Hydraulic SystemBazil Suhaimi100% (1)

- Section 7.1: Wheel Drive Circuit - General SystemDokumen33 halamanSection 7.1: Wheel Drive Circuit - General SystemАндрей ТарковскийBelum ada peringkat

- Basic Hydraulics: Module 1: Introduction To HydraulicsDokumen43 halamanBasic Hydraulics: Module 1: Introduction To HydraulicsBayu RafliBelum ada peringkat

- Module 19 - Main Transformer Step Down Transformer and GCBDokumen67 halamanModule 19 - Main Transformer Step Down Transformer and GCBDipayan DasBelum ada peringkat

- Dmms Module 4Dokumen29 halamanDmms Module 4Luis OvalleBelum ada peringkat

- HP Question Paper 2023Dokumen3 halamanHP Question Paper 2023Monika BBelum ada peringkat

- Basic Hydraulics and PneumaticsDokumen41 halamanBasic Hydraulics and PneumaticsInnocent katengulaBelum ada peringkat

- Unit 2Dokumen6 halamanUnit 2hariharanbookBelum ada peringkat

- 8-1 - PDF - A - ZF CPower - Hydrostatic-Mechanical Powersplit TransmissionDokumen8 halaman8-1 - PDF - A - ZF CPower - Hydrostatic-Mechanical Powersplit Transmissionwalk111Belum ada peringkat

- Hydraulic Brake Systems and Components For Off-Highway Vehicles and EquipmentDokumen10 halamanHydraulic Brake Systems and Components For Off-Highway Vehicles and EquipmentJenner Volnney Quispe ChataBelum ada peringkat

- Actuation SystemDokumen11 halamanActuation SystemNavendu GuptaBelum ada peringkat

- AHP Question BankDokumen11 halamanAHP Question Bankduraiprakash83Belum ada peringkat

- Chap 1. Fundamental PrinciplesDokumen37 halamanChap 1. Fundamental Principlesbucyeye shema mireilleBelum ada peringkat

- CE1310 - Applied Hydraulics & PneumaticsDokumen10 halamanCE1310 - Applied Hydraulics & PneumaticsShyam MechBelum ada peringkat

- Hydraulic NoiseDokumen4 halamanHydraulic NoiseShyam KumarBelum ada peringkat

- Employing Analogue and Digital Solenoid Hydraulic Valves in Position Control SystemDokumen18 halamanEmploying Analogue and Digital Solenoid Hydraulic Valves in Position Control SystemKadi KadiroBelum ada peringkat

- Basic Hydraulics and Pneumatics: Module 1: Introduction To HydraulicsDokumen42 halamanBasic Hydraulics and Pneumatics: Module 1: Introduction To HydraulicsKevin ArteagaBelum ada peringkat

- BB831 Xa01xen E1Dokumen75 halamanBB831 Xa01xen E1Khaled Mahran100% (1)

- C4 - Components in Hydraulic SystemDokumen64 halamanC4 - Components in Hydraulic SystemKubheran SelvathuraiBelum ada peringkat

- Nominal Pipe Size in 1 2 3 4Dokumen5 halamanNominal Pipe Size in 1 2 3 4Sherin JohnBelum ada peringkat

- US-123218-06 MRB v1Dokumen1.726 halamanUS-123218-06 MRB v1sergioBelum ada peringkat

- LX02 19-09-19Dokumen106 halamanLX02 19-09-19jesus david villalobos rodriguezBelum ada peringkat

- Plumbing SystemDokumen16 halamanPlumbing SystemVholts Villa VitugBelum ada peringkat

- Section 4Dokumen5 halamanSection 4Eslam HusseinBelum ada peringkat

- 4L80 E VacTestLocationsDokumen4 halaman4L80 E VacTestLocationsPedroMecanico75% (4)

- Pump Test Analysis - Lecture - 8Dokumen8 halamanPump Test Analysis - Lecture - 8ritesh shawBelum ada peringkat

- Power Train Hydraulic System d7gDokumen3 halamanPower Train Hydraulic System d7gcristian chuquicondor torres100% (2)

- Tri P10Dokumen10 halamanTri P10Dvd Davide La CruzBelum ada peringkat

- Education City CHW Pump HeadDokumen33 halamanEducation City CHW Pump HeadAdnan AttishBelum ada peringkat

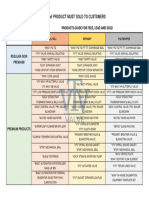

- List of Product Must Sold To Customers: Products Guide For Feed, Lead and SoldDokumen1 halamanList of Product Must Sold To Customers: Products Guide For Feed, Lead and SoldFendy ShirahBelum ada peringkat

- Routing Schematic Diagram: TRUE R5.500Dokumen2 halamanRouting Schematic Diagram: TRUE R5.500zamir zamirBelum ada peringkat

- 02 Ausschreibungstexte enDokumen35 halaman02 Ausschreibungstexte enneels06274Belum ada peringkat

- Brand FC PDFDokumen4 halamanBrand FC PDFhaggBelum ada peringkat

- Brake Diagram R620Dokumen1 halamanBrake Diagram R620heyru kiswantoBelum ada peringkat

- Pressure Regulating Valves: - AGECT-PRV-2015Dokumen10 halamanPressure Regulating Valves: - AGECT-PRV-2015Irwansyah CahyaBelum ada peringkat

- 7" Cementing Job Preparation For Pb-12 Wasundara Cementing: 1. Finding ReportDokumen1 halaman7" Cementing Job Preparation For Pb-12 Wasundara Cementing: 1. Finding ReportAfief Ma'rufBelum ada peringkat

- BoQ MEP Club House KosongDokumen53 halamanBoQ MEP Club House KosongkelikBelum ada peringkat

- Lab Report 2: BTM 2243 Fluid Power TechnologyDokumen5 halamanLab Report 2: BTM 2243 Fluid Power TechnologyIbrahim AdhamBelum ada peringkat

- Ehc Comet Electric Combi Boiler BrochureDokumen4 halamanEhc Comet Electric Combi Boiler BrochureroaltmatBelum ada peringkat

- Piston Pumps: "A" Series Piston Pumps Variable Displacement-Single, Double, Variable / Fixed DoubleDokumen91 halamanPiston Pumps: "A" Series Piston Pumps Variable Displacement-Single, Double, Variable / Fixed DoubleCARLOS RAMIREZBelum ada peringkat

- Loader Hydraulic Training CoursewareDokumen159 halamanLoader Hydraulic Training CoursewareGeorge Jhonson100% (22)

- Addis Ababa Science and Technology UniversityDokumen6 halamanAddis Ababa Science and Technology UniversitydemiseBelum ada peringkat

- Check List Hydrant in Door: NO Tanggal Dept Lokasi BOX Hose 2,5'' Hose 1.5'' Nozzle 1,5''Dokumen2 halamanCheck List Hydrant in Door: NO Tanggal Dept Lokasi BOX Hose 2,5'' Hose 1.5'' Nozzle 1,5''Bella ArieschaBelum ada peringkat

- Above and Below Ground Systems: Trade Catalogue - January 2022Dokumen146 halamanAbove and Below Ground Systems: Trade Catalogue - January 2022ANEBELLABelum ada peringkat

- Listado de Instrumentos - DescripciónDokumen33 halamanListado de Instrumentos - DescripciónDaniel Camargo Perez100% (1)

- Reading Plumbing PlansDokumen12 halamanReading Plumbing Planssolupa2000100% (1)

- Bronzeystrainer - Kvs 200 TDokumen1 halamanBronzeystrainer - Kvs 200 TTiến Lý NhậtBelum ada peringkat

- 06 Asme Teoria de MaterialesDokumen340 halaman06 Asme Teoria de MaterialesalexBelum ada peringkat

- Load Sense ControlDokumen2 halamanLoad Sense ControldnkBelum ada peringkat