Filtration in Hydrotreating

Diunggah oleh

ck19654840Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Filtration in Hydrotreating

Diunggah oleh

ck19654840Hak Cipta:

Format Tersedia

Filtration

Applications

in Hydrotreating

Hydrotreating is an essential refinery process in crude distillation with The most common filtration problems include solid and liquid

the goal of removing feed contaminants from downstream processes, contaminants in the fluid and gas streams originating from upstream

as well as converting low-value gas oils into valuable products that equipment, storage tanks and piping. These contaminants will foul the

meet stringent clean fuels specifications. Hydrotreaters remove sulfur reactor beds resulting in higher differential pressure that leads to

and other impurities from feedstock through catalytic conversion in a reduction in recycle hydrogen compressor performance. This will

hydrogen-rich environment over fixed catalyst beds at high cause refiners to reduce gas oil throughput in order to maintain the

temperatures and pressures. proper hydrogen to gas oil ratio resulting in direct revenue losses.

Contamination fouling will also cause catalyst deactivation (coking)

Types of Hydrotreating requiring refiners to raise temperatures in the reactor to compensate.

• Gasoline Hydrotreating If elevated long enough, deactivation occurs making it difficult to

Removes sulfur from gasoline blending components and reduces the maintain on-spec product leading to unplanned shutdowns to

olefins and aromatics content by saturating the double bonds with replaced fouled catalyst. In addition, contamination in hydrotreater

hydrogen. feed streams will cause problems in heat exchangers and hydrogen

compressors leading to costly repairs and downtime.

• Jet Fuel Hydrotreating

Improves the burning characteristics of jet fuel by increasing the

smoke point at which unburned hydrocarbons are released as smoke.

• Distillates Hydrotreating

Distillates used for diesel fuel are hydrotreated to reduce sulfur content

to meet ultra-low level sulfur mandates. In addition, hydrotreating

cracked light oils reduces the amount of aromatics compounds and

raises the octane levels.

• Cat Feed and Reformer Feed Hydrotreating

Cat reformer feeds are almost always hydrotreated prior to entering the

catalyst to protect the equipment and maintain optimal operating jonellinc.com • sales@jonellinc.com

conditions.

254-559-7591

• Additional Hydroteating Processes

Pyrolysis Gas, Kerosene, Residual Fuels, etc.

Benefits of an Optimized Hydrotreater

Filtration System include:

• Maintain stringent clean fuel requirements

• Improve production and operation efficiency

• Extend catalyst bed life

• Protect downstream equipment

• Reduce process upsets and downtime Global Filter • Jonell

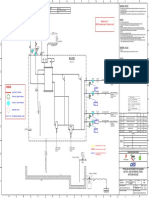

Jonell Filtration Applications in Hydrotreating

Quench Hydrogen Recycle Make-up Hydrogen

Hydrotreating Process Steps Compressor

• Hydrotreater feed is filtered to remove solid and

liquid contaminants and then is preheated by the

reactor effluent.

• Hydrogen is combined with the feed and heated

using a fired heater to the desired hydrotreating

temperature.

• The feed and hydrogen pass through a

hydrogenation reactor packed with various This schematic should be viewed

catalysts depending on the specific reaction as a general example of where

required. Fired

filtration systems could be located

Reactor

• Reactor effluent is cooled and enters the Heater within a hydrotreating process.

separator to separate the hydrogen from the liquid These processes will vary between

hydrocarbons and acid gas. 5 companies and facilities. As

such, each application should

• Purged hydrogen is filtered and recycled with Jonell Micro-LOKTM

or Micro-DEPTM be reviewed and considered

make-up hydrogen. Series Liquid/Gas

Coalescing Elements individually in order to choose the

• Acid gases are separated from the hydrocarbon Liquid/Gas correct system technology.

liquids in the steam stripper. Coalescer

• Hydrocarbon liquids are filtered to remove solid

and liquid contaminants before transfer to

fractionation.

Jonell LiquiPleatTM H2S Acid Gas

HF Series "High to Treatment

Flow" Liquid

Product to

Reactor Fractionator

Elements

1 Liquid/Liquid

Coalescer

4

Liquid/Liquid

Liquid Coalescer

Jonell

Particle Feed/Effluent Jonell LiquiPleatTM PhasePURTM

Hydrotreater Filter Exchanger HF Series or Phase-LOKTM Series

Feed "High Flow" Liquid/Liquid

Jonell PhasePURTM or 2 Liquid Elements Coalescing Elements

Phase-LOKTM Series

Liquid/Liquid Steam 3

Coalescing Elements Stripper

Effluent Cooler Separator

Liquid

Particle

Filter

Jonell Filter Solution Filter Purpose Filter Benefit

1 LiquiPleatTM HF Series (High Flow) Hydrotreater feed filtration removes Prevents unscheduled reactor downtime;

filter elements solid contaminants such as scale, reduced fouling in heat exchangers extending

rust, and solid particles time between maintenance and shutdowns;

fewer catalyst change-outs

2 PhasePUR™ or Phase-LOK™ Removal of water from hydrotreater Prevents unscheduled reactor downtime,

Series coalescing elements feedstock heat exchanger fouling, and extends

catalyst bed life

3 LiquiPleat™ HF Series Removes solid contaminants Protects downstream equipment,

(High Flow) filter elements such as scale and rust from reduces maintenance and labor costs

desulfurized product

4 PhasePUR™ or Phase-LOK™ Water removal from stabilized fuel Maintains liquid fuel specifications,

Series coalescing elements protects downstream equipment,

and reduces maintenance costs

5 Micro-LOK ™ or Micro-DEP™ Removal of liquids and solids Efficient hydrogen compressor operation

Series coalescing elements from recycle hydrogen and significantly reduced maintenance costs

Hydrotreating 10/16

Anda mungkin juga menyukai

- MRAP-TM 9-2355-106-23-1 MaxxPro Base PDFDokumen1.452 halamanMRAP-TM 9-2355-106-23-1 MaxxPro Base PDFabduallah muhammad50% (2)

- Case Crawler Excavator Cx75sr Cx80 Tier 3 Service ManualDokumen630 halamanCase Crawler Excavator Cx75sr Cx80 Tier 3 Service ManualPirates Ars100% (15)

- Gouging Procedure PDFDokumen11 halamanGouging Procedure PDFck19654840100% (1)

- 10 1016@j Jngse 2016 01 016Dokumen37 halaman10 1016@j Jngse 2016 01 016saiful bahriBelum ada peringkat

- Filter Separator English LetterDokumen2 halamanFilter Separator English Lettermarcoo8Belum ada peringkat

- UFC-85 Plants For Urea Fertilizer Projects: Recommended DosageDokumen8 halamanUFC-85 Plants For Urea Fertilizer Projects: Recommended Dosagevaratharajan g rBelum ada peringkat

- Medical Gas Pipeline Systems Ð: Part 1: Terminal Units For Compressed Medical Gases and VacuumDokumen18 halamanMedical Gas Pipeline Systems Ð: Part 1: Terminal Units For Compressed Medical Gases and Vacuumck19654840100% (2)

- JIG Bulletin 60 PDFDokumen6 halamanJIG Bulletin 60 PDFck19654840Belum ada peringkat

- Feasability Study For LNG Filling Station Infrastructure - EUDokumen307 halamanFeasability Study For LNG Filling Station Infrastructure - EUBenoit PuyoBelum ada peringkat

- Chart of AccountsDokumen21 halamanChart of AccountsJayRellvic Guy-ab100% (1)

- SOLA5052 - Biomass - '14 NotesDokumen19 halamanSOLA5052 - Biomass - '14 Notesf1attyBelum ada peringkat

- MAHLE IF PremiumSelectElements ENDokumen6 halamanMAHLE IF PremiumSelectElements ENJamin SmtpngBelum ada peringkat

- Seprasol Plus: Liquid/Gas CoalescersDokumen4 halamanSeprasol Plus: Liquid/Gas CoalescersSiavash YarahmadiBelum ada peringkat

- Cone Design ToolDokumen1 halamanCone Design ToolPramod KumarBelum ada peringkat

- AX5 Vaporizer Electric Water Bath Type LPG VaporizerDokumen2 halamanAX5 Vaporizer Electric Water Bath Type LPG VaporizerRicky DermawanBelum ada peringkat

- Coalescer PallDokumen16 halamanCoalescer PallJeEJyZaBelum ada peringkat

- 503 Systems - Indirect Fired Heaters - Eng - Apr2010 PDFDokumen8 halaman503 Systems - Indirect Fired Heaters - Eng - Apr2010 PDFsvnaik14Belum ada peringkat

- Flare Gas Recovery Data Sheet PDFDokumen1 halamanFlare Gas Recovery Data Sheet PDFMohamed AdelBelum ada peringkat

- Special Closures Literature2Dokumen2 halamanSpecial Closures Literature2ruben'sBelum ada peringkat

- FL1627Dokumen2 halamanFL1627Isaac Montero BarreraBelum ada peringkat

- Standard Hook-Up Wires & Cables For ElectronicsDokumen124 halamanStandard Hook-Up Wires & Cables For ElectronicsdlstoneBelum ada peringkat

- Petrogas Filtration CatalogueDokumen12 halamanPetrogas Filtration Catalogueleandroperao5374Belum ada peringkat

- KIRK KVME Mist EliminatorsDokumen2 halamanKIRK KVME Mist EliminatorsSHIBelum ada peringkat

- WelChem BubbleCapTray 2020-2Dokumen6 halamanWelChem BubbleCapTray 2020-2Joel OkohBelum ada peringkat

- Delivering Excellence in Combustion and Process HeatingDokumen11 halamanDelivering Excellence in Combustion and Process HeatingsajjadyasinBelum ada peringkat

- C:/Users/UDI/Job/PUSTEK E&T/PROJECT FOSTER/Air Cooler - Htri: 48 InchDokumen1 halamanC:/Users/UDI/Job/PUSTEK E&T/PROJECT FOSTER/Air Cooler - Htri: 48 InchFadhila Ahmad AnindriaBelum ada peringkat

- VGS Vane Separators Are Recommended ForDokumen1 halamanVGS Vane Separators Are Recommended ForSanthu PeelaBelum ada peringkat

- FItrLTERS PDFDokumen4 halamanFItrLTERS PDFAriz Joelee ArthaBelum ada peringkat

- Document Submission Status: FOR APPROVAL: Vung Ang 1 Thermal Power Plant 2 X 600Mw Lot M4A Cooling Water System (Bop)Dokumen10 halamanDocument Submission Status: FOR APPROVAL: Vung Ang 1 Thermal Power Plant 2 X 600Mw Lot M4A Cooling Water System (Bop)khang10182Belum ada peringkat

- E 106Dokumen1 halamanE 106Bith SMGBelum ada peringkat

- Pressurized Glycol Dehy SystemsDokumen11 halamanPressurized Glycol Dehy SystemsJagan BoseBelum ada peringkat

- Ultipor HT For Hot Liquid ServiceDokumen2 halamanUltipor HT For Hot Liquid ServiceMustafa DaoudBelum ada peringkat

- Flare Gas Recovery PDFDokumen13 halamanFlare Gas Recovery PDFSadad MohamadBelum ada peringkat

- Quick-Opening Closures SurveyDokumen13 halamanQuick-Opening Closures SurveyAjmi HmidaBelum ada peringkat

- 3.0 Systems Division-FiltersDokumen8 halaman3.0 Systems Division-Filtersmatteo2009Belum ada peringkat

- AFRC - Improving Performance of Coker HeatersDokumen29 halamanAFRC - Improving Performance of Coker Heatersashutosh_garg_10Belum ada peringkat

- Hydrocarbon Recovery: JUNIO 2017Dokumen32 halamanHydrocarbon Recovery: JUNIO 2017Soniale Sánchez GómezBelum ada peringkat

- A Quick Look at DesaltingDokumen12 halamanA Quick Look at Desaltingananth2012Belum ada peringkat

- Thermal Degassing Fundamentals R4i1 enDokumen6 halamanThermal Degassing Fundamentals R4i1 enAnonymous v5uipHBelum ada peringkat

- Bunner ControlDokumen19 halamanBunner ControlHai NguyenBelum ada peringkat

- 143 756 Flowatch 2013 1Dokumen8 halaman143 756 Flowatch 2013 1YLW-BEKASIBelum ada peringkat

- Natural Gas Filtration & Separation: To Separate Solid & Liquid Impurities From Natural GasDokumen7 halamanNatural Gas Filtration & Separation: To Separate Solid & Liquid Impurities From Natural GasMehdi Hajd KacemBelum ada peringkat

- BETTIS Product Selection Guide: A Complete Offering of Valve Automation SolutionsDokumen6 halamanBETTIS Product Selection Guide: A Complete Offering of Valve Automation SolutionsVinothkumarBelum ada peringkat

- MP60P70Dokumen28 halamanMP60P70903352Belum ada peringkat

- Amberjet 4200 DatasheetDokumen2 halamanAmberjet 4200 DatasheetXiaLUBelum ada peringkat

- Appendix 1 - Mark-Up PID Service Test Antifoam SkigDokumen2 halamanAppendix 1 - Mark-Up PID Service Test Antifoam SkigARDI UMAR ZULFIKARBelum ada peringkat

- DesalterDokumen2 halamanDesalterHimanshu SharmaBelum ada peringkat

- Water Bath Heater Writeup PDFDokumen2 halamanWater Bath Heater Writeup PDFJayesh SanganiBelum ada peringkat

- Random PackingDokumen4 halamanRandom PackingAadam AryanBelum ada peringkat

- Redundant Solenoid ValveDokumen2 halamanRedundant Solenoid ValveAmanda PorterBelum ada peringkat

- Castable-Free Fired HeaterDokumen4 halamanCastable-Free Fired HeaterchemengseliemBelum ada peringkat

- Process Vessels 93851 - 18 PDFDokumen19 halamanProcess Vessels 93851 - 18 PDFNector Jr. GuevarraBelum ada peringkat

- Design of Shell & Tube HX (Unprotected For Expert Excel Users)Dokumen31 halamanDesign of Shell & Tube HX (Unprotected For Expert Excel Users)Sameer ChaturvediBelum ada peringkat

- Waste Incineration Heat Recovery at Roche IrelandDokumen12 halamanWaste Incineration Heat Recovery at Roche IrelandidrieshamidiBelum ada peringkat

- Compressors How To Achieve High Reliability & Availability (Electronics)Dokumen55 halamanCompressors How To Achieve High Reliability & Availability (Electronics)Anonymous IGtWHoi0Belum ada peringkat

- CECO Environmental Presentaton - Gabelli Q122 Waste Environ. Serv. Symposium - 033122Dokumen28 halamanCECO Environmental Presentaton - Gabelli Q122 Waste Environ. Serv. Symposium - 033122teddyfang21Belum ada peringkat

- Filtration and Separation in RefineriesDokumen30 halamanFiltration and Separation in RefineriesprogerBelum ada peringkat

- 3B 17644019 Proses MeroxDokumen1 halaman3B 17644019 Proses MeroxMohammad Rezza PachruraziBelum ada peringkat

- Gas (Amine) Sweetening Process - Jonell Filtration Applications GasSweet 1015Dokumen2 halamanGas (Amine) Sweetening Process - Jonell Filtration Applications GasSweet 1015Bob PeppingBelum ada peringkat

- $TEMA Sheet Gas Chiller Rev 2Dokumen1 halaman$TEMA Sheet Gas Chiller Rev 2HudaFiHayyatBelum ada peringkat

- Gas Filter Separators 4Dokumen8 halamanGas Filter Separators 4Anonymous bHh1L1Belum ada peringkat

- E07 QDokumen20 halamanE07 QSoledad Fernández SantosBelum ada peringkat

- Chlorine: International Thermodynamic Tables of the Fluid StateDari EverandChlorine: International Thermodynamic Tables of the Fluid StateBelum ada peringkat

- Preparation of Catalysts II: Scientific Bases for the Preparation of Heterogeneous CatalystsDari EverandPreparation of Catalysts II: Scientific Bases for the Preparation of Heterogeneous CatalystsBelum ada peringkat

- Hydro CrackingDokumen25 halamanHydro CrackingBharat KumarBelum ada peringkat

- HydrocrackingDokumen24 halamanHydrocrackingSaj BhaiBelum ada peringkat

- Chapter 5a - HydrocrackingDokumen26 halamanChapter 5a - Hydrocrackingazizia harmes0% (1)

- Calculating Maximum Tube Metal TemperaturesDokumen12 halamanCalculating Maximum Tube Metal Temperaturesck19654840Belum ada peringkat

- Document PDFDokumen4 halamanDocument PDFck19654840Belum ada peringkat

- API 579 Fitness For Service For Nozzles and Flanges (APIFFSB) Module OverviewDokumen49 halamanAPI 579 Fitness For Service For Nozzles and Flanges (APIFFSB) Module Overviewck19654840Belum ada peringkat

- G4051 S45C PDFDokumen1 halamanG4051 S45C PDFck19654840100% (1)

- Spherical Pressure Vessels PDFDokumen10 halamanSpherical Pressure Vessels PDFck19654840Belum ada peringkat

- Radiation Protection Program PDFDokumen49 halamanRadiation Protection Program PDFck19654840Belum ada peringkat

- Cooling Tower Components PDFDokumen4 halamanCooling Tower Components PDFck19654840Belum ada peringkat

- Distillation Column Basics PDFDokumen4 halamanDistillation Column Basics PDFck19654840Belum ada peringkat

- NDT RT PDFDokumen13 halamanNDT RT PDFck19654840Belum ada peringkat

- Thermo Scientific Niton XL3t: A History of InnovationDokumen2 halamanThermo Scientific Niton XL3t: A History of Innovationck19654840Belum ada peringkat

- Felleslab: Distillation Columns: SeparationDokumen20 halamanFelleslab: Distillation Columns: Separationck19654840Belum ada peringkat

- Technical Bulletin: Hydrant Servicer Filter Monitor VesselsDokumen3 halamanTechnical Bulletin: Hydrant Servicer Filter Monitor Vesselsck19654840Belum ada peringkat

- Product Quality: Jet Fuel ConductivityDokumen4 halamanProduct Quality: Jet Fuel Conductivityck19654840Belum ada peringkat

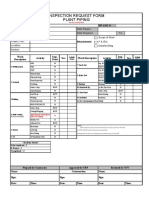

- Inspection Request For WeldingDokumen1 halamanInspection Request For Weldingck19654840Belum ada peringkat

- Inspection Request Form Plant PipingDokumen1 halamanInspection Request Form Plant Pipingck19654840Belum ada peringkat

- (Commercial Vehicle Technology) Michael Hilgers, Wilfried Achenbach - The Diesel Engine-Springer Vieweg (2021)Dokumen85 halaman(Commercial Vehicle Technology) Michael Hilgers, Wilfried Achenbach - The Diesel Engine-Springer Vieweg (2021)Shah SchwarzmmanBelum ada peringkat

- Wynns ProfessionalDokumen11 halamanWynns ProfessionalLiviu PopescuBelum ada peringkat

- Plogarithm Edited Report 1 NowDokumen44 halamanPlogarithm Edited Report 1 NowSrinivasa bnBelum ada peringkat

- 04 Saripah SobahDokumen8 halaman04 Saripah SobahArdifal JumaidiBelum ada peringkat

- 2E F1 eDokumen84 halaman2E F1 eRodel Andales100% (1)

- Astm d975 2007Dokumen36 halamanAstm d975 2007Osama FouadBelum ada peringkat

- Performance Analysis of Biodiesel For Domestic UseDokumen6 halamanPerformance Analysis of Biodiesel For Domestic UseTeshome DengisoBelum ada peringkat

- AFES AT6002 Notes PDFDokumen79 halamanAFES AT6002 Notes PDFrahul100% (1)

- Common Rail Diesel InjectionDokumen13 halamanCommon Rail Diesel InjectionDejan Matic67% (3)

- Wartsila Me Operations ManualDokumen373 halamanWartsila Me Operations ManualsridharsharmaBelum ada peringkat

- Auxiliary Heater PDFDokumen32 halamanAuxiliary Heater PDFab23Belum ada peringkat

- 1 s2.0 S0016236121017002 MainDokumen22 halaman1 s2.0 S0016236121017002 MainbcherejiBelum ada peringkat

- IROX 2000 Irox Diesel: Improvement Through InnovationDokumen8 halamanIROX 2000 Irox Diesel: Improvement Through InnovationIsaac Florencia CruzBelum ada peringkat

- GigaDokumen5 halamanGigaWahidSyahruRamadhanBelum ada peringkat

- Clean Fuel TechnologyDokumen52 halamanClean Fuel TechnologyGarry DavidBelum ada peringkat

- UOP Hydroprocessing Innovations Supplement TechDokumen0 halamanUOP Hydroprocessing Innovations Supplement Techasrahaman9100% (1)

- Generating of Fuel From Plastic WasteDokumen6 halamanGenerating of Fuel From Plastic WasteInternational Journal of Innovative Science and Research TechnologyBelum ada peringkat

- Mustafa Akbarzai Full AnallysisDokumen91 halamanMustafa Akbarzai Full AnallysisHashir KhanBelum ada peringkat

- DDokumen45 halamanDLeon PeterBelum ada peringkat

- Outline of Diesel Hydrotreating Unit (DHT Unit)Dokumen4 halamanOutline of Diesel Hydrotreating Unit (DHT Unit)Anwar SadatBelum ada peringkat

- Effect of Fuel Magnetism On Industrial Oil Burner Performance Burning Waste Cooking OilDokumen13 halamanEffect of Fuel Magnetism On Industrial Oil Burner Performance Burning Waste Cooking OilĐược Phùng100% (1)

- 04 Chapter 4Dokumen39 halaman04 Chapter 4korangaprakashBelum ada peringkat

- Amsoil Premium API CJ-4 5W-40 Synthetic Diesel Oil (DEO) - Data BulletinDokumen2 halamanAmsoil Premium API CJ-4 5W-40 Synthetic Diesel Oil (DEO) - Data BulletinamsoilromaniaBelum ada peringkat

- Journal of Analytical and Applied PyrolysisDokumen9 halamanJournal of Analytical and Applied PyrolysisAruzza AraújoBelum ada peringkat

- High Fuel Prices in India What Are The CausesDokumen3 halamanHigh Fuel Prices in India What Are The CausesSumanta PaulBelum ada peringkat