SSEG-003 ElecGlycolConversion Web

Diunggah oleh

Anonymous bHh1L1Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

SSEG-003 ElecGlycolConversion Web

Diunggah oleh

Anonymous bHh1L1Hak Cipta:

Format Tersedia

ENERGY EXCHANGE PUMP TO

ELECTRIC GLYCOL PUMP CONVERSION

THE BASICS

The Kimray Electric Glycol Pump is a robust glycol circulation

solution. Below are some steps you can take to simplify the

installation and operation of the pump.

The pump should be securely mounted to the dehy-

dration unit.

Use flexible hoses for the inlet and outlet of the pump to

reduce vibration. Even though the Kimray pump is nearly

pulsation free, vibration may occur.

Install the hoses as straight as possible. When installing

bypass piping, avoid using 90 degree connections. Make

sure to use isolation valves before and after the pump and

around bypass lines.

Unlike the energy exchange pump, which has four connections,

the Kimray electric pump has two connections. The inlet to the

electric pump is supplied from the dry glycol, low-pressure line

coming from the reboiler. The electric pump requires hydrostatic

head pressure to supply glycol to the pump; it will not pull the

glycol. The pump should be mounted to ensure proper glycol

feed to the pump. It will need to be mounted several feet lower

than the reboiler surge tank. The outlet of the electric pump will

be connected to the dry glycol, high-pressure line going to the

contact tower.

ADJUSTING THE FLOW RATE

The flow rate of the electric pump is directly proportional to the Bypass Loop - With the motor mounted directly to the

RPMs of the pump shaft. Varying the flow rate of the pump requires pump, a bypass loop from the pump outlet to the reboiler

an external method for reducing the RPM of the shaft. is installed. The motor and pump will run at a fixed RPM

and flow rate. The surplus of glycol is diverted back to

This can be accomplished in several ways:

the reboiler by way of the bypass loop. This will require

the installation of a metering valve between the pump

VFD (Variable Frequency Drive) - A VFD receives an

outlet and reboiler with a check valve installed on the

input from the systems control computer to regulate the

pump outlet between the metering valve connections

motor’s RPMs. This results in an increase or decrease of

and the contact tower.

the pump’s flow rate.

Pulley System - Pulleys can be connected between

the motor and the pump to vary the speed of the pump.

The size of the pulleys can be calculated to achieve the

correct RPMs of the pump and the desired flow rate.

This method does not require an external controller to

increase or decrease motor speed.

ADAPTING THE CONTACT TOWER

With a Kimray Energy Exchange Pump installation, the high- an electric pump. This will require an external float cage

pressure wet glycol from the contact tower enters the Kimray to be installed on the contact tower.

pump. When using a Kimray Electric Glycol Pump, this connection

is no longer required; the high-pressure wet glycol is piped Electronic Level Controller - An electronic level

directly to the reboiler. The electric pump receives the glycol from controller can give you emissions free level control. This

the low-pressure dry glycol exiting the reboiler. will require an external float cage to be installed on the

contact tower.

The electric pump will not maintain a constant glycol level in

the contact tower. The following additions will need to be made Control Valve - The control valve will need to be sized

to compensate: appropriately for the proper glycol flow rate. The control

valve should be installed on the glycol outlet piping of

Level Controller - A level controller will need to be added the contact tower. The valve pressure rating needs to

to the contact tower to regulate the glycol level. be equal or higher than the vessel pressure rating. It

There are several options available for level control: can be pneumatically operated from the level control or

electronically actuated to eliminate emissions.

Pneumatic Level Controller - A pneumatic level controller

is the most popular and practical method of converting to

USING THE

The energy exchange pump can remain wet glycol line will need to be interrupted

as a back-up to the electric pump. This is with two isolated valves connected to the

accomplished by using bypass loops and energy exchange pump. The dry glycol line

ENERGY

isolation valves. The bypass valves can be will also need to be interrupted with two

electric if you prefer an automatic switch in isolated valves connected to the energy

the event of a power loss, or you can use ball exchange pump.

EXCHANGE

valves for manual operation.

The electric pump will need isolation valves

The contact tower will need a bypass loop on the inlet and outlet glycol lines for when

PUMP AS

around the glycol control valve. This will the energy exchange pump is in use.

allow the energy exchange pump to control

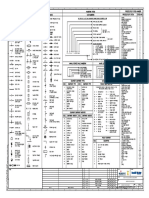

the glycol level in the contact tower. Note the P & ID drawing on the next page.

BACK-UP The energy exchange pump will need

isolation valves on all four glycol lines. The

For more information visit Kimray.com

TYPICAL ELECTRIC GLYCOL PUMP INSTALLATION

WITH ENERGY EXCHANGE BACK-UP

High Pressure Low Pressure

Contacting System TIC Vapor

Regeneration System

TCV Outlet

Reflux

Column

Gas/Glycol

Heat Exchanger

Gas To Fuel, Sales,

LC Instruments, etc. Surge Reboiler

Gas

Outlet Skimmer LC

Wet Glycol Fuel

Glycol Gas

Gas Glycol/Glycol

Inlet Scrubber LCV NGL Heat Exchanger

Condensate

Contact

Tower

To Drain Sock Charcoal

Filter Filter

Dry Glycol

Energy Exchange

Back-up Pump

Glycol

Circulation Pump

TYPICAL KIMRAY

ELECTRIC GLYCOL PUMP INSTALLATION

High Pressure Low Pressure Vapor

Regeneration System TIC

Contacting System TCV Outlet

Wet Glycol Reflux

Column

Distillation

Column

Gas To Fuel, Sales,

LCV Instruments, etc. Surge Reboiler

LC

Skimmer LC

Fuel

Glycol Gas

Gas/Glycol

Gas Scrubber Heat Exchanger Glycol/Glycol

Inlet Heat Exchanger

Contact NGL

Tower To Gas Condensate Sock Charcoal

Drain Outlet Filter Filter Dry Glycol

Glycol

Circulation Pump

Kimray.com

© 2014 Kimray, Inc. 2/16 SSEG-003 Electric Glycol Conversion

Anda mungkin juga menyukai

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Dari EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Penilaian: 2.5 dari 5 bintang2.5/5 (3)

- Application of VFD in Cycling Pumps in Thermal Power PlantDokumen10 halamanApplication of VFD in Cycling Pumps in Thermal Power PlantJose Manuel FreitasBelum ada peringkat

- Hydraulic-Electric Analogies:: Hydraulic Power Conversion, Part 2Dokumen2 halamanHydraulic-Electric Analogies:: Hydraulic Power Conversion, Part 2Anonymous erirwceBelum ada peringkat

- PWM and Pump Control ExplainedDokumen1 halamanPWM and Pump Control Explainedolsonjames544Belum ada peringkat

- Pump and Motor Failure in A Hot Potassium-Carbonate SystemAiche-1981-010Dokumen4 halamanPump and Motor Failure in A Hot Potassium-Carbonate SystemAiche-1981-010Hsein WangBelum ada peringkat

- Sump PumpDokumen5 halamanSump PumpTanvir ChowdhuryBelum ada peringkat

- PL 100 Bomba Gas LPGDokumen16 halamanPL 100 Bomba Gas LPGmarvin2008Belum ada peringkat

- Part 5 - Two Approaches To Capacity Control - A7545Dokumen4 halamanPart 5 - Two Approaches To Capacity Control - A7545alfador_yxBelum ada peringkat

- TurbineDokumen28 halamanTurbinedilbagh_scribd100% (1)

- MCT 2Dokumen3 halamanMCT 2Sylesh SreehariBelum ada peringkat

- Chapter Three Automatic Generation ControlDokumen53 halamanChapter Three Automatic Generation ControlLemessa YalewBelum ada peringkat

- Cold Startup Procedure 250 MWDokumen7 halamanCold Startup Procedure 250 MWPrudhvi RajBelum ada peringkat

- Reliable Technology For Continuous Operation: Technical DescriptionDokumen12 halamanReliable Technology For Continuous Operation: Technical DescriptionPaola Armas100% (1)

- WS Module 3Dokumen92 halamanWS Module 3sebastian vindro jude PanimayamBelum ada peringkat

- TurbineDokumen28 halamanTurbinesuri345Belum ada peringkat

- Kurimat Solar GTO - 601-700Dokumen100 halamanKurimat Solar GTO - 601-700Mohamed AbdelbadieBelum ada peringkat

- Piston and Bladder Type Safety Note: Applications: Hydraulic AccumulatorsDokumen3 halamanPiston and Bladder Type Safety Note: Applications: Hydraulic AccumulatorsconimecBelum ada peringkat

- Mini Hydal Power PlantDokumen18 halamanMini Hydal Power PlantNoufalBelum ada peringkat

- (G) 72K Series Installation and Operation Instruction: Electrohydraulic ServovalveDokumen4 halaman(G) 72K Series Installation and Operation Instruction: Electrohydraulic Servovalvephankhoa83-1Belum ada peringkat

- Manual-Boiler-Feed-IND (1) - 10-14 PDFDokumen5 halamanManual-Boiler-Feed-IND (1) - 10-14 PDFHicham IdrisiBelum ada peringkat

- Automotive Engineering 56 Automotive Engineering: Delivery ValveDokumen4 halamanAutomotive Engineering 56 Automotive Engineering: Delivery Valveanantheshk100% (1)

- ABB Instrumentation: Pipeline Booster Station Control SystemsDokumen6 halamanABB Instrumentation: Pipeline Booster Station Control SystemsPatricio AcuñaBelum ada peringkat

- CCI Power ApplicationsDokumen57 halamanCCI Power Applicationssukanya_ravichandran100% (1)

- ChecktronicDokumen12 halamanChecktronicYaslin Maria Marquez HernandezBelum ada peringkat

- Goulds/Vogel Hydrovar: What Is The Hydrovar?Dokumen25 halamanGoulds/Vogel Hydrovar: What Is The Hydrovar?Israel ColinaBelum ada peringkat

- Pajero Full 2008 15Dokumen81 halamanPajero Full 2008 15Antonio Gaspar100% (1)

- 4801 GBDokumen2 halaman4801 GBMuhd Khir Razani100% (1)

- Camless EnginesDokumen10 halamanCamless EnginesGaurav ShindolkarBelum ada peringkat

- Starting SystemDokumen34 halamanStarting SystemGetachew Tikue100% (2)

- Hydraulic and Pneumatic Systems by Batch1 17M101,102,107,108,109,110Dokumen49 halamanHydraulic and Pneumatic Systems by Batch1 17M101,102,107,108,109,110Agash ChellappaBelum ada peringkat

- Power Unit PDFDokumen17 halamanPower Unit PDFgawaBelum ada peringkat

- Pompa de Curent Continuu Laing PliantDokumen4 halamanPompa de Curent Continuu Laing Pliantsamasca_serbanBelum ada peringkat

- Fairbanks Nijhuis Fire Pumps Brochure PDFDokumen8 halamanFairbanks Nijhuis Fire Pumps Brochure PDFEko ParjonoBelum ada peringkat

- 1300-121 Systems One Seed Jet II Closed Center Hydraulic System ManualDokumen12 halaman1300-121 Systems One Seed Jet II Closed Center Hydraulic System Manualwasihun wodajeBelum ada peringkat

- Cooling Tower Pumping and PipingDokumen52 halamanCooling Tower Pumping and PipingRony henneryBelum ada peringkat

- Governing, Ignition System, Fire OrderDokumen33 halamanGoverning, Ignition System, Fire OrderProf. Jignesh Sohaliya100% (1)

- Governing SystemDokumen8 halamanGoverning SystemVamsikrishna LakamsaniBelum ada peringkat

- Maintaining HVAC Pumps: Source: HVAC Pump HandbookDokumen6 halamanMaintaining HVAC Pumps: Source: HVAC Pump HandbookDaring CodybillyBelum ada peringkat

- Application Induction Motor FOR Water Pumping: OF SolarDokumen4 halamanApplication Induction Motor FOR Water Pumping: OF Solararadhyula praveenraju yadavBelum ada peringkat

- Steam Turbine CogenerationDokumen5 halamanSteam Turbine CogenerationChemical engineeringBelum ada peringkat

- SUN Compression TesterDokumen8 halamanSUN Compression TesterWongstorn DamrongmaneeBelum ada peringkat

- Governing System of TurbineDokumen8 halamanGoverning System of Turbinebimal213100% (1)

- Hydromatic: Submersible Sewage PumpDokumen10 halamanHydromatic: Submersible Sewage Pumpاحمد همامBelum ada peringkat

- 3-Way Temperature Control Valve: Model G, Versions GEF, GPD and AccessoriesDokumen19 halaman3-Way Temperature Control Valve: Model G, Versions GEF, GPD and AccessoriesFirman SetyajiBelum ada peringkat

- MAUPOUX 2010 Solar Water PumpingDokumen9 halamanMAUPOUX 2010 Solar Water PumpingNirob MahmudBelum ada peringkat

- Servo Electrohydraulic760 - CDS6541 - GDokumen4 halamanServo Electrohydraulic760 - CDS6541 - GGuillermoBelum ada peringkat

- D S Henderson Napier University, UK.: Variable Speed Electric Drives - Characteristics and ApplicationsDokumen8 halamanD S Henderson Napier University, UK.: Variable Speed Electric Drives - Characteristics and ApplicationsscrsanBelum ada peringkat

- Models S3S (D) /S4S (D) and SB3S (D) /SB4S (D) : Submersible Sewage Pump Dual Seal PumpsDokumen12 halamanModels S3S (D) /S4S (D) and SB3S (D) /SB4S (D) : Submersible Sewage Pump Dual Seal PumpsGautami Ashok ArkadeBelum ada peringkat

- GOVERNORS - Speed and Droop Control FundamentalsDokumen23 halamanGOVERNORS - Speed and Droop Control FundamentalsMoetaz TahaBelum ada peringkat

- Control Valve 1103Dokumen5 halamanControl Valve 1103partho143Belum ada peringkat

- Seminar Report ON "Solar Pump"Dokumen32 halamanSeminar Report ON "Solar Pump"api-19775783100% (2)

- Chapter - 1: Cycle Operated Centrifugal Water PumpDokumen44 halamanChapter - 1: Cycle Operated Centrifugal Water PumpTushar KhorateBelum ada peringkat

- Valve Actuator Selection GuideDokumen3 halamanValve Actuator Selection GuideBramJanssen76100% (1)

- Maximizing Hydroelectric Turbine Performance and ReliabilityDokumen6 halamanMaximizing Hydroelectric Turbine Performance and Reliabilityturbo385Belum ada peringkat

- Fire Pumps in Accordance EN 12845+A2 GuideDokumen30 halamanFire Pumps in Accordance EN 12845+A2 GuideNajaf HussainBelum ada peringkat

- Reciprocating and Jet Hydraulic PumpsDokumen8 halamanReciprocating and Jet Hydraulic PumpsИлияс ИсатайулыBelum ada peringkat

- Chrysler New Yorker 1988 1989 1990 1991 1992 1993 Repair Service Manual FREE PDF DOWNLOADDokumen40 halamanChrysler New Yorker 1988 1989 1990 1991 1992 1993 Repair Service Manual FREE PDF DOWNLOADsen til100% (3)

- Stan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineDari EverandStan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazinePenilaian: 5 dari 5 bintang5/5 (1)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Dari EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Belum ada peringkat

- Settling Velocity (Deposition) Stokes' Law: - Stokes' Solution With The AssumptionsDokumen4 halamanSettling Velocity (Deposition) Stokes' Law: - Stokes' Solution With The AssumptionsGireesh Gowda GiriBelum ada peringkat

- Revised Process Datasheet For Deaerator Ma-1018 - Rev 001 - SignedDokumen10 halamanRevised Process Datasheet For Deaerator Ma-1018 - Rev 001 - SignedAnonymous bHh1L1Belum ada peringkat

- KCD 11176R2: 11176R2.xlsx Page 1 of 9 6/14/22Dokumen9 halamanKCD 11176R2: 11176R2.xlsx Page 1 of 9 6/14/22Anonymous bHh1L1Belum ada peringkat

- BS&B Process System Inc Fired Heater Input SheetDokumen52 halamanBS&B Process System Inc Fired Heater Input SheetAnonymous bHh1L1Belum ada peringkat

- Bk91 1310 CPF 114 Mef Das 0003 - C - Data Sheet For Stabilizer (CPF 114 C 03cpf 214 C 03)Dokumen34 halamanBk91 1310 CPF 114 Mef Das 0003 - C - Data Sheet For Stabilizer (CPF 114 C 03cpf 214 C 03)Anonymous bHh1L1Belum ada peringkat

- Techno-Commercial OfferDokumen17 halamanTechno-Commercial OfferAnonymous bHh1L1Belum ada peringkat

- q226030 Gdu PidDokumen17 halamanq226030 Gdu PidAnonymous bHh1L1Belum ada peringkat

- Revised Process Datasheet For Deaerator Ma-1018 - Rev 001 - SignedDokumen10 halamanRevised Process Datasheet For Deaerator Ma-1018 - Rev 001 - SignedAnonymous bHh1L1Belum ada peringkat

- Macelo Vargas Querino Federal University of Santa Catarina Brazil R N R NDokumen16 halamanMacelo Vargas Querino Federal University of Santa Catarina Brazil R N R NAnonymous bHh1L1Belum ada peringkat

- Leading Tray TechnologyDokumen24 halamanLeading Tray TechnologyAnonymous bHh1L1Belum ada peringkat

- TENDER NO: 22-054-730 Request For Quotation: of 25 REV: 0 DATE: MAY 05, 2021Dokumen25 halamanTENDER NO: 22-054-730 Request For Quotation: of 25 REV: 0 DATE: MAY 05, 2021Anonymous bHh1L1Belum ada peringkat

- Extracted Pages From MCB-0004-11AA-M-A27-0013-B2 LDV-A ITB For Gas Dehydration Package UpdatedDokumen3 halamanExtracted Pages From MCB-0004-11AA-M-A27-0013-B2 LDV-A ITB For Gas Dehydration Package UpdatedAnonymous bHh1L1Belum ada peringkat

- PTG Gas Coalescing FiltersDokumen6 halamanPTG Gas Coalescing FiltersAnonymous bHh1L1Belum ada peringkat

- M 367 ContentDokumen55 halamanM 367 ContentAnonymous bHh1L1Belum ada peringkat

- Gas Filter Separators 4Dokumen8 halamanGas Filter Separators 4Anonymous bHh1L1Belum ada peringkat

- Merchant Other Up I DisplayDokumen2 halamanMerchant Other Up I DisplayAnonymous bHh1L1Belum ada peringkat

- Gas Particulate Filter 1 1Dokumen4 halamanGas Particulate Filter 1 1Anonymous bHh1L1Belum ada peringkat

- Peco Series PCHG: Peach Dynasep Peach Depth Style Gas Filter-Separator CartridgesDokumen2 halamanPeco Series PCHG: Peach Dynasep Peach Depth Style Gas Filter-Separator CartridgesSiavash YarahmadiBelum ada peringkat

- Re-Issued For Construction - Surface Facility Design Process P&IDs R1 (Mod 05)Dokumen1 halamanRe-Issued For Construction - Surface Facility Design Process P&IDs R1 (Mod 05)Anonymous bHh1L1Belum ada peringkat

- Certificate of Achievement: Gowrishankar NsDokumen1 halamanCertificate of Achievement: Gowrishankar NsAnonymous bHh1L1Belum ada peringkat

- DurathermVsTherminolVsDowtherm Es en HSEDokumen5 halamanDurathermVsTherminolVsDowtherm Es en HSEAnonymous bHh1L1Belum ada peringkat

- ROTECH Queries To Rotech API 682 Q206033Dokumen1 halamanROTECH Queries To Rotech API 682 Q206033Anonymous bHh1L1Belum ada peringkat

- Permit Sample Evaluation Natural Gas Fired Boiler 5-20 Mmbtu/HrDokumen8 halamanPermit Sample Evaluation Natural Gas Fired Boiler 5-20 Mmbtu/HrAnonymous bHh1L1Belum ada peringkat

- Read MineDokumen1 halamanRead MineAnonymous bHh1L1Belum ada peringkat

- NotesDokumen1 halamanNotesAnonymous bHh1L1Belum ada peringkat

- Gowrishankar NSDokumen1 halamanGowrishankar NSAnonymous bHh1L1Belum ada peringkat

- Kern Method Heat ExchangerDokumen30 halamanKern Method Heat ExchangerCS100% (3)

- HDFC Ergo 1737761219Dokumen1 halamanHDFC Ergo 1737761219Anonymous bHh1L1Belum ada peringkat

- Read MeDokumen1 halamanRead MeAnonymous bHh1L1Belum ada peringkat

- Analyzer and ChromatographDokumen1 halamanAnalyzer and ChromatographAnonymous bHh1L1Belum ada peringkat

- Safety Data Sheet: 1. IdentificationDokumen7 halamanSafety Data Sheet: 1. IdentificationKhobeb MuslimBelum ada peringkat

- Bock09 - Video Compression SystemsDokumen300 halamanBock09 - Video Compression SystemsWong_Ngee_SengBelum ada peringkat

- International Standard Paper SizesDokumen34 halamanInternational Standard Paper SizesAman KumarBelum ada peringkat

- Aspire 7535 ManualDokumen220 halamanAspire 7535 ManualinklabsBelum ada peringkat

- Karunungang BayanDokumen6 halamanKarunungang BayanGeronimo DiazBelum ada peringkat

- Subcontracting Process in Production - SAP BlogsDokumen12 halamanSubcontracting Process in Production - SAP Blogsprasanna0788Belum ada peringkat

- What Is New in API 610 11th EdDokumen6 halamanWhat Is New in API 610 11th EdAnonymous 1XHScfCIBelum ada peringkat

- Harmonization of HR Policies - RoughDokumen119 halamanHarmonization of HR Policies - RoughFrancis SoiBelum ada peringkat

- Advent of SkyscrapersDokumen27 halamanAdvent of SkyscrapersJoshua AlboBelum ada peringkat

- Mathematics (Course 18)Dokumen24 halamanMathematics (Course 18)NickBelum ada peringkat

- Grade 8 MAPEH ReviewerDokumen4 halamanGrade 8 MAPEH ReviewerVictoria DelgadoBelum ada peringkat

- Marshall Abby - Chess Cafe - The Openings Explained - 1-63, 2015-OCR, 682pDokumen682 halamanMarshall Abby - Chess Cafe - The Openings Explained - 1-63, 2015-OCR, 682pArtur MałkowskiBelum ada peringkat

- Atcmorse PDFDokumen50 halamanAtcmorse PDFdivyansh bansalBelum ada peringkat

- What Makes A Cup of NESCAFÉ So Special? The Best Coffee Beans andDokumen4 halamanWhat Makes A Cup of NESCAFÉ So Special? The Best Coffee Beans andYenny YanyanBelum ada peringkat

- HYSYSDokumen390 halamanHYSYSEfosaUwaifoBelum ada peringkat

- BJT Common Emitter Characteristics: Experiment 6Dokumen5 halamanBJT Common Emitter Characteristics: Experiment 6beesahBelum ada peringkat

- DM HSD GU35 URAS2 Technical Guidelines For Usage of Rope Access System V2.1Dokumen20 halamanDM HSD GU35 URAS2 Technical Guidelines For Usage of Rope Access System V2.1Natalie BlackmoreBelum ada peringkat

- Electric Circuits 1 MSDokumen4 halamanElectric Circuits 1 MSEvaBelum ada peringkat

- Baccano! NDS 1931 The Grand Punk Railroad Secret EpisodeDokumen38 halamanBaccano! NDS 1931 The Grand Punk Railroad Secret EpisodeAymen AlhajBelum ada peringkat

- Bright Ideas 2 Unit 1 Test-Fusionado-Páginas-1-33Dokumen33 halamanBright Ideas 2 Unit 1 Test-Fusionado-Páginas-1-33Eleonora Graziano100% (1)

- Lista de Productos Nov 2018Dokumen10 halamanLista de Productos Nov 2018MoisesManuelBravoLeonBelum ada peringkat

- Candaza, HM Pe4l Reaction PaperDokumen5 halamanCandaza, HM Pe4l Reaction Papermaria isabel candazaBelum ada peringkat

- Genmega G2500Dokumen103 halamanGenmega G2500tchindaforentBelum ada peringkat

- Polymer Structures: Issues To Address..Dokumen34 halamanPolymer Structures: Issues To Address..Eugene Embalzado Jr.Belum ada peringkat

- BR Safetymatrix enDokumen12 halamanBR Safetymatrix enHamidreza MoaddeliBelum ada peringkat

- 4864.21 - Optics System 2Dokumen39 halaman4864.21 - Optics System 2Edgar Jose Aponte MartinezBelum ada peringkat

- Sabas fOR THE FRCR 2aDokumen9 halamanSabas fOR THE FRCR 2aMohammad Shafiq0% (1)

- Serial Interface RS485 (RS422) Configuration InstructionsDokumen20 halamanSerial Interface RS485 (RS422) Configuration Instructionsyana sopian hidayatBelum ada peringkat

- MIMSDokumen3 halamanMIMSFrancineAntoinetteGonzalesBelum ada peringkat