3D. Switchgear SA

Diunggah oleh

aviral mishraHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

3D. Switchgear SA

Diunggah oleh

aviral mishraHak Cipta:

Format Tersedia

Volume- II Tech.Spec.

Switchgear-SA

MODEL TECHNICAL SPECIFICATION

SECTION: SWITCHGEAR - SURGE ARRESTER

STQ-3054 Page 1 of 13 400 kV S/s Behman Jassa Singh

Volume- II Tech.Spec.Switchgear-SA

SWITCHGEAR – SURGE ARRESTERS

CONTENTS

Clause.No. Description Page No.

1.0 General 4

2.0 Duty requirements 4

3.0 Constructional Features 6

4.0 Fittings And Accessories 7

5.0 Tests 8

6.0 Mandatory Spares 9

7.0 Technical Parameters 10

8.0 Pre-Commissioning Tests 10

STQ-3054 Page 2 of 13 400 kV S/s Behman Jassa Singh

Volume- II Tech.Spec.Switchgear-SA

SWITCHGEAR - SURGE ARRESTERS

1.0 GENERAL:

1.1 The Surge arresters shall conform to IEC: 60099-4 except to the extent

modified in the specification and shall also be in accordance with

requirements under Section -GTR.

1.2 The Surge Arrestors shall be designed for use in the geographic and

meteorological conditions as given in Section-GTR and Section-

Project.

2.0 DUTY REQUIREMENTS:

a. The surge arresters shall be of heavy duty station class and gapless

type without any series or shunt gaps.

b. The surge arresters shall be capable of discharging over-voltages

occurring during switching of unloaded transformers, reactors and long

lines.

c. 420 kV class Surge arresters shall be capable of discharging of severe

re-energisation switching surges on a 400kV, 450km long line with

Surge impedance of 300 ohms and capacitance of 11.986nF/km and

over voltage factor of 2.3 p.u. Similarly, 800kV class Surge arresters

shall be capable of discharging of severe re-energisation switching

surges on a 765kV, 450km line with Surge impedance of 270 ohms and

capacitance of 13 nF/km.

d. 420kV class arrester shall be capable of discharging energy equivalent

to class 4 of IEC for a 420kV system on two successive operations

followed immediately by 50 Hz energisation with a sequential voltage

profile as specified below:

650 kVp for 3 peaks

575 kVp for 0.1 Sec

550 kVp for 1 seconds

475 kVp for 10 seconds

800kV class arrester shall be capable of discharging energy

equivalent to class 5 of IEC for an 800kV system on two

successive operations followed immediately by 50 Hz energisation

with a sequential voltage profile as specified below:

STQ-3054 Page 3 of 13 400 kV S/s Behman Jassa Singh

Volume- II Tech.Spec.Switchgear-SA

1000 kVp for 3 peaks

910 kVp for 0.1 Sec

885 kVp for 1 seconds

866 kVp for 10 seconds

e. 245/145 kV class arrester shall be capable for discharging energy

equivalent to class 3 of IEC for 245/145 kV system on two

successive operations.

f. The surge arresters shall be suitable for withstanding forces as

defined in Section-GTR.

g. The reference current of the arresters shall be high enough to

eliminate the influence of grading and stray capacitance on the

measured reference voltage.

h. The surge arresters are being provided to protect the following

equipment whose insulation levels are indicated in the table given

below:-

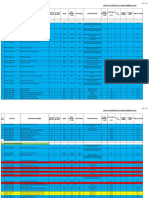

Equipment to Lightning Switching Lightning Switching Lightning Lightning

be protected impulse(kVp) surge(kV) impulse(kVp) surge(kV) impulse(kVp) surge(kVp)

for800 kV for 800 for 420 kV for 420 for 245 kV for 145 kV

system kV system kV ystem system system

system

Power + 1950 + 1550 + 1300 + 1050 + 950 + 550

transformer

+ 1950 + 1550 + 1300 + 1050 + 950 + 550

Reactor

Instrument + 2100 + 1550 + 1425 + 1050 + 1050 + 650

Transformer

CB/Isolator + 2100 + 1550 + 1425 + 1050 + 1050 + 650

Phase to

ground

+ 2100 + 1050 + 750

CB/Isolator (- + 1140 (- + 1425 (- + 900 (- (for (for

Across open CB

/+457) /+653) /+240) /+345) ) Isolator)

contacts + 1200

(for

Isolator

)

STQ-3054 Page 4 of 13 400 kV S/s Behman Jassa Singh

Volume- II Tech.Spec.Switchgear-SA

i. The duty cycle of CB installed in 800/420/245/145 kV System of the

Employer shall be O-0.3 sec-CO-3 min-CO. The Surge Arrester

shall be suitable for such circuit breaker duties in the system.

3.0 CONSTRUCTIONAL FEATURES:

The features and constructional details of surge arresters shall be in

accordance with requirement stipulated hereunder:

a) The non-linear blocks shall be of sintered metal oxide material.

These shall be provided in such a way as to obtain robust

construction, with excellent mechanical and electrical properties

even after repeated operations.

b) The surge arresters shall be fitted with pressure relief devices

suitable for preventing violent failure of insulator housing and

providing path for flow of rated fault currents in the event of arrester

failure.

c) The arresters shall not fail due to arrester porcelain insulator

contamination.

d) Seals shall be provided in such a way that these are always

effectively maintained even when discharging rated lightning

current.

e) Outer insulator for 90kV and above shall be polymer conforming to

requirements stipulated in Section-GTR. For 60kV and below, outer

insulator shall be porcelain/polymer conforming to requirements

stipulated in Section-GTR. Terminal connectors shall conform to

requirements stipulated under Section-GTR.

The outer insulator housing shall be so coordinated that external

flashover will not occur due to application of any impulse or

switching surge voltage upto the maximum design value for

arrester.

f) The end fittings shall be made of corrosion proof material and

preferably be nonmagnetic.

g) The name plate shall conform to the requirements of IEC

incorporating the year of manufacture.

h) The following details shall be furnished for quality checks:

i) The heat treatment cycle details alongwith necessary quality

checks used for individual blocks and insulation layer formed

across each block.

STQ-3054 Page 5 of 13 400 kV S/s Behman Jassa Singh

Volume- II Tech.Spec.Switchgear-SA

ii) Metalizing coating thickness for reduced resistance between

adjacent discs

i) The manufacturer will submit Data for rejection rate of ZnO blocks

during manufacturing/operation for the past three years.

j) The sealing arrangement of the Surge Arrester stacks shall be done

incorporating grooved flanges with the O-rings/elliptical cross-

section gaskets of Neoprene or Butyl rubber.

k) Arresters shall be of hermetically sealed units, self supporting

construction, suitable for mounting on tubular support

structures. However, 765 kV Surge Arrester shall be suitable

for mounting on lattice type support structures.

l) For 624kV Surge arresters, number of stacks shall be three (3).

The FRP tube outer diameter shall be 300mm (min) and FRP

tube thickness shall be 25mm (min).

4.0 FITTINGS AND ACCESSORIES:

a) Arresters shall be complete with insulating base having provision for

bolting to flat surface of structure.

b) Self contained discharge counters, suitably enclosed for outdoor

use and requiring no auxiliary or battery supply for operation shall

be provided for each single pole unit alongwith necessary

connection arrangement. Suitable leakage current meters should

also be provided. The reading of milliammeter and counters shall be

visible through an inspection glass panel. The terminals shall be

robust and of adequate size and shall be so located that incoming

and outgoing connections are made with minimum possible bends.

The surge counter shall be provided with a potential free contact

rated for 220 Volt (DC) which shall close whenever a surge is

recorded by the surge monitor. Necessary arrangement shall be

provided for extending the contact information to Substation

Automation System/RTU.

c) Surge monitor consisting of discharge counters and milliammeters

should be suitable to be mounted on support structure of the

arrester and should be tested for IP66 degree of protection. The

standard supporting structure for surge arrester should be provided

with a mounting pad, for fixing the surge monitor. The surge monitor

should be suitable for mounting on this standard mounting pad. Also

all nuts, bolts, washers etc. required for fixing the surge monitor

shall be supplied by the Contractor.

The arrangement for Surge Monitor enclosure fixing to the structure

shall be at its rear/bottom. Connection between the Surge Arrester

STQ-3054 Page 6 of 13 400 kV S/s Behman Jassa Singh

Volume- II Tech.Spec.Switchgear-SA

base and Surge Monitor shall be through a 2.0 m (minimum) long

insulated copper rod/strip of at least 75 sq.mm cross sectional area.

The cable shall be terminated at rear/bottom side of the Surge

Monitor. The gaskets of the surge monitors shall be of Neoprene,

Butyl or equivalent material.

d) Grading/corona rings shall be provided on each complete arrester

unit, as required. Suitable terminal connectors shall be supplied by

the Contractor.

5.0 TESTS:

5.1 In accordance with the requirements stipulated under Section-GTR, the

surge arresters should have been type tested as per IEC/IS and shall be

subjected to routine and acceptance tests in accordance with IEC.

Test reports for all type tests as per IEC-60099-4 including following

additional type tests (additional type tests are required for Surge

Arresters above 72.5 kV class only) shall also be submitted for the

Employer’s review:

i) Radio interference voltage test.

ii) Seismic withstand test as per Annexure-B of Section-GTR.

iii) Accelerated aging test.

Test to verify the Power frequency versus time characteristics:

Temporary over voltage profile for 216 kV and below rated arresters to be

mutually agreed.

Each metal oxide block of surge arresters shall be tested for the

guaranteed specific energy capability in addition to the

routine/acceptance test as per IEC: 60099-4.

5.2 (a) Acceptance Tests:

1. Measurement of power frequency reference voltage of the arrester

units.

2. Lightning Impulse Residual voltage on arrester units as per IEC

clause 6.3.2.

3. Internal Ionisation or partial Discharge test.

(b) Special Acceptance Test:

1. Thermal stability test on three sections as per IEC Clause 7.2.2.

STQ-3054 Page 7 of 13 400 kV S/s Behman Jassa Singh

Volume- II Tech.Spec.Switchgear-SA

2. Aging test for Zinc oxide blocks is to be carried out on 3 samples for

72 hours at maximum continuous over voltage (MCOV) and at a

temperature of 115°C. Acceptance norm being Ir (resistive

current)/watt loss shall remain or decrease at the end of 72 hrs from

the value taken after 1 hour of start of test.

3. Wattloss test.

(c) Routine Tests:

1. Sealing test: Water dip test at 1.5m depth from top of Surge Arrestor

for 30 minutes shall be performed during assembly of Surge

Arrester stacks (followed by other routine tests, i.e. P.D.

Measurement, Reference Voltage, Residual Voltage & IR

measurement).

2. Measurement of reference voltage.

3. Residual voltage test of arrester unit.

4. Internal Ionisation test or partial discharge test.

5. Verticality check on completely assembled Surge arresters as a

sample test on each lot.

(d) Routine Tests on Surge Monitors:

The Surge monitors shall be connected in series with the test

specimens during residual voltage and current impulse withstand

tests to verify efficacy of the same. Additional routine/ functional

tests with one 100A and 10kA current impulse (8/20 micro sec.)

shall also be performed on the Surge monitor.

Surge monitors shall be routinely tested for water dip test at 1.5m

depth for 30 minutes. No water vapors shall be visible on the

monitor glass.

(e) Routine Tests on insulators

All routine tests shall be conducted on the hollow column

insulators as per IEC 62155. Polymer housing shall be tested in

accordance to IEC-61462.

6.0 MANDATORY SPARES:

Bidder shall include in his proposal mandatory spares as mentioned in

the Bidding Documents.

STQ-3054 Page 8 of 13 400 kV S/s Behman Jassa Singh

Volume- II Tech.Spec.Switchgear-SA

7.0 TECHNICAL PARAMETERS: The technical parameters shall be as

per enclosed Annexure-I.

8.0 PRE-COMMISSIONING TESTS

8.1 An indicative list of tests is given below.

(a) Operation check of LA counters.

(b) Insulation resistance measurement

(c) Capacitance and Tan delta measurement of individual stacks.

(d) Third harmonic resistive current measurement (to be conducted after

energisation.)

(e) Contractor shall perform any additional test based on specialties of

the items as per the field Q.P./Instructions of the equipment

manufacturer or Employer without any extra cost to the Employer.

The Contractor shall arrange all instruments required for conducting

these tests alongwith calibration certificates at his own cost.

For pre-commissioning procedures and formats for Surge Arresters,

Doc.No.: CF/SA/08/R-4 dtd-01/04/2013 under PSTCL Document no. D-2-

01-03-01-04 will be reference document. This document will be

available at respective sites and shall be referred by the contractor.

A

n

n

e

x

u

r

STQ-3054 Page 9 of 13 400 kV S/s Behman Jassa Singh

Volume- II Tech.Spec.Switchgear-SA

1. Technical Parameters for

765kV, 400kV, 220kV and 132kV

Surge Arresters (with Polymer

Housing)

Sl. Description Unit 800kV SA 420kV SA 245kV SA 145kV SA

No.

1 NominalSystem kV, rms 765 400 220 132

Operating voltage

2 Rated frequency Hz 50 50 50 50

3 No. of Poles No. 1 1 1 1

4 Design ambient °C 50 50 50 50

temperature

5 Rated arrester kV 624 336 216 120

voltage

6 Continuous kV 490 267 168 102

operating voltage

at 50 deg.C

7 Nominal discharge 20 kA of 8/20 20 kA of 8/20 10 kA of 8/20 10 kA of 8/20

current microsecond microsecond microsecond microsecond

wave wave wave wave

8 Discharge current 20 kA of 8/20 20 kA of 8/20 10 kA of 8/20 10 kA of 8/20

at which insulation microsecond microsecond microsecond microsecond

co-ordination will wave wave wave wave

be done

9 Minimum kJ/kV 13kJ/kV 12kJ/kV 5kJ/kV 5kJ/kV

discharge

capability (referred

to rated arrester

Voltage) or

corresponding to

minimum

discharge voltage

as per clause-2.0

(d) whichever is

higher

10 Max. switching kVp 1180 (at 1kA) 670(at 2kA) 500 (at 1kA) 280 (at 1kA)

surge residual 1220 (at 2kA) 650 (at

voltage 500A)

11 Max. residual voltage at

i) 5kA kVp - - 560 310

ii) 10 kA nominal kVp - 800 600 330

discharge current

iii) 20 kA nominal kVp 1480 850 - -

discharge current

STQ-3054 Page 10 of 13 400 kV S/s Behman Jassa Singh

Volume- II Tech.Spec.Switchgear-SA

Sl. Description Unit 800kV SA 420kV SA 245kV SA 145kV SA

No.

iv) Steep fronted wave kVp 1480 925 - -

residual voltage at

20 kA

12 Long duration 5 4 3 3

discharge class {Refer clause {Refer clause

2.0(d)} 2.0(d)}

13 High current short kAp 100 100 100 100

duration test

value(4/10 micro

second wave)

14 Current for kA rms 63 40 / 50 / 63 40 / 50 (as 40

pressure relief test (as applicable)

applicable)

15 Low current long As per IEC

duration test value

16 Insulation Level

a) Full wave impulse withstand voltage (1.2/50 microsec.)

i) Arrester Housing kVpeak As per ±1425 ±1050 ±650

IEC:60099-4

b) Switching impulse withstand voltage (250/2500 micro-second) dry and wet

i) Arrester Housing kV As per ± 1050 -NA- -NA-

peak IEC:60099-4

c) One minute power frequency dry withstand voltage

i) Arrester Housing kV rms 830 630 460 275

17 Max. radio micro 2500 at 508 500 at 266 500 at 156 500 at 92

interference volts kVrms kVrms kVrms kVrms

voltage for

frequency

between0.5 MHz

and 2 MHz. in all

positions

18 Minimum mm As per As per As per As per

Creepage distance Section-GTR Section-GTR Section-GTR Section-GTR

19 Cantilever kg 500 350 150 150

Strength (for 1

minute withstand

test)

20 Maximum mm 200 200 200 200

deflection at

above cantilever

load

21 Seismic As per As per As per As per

acceleration IS:1893 IS:1893 IS:1893 IS:1893

STQ-3054 Page 11 of 13 400 kV S/s Behman Jassa Singh

Volume- II Tech.Spec.Switchgear-SA

Sl. Description Unit 800kV SA 420kV SA 245kV SA 145kV SA

No.

22 Partial Discharge ≤ 10pC ≤ 10pC ≤ 10pC ≤ 10pC

at 1.05 COV

23 System neutral Effectively Effectively Effectively Effectively

earthing Earthed Earthed Earthed Earthed

Note: The above insulation levels are applicable for altitude up to 1000 meters

above M.S.L. For higher altitudes, suitable correction factor as per relevant

IEC shall be applied.

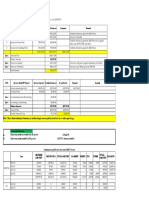

2. Technical parameters for 72.5kV, 36 kV and 11 kV CLASS SURGE ARRESTER

(with Porcelain /Polymer Housing)

Sl. Description Unit 72.5kV SA 36kV SA 12kV SA

No.

1 Nominal System kV, rms 66kV 33kV 11kV

Operating voltage

2 Rated frequency Hz 50 50 50

3 No. of Poles No. 1 1 1

4 Design ambient °C 50 50 50

temperature

5 Rated arrester voltage kV 60 30 9

6 Continuous operating kVrms 51 25 7.2

voltage at 50 deg.C

7 Nominal discharge kA 10 kA of 8/20 microsecond wave

current

8 Discharge current at kA 10 kA of 8/20 microsecond wave

which insulation co-

ordination will be done

9 Minimum discharge kJ/kV 4 4 4

capability (referred to

rated arrester Voltage)

or corresponding to

minimum discharge

voltage as per clause-

2.0 (d) whichever is

higher

10 Max. switching surge kVp 136 (at 1kA) 72 (at 1kA) 22.4 (at 1kA)

residual voltage

11 Max. residual voltage at

i) 5kA kVp 160 85 26

ii) 10 kA nominal kVp 170 90 28

STQ-3054 Page 12 of 13 400 kV S/s Behman Jassa Singh

Volume- II Tech.Spec.Switchgear-SA

discharge current

iii) 20 kA nominal kVp 190 -- --

discharge current

iv) Steep fronted wave kVp 190 -- --

residual voltage at 10

kA

Long duration 3 2 2

discharge class

13 High current short kArms 100 100 100

duration test

value(4/10 micro

second wave)

14 Current for pressure kAp 40 25 25

relief test

15 Low current long As per IEC

duration test value

16 Insulation Level

a) Full wave impulse withstand voltage (1.2/50 microsec.)

i) Arrester Housing kVpeak 325 170 75

b) One minute power frequency dry withstand voltage

i) Arrester Housing kV rms 140 70 28

17 Minimum Creepage mm As per As per As per

distance Section-GTR Section-GTR Section-GTR

18 Cantilever Strength kg 150 150 150

(for 1 minute

withstand test)

20 Maximum deflection mm 200 200 200

at above cantilever

load

21 Seismic acceleration As per As per As per

IS:1893 IS:1893 IS:1893

Note: The above insulation levels are applicable for altitude up to 1000 meters

above M.S.L. For higher altitudes, suitable correction factor as per relevant

IEC shall be applied.

STQ-3054 Page 13 of 13 400 kV S/s Behman Jassa Singh

Anda mungkin juga menyukai

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Fuse Catalog Nte-ElectronicsDokumen32 halamanFuse Catalog Nte-ElectronicsSamir AbauBelum ada peringkat

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- 3C. Switchgear IsolatorDokumen17 halaman3C. Switchgear Isolatoraviral mishraBelum ada peringkat

- Hand Book The Indian Electricity Rules1956Dokumen148 halamanHand Book The Indian Electricity Rules1956Vivek Kumar100% (8)

- Fault Level CalDokumen2 halamanFault Level Calaviral mishraBelum ada peringkat

- 220kV CABLE SCHEDULE JASIDIHDokumen94 halaman220kV CABLE SCHEDULE JASIDIHaviral mishraBelum ada peringkat

- 220kV CABLE SCHEDULE JASIDIHDokumen94 halaman220kV CABLE SCHEDULE JASIDIHaviral mishraBelum ada peringkat

- SF6 Partial Discharge MonitorDokumen6 halamanSF6 Partial Discharge Monitoraviral mishraBelum ada peringkat

- Ponda Title Block-ModelDokumen1 halamanPonda Title Block-Modelaviral mishraBelum ada peringkat

- Travel ExpenseDokumen2 halamanTravel ExpenseDEBASMIT GUPTABelum ada peringkat

- LOAD LIST / MOTOR LIST (Crude Distillation Unit) : 101-PA-1018A/B Desaulter Makeup Pump 1 1Dokumen9 halamanLOAD LIST / MOTOR LIST (Crude Distillation Unit) : 101-PA-1018A/B Desaulter Makeup Pump 1 1aviral mishraBelum ada peringkat

- Banda Junction Boxes ApprovalDokumen17 halamanBanda Junction Boxes Approvalaviral mishraBelum ada peringkat

- SR - No. Date Description From ToDokumen2 halamanSR - No. Date Description From Toaviral mishraBelum ada peringkat

- Balia-Bhiwadi IEAR (Final)Dokumen31 halamanBalia-Bhiwadi IEAR (Final)aviral mishraBelum ada peringkat

- R S PowerDokumen1 halamanR S Poweraviral mishraBelum ada peringkat

- Sifang QueriesDokumen3 halamanSifang Queriesaviral mishraBelum ada peringkat

- Iear Wrssii (Set A)Dokumen37 halamanIear Wrssii (Set A)aviral mishraBelum ada peringkat

- Aluminium Pipe Bus PDFDokumen6 halamanAluminium Pipe Bus PDFaviral mishraBelum ada peringkat

- EMDG-C10065-01-7600 Relay Selection Guide Edition 6 enDokumen1 halamanEMDG-C10065-01-7600 Relay Selection Guide Edition 6 enaviral mishraBelum ada peringkat

- EMDG-C10065-01-7600 Relay Selection Guide Edition 6 enDokumen48 halamanEMDG-C10065-01-7600 Relay Selection Guide Edition 6 enmido2112Belum ada peringkat

- Overall General Arrangement Layout Jaunpur (U.p) 26-03-2019) - PreviousDokumen1 halamanOverall General Arrangement Layout Jaunpur (U.p) 26-03-2019) - Previousaviral mishraBelum ada peringkat

- Cable Glands Selectin ChartDokumen11 halamanCable Glands Selectin Chartcherif yahyaouiBelum ada peringkat

- Is 5082 1998 PDFDokumen11 halamanIs 5082 1998 PDFRa Hul0% (1)

- CM Cc9000 Eng Int C Comp Catalogue - 6Dokumen36 halamanCM Cc9000 Eng Int C Comp Catalogue - 6Amauri SilvaBelum ada peringkat

- Varistors - Cross ReferenceDokumen3 halamanVaristors - Cross ReferencepatrickBelum ada peringkat

- Datasheet - Live: Metal Oxide Varistors TNRDokumen15 halamanDatasheet - Live: Metal Oxide Varistors TNRyoi sigit70Belum ada peringkat

- Suppliers & Project For Diff KVDokumen79 halamanSuppliers & Project For Diff KVapi-25885200Belum ada peringkat

- Zelio: and To AssembleDokumen20 halamanZelio: and To AssembleaavdBelum ada peringkat

- Catalogo Pararrayo - IndelDokumen9 halamanCatalogo Pararrayo - IndelYonatan Pallin YalleBelum ada peringkat

- Basic Principles of Electrical TechnologyDokumen43 halamanBasic Principles of Electrical TechnologysamBelum ada peringkat

- Surge Arresters: Varistar Storm Trapper High Energy Mov Arrester Installation InstructionsDokumen2 halamanSurge Arresters: Varistar Storm Trapper High Energy Mov Arrester Installation InstructionsAgussalim AddinBelum ada peringkat

- (Barnes J.R.) Designing Electronic Systems For ESDDokumen8 halaman(Barnes J.R.) Designing Electronic Systems For ESDJHYBelum ada peringkat

- Fuse Bible Complete PDFDokumen162 halamanFuse Bible Complete PDFmirkodeBelum ada peringkat

- PAPER - Transient Recovery Voltage at Series Compensated Transmission Lines in BrazilDokumen6 halamanPAPER - Transient Recovery Voltage at Series Compensated Transmission Lines in BrazilWilian GuamánBelum ada peringkat

- Watts Technical CatalogueDokumen77 halamanWatts Technical CatalogueMuhidin KozicaBelum ada peringkat

- Electrical and Temperature Correlation To Monitor Fault Condition of Zno Surge ArresterDokumen5 halamanElectrical and Temperature Correlation To Monitor Fault Condition of Zno Surge ArresterLucho RufoBelum ada peringkat

- Workhorse 300s ManualDokumen38 halamanWorkhorse 300s ManualkennyBelum ada peringkat

- Lightning ArresterDokumen18 halamanLightning ArresterDinesh Prasad SenapatiBelum ada peringkat

- Ds2X0-Xxdc Series: DC Power Surge ProtectorDokumen1 halamanDs2X0-Xxdc Series: DC Power Surge ProtectorEhsan RohaniBelum ada peringkat

- OVR PV T1-T2 12.5-1000 P QS (2CTB812120R1000) : Key FeaturesDokumen1 halamanOVR PV T1-T2 12.5-1000 P QS (2CTB812120R1000) : Key FeaturesMohammad NasarBelum ada peringkat

- 360209-A InstallationDokumen19 halaman360209-A InstallationadiegooscarBelum ada peringkat

- PVI-134.0-400.0 BCD.00382 EN RevB PDFDokumen4 halamanPVI-134.0-400.0 BCD.00382 EN RevB PDFbacuoc.nguyen356Belum ada peringkat

- DILET70ADokumen28 halamanDILET70AObrian MahurureBelum ada peringkat

- GK 3000 Variable Frequency Drive User ManualDokumen137 halamanGK 3000 Variable Frequency Drive User ManualAnonymous Z3C8JRlBelum ada peringkat

- Varistor Geral (Ótima Tabela) PDFDokumen11 halamanVaristor Geral (Ótima Tabela) PDFTARC2525Belum ada peringkat

- AC31 System ConfigurationDokumen150 halamanAC31 System ConfigurationAlan Portela VieiraBelum ada peringkat

- DA10D Product ManualDokumen8 halamanDA10D Product ManualLeo VazquezBelum ada peringkat

- FINAL BROCHURE Bowthorpe EMP 150802 PDFDokumen16 halamanFINAL BROCHURE Bowthorpe EMP 150802 PDFfernando romero sotoBelum ada peringkat

- Reyrolle Solkor RF - ManualDokumen74 halamanReyrolle Solkor RF - ManualTunLi AngBelum ada peringkat

- Installations - EMV-Guide-ENG V1.43Dokumen47 halamanInstallations - EMV-Guide-ENG V1.43sayed atefBelum ada peringkat

- Electrical Component For Railways IndustryDokumen18 halamanElectrical Component For Railways Industryvoltus88Belum ada peringkat

- Media Tension 09 PDFDokumen12 halamanMedia Tension 09 PDFDaniel GaitanBelum ada peringkat