Spiral Wound Gasket Compressibility PDF

Diunggah oleh

Peeyush VaishJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Spiral Wound Gasket Compressibility PDF

Diunggah oleh

Peeyush VaishHak Cipta:

Format Tersedia

Proceedings of the ASME 2013 Pressure Vessels and Piping Conference

PVP2013

July 14-18, 2013, Paris, France

PVP2013-97008

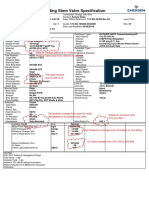

SPIRAL WOUND GASKET COMPRESSIBILITY

AND PRESSURE RATINGS

John McCarthy A. Fitzgerald Waterland, III (Jerry) Dan Reid

Dominion Generation VSP Technologies, Inc. VSP Technologies, Inc.

Chesapeake, VA U.S.A. Prince George, VA U.S.A. Houston, TX U.S.A.

john.d.mccarthy@dom.com jerry.waterland@vsptechnologies.com dan.reid@vsptechnologies.com

ABSTRACT GASKET DENSITY

The industry practice of using pressure rating An important function of any gasket is to be soft enough

nomenclature to describe spiral wound gasket compressibility to compress and conform to the seating surface imperfections,

can contribute to some level of confusion regarding the proper and at the same time be stiff enough to resist the applied

design and selection of these gaskets. This situation can result forces without damage. The ability of a gasket to deform as

in a misconception that a more easily compressed “soft” desired under a given load is described as its

gasket (for example, “0-999 psi” rating) cannot be used in a “compressibility”. In the case of spiral wound gaskets

higher pressure application. This is not necessarily true, and in “compressibility” represents a measure of the gasket density.

many cases a softer (less dense) gasket construction can

actually be beneficial in both high and low pressure The images below illustrate how the gasket sealing

applications. This article addresses both the terminology used element (windings and filler) may be manufactured to

to describe spiral wound gasket compressibility and the design different densities (stiffness) to support the compressive forces

characteristics of these gaskets in an effort to improve the applied either from bolting, or from internal pressure if that

understanding of this subject. internal pressure is used to compress the gasket.

INTRODUCTION

Most manufacturers rate the compressibility of their spiral

wound pipe flange gaskets as “400#”, “600#”, “900#”, etc., to

match the ASME B16.5 pressure class of the piping system in

which they are used. Windings-only spiral wound gaskets are

typically assigned a compressibility rating using pressure units

of “0-999 psi”, “1,000-3,000 psi”, etc. While in some cases the

gasket compressibility rating is directly related to the

operating pressure of the application, in many other cases

there is no such relationship. This difference has to do

primarily with the design of the gasket and the gasket seating

area.

Figure 1 Cross sectional view of spiral wound gaskets

with an outer centering / compression-stop ring [1]

1 Copyright © 2013 by ASME

Downloaded From: http://proceedings.asmedigitalcollection.asme.org/ on 01/29/2016 Terms of Use: http://www.asme.org/about-asme/terms-of-use

GASKET SEATING SURFACE DESIGNS

The following images depict a few of the many types of

flange face arrangements that are used in piping systems and

equipment design. Gasketed joints that rely on metal-to-metal

contact to avoid gasket over-compression are referred to as

“hard” joints. Joints that rely on gasket stiffness alone to resist

over-compression are called “soft” joints. According to EPRI,

hard joints are an “industry-recommended practice” for

reliable performance [1].

The first flange type, shown in Figure 2, is identified as

“Male and Female”. A version of this design is often used for Figure 3 “Hard” joint, raised face flanges with a spiral wound

equipment covers and manway doors. In the case of boiler gasket equipped with an outer compression-stop ring [2]

manway doors the force used to compress the gasket is

typically not generated by bolting, but is supplied by internal The third flange type shown in Figure 4 below, “Flat Face

pressure acting on the surface of the door itself. In this to Recess”, is a “hard” joint design. It provides the gasket with

application, it is often impractical to incorporate a protection against over-compression because the gasket sits in

compression-stop ring, so the gasket density alone must a protected recessed area. This eliminates the need for either

support the force applied by internal pressure. In addition, the an outer or inner ring gasket compression-stop, or a higher

gasket must be soft enough to deform and seal under the density construction of the gasket sealing element. In this case,

available load. In these cases, it becomes critical to use a low a low density gasket construction is often the best choice. A

density gasket in low pressure applications (0-999 psi), and a higher density gasket may be used, but only if there is

high density gasket in higher pressure applications (1,000 – adequate bolting available to properly compress the gasket.

3,000 psi). This is a typical “soft” joint design.

Figure 4 “Hard” joint, flat face to recess flanges with

Figure 2 “Soft” joint male and female flanges with a windings-only spiral wound gasket [2]

a windings-only spiral wound gasket [2]

OPERATING CHARACTERISTICS OF SPIRAL

In the second flange type, shown in Figure 3 and WOUND GASKETS

described as “Raised Face”, the amount of force applied to

compress the gasket is determined strictly by the amount of Figure 5 on the following page shows a schematic cross-

bolting available. If a windings-only gasket were to be used in section of a spiral wound gasket contained between two pipe

this application, the gasket density would need to be adequate flanges. The gasket windings and filler are shown in pink

to resist the bolting load, which is defined by the pressure color. The gasket is fitted with reinforcement on the inside

class (400, 600, 900, etc.). However, the more conventional diameter (ID), and an outer “compression-stop” ring on the

approach for this application is to use a gasket design that outside diameter (OD), both shown in green color. Over-

incorporates an outer metallic “compression-stop” ring, shown compression of the gasket is prevented by the compression-

in the image on the right of Figure 3. The use of a properly stop ring, which also serves to contain the gasket and oppose

selected and assembled gasket of this style, compressed down internal system pressure. The bolting serves to keep the

to the outer ring, results in a “hard” joint design that prevents flanges in contact with the gasket and oppose the internal

over-compression of the gasket, and allows the use of a lower pressure that is trying to separate the flanges.

density (softer) gasket.

2 Copyright © 2013 by ASME

Downloaded From: http://proceedings.asmedigitalcollection.asme.org/ on 01/29/2016 Terms of Use: http://www.asme.org/about-asme/terms-of-use

One of the unique features inherent in the design of this Extrusion of the gasket towards the OD is prevented either by

spiral wound gasket is that the windings and filler will deform a compression-stop ring, or by confining a windings-only

to provide a balanced resistance to increasing internal gasket in a recessed seating area. Therefore, for a properly

pressure. As internal system pressure acts against the ID of the designed spiral wound gasketed joint, the internal pressure

gasket, the windings are radially compressed, which leads to rating of the application will have little bearing on the choice

the filler being squeezed outward and against the flange faces of gasket density. Under these conditions, a softer gasket

[3]. Due to the concave (chevron) shape and orientation of the density can be beneficial, both to promote flowability of the

metal windings facing the internal pressure, the more the filler (which produces maximum contact between the filler

internal pressure increases, the more sealing force is generated and the seating surfaces), and to reduce the amount of bolting

required to compress the gasket.

against the flanges. This assumes of course that the bolting

tension is sufficient to keep the flange faces in contact with the

GASKET COMPRESSIBILITY RATINGS – PIPE

gasket. A photo of this gasket style is shown in Figure 6.

FLANGE GASKETS

Spiral wound gasket manufacturers have typically

supplied their gaskets with different densities to match the

bolting loads of the application. In the case of pipe flange

gaskets, these densities are often identified using the

nomenclature of the associated piping pressure class (for

example, “400#”, “600#”, etc.). However, as discussed

previously, these different gasket densities are not intended to

resist design operating pressures, but are instead presumably

selected to accommodate the bolting loads developed in each

Internal of these pressure classes.

Pressure

The graph shown in Figure 7 illustrates how the ratio of

bolt tensile stress area to gasket seating area varies for NPS

Figure 5 Cross section of a spiral wound gasket with inner (Nominal Pipe Size) 4 ASME B16.5 weld neck flanges in

and outer rings installed between raised face flanges classes 150 through 1500. The inside diameter of the raised

face seating area has been chosen based on typical pipe

schedules for each flange pressure class. This trend may be

used to compare the relative amount of bolting force available

per square inch of gasket seating area across the full range of

pressure classes.

Ratio of Bolt Tensile Stress Area to Raised

Face Area - NPS 4 Flanges

40

1500

35

900

30

25

Percent

400

20

600

15

300

10

150

5

0

Figure 6 Photo of a typical pipe flange spiral wound Pressure Class

gasket with inner and outer metal rings

Figure 7 Ratio of bolt tensile stress area to raised face area

In many spiral wound gasket applications, gasket over-

NPS 4 flanges

compression is prevented by the use of a compression-stop

ring, or, if a windings-only gasket is used, by installing the

The trend shown by this graph is similar to the trends for

gasket in a protective recessed seating area (Figure 4).

other flange sizes, such as NPS 2, 8, and 12, which all indicate

3 Copyright © 2013 by ASME

Downloaded From: http://proceedings.asmedigitalcollection.asme.org/ on 01/29/2016 Terms of Use: http://www.asme.org/about-asme/terms-of-use

a generally increasing available bolt load per square inch of

Manufacturer "B"

seating area along with increasing flange pressure class. If

manufacturers are designing their spiral wound gaskets to 100000

900 1500

Modulus of Elasticity (psi)

correlate with this increasing compressive force per unit area, 80000

then one would expect to see corresponding changes in gasket 300

600

modulus of elasticity (gasket stiffness) along with increasing 60000

150

gasket pressure class ratings. 40000

The graphs in Figures 8 and 9 show plots of compressive 20000

modulus of elasticity for gaskets supplied by two international 0

spiral wound gasket manufacturers for pressure classes 150 Pressure Class

through 1500. These plots were derived from 1995 ROTT test

data, shown in Table 1 on page 8, performed on a random

Figure 9 Variation in gasket modulus of elasticity with

sample of two spiral wound gaskets (averaged) for each of the

pressure class rating - Manufacturer “B”

indicated pressure classes for each manufacturer. The ROTT

testing was performed by an independent laboratory and was

used to identify and quantify stress/leakage and

stress/deflection characteristics of these standard ASME Manufacturer "A"

B16.20 spiral wound gaskets. 0.0005

Leak Rate (mg/sec)

0.0004

While Figure 7 on the previous page shows an increase in 0.0003

available compressive force per unit area of about 270% from

0.0002

class 150 to class 1500, Figures 8 and 9 show a maximum

0.0001

increase in gasket modulus of elasticity of only about 66%

0

over this same range. In addition, the shapes of the trend lines 40000 60000 80000 100000 120000

for the two gasket manufacturers seem to exhibit little

Modulus of Elasticity (psi)

similarity where modulus of elasticity is concerned.

Figure 10 Leak rate versus modulus of elasticity -

Manufacturer "A"

Manufacturer “A”

120000

600 1500

Modulus of Elasticity (psi)

100000

900

80000 Manufacturer "B"

60000 0.0005

300

Leak Rate (mg/sec)

150

40000 0.0004

0.0003

20000

0.0002

0

Pressure Class 0.0001

0

Figure 8 Variation in gasket modulus of elasticity with 40000 60000 80000 100000 120000

pressure class rating - Manufacturer “A” Modulus of Elasticity (psi)

Since leak rate is a primary criterion for judging gasket

performance, these varying approaches to gasket design may Figure 11 Leak rate versus modulus of elasticity -

lead one to question how differing gasket moduli of elasticity Manufacturer “B”

may affect leak rate. The two graphs in Figures 10 and 11, for

the same manufacturers “A” and “B”, show trends of

measured leak rate versus compressive modulus of elasticity. This data suggests that within the range of gasket moduli

These leak rates were measured during the 1995 ROTT test at of elasticity used by these manufacturers, and within the

400 psi internal pressure. Except for an unexplained anomaly parameters of this ROTT test, modulus of elasticity seems to

involving two class 150 gaskets from manufacturer “B”, all have no significant, defined effect on spiral wound gasket leak

measured leak rates were below 0.0001 mg/sec. rate.

4 Copyright © 2013 by ASME

Downloaded From: http://proceedings.asmedigitalcollection.asme.org/ on 01/29/2016 Terms of Use: http://www.asme.org/about-asme/terms-of-use

As there are no enforced standards1 for specific

pressure/compression construction of spiral wound gaskets,

there is no standardization in filler density for various pressure

classes between manufacturers. For the same pressure class

gasket, it is not unusual to see extreme variation in the filler

density in gaskets supplied by different manufacturers [3].

The bar graph shown in Figure 12 below illustrates the

amount of variation that may be found in spiral wound gasket

construction among manufacturers, and even within a single

manufacturer, for the same NPS gasket and pressure class. In

this example, calibrated calipers were used to measure sealing

element cross-sectional width, and a magnifying comparator

was used to count the number of windings. Winding density

varied between 27 and 38 windings-per-inch, or 29% across

the range of gaskets tested.

Figure 13 Variation in winding density for the same size

1/2"

NPS 1/2 x 150, 150B16.20,

ASME SW Gaskets

304/FG with Outer Ring

and pressure class spiral wound gasket - NPS 1 x 150

40

38

Manufacturers “A” (top) and “Z” (bottom)

Windings

36

34 Windings/Inch

32

30

28

26

24

22

20

18

16

14

12

10

8

6

4

2

0

Garlock Garlock Flexitallic Flexitallic Flexitallic TEADIT TEADIT TEADIT

X X Y Y Y Z Z Z

Brand

Figure 12 Spiral wound gasket construction for manufacturers “X”,

“Y”, and “Z”, size 1/2”, pressure class 150

The photos in Figure 13 provide a visual example of a

variation in winding density for two comparable spiral wound

gaskets from two different manufacturers, each supposedly

constructed per ASME B16.20 manufacturing requirements. Figure 14 Variation in winding density for the same

The photos in Figure 14 show another example of variation in manufacturer, size, and pressure class spiral wound gasket,

winding density, but this time using gaskets of the same size NPS 3 x 150, manufactured in Korea (top photo) and

and pressure class from the same manufacturer. The samples Mexico (bottom photo)

were chosen to show extremes of variation in commercially

available spiral wound gaskets. The samples were taken from One would expect that spiral wound gaskets of the same size

typical warehouse inventories, which included a nuclear and pressure class should be identical regardless of the

generating facility, and they are expected to be used in manufacturer or batch in which they were produced. This lack

production equipment. of standardization and manufacturing control can result in

differing compression characteristics and unpredictable

1

ASME standard B16.20A, paragraph 3.2.6, describes compressibility sealing performance for the end user.

requirements for spiral wound gaskets. However, these limits are routinely

exceeded by many gasket manufacturers. According to a year 2000 EPRI

report, “less than half of the gaskets tested reached full compression at 30 ksi

bolt stress” (as required by the ASME standard) “but… most gaskets had

reached full compression at a 60 ksi bolt stress” [4].

5 Copyright © 2013 by ASME

Downloaded From: http://proceedings.asmedigitalcollection.asme.org/ on 01/29/2016 Terms of Use: http://www.asme.org/about-asme/terms-of-use

The inconsistencies in spiral wound gasket construction DISCUSSION

have influenced the authors of this paper to work towards

development of gasket standards which exceed the The question is, will a low-density construction gasket

requirements of ASME B16.20, Metallic Gaskets for Pipe perform acceptably in a high pressure application? The answer

Flanges – Ring-Joint, Spiral-Wound, and Jacketed. These appears to be yes, when constructed with an inner or outer

more aggressive standards require non-buckling, controlled- ring, or if used in a properly sized groove; both of which limit

density design of windings and filler, and low-stress-to-seal compression and prevent over-compression. If the gasket is

construction for all ASME flange pressure classes. These used in a boiler drum door or handhole application, which is

standards are currently in use throughout one electric utility. sealed by internal pressure and lacks similar protections, the

In contrast to the use of varying gasket densities described answer is no. The high internal pressure acting against the

previously, the resulting alternative design spiral wound hydrostatic area of the drum door or handhole cover will

gasket, shown in Figure 15, incorporates a single, low density develop a very high compressive stress on the gasket. If the

construction for all pressure classes from class 150 through gasket is not designed to resist this stress, it can over-compress

class 2500. and over-stress the gasket resulting in failure.

The photo in Figure 16 shows an example of different

density boiler manway gaskets. These “windings only”

gaskets are constructed using alternating layers of stainless

steel windings and compressible flexible graphite filler

material. The higher density construction gasket on the left is

designed to resist higher internal boiler pressures, which

would tend to over-compress and crush the lower density

gasket shown on the right. The photos in Figure 17 on the

following page show a failed boiler manway door gasket. This

failure was due to the use of an incorrect “low density” (0-999

psi rating) spiral wound gasket as opposed to a required “high

density” (1,000 – 3,000 psi rating) gasket in a high pressure

boiler drum application (2,400 psig).

1,000- 0-999

Figure 15 Spiral wound gasket with anti-buckling, controlled- 3,000 psi psi

rating rating

density windings and filler, and low-stress-to-seal construction

(Note: no inner ring required)

GASKET COMPRESSIBILITY RATINGS – WINDINGS-

ONLY GASKETS

The ratings used to identify windings-only gaskets follow

a convention similar to that used for pipe flange gaskets. In

windings-only gasket applications, which involve primarily

equipment joints (as opposed to pipe flanges), gasket densities

are described in relation to the design pressure of the

application. Typical identifiers are “0-999 psi” and “1,000- Figure 16 Comparison of high-density (left) and low-density

3,000 psi”. However, as with pipe flange gaskets, the choice (right) boiler manway spiral wound gasket constructions

of gasket density is more directly related to the compressive

load applied to the gasket by the bolting. One exception to this

rule is unconfined boiler manway or handhole door gaskets,

which do rely on gasket density to resist forces applied by

internal system pressure. This is one of the few applications

where one must ensure that the correct winding density is

specified and received.

6 Copyright © 2013 by ASME

Downloaded From: http://proceedings.asmedigitalcollection.asme.org/ on 01/29/2016 Terms of Use: http://www.asme.org/about-asme/terms-of-use

The photo in Figure 18 shows an example of how spiral

wound gaskets were manufactured prior to introduction of the

compression-stop ring. The extended loops allowed support of

the gasket by the bolting and centering of the gasket on the

raised-face piping flanges. In the absence of a compression-

stop ring, the sealing element density had to be designed to

support the entire compressive force of the bolting.

With the introduction of the compression-stop ring, it

became less important to design the sealing element to support

the bolting load. However, it appears that the conventional

approach still used by most manufacturers is to vary the gasket

density in general relation to the available bolt load.

Figure 17 Failed manway gasket on a boiler drum door.

Operating conditions: 2400 psig @ 600F.

Figure 18 “Loop Winding” spiral wound gasket [5]

Why are windings-only spiral wound gaskets usually

specified as either “0-999 psi” or “1,000-3,000 psi”, even if

CONCLUSION

they are to be used in designs that protect the gasket against

over-compression? One reason is to protect against the

While spiral wound gasket density is often defined simply

inadvertent use of a high density gasket in a low bolt-load

by describing the number of windings per inch, there are also

application, where bolt load is the only means of compressing

additional factors to consider. These include filler thickness,

the gasket. Low pressure applications typically involve bolting

winding assembly pressure, number of windings without filler,

that would be inadequate to properly compress the harder,

number of spot welds, and how the sealing element is

high-density gaskets. By using low density gaskets (“0-999

constrained between the inner and outer rings, if used. All of

psi” construction) in low pressure applications, and high

these factors contribute to the compressibility of a gasket

density gaskets (“1,000 – 3,000 psi” construction) in high

under a load, which is demonstrated in Figure 19 on the

pressure applications, this problem may be avoided.

following page. They also determine how well a gasket will

perform in simulated laboratory testing and, more importantly,

Why haven’t more manufacturers of pipe flange spiral

under actual field conditions.

wound gaskets standardized on the use of low density

construction windings and filler for all pressure classes, along

The use of pressure rating nomenclature alone to describe

with other optional design improvements? To answer this

spiral wound gasket performance can also introduce confusion

question, a review of the history of spiral wound gaskets may

about the true design characteristics of these gaskets. A similar

be helpful.

ambiguity may be found in the conventional terminology used

to describe pressure classes, which are often referred to as

Flexitallic is credited with developing the first industrial

“150 pound”, “300 pound”, etc. instead of the correct class

spiral wound gasket approximately 100 years ago, in 1912.

150, class 300, etc. Just as a “150 pound” descriptor may

The basic design of the spiral wound gaskets produced by

incorrectly imply a maximum design pressure of 150 psi, so

most manufacturers today has not changed significantly since

too can a “0-999 psi” gasket rating incorrectly suggest a

the mid-1900s, when the outer compression-stop ring was first

maximum design pressure of 999 psi. An understanding of

introduced. This track record is a testament to the robust

these distinctions will help the end-user to better select spiral

nature of this impressively simple design.

7 Copyright © 2013 by ASME

Downloaded From: http://proceedings.asmedigitalcollection.asme.org/ on 01/29/2016 Terms of Use: http://www.asme.org/about-asme/terms-of-use

wound gaskets for individual applications and to properly [3] Waterland, A.F., 2009, “Analysis of the Compression

assess root causes during investigations of gasketed joint Behavior of Spiral Wound Gaskets, ASME Pressure

failures. Vessels and Piping Conference, PVP2009-7742, p.1

[4] Hunt, S., Gross, D., and Moroney, V., 2000, Bolt

Preload Stress for ANSI Raised-Face Flanges Using

Spiral-Wound Gaskets: Sealing Technology & Plant

Load / Compression Comparison

30000 Windings Only, 5.5" ID x 6" OD x 0.175" Thickness Leakage Reduction Series. EPRI, Palo Alto, CA p. 2-20

[5] VSP Technologies, 2012, Loop Winding Gasket Photo

25000 [6] Bouzid, H., Derenne, M., and Payne, J.R. (JPAC, Inc.),

1995, Tightness Testing and Research Laboratory (TTRL)

20000

ROTT and HOTT Testing of SW Gasket Styles

Applied Load (lb)

15000

10000

#14 VSPDensity"

"Low 5.5 x 6" Winding-Only

"Medium

#15 VSP 5.5 Density"

x 6" Winding-Only

5000

"High

#16 VSPDensity"

5.5 x 6" Winding-Only

0

0 0.01 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 0.1

Gasket Compression (in)

Figure 19 Compressibility performance of “Low”, “Medium”,

and “High” density construction spiral wound gaskets

Highest Part A Stress, Leak Rate @ 400 psi Calculations

Compressive

Original Gasket Modulus

Gasket Gasket Gasket Compressed of Elasticity

Pressure Deflection Thickness Stress Leak Rate Thickness Stress/Strain

Manuf. Class (inches) (inches) (psi) (mg/sec) (inches) (psi)

A 150 0.032 0.179 10,061 0.0000903 0.147 56,279

A 150 0.031 0.179 11,354 0.0000883 0.148 65,560

A 300 0.044 0.176 15,148 0.0000241 0.132 60,592

A 300 0.044 0.176 15,091 0.0000204 0.132 60,364

A 600 0.027 0.182 15,128 0.0000277 0.155 101,974

A 600 0.027 0.182 15,104 0.0000448 0.155 101,812

A 900 0.035 0.18 15,142 0.0000843 0.145 77,873

A 900 0.037 0.18 15,110 0.0000540 0.143 73,508

A 1500 0.028 0.18 15,124 0.0000622 0.152 97,226

A 1500 0.026 0.18 15,197 0.0000534 0.154 105,210

B 150 0.037 0.183 11,450 0.0004320 0.146 56,631

B 150 0.036 0.183 11,394 0.0004660 0.147 57,920

B 300 0.037 0.18 15,078 0.0000900 0.143 73,352

B 300 0.037 0.18 15,078 0.0000847 0.143 73,352

B 600 0.041 0.183 15,167 0.0000887 0.142 67,697

B 600 0.039 0.183 15,157 0.0000874 0.144 71,121

B 900 0.033 0.183 15,198 0.0000861 0.150 84,280

B 900 0.032 0.183 15,177 0.0000848 0.151 86,793

B 1500 0.031 0.181 15,135 0.0000841 0.150 88,369

B 1500 0.031 0.181 15,194 0.0000844 0.150 88,713

Table 1- 1995 ROTT (ROom Temperature Tightness) test data for

NPS 4, 304/FG inner ring spiral wound gaskets [6]

REFERENCES

[1] Bridges, M., 2002 Sealing Technology & Plant Leakage

Reduction Series: TR-111413, TR-111472, TR-

114761,1000066, 1000922, 1000923, 1000972, &

1003150, Bolted Joints with Spiral Wound Gaskets, slides

32, 36, EPRI, Palo Alto, CA 1007072

[2] Flexitallic, 2011, Gasket Design Criteria, Section I –

Gasket Selection, page 33

8 Copyright © 2013 by ASME

Downloaded From: http://proceedings.asmedigitalcollection.asme.org/ on 01/29/2016 Terms of Use: http://www.asme.org/about-asme/terms-of-use

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- Describe The Shape of The Plastic Zone Ahead of A Crack Tip and Particularly How This Varies Between Plane Stress and Plane Strain SituationsDokumen6 halamanDescribe The Shape of The Plastic Zone Ahead of A Crack Tip and Particularly How This Varies Between Plane Stress and Plane Strain SituationsAndrew SpiteriBelum ada peringkat

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Model YK (Style H) Centrifugal Liquid ChillersDokumen56 halamanModel YK (Style H) Centrifugal Liquid ChillersAbdulSattarBelum ada peringkat

- KSDB Channagiri Planning 04.08.2022Dokumen17 halamanKSDB Channagiri Planning 04.08.2022RavikumarBelum ada peringkat

- Us Lea Insul-Tube V1 Lres 0520Dokumen2 halamanUs Lea Insul-Tube V1 Lres 0520Carlos MoralesBelum ada peringkat

- 1482407553balmerol Ropelube 1000 PdsDokumen2 halaman1482407553balmerol Ropelube 1000 PdsKapil GoyalBelum ada peringkat

- Series 4000 - Bituminous Layers and SealsDokumen52 halamanSeries 4000 - Bituminous Layers and SealsBatenda Felix0% (1)

- CUTOUT Fuse Holders: (Standard)Dokumen9 halamanCUTOUT Fuse Holders: (Standard)MadyBelum ada peringkat

- Silica and Silicon in TextilesDokumen7 halamanSilica and Silicon in Textilespuja_14Belum ada peringkat

- POLYMERSDokumen17 halamanPOLYMERSNur Nabila HudaBelum ada peringkat

- Bed Material Specification CFBC BoilerDokumen1 halamanBed Material Specification CFBC BoilerElavarasan RamalingamBelum ada peringkat

- Kahn SystemDokumen5 halamanKahn SystemLeo da LeonBelum ada peringkat

- PolyScience 1.5 HP Chiller - 110-392 Durachill 1.5 HP 01-05-2022Dokumen57 halamanPolyScience 1.5 HP Chiller - 110-392 Durachill 1.5 HP 01-05-2022hsghdBelum ada peringkat

- Selection Guide: Air and Liquid ProductsDokumen15 halamanSelection Guide: Air and Liquid ProductsClaudiu PopicaBelum ada peringkat

- 1St Floor Lintel and False Slab Layout: Mani Civil WorksDokumen1 halaman1St Floor Lintel and False Slab Layout: Mani Civil Worksmanilesnarf5Belum ada peringkat

- Batel - Presentation 2020r1Dokumen63 halamanBatel - Presentation 2020r1HÜSEYİN GÜRTAŞBelum ada peringkat

- Fence Engineering ManualDokumen30 halamanFence Engineering ManualvklsBelum ada peringkat

- Quotation For Rapicon WallDokumen2 halamanQuotation For Rapicon WallDebkumar ChowdhuryBelum ada peringkat

- Sbsfid 12858 DifDokumen20 halamanSbsfid 12858 DifYIBELTAL EBABU100% (2)

- Liebert PEX+: High Efficiency. Modular-Type Precision Air Conditioning UnitDokumen19 halamanLiebert PEX+: High Efficiency. Modular-Type Precision Air Conditioning Unitjuan guerreroBelum ada peringkat

- Coating PrcessDokumen21 halamanCoating PrcessJatin GadhokBelum ada peringkat

- Bearing Smearing and Its CausesDokumen6 halamanBearing Smearing and Its Causesbarry nancooBelum ada peringkat

- Ecological Bricks From Dimension Stone Waste and Polyester Resin PDFDokumen9 halamanEcological Bricks From Dimension Stone Waste and Polyester Resin PDFNovita Hillary Christy DamanikBelum ada peringkat

- 2.0 Basic Concepts On ThermodynamicsDokumen17 halaman2.0 Basic Concepts On ThermodynamicsLeo JohnBelum ada peringkat

- Asdfasr 2 Q 4235Dokumen3 halamanAsdfasr 2 Q 4235Claire BernardBelum ada peringkat

- Sunshade Mounting BracketDokumen3 halamanSunshade Mounting Bracketfaisal84inBelum ada peringkat

- Materials Review QuestionDokumen20 halamanMaterials Review QuestionJefferson Kevin LerioBelum ada peringkat

- IPC - 13 (B) 17 PQC Cube RegisterDokumen15 halamanIPC - 13 (B) 17 PQC Cube RegisterBscpl Repalle to EeppurpalemBelum ada peringkat

- Epolam 5015Dokumen2 halamanEpolam 5015Eduardo JoseBelum ada peringkat

- We Care We CareDokumen8 halamanWe Care We CareRamaKrishna ABelum ada peringkat

- UEME3112 Fluid Mechanics II May 2019 CFD Assignment: Laminar Pipe FlowDokumen18 halamanUEME3112 Fluid Mechanics II May 2019 CFD Assignment: Laminar Pipe FlowSaranya KannanBelum ada peringkat