PIPELINE WALL THICKNESS CALCULATIONS

Diunggah oleh

Mohsin RazaJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

PIPELINE WALL THICKNESS CALCULATIONS

Diunggah oleh

Mohsin RazaHak Cipta:

Format Tersedia

PIPELINE WALL THICKNESS CALCULATIONS

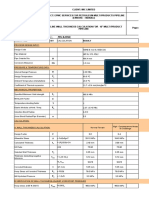

AS PER ASME B 31.4

PROJECT: Detailed Route Survey and Front End Engineering Design

(FEED) of Machike-Thallian-Taru Jabba WOP

Job Number: 2832

Date Jan. 01, 2019

Section Thallian - ARL

Chainage 0 + 41.5 Km

Length 50 Km

Piping Specification: API 5L (SAW)

Piping Code: ASME B31.4

Discharge Pressure (Operating) 725 Psig

Design Pressure (P): 800 Psig 797.5

Design Pressure Margin 10.3 %

Design Temperature: 140 o

F

Nominal Pipe Diameter: 10 in

Outside Dia. of Pipe (Do): 10.75 in

Additional Thickness (A): 1.5 mm

(Corrosion Allowance)

Pipe Material: API 5L Gr. X 70

Max. Allowable Stress Value (SE): 70300 Psi Table D-1

Joint Factor (Ej): 1 Table 841.115A

Design Factor (F): 0.72 Table 841.114 A/B

Temperature Factor (T): 1 Table 841.116 A

Minimum Wall Thickness without C.A. :

2.16 mm

Calculated Wall Thickness with C.A. : 3.66 mm

Selected Wall Thickness / Weight 4.8 mm / Kg

[ Dia. to W.T. Ratio =< 96 per DEP] OK

Doc. No. : 2832-DC-001 Rev. 0 Page 1

PIPELINE WALL THICKNESS CALCULATIONS

AS PER ASME B 31.4

Code Requirements :

Hoop Stress (SH) as per Code SH ≤ 0.72 SMYS = 50616 Psi

Longitudinal Compression (SC) Stress SL + SH ≤ 0.9 SMYS = 63270 Psi

Where : SH = P x D / 2 x t

SL = E x α x (T2 - T1) - γ x SH

Modulus of Elasticity (E) 29000000 Psi

Linear Co-efficient of Thermal Expansion (α) 0.0000065

Poisson's Ratio (γ) 0.3

Tie-in Temperature T1 60 o

F

Pipe Wall Thickness Calculations By Compressive Stress (Exclusive of Allowances):

SL + SH = 0.9 SMYS

0.9 SMYS = E x α x (T2 - T1) - γ x SH + SH

SC = 0.9 SMYS = E x α x (T2 - T1) + 0.7 x (P x D / 2 x t)

= 15080 + 0.35 x P x D / t

0.35 x P x D / t = SC - 15080

t = 0.35 x P x D / (Sc - 15080 0.062 Inch

1.587 mm

Minimum Pipe Wall Thickness by Compressive Stress 1.587 mm

Pipe Wall Thickness Calculations By Hoop Stress (Exclusive of Allowances) :

0.72 SMYS = P x D / 2 x t

t= P x D / (2 x 0.72 x SMYS) 0.085 Inch

2.158 mm

RESULTS : HOOP STRESS GOVERNS I.E., t = 2.158 mm

Doc. No. : 2832-DC-001 Rev. 0 Page 2

PIPELINE WALL THICKNESS CALCULATIONS

AS PER ASME B 31.4

PROJECT: Detailed Route Survey and Front End Engineering Design

(FEED) of Machike-Thallian-Taru Jabba WOP

Job Number: 2832

Date Jan. 01, 2019

Section Thallian-Taru Jabba

Chainage 129.5 + 172 Km

Length 50 Km

Piping Specification: API 5L (SAW)

Piping Code: ASME B31.4

Discharge Pressure (Operating) 793 Psig

Design Pressure (P): 873 Psig 872.3

Design Pressure Margin 10.1 %

Design Temperature: 122 o

F

Nominal Pipe Diameter: 10 in

Outside Dia. of Pipe (Do): 10.75 in

Additional Thickness (A): 1.5 mm

(Corrosion Allowance)

Pipe Material: API 5L Gr. X 70

Max. Allowable Stress Value (SE): 70300 Psi Table D-1

Joint Factor (Ej): 1 Table 841.115A

Design Factor (F): 0.72 Table 841.114 A/B

Temperature Factor (T): 1 Table 841.116 A

Minimum Wall Thickness without C.A. :

2.35 mm

Calculated Wall Thickness with C.A. : 3.85 mm

Selected Wall Thickness 4.8 mm

[ Dia. to W.T. Ratio =< 96 per DEP] OK

Doc. No. : 2832-DC-001 Rev. 0 Page 3

PIPELINE WALL THICKNESS CALCULATIONS

AS PER ASME B 31.4

Code Requirements :

Hoop Stress (SH) as per Code SH ≤ 0.72 SMYS = 50616 Psi

Longitudinal Compression (SC) Stress SL + SH ≤ 0.9 SMYS = 63270 Psi

Where : SH = P x D / 2 x t

SL = E x α x (T2 - T1) - γ x SH

Modulus of Elasticity (E) 29000000 Psi

Linear Co-efficient of Thermal Expansion (α) 0.0000065

Poisson's Ratio (γ) 0.3

Tie-in Temperature T1 60 o

F

Pipe Wall Thickness Calculations By Compressive Stress (Exclusive of Allowances):

SL + SH = 0.9 SMYS

0.9 SMYS = E x α x (T2 - T1) - γ x SH + SH

SC = 0.9 SMYS = E x α x (T2 - T1) + 0.7 x (P x D / 2 x t)

= 11687 + 0.35 x P x D / t

0.35 x P x D / t = SC - 11687

t = 0.35 x P x D / (Sc - 11687 0.064 Inch

1.617 mm

Minimum Pipe Wall Thickness by Compressive Stress 1.617 mm

Pipe Wall Thickness Calculations By Hoop Stress (Exclusive of Allowances) :

0.72 SMYS = P x D / 2 x t

t= P x D / (2 x 0.72 x SMYS) 0.093 Inch

2.355 mm

RESULTS : HOOP STRESS GOVERNS I.E., t = 2.355 mm

Doc. No. : 2832-DC-001 Rev. 0 Page 4

PIPELINE WALL THICKNESS CALCULATIONS

AS PER ASME B 31.4

PROJECT: Detailed Route Survey and Front End Engineering Design

(FEED) of Machike-Thallian-Taru Jabba WOP

Job Number: 2832

Date Jan. 01, 2019

Section Machike - Thallian

Chainage 0 + 50 Km

Length 50 Km

Piping Specification: API 5L (SAW)

Piping Code: ASME B31.4

Discharge Pressure (Operating) 853 Psig

Design Pressure (P): 1000 Psig 938.3

Design Pressure Margin 17.2 %

Design Temperature: 140 o

F

Nominal Pipe Diameter: 10 in

Outside Dia. of Pipe (Do): 10.75 in

Additional Thickness (A): 1.5 mm

(Corrosion Allowance)

Pipe Material: API 5L Gr. X 70

Max. Allowable Stress Value (SE): 70000 Psi Table D-1

Joint Factor (Ej): 1 Table 841.115A

Design Factor (F): 0.72 Table 841.114 A/B

Temperature Factor (T): 1 Table 841.116 A

Minimum Wall Thickness without C.A. :

2.71 mm

Calculated Wall Thickness with C.A. : 4.21 mm

Selected Wall Thickness / Weight 6.4 mm / Kg

[ Dia. to W.T. Ratio =< 96 per DEP] OK

Doc. No. : 2832-DC-001 Rev. 0 Page 5

PIPELINE WALL THICKNESS CALCULATIONS

AS PER ASME B 31.4

Code Requirements :

Hoop Stress (SH) as per Code SH ≤ 0.72 SMYS = 50400 Psi

Longitudinal Compression (SC) Stress SL + SH ≤ 0.9 SMYS = 63000 Psi

Where : SH = P x D / 2 x t

SL = E x α x (T2 - T1) - γ x SH

Modulus of Elasticity (E) 29000000 Psi

Linear Co-efficient of Thermal Expansion (α) 0.0000065

Poisson's Ratio (γ) 0.3

Tie-in Temperature T1 60 o

F

Pipe Wall Thickness Calculations By Compressive Stress (Exclusive of Allowances):

SL + SH = 0.9 SMYS

0.9 SMYS = E x α x (T2 - T1) - γ x SH + SH

SC = 0.9 SMYS = E x α x (T2 - T1) + 0.7 x (P x D / 2 x t)

= 15080 + 0.35 x P x D / t

0.35 x P x D / t = SC - 15080

t = 0.35 x P x D / (Sc - 15080 0.079 Inch

1.994 mm

Minimum Pipe Wall Thickness by Compressive Stress 1.994 mm

Pipe Wall Thickness Calculations By Hoop Stress (Exclusive of Allowances) :

0.72 SMYS = P x D / 2 x t

t= P x D / (2 x 0.72 x SMYS) 0.107 Inch

2.709 mm

RESULTS : HOOP STRESS GOVERNS I.E., t = 2.709 mm

Doc. No. : 2832-DC-001 Rev. 0 Page 6

PIPELINE WALL THICKNESS CALCULATIONS

AS PER ASME B 31.4

PROJECT: Detailed Route Survey and Front End Engineering Design

(FEED) of Machike-Thallian-Taru Jabba WOP

Job Number: 2832

Date Aug. 31, 2018

Section Thallian - Taru Jabba

Calculations By: Shoaib Siddiqui

Product HSD / Mogas

Piping Specification: API 5L (SAW)

Piping Code: ASME B31.4

Design Pressure (P): 900 Psi

Design Temperature: 140 o

F

Nominal Pipe Diameter: 10 in

Outside Dia. of Pipe (Do): 10 in

Additional Thickness (A): 1.5 mm

(Corrosion Allowance)

Pipe Material: API 5L Gr. X 70

Max. Allowable Stress Value (SE): 70000 Psi Table D-1

Joint Factor (Ej): 1 Table 841.115A

Design Factor (F): 0.72 Table 841.114 A/B

Temperature Factor (T): 1 Table 841.116 A

Minimum Wall Thickness without C.A. :

2.27 mm

Calculated Wall Thickness with C.A. : 3.77 mm

Selected Wall Thickness 5.16 mm

[ Dia. to W.T. Ratio =< 96 per DEP] OK

Doc. No. : 2832-DC-001 Rev. 0 Page 7

PIPELINE WALL THICKNESS CALCULATIONS

AS PER ASME B 31.4

Code Requirements :

Hoop Stress (SH) as per Code SH ≤ 0.72 SMYS = 50400 Psi

Longitudinal Compression (SC) Stress SL + SH ≤ 0.9 SMYS = 63000 Psi

Where : SH = P x D / 2 x t

SL = E x α x (T2 - T1) - γ x SH

Modulus of Elasticity (E) 29000000 Psi

Linear Co-efficient of Thermal Expansion (α) 0.0000065

Poisson's Ratio (γ) 0.3

Tie-in Temperature T1 60 o

F

Pipe Wall Thickness Calculations By Compressive Stress (Exclusive of Allowances):

SL + SH = 0.9 SMYS

0.9 SMYS = E x α x (T2 - T1) - γ x SH + SH

SC = 0.9 SMYS = E x α x (T2 - T1) + 0.7 x (P x D / 2 x t)

= 15080 + 0.35 x P x D / t

0.35 x P x D / t = SC - 15080

t = 0.35 x P x D / (Sc - 15080 0.066 Inch

1.670 mm

Minimum Pipe Wall Thickness by Compressive Stress 1.670 mm

Pipe Wall Thickness Calculations By Hoop Stress (Exclusive of Allowances) :

0.72 SMYS = P x D / 2 x t

t= P x D / (2 x 0.72 x SMYS) 0.089 Inch

2.268 mm

RESULTS : HOOP STRESS GOVERNS I.E., t = 2.268 mm

Doc. No. : 2832-DC-001 Rev. 0 Page 8

PIPELINE WALL THICKNESS CALCULATIONS

AS PER ASME B 31.4

PROJECT: Detailed Route Survey and Front End Engineering Design

(FEED) of Machike-Thallian-Taru Jabba WOP

Job Number: 2832

Date Aug. 31, 2018

Section Thallian - Taru Jabba

Calculations By: Shoaib Siddiqui

Product HSD / Mogas

Piping Specification: API 5L (SAW)

Piping Code: ASME B31.4

1017 Psig 10%

Design Pressure (P): 1250 Psig 1118.7

Design Margin 22.91052114 Psi

Design Temperature: 140 o

F

Nominal Pipe Diameter: 12 in

Outside Dia. of Pipe (Do): 12.75 in

Additional Thickness (A): 1.5 mm

(Corrosion Allowance)

Pipe Material: API 5L Gr. X 70

Max. Allowable Stress Value (SE): 70000 Psi Table D-1

Joint Factor (Ej): 1 Table 841.115A

Design Factor (F): 0.72 Table 841.114 A/B

Temperature Factor (T): 1 Table 841.116 A

Minimum Wall Thickness without C.A. :

4.02 mm

Calculated Wall Thickness with C.A. : 5.52 mm

Selected Wall Thickness 5.2 mm

[ Dia. to W.T. Ratio =< 96 per DEP] OK

Doc. No. : 2832-DC-001 Rev. 0 Page 9

PIPELINE WALL THICKNESS CALCULATIONS

AS PER ASME B 31.4

Code Requirements :

Hoop Stress (SH) as per Code SH ≤ 0.72 SMYS = 50400 Psi

Longitudinal Compression (SC) Stress SL + SH ≤ 0.9 SMYS = 63000 Psi

Where : SH = P x D / 2 x t

SL = E x α x (T2 - T1) - γ x SH

Modulus of Elasticity (E) 29000000 Psi

Linear Co-efficient of Thermal Expansion (α) 0.0000065

Poisson's Ratio (γ) 0.3

Tie-in Temperature T1 60 o

F

Pipe Wall Thickness Calculations By Compressive Stress (Exclusive of Allowances):

SL + SH = 0.9 SMYS

0.9 SMYS = E x α x (T2 - T1) - γ x SH + SH

SC = 0.9 SMYS = E x α x (T2 - T1) + 0.7 x (P x D / 2 x t)

= 15080 + 0.35 x P x D / t

0.35 x P x D / t = SC - 15080

t = 0.35 x P x D / (Sc - 15080 0.116 Inch

2.957 mm

Minimum Pipe Wall Thickness by Compressive Stress 2.957 mm

Pipe Wall Thickness Calculations By Hoop Stress (Exclusive of Allowances) :

0.72 SMYS = P x D / 2 x t

t= P x D / (2 x 0.72 x SMYS) 0.158 Inch

4.016 mm

RESULTS : HOOP STRESS GOVERNS I.E., t = 4.016 mm

Doc. No. : 2832-DC-001 Rev. 0 Page 10

PIPELINE WALL THICKNESS CALCULATIONS

AS PER ASME B 31.4

PROJECT: Detailed Route Survey and Front End Engineering Design

(FEED) of Machike-Thallian-Taru Jabba WOP

Job Number: 2832

Date Aug. 31, 2018

Section Thallian - Taru Jabba

Calculations By: Shoaib Siddiqui

Product HSD / Mogas

Piping Specification: API 5L (SAW)

Piping Code: ASME B31.4

1285 Psig 10%

Design Pressure (P): 1420 Psig 1413.5

Design Margin 10.50583658 Psi

Design Temperature: 140 o

F

Nominal Pipe Diameter: 12 in

Outside Dia. of Pipe (Do): 12.75 in

Additional Thickness (A): 1.5 mm

(Corrosion Allowance)

Pipe Material: API 5L Gr. X 70

Max. Allowable Stress Value (SE): 70000 Psi Table D-1

Joint Factor (Ej): 1 Table 841.115A

Design Factor (F): 0.72 Table 841.114 A/B

Temperature Factor (T): 1 Table 841.116 A

Minimum Wall Thickness without C.A. :

4.56 mm

Calculated Wall Thickness with C.A. : 6.06 mm

Selected Wall Thickness 5.2 mm

[ Dia. to W.T. Ratio =< 96 per DEP] OK

Doc. No. : 2832-DC-001 Rev. 0 Page 11

PIPELINE WALL THICKNESS CALCULATIONS

AS PER ASME B 31.4

Code Requirements :

Hoop Stress (SH) as per Code SH ≤ 0.72 SMYS = 50400 Psi

Longitudinal Compression (SC) Stress SL + SH ≤ 0.9 SMYS = 63000 Psi

Where : SH = P x D / 2 x t

SL = E x α x (T2 - T1) - γ x SH

Modulus of Elasticity (E) 29000000 Psi

Linear Co-efficient of Thermal Expansion (α) 0.0000065

Poisson's Ratio (γ) 0.3

Tie-in Temperature T1 60 o

F

Pipe Wall Thickness Calculations By Compressive Stress (Exclusive of Allowances):

SL + SH = 0.9 SMYS

0.9 SMYS = E x α x (T2 - T1) - γ x SH + SH

SC = 0.9 SMYS = E x α x (T2 - T1) + 0.7 x (P x D / 2 x t)

= 15080 + 0.35 x P x D / t

0.35 x P x D / t = SC - 15080

t = 0.35 x P x D / (Sc - 15080 0.132 Inch

3.359 mm

Minimum Pipe Wall Thickness by Compressive Stress 3.359 mm

Pipe Wall Thickness Calculations By Hoop Stress (Exclusive of Allowances) :

0.72 SMYS = P x D / 2 x t

t= P x D / (2 x 0.72 x SMYS) 0.180 Inch

4.562 mm

RESULTS : HOOP STRESS GOVERNS I.E., t = 4.562 mm

Doc. No. : 2832-DC-001 Rev. 0 Page 12

PIPELINE WALL THICKNESS CALCULATIONS

AS PER ASME B 31.4

PROJECT: Detailed Route Survey and Front End Engineering Design

(FEED) of Machike-Thallian-Taru Jabba WOP

Job Number: 2832

Date Aug. 31, 2018

Section Machike - Thallian

Calculations By: Shoaib Siddiqui

Product HSD / Mogas

Piping Specification: API 5L (SAW)

Piping Code: ASME B31.4

Design Pressure (P): 850 Psi

Design Temperature: 140 o

F

Nominal Pipe Diameter: 18 in

Outside Dia. of Pipe (Do): 18 in

Additional Thickness (A): 1.5 mm

(Corrosion Allowance)

Pipe Material: API 5L Gr. X 70

Max. Allowable Stress Value (SE): 70000 Psi Table D-1

Joint Factor (Ej): 1 Table 841.115A

Design Factor (F): 0.72 Table 841.114 A/B

Temperature Factor (T): 1 Table 841.116 A

Minimum Wall Thickness without C.A. :

3.86 mm

Calculated Wall Thickness with C.A. : 5.36 mm

Selected Wall Thickness 6.4 mm

[ Dia. to W.T. Ratio =< 96 per DEP] OK

Doc. No. : 2832-DC-001 Rev. 0 Page 13

PIPELINE WALL THICKNESS CALCULATIONS

AS PER ASME B 31.4

Code Requirements :

Hoop Stress (SH) as per Code SH ≤ 0.72 SMYS = 50400 Psi

Longitudinal Compression (SC) Stress SL + SH ≤ 0.9 SMYS = 63000 Psi

Where : SH = P x D / 2 x t

SL = E x α x (T2 - T1) - γ x SH

Modulus of Elasticity (E) 29000000 Psi

Linear Co-efficient of Thermal Expansion (α) 0.0000065

Poisson's Ratio (γ) 0.3

Tie-in Temperature T1 60 o

F

Pipe Wall Thickness Calculations By Compressive Stress (Exclusive of Allowances):

SL + SH = 0.9 SMYS

0.9 SMYS = E x α x (T2 - T1) - γ x SH + SH

SC = 0.9 SMYS = E x α x (T2 - T1) + 0.7 x (P x D / 2 x t)

= 15080 + 0.35 x P x D / t

0.35 x P x D / t = SC - 15080

t = 0.35 x P x D / (Sc - 15080 0.112 Inch

2.838 mm

Minimum Pipe Wall Thickness by Compressive Stress 2.838 mm

Pipe Wall Thickness Calculations By Hoop Stress (Exclusive of Allowances) :

0.72 SMYS = P x D / 2 x t

t= P x D / (2 x 0.72 x SMYS) 0.152 Inch

3.855 mm

RESULTS : HOOP STRESS GOVERNS I.E., t = 3.855 mm

Doc. No. : 2832-DC-001 Rev. 0 Page 14

PIPELINE WALL THICKNESS CALCULATIONS

AS PER ASME B 31.4

PROJECT: Detailed Route Survey and Front End Engineering Design

(FEED) of Machike-Thallian-Taru Jabba WOP

Job Number: 2832

Date Jan. 01, 2019

Section Machike - Thallian

Chainage 0 + 50 Km

Length 50 Km

Piping Specification: API 5L (SAW)

Piping Code: ASME B31.4

Discharge Pressure (Operating) 352 Psig

Design Pressure (P): 388 Psig 387.2

Design Pressure Margin 10.0 %

Design Temperature: 140 o

F

Nominal Pipe Diameter: 18 in

Outside Dia. of Pipe (Do): 18 in

Additional Thickness (A): 1.5 mm

(Corrosion Allowance)

Pipe Material: API 5L Gr. X 70

Max. Allowable Stress Value (SE): 70000 Psi Table D-1

Joint Factor (Ej): 1 Table 841.115A

Design Factor (F): 0.72 Table 841.114 A/B

Temperature Factor (T): 1 Table 841.116 A

Minimum Wall Thickness without C.A. :

1.76 mm

Calculated Wall Thickness with C.A. : 3.26 mm

Selected Wall Thickness / Weight 6.4 mm / Kg

[ Dia. to W.T. Ratio =< 96 per DEP] OK

Doc. No. : 2832-DC-001 Rev. 0 Page 15

PIPELINE WALL THICKNESS CALCULATIONS

AS PER ASME B 31.4

Code Requirements :

Hoop Stress (SH) as per Code SH ≤ 0.72 SMYS = 50400 Psi

Longitudinal Compression (SC) Stress SL + SH ≤ 0.9 SMYS = 63000 Psi

Where : SH = P x D / 2 x t

SL = E x α x (T2 - T1) - γ x SH

Modulus of Elasticity (E) 29000000 Psi

Linear Co-efficient of Thermal Expansion (α) 0.0000065

Poisson's Ratio (γ) 0.3

Tie-in Temperature T1 60 o

F

Pipe Wall Thickness Calculations By Compressive Stress (Exclusive of Allowances):

SL + SH = 0.9 SMYS

0.9 SMYS = E x α x (T2 - T1) - γ x SH + SH

SC = 0.9 SMYS = E x α x (T2 - T1) + 0.7 x (P x D / 2 x t)

= 15080 + 0.35 x P x D / t

0.35 x P x D / t = SC - 15080

t = 0.35 x P x D / (Sc - 15080 0.051 Inch

1.296 mm

Minimum Pipe Wall Thickness by Compressive Stress 1.296 mm

Pipe Wall Thickness Calculations By Hoop Stress (Exclusive of Allowances) :

0.72 SMYS = P x D / 2 x t

t= P x D / (2 x 0.72 x SMYS) 0.069 Inch

1.760 mm

RESULTS : HOOP STRESS GOVERNS I.E., t = 1.760 mm

Doc. No. : 2832-DC-001 Rev. 0 Page 16

PIPELINE WALL THICKNESS CALCULATIONS

AS PER ASME B 31.4

PROJECT: Detailed Route Survey and Front End Engineering Design

(FEED) of Machike-Thallian-Taru Jabba WOP

Job Number: 2832

Date Oct. 10, 2019

Section Machike - Thallian

Chainage 100 +148 Km

Length 50 Km

Piping Specification: API 5L 46th Edition 2018

Type SAW

Piping Code: ASME B31.4 Edition 2016

Discharge Pressure (Operating) 1245 Psig

Design Pressure (P): 1369.5 Psig

Design Pressure Margin 10.0 %

Design Temperature: 140 o

F

Nominal Pipe Diameter: 20 in

Outside Dia. of Pipe (Do): 20 in

Additional Thickness (A): 1.5 mm

(Corrosion Allowance)

Pipe Material: API 5L Gr. X 70

Max. Allowable Stress Value (SE): 70300 Psi Table H.2 (API 5L)

Weld Joint Factor (E): 1 Table 403.2.1-1

Design Factor (F): 0.72 Clause 403.2

6.87 mm

Calculated Wall Thickness with C.A. : 8.37 mm

Selected Wall Thickness 7.1 mm

[ D/t Ratio < 100 per Clause 403.2.5] OK

Doc. No. : 2832-DC-001 Rev. 0 Page 17

PIPELINE WALL THICKNESS CALCULATIONS

AS PER ASME B 31.4

Code Requirements :

Hoop Stress (SH) as per Code SH ≤ 0.72 SMYS = 50616 Psi

Longitudinal Compression (SC) Stress SL + SH ≤ 0.9 SMYS = 63270 Psi

Where : SH = P x D / 2 x t

SL = E x α x (T2 - T1) - γ x SH

Modulus of Elasticity (E) 29000000 Psi

Linear Co-efficient of Thermal Expansion (α) 0.0000065

Poisson's Ratio (γ) 0.3

Tie-in Temperature T1 60 o

F

Pipe Wall Thickness Calculations By Compressive Stress (Exclusive of Allowances):

SL + SH = 0.9 SMYS

0.9 SMYS = E x α x (T2 - T1) - γ x SH + SH

SC = 0.9 SMYS = E x α x (T2 - T1) + 0.7 x (P x D / 2 x t)

= 15080 + 0.35 x P x D / t

0.35 x P x D / t = SC - 15080

t = 0.35 x P x D / (Sc - 15080 0.199 Inch

5.053 mm

Minimum Pipe Wall Thickness by Compressive Stress 5.053 mm

Pipe Wall Thickness Calculations By Hoop Stress (Exclusive of Allowances) :

0.72 SMYS = P x D / 2 x t

t= P x D / (2 x 0.72 x SMYS) 0.271 Inch

6.872 mm

RESULTS : HOOP STRESS GOVERNS I.E., t = 6.872 mm

Doc. No. : 2832-DC-001 Rev. 0 Page 18

PIPELINE WALL THICKNESS CALCULATIONS

AS PER ASME B 31.4

PROJECT: Detailed Route Survey and Front End Engineering Design

(FEED) of Machike-Thallian-Taru Jabba WOP

Job Number: 2832

Date Oct. 10, 2019

Section Machike - Thallian

Chainage 100 +148 Km

Length 50 Km

Piping Specification: API 5L 46th Edition 2018

Type SAW

Piping Code: ASME B31.4 Edition 2016

Discharge Pressure (Operating) 1152 Psig

Design Pressure (P): 1267.2 Psig

Design Pressure Margin 10.0 %

Design Temperature: 140 o

F

Nominal Pipe Diameter: 20 in

Outside Dia. of Pipe (Do): 20 in

Additional Thickness (A): 1.5 mm

(Corrosion Allowance)

Pipe Material: API 5L Gr. X 70

Max. Allowable Stress Value (SE): 70300 Psi Table H.2 (API 5L)

Weld Joint Factor (E): 1 Table 403.2.1-1

Design Factor (F): 0.72 Clause 403.2

6.36 mm

Calculated Wall Thickness with C.A. : 7.86 mm

Selected Wall Thickness 7.1 mm

[ D/t Ratio < 100 per Clause 403.2.5] OK

Doc. No. : 2832-DC-001 Rev. 0 Page 19

PIPELINE WALL THICKNESS CALCULATIONS

AS PER ASME B 31.4

Code Requirements :

Hoop Stress (SH) as per Code SH ≤ 0.72 SMYS = 50616 Psi

Longitudinal Compression (SC) Stress SL + SH ≤ 0.9 SMYS = 63270 Psi

Where : SH = P x D / 2 x t

SL = E x α x (T2 - T1) - γ x SH

Modulus of Elasticity (E) 29000000 Psi

Linear Co-efficient of Thermal Expansion (α) 0.0000065

Poisson's Ratio (γ) 0.3

Tie-in Temperature T1 60 o

F

Pipe Wall Thickness Calculations By Compressive Stress (Exclusive of Allowances):

SL + SH = 0.9 SMYS

0.9 SMYS = E x α x (T2 - T1) - γ x SH + SH

SC = 0.9 SMYS = E x α x (T2 - T1) + 0.7 x (P x D / 2 x t)

= 15080 + 0.35 x P x D / t

0.35 x P x D / t = SC - 15080

t = 0.35 x P x D / (Sc - 15080 0.184 Inch

4.675 mm

Minimum Pipe Wall Thickness by Compressive Stress 4.675 mm

Pipe Wall Thickness Calculations By Hoop Stress (Exclusive of Allowances) :

0.72 SMYS = P x D / 2 x t

t= P x D / (2 x 0.72 x SMYS) 0.250 Inch

6.359 mm

RESULTS : HOOP STRESS GOVERNS I.E., t = 6.359 mm

Doc. No. : 2832-DC-001 Rev. 0 Page 20

PIPELINE WALL THICKNESS CALCULATIONS

AS PER ASME B 31.4

PROJECT: Detailed Route Survey and Front End Engineering Design

(FEED) of Machike-Thallian-Taru Jabba WOP

Job Number: 2832

Date Jan. 01, 2019

Section Machike - Thallian

Chainage 220 + 265 Km

Length 50 Km

Piping Specification: API 5L (SAW)

Piping Code: ASME B31.4

Discharge Pressure (Operating) 274 Psig

Design Pressure (P): 301 Psig

Design Pressure Margin 10.0 %

Design Temperature: 122 o

F

Nominal Pipe Diameter: 18 in

Outside Dia. of Pipe (Do): 18 in

Additional Thickness (A): 1.5 mm

(Corrosion Allowance)

Pipe Material: API 5L Gr. X 70

Max. Allowable Stress Value (SE): 70300 Psi Table D-1

Joint Factor (Ej): 1 Table 841.115A

Design Factor (F): 0.72 Table 841.114 A/B

Temperature Factor (T): 1 Table 841.116 A

Minimum Wall Thickness without C.A. :

1.36 mm

Calculated Wall Thickness with C.A. : 2.86 mm

Selected Wall Thickness 6.4 mm

[ Dia. to W.T. Ratio =< 96 per DEP] OK

Doc. No. : 2832-DC-001 Rev. 0 Page 21

PIPELINE WALL THICKNESS CALCULATIONS

AS PER ASME B 31.4

Code Requirements :

Hoop Stress (SH) as per Code SH ≤ 0.72 SMYS = 50616 Psi

Longitudinal Compression (SC) Stress SL + SH ≤ 0.9 SMYS = 63270 Psi

Where : SH = P x D / 2 x t

SL = E x α x (T2 - T1) - γ x SH

Modulus of Elasticity (E) 29000000 Psi

Linear Co-efficient of Thermal Expansion (α) 0.0000065

Poisson's Ratio (γ) 0.3

Tie-in Temperature T1 60 o

F

Pipe Wall Thickness Calculations By Compressive Stress (Exclusive of Allowances):

SL + SH = 0.9 SMYS

0.9 SMYS = E x α x (T2 - T1) - γ x SH + SH

SC = 0.9 SMYS = E x α x (T2 - T1) + 0.7 x (P x D / 2 x t)

= 11687 + 0.35 x P x D / t

0.35 x P x D / t = SC - 11687

t = 0.35 x P x D / (Sc - 11687 0.037 Inch

0.934 mm

Minimum Pipe Wall Thickness by Compressive Stress 0.934 mm

Pipe Wall Thickness Calculations By Hoop Stress (Exclusive of Allowances) :

0.72 SMYS = P x D / 2 x t

t= P x D / (2 x 0.72 x SMYS) 0.054 Inch

1.359 mm

RESULTS : HOOP STRESS GOVERNS I.E., t = 1.359 mm

Doc. No. : 2832-DC-001 Rev. 0 Page 22

PIPELINE WALL THICKNESS CALCULATIONS

AS PER ASME B 31.4

PROJECT: Detailed Route Survey and Front End Engineering Design

(FEED) of Machike-Thallian-Taru Jabba WOP

Job Number: 2832

Date Jan. 01, 2019

Section Machike - Thallian

Chainage 50 + 100 Km

Length 50 Km

Piping Specification: API 5L (SAW)

Piping Code: ASME B31.4

Discharge Pressure (Operating) 757 Psig

Design Pressure (P): 900 Psig 832.7

Design Pressure Margin 15.9 %

Design Temperature: 140 o

F

Nominal Pipe Diameter: 18 in

Outside Dia. of Pipe (Do): 18 in

Additional Thickness (A): 1.5 mm

(Corrosion Allowance)

Pipe Material: API 5L Gr. X 70

Max. Allowable Stress Value (SE): 70300 Psi Table D-1

Joint Factor (Ej): 1 Table 841.115A

Design Factor (F): 0.72 Table 841.114 A/B

Temperature Factor (T): 1 Table 841.116 A

Minimum Wall Thickness without C.A. :

4.06 mm

Calculated Wall Thickness with C.A. : 5.56 mm

Selected Wall Thickness / Weight 6.4 mm / Kg

[ Dia. to W.T. Ratio =< 96 per DEP] OK

Doc. No. : 2832-DC-001 Rev. 0 Page 23

PIPELINE WALL THICKNESS CALCULATIONS

AS PER ASME B 31.4

Code Requirements :

Hoop Stress (SH) as per Code SH ≤ 0.72 SMYS = 50616 Psi

Longitudinal Compression (SC) Stress SL + SH ≤ 0.9 SMYS = 63270 Psi

Where : SH = P x D / 2 x t

SL = E x α x (T2 - T1) - γ x SH

Modulus of Elasticity (E) 29000000 Psi

Linear Co-efficient of Thermal Expansion (α) 0.0000065

Poisson's Ratio (γ) 0.3

Tie-in Temperature T1 60 o

F

Pipe Wall Thickness Calculations By Compressive Stress (Exclusive of Allowances):

SL + SH = 0.9 SMYS

0.9 SMYS = E x α x (T2 - T1) - γ x SH + SH

SC = 0.9 SMYS = E x α x (T2 - T1) + 0.7 x (P x D / 2 x t)

= 15080 + 0.35 x P x D / t

0.35 x P x D / t = SC - 15080

t = 0.35 x P x D / (Sc - 15080 0.118 Inch

2.989 mm

Minimum Pipe Wall Thickness by Compressive Stress 2.989 mm

Pipe Wall Thickness Calculations By Hoop Stress (Exclusive of Allowances) :

0.72 SMYS = P x D / 2 x t

t= P x D / (2 x 0.72 x SMYS) 0.160 Inch

4.065 mm

RESULTS : HOOP STRESS GOVERNS I.E., t = 4.065 mm

Doc. No. : 2832-DC-001 Rev. 0 Page 24

Anda mungkin juga menyukai

- ASME B31.4-Wall Thickness Calc For 6 InchDokumen2 halamanASME B31.4-Wall Thickness Calc For 6 InchBagus Sukoco KocoBelum ada peringkat

- Wall Thickness Calculation ASME B31!8!2007Dokumen1 halamanWall Thickness Calculation ASME B31!8!2007shafeeqm3086Belum ada peringkat

- Calculation Sheet For Slug CatcherDokumen12 halamanCalculation Sheet For Slug CatcherchumaBelum ada peringkat

- Pipe Thickness Calculation For Straight Pipe Under Internal PressureDokumen7 halamanPipe Thickness Calculation For Straight Pipe Under Internal PressureMakhdoom Ibad HashmiBelum ada peringkat

- ASME B31 8 Riser CalcDokumen12 halamanASME B31 8 Riser CalcEmmanuel LawrenceBelum ada peringkat

- ISO 13623 pipe wall thickness calculation for Mahani-2 projectDokumen6 halamanISO 13623 pipe wall thickness calculation for Mahani-2 projectRanjan KumarBelum ada peringkat

- ASME B31.4 Riser CalcDokumen14 halamanASME B31.4 Riser CalcCastorNoroñoBelum ada peringkat

- Gas Line - 20 BargDokumen22 halamanGas Line - 20 Bargsaravanakkumar boominahtan100% (1)

- Pipeline Wall Thickness Calculation: 3.2 Calculated Using SCH WT W/o CorrosionDokumen2 halamanPipeline Wall Thickness Calculation: 3.2 Calculated Using SCH WT W/o CorrosionImmanuel SBelum ada peringkat

- Combined Stress Calc Rev. 2Dokumen12 halamanCombined Stress Calc Rev. 2babu75% (4)

- HDD Installation CalculationsDokumen4 halamanHDD Installation Calculationslive4sankar100% (1)

- Pipe Wall Thickness Calculation (As Per Asme B31.3 Section 304.1.2)Dokumen1 halamanPipe Wall Thickness Calculation (As Per Asme B31.3 Section 304.1.2)farhadBelum ada peringkat

- Wall THK Calculation Asme b31.4Dokumen5 halamanWall THK Calculation Asme b31.4Dwi Hermawan100% (2)

- Pipeline Buoyancy AnalysisDokumen12 halamanPipeline Buoyancy AnalysisbonnicoBelum ada peringkat

- ASME B31.3.4.8 Wall Thickness CalculatorDokumen26 halamanASME B31.3.4.8 Wall Thickness Calculatoreko123Belum ada peringkat

- Document Frontsheet: Project: 3930 - 9 - Olefin Complex Ethane Cracking PlantDokumen49 halamanDocument Frontsheet: Project: 3930 - 9 - Olefin Complex Ethane Cracking Plantsusa2536Belum ada peringkat

- Pipe Wall Thickness Calc Per ASME B31.8Dokumen1 halamanPipe Wall Thickness Calc Per ASME B31.8ktejankarBelum ada peringkat

- Pipe Is Under Clamping ForceDokumen7 halamanPipe Is Under Clamping ForceALP69Belum ada peringkat

- API RP 1102 SpreadsheetDokumen6 halamanAPI RP 1102 Spreadsheetm_michael_cBelum ada peringkat

- Pipe Size Flange Rating Operating Condition: E F SFDokumen4 halamanPipe Size Flange Rating Operating Condition: E F SFvivekpec100% (1)

- Calculation of PipeReinforcement ASMEB31.1Dokumen3 halamanCalculation of PipeReinforcement ASMEB31.1jayaarnav100% (1)

- Wall THK Calculation Asme b31.4Dokumen7 halamanWall THK Calculation Asme b31.4Luis Jose Duran100% (1)

- Pipeline Calculations - ASAB Gas Lift LinesDokumen11 halamanPipeline Calculations - ASAB Gas Lift LinesSaqib LaeeqBelum ada peringkat

- Reinforcement CheckDokumen2 halamanReinforcement Checkviv0102Belum ada peringkat

- Wall Thickness Calculation Verification under StressDokumen1 halamanWall Thickness Calculation Verification under StresshhgjdfBelum ada peringkat

- Trunnion Calcualtion SheetDokumen22 halamanTrunnion Calcualtion SheetAbhijit0% (1)

- Attachment - 1 Document No. 081113B-CL-303-R0 Permissible Elastic Bend Limit Calculation (48in Hassyan Gas Pipeline Location Class 4)Dokumen4 halamanAttachment - 1 Document No. 081113B-CL-303-R0 Permissible Elastic Bend Limit Calculation (48in Hassyan Gas Pipeline Location Class 4)ISRAEL PORTILLOBelum ada peringkat

- GF-OGF4-P-CA-2001 - Pipeline Design Report - Rev 0 - AFC...Dokumen60 halamanGF-OGF4-P-CA-2001 - Pipeline Design Report - Rev 0 - AFC...Rami KsidaBelum ada peringkat

- Permissible Elastic Bend Limit Calculations for PipelinesDokumen4 halamanPermissible Elastic Bend Limit Calculations for Pipelinesheldermanuel100Belum ada peringkat

- Thickness Analysis ReportDokumen9 halamanThickness Analysis ReportEhtisham AndrAbiBelum ada peringkat

- Wall Thickness Calculation of 36in Gas PipelineDokumen1 halamanWall Thickness Calculation of 36in Gas PipelineLU1228100% (3)

- PSV Force Rev0bDokumen1 halamanPSV Force Rev0bdumbledoreaaaaBelum ada peringkat

- Modification Thickness of A FlangeDokumen3 halamanModification Thickness of A FlangePeter PerezBelum ada peringkat

- PY SEW Do P T: Pipe Wall Thickness Calculation SheetDokumen1 halamanPY SEW Do P T: Pipe Wall Thickness Calculation Sheetanon_714194540Belum ada peringkat

- Piepline Thickness CalculationDokumen6 halamanPiepline Thickness CalculationAneeq NaufalBelum ada peringkat

- Pipe Branch Connection CalculationDokumen3 halamanPipe Branch Connection Calculationsaravoot_jBelum ada peringkat

- Wall Thickness Calculation Followed B31.8 PDFDokumen3 halamanWall Thickness Calculation Followed B31.8 PDFBPCL HCULOBS100% (1)

- HDPE Pipe Thickness CalculationsDokumen5 halamanHDPE Pipe Thickness CalculationsBudi SantonyBelum ada peringkat

- PSV Reaction Force CalculationDokumen1 halamanPSV Reaction Force CalculationAndrei Ionut UtaBelum ada peringkat

- Heat loss from a buried oil line: Conduction shape factor and insulation effectDokumen20 halamanHeat loss from a buried oil line: Conduction shape factor and insulation effectJuan Pablo ApazaBelum ada peringkat

- Safety Valve Reaction Foce Calculation: Isometric: 10Lbg10Br192, Rev. A Project: Kat065 Raslaffan BDokumen4 halamanSafety Valve Reaction Foce Calculation: Isometric: 10Lbg10Br192, Rev. A Project: Kat065 Raslaffan BAnonymous Iev5ggSRBelum ada peringkat

- Upheaval Buckling Calculation 24Dokumen10 halamanUpheaval Buckling Calculation 24Moustafa Fares100% (1)

- ASME Ver1 4 (Beta)Dokumen2 halamanASME Ver1 4 (Beta)arunradBelum ada peringkat

- Gas Line Capacity CalculationDokumen2 halamanGas Line Capacity CalculationMario Mendoza100% (1)

- Design Calculations For Pressure ShellDokumen33 halamanDesign Calculations For Pressure ShellGeorge GeorgianBelum ada peringkat

- Imperial Piping Weight Load Calculation WorkbookDokumen13 halamanImperial Piping Weight Load Calculation WorkbookKakoDa100% (1)

- Es Emp Iocal Colo en 13480Dokumen25 halamanEs Emp Iocal Colo en 13480castibraBelum ada peringkat

- Pipe Thickness Calculation AS Per ASME 31.3Dokumen11 halamanPipe Thickness Calculation AS Per ASME 31.3Anonymous Iev5ggSRBelum ada peringkat

- Pipe Thickness Calculation Data SheetDokumen1 halamanPipe Thickness Calculation Data SheetAnonymous 6ZWS6IG2J9Belum ada peringkat

- QR4798 16x12 600# HTF - CALCDokumen3 halamanQR4798 16x12 600# HTF - CALCjasamaBelum ada peringkat

- WT Calculation - Pipelines With CRA CladDokumen6 halamanWT Calculation - Pipelines With CRA CladShankar VadivelBelum ada peringkat

- Calculation Sheet: WT-CAL-CO2-003Dokumen4 halamanCalculation Sheet: WT-CAL-CO2-003babu100% (1)

- ASME B31.4-Wall Thickness CalDokumen2 halamanASME B31.4-Wall Thickness CalBagus Sukoco Koco100% (1)

- Cálculo de La Silleta ParcialDokumen3 halamanCálculo de La Silleta ParcialALBERTO COCOM CELAYABelum ada peringkat

- Basis of Design - PIG LAUNCHER 16 DESIGN 2014Dokumen27 halamanBasis of Design - PIG LAUNCHER 16 DESIGN 2014Andreas Schlager100% (1)

- Pig Receiver Design CalculationDokumen27 halamanPig Receiver Design CalculationAndreas SchlagerBelum ada peringkat

- IS 13920 Beam Reinforcement SpecificationsDokumen7 halamanIS 13920 Beam Reinforcement Specificationsyedida viswanadhBelum ada peringkat

- Wall Thickness 2Dokumen18 halamanWall Thickness 2Imam Zulfir RamandhaBelum ada peringkat

- VSL CalDokumen50 halamanVSL CalEmrahCayboyluBelum ada peringkat

- Ibr Stand PipeDokumen11 halamanIbr Stand PipeP s JagatheesanBelum ada peringkat

- Water Ambient Test - SSDokumen2 halamanWater Ambient Test - SSMohsin RazaBelum ada peringkat

- TOGH Well # 1 Post Completion ResultsDokumen1 halamanTOGH Well # 1 Post Completion ResultsMohsin RazaBelum ada peringkat

- Curves Are Approximate, Pump Is Guaranteed For One Set of Conditions Capacity, Head, and PowerDokumen4 halamanCurves Are Approximate, Pump Is Guaranteed For One Set of Conditions Capacity, Head, and PowerMohsin RazaBelum ada peringkat

- Exam SSDokumen1 halamanExam SSMohsin RazaBelum ada peringkat

- CommentsDokumen9 halamanCommentsMohsin RazaBelum ada peringkat

- Tier 2 & 5 Sponsors PDFDokumen1.915 halamanTier 2 & 5 Sponsors PDFMohsin RazaBelum ada peringkat

- Hydraulic and Surge Analysis in A Pipeline Network Using PipelineStudioDokumen8 halamanHydraulic and Surge Analysis in A Pipeline Network Using PipelineStudioAnonymous WNWk1h2Belum ada peringkat

- Exam - Return To Normal - SSDokumen1 halamanExam - Return To Normal - SSMohsin RazaBelum ada peringkat

- HRL PDFDokumen1 halamanHRL PDFMohsin RazaBelum ada peringkat

- Section 3 - Technical PackageDokumen39 halamanSection 3 - Technical PackageMohsin RazaBelum ada peringkat

- Togh HydraulicsDokumen2 halamanTogh HydraulicsMohsin RazaBelum ada peringkat

- 2Dokumen17 halaman2Mohsin RazaBelum ada peringkat

- Procedures For Pigging OperationsDokumen5 halamanProcedures For Pigging Operationsテレブリコ ジェファーソン78% (9)

- 4Dokumen20 halaman4Mohsin RazaBelum ada peringkat

- Pump House Pool FireDokumen15 halamanPump House Pool FireMohsin RazaBelum ada peringkat

- Loading Gantry Pool Fire PDFDokumen16 halamanLoading Gantry Pool Fire PDFMohsin RazaBelum ada peringkat

- Your pathway to professionalismDokumen14 halamanYour pathway to professionalismMohsin RazaBelum ada peringkat

- 5110.003.10 PIG-SIG V Pig Passage Indicator FINALDokumen8 halaman5110.003.10 PIG-SIG V Pig Passage Indicator FINALtheloniussherekBelum ada peringkat

- EJMA Bellows CalculatorDokumen6 halamanEJMA Bellows Calculatorsammar_10Belum ada peringkat

- Refrigeration FundamentalsDokumen92 halamanRefrigeration FundamentalsThomas Westgate100% (1)

- ELEC 103: Week 3 - PressureDokumen52 halamanELEC 103: Week 3 - PressurebharathaninBelum ada peringkat

- Conversion TablesDokumen4 halamanConversion TablesChetan GadiaBelum ada peringkat

- Eja510-530 Gs01c31f01-01enDokumen11 halamanEja510-530 Gs01c31f01-01enpalebejoBelum ada peringkat

- Series: Pressure Gauge For General PurposeDokumen32 halamanSeries: Pressure Gauge For General Purpose30101985Belum ada peringkat

- Type 357 Control Valves: Bulletin 51.2:357Dokumen10 halamanType 357 Control Valves: Bulletin 51.2:357Datt NguyenBelum ada peringkat

- Meehanite Handbook2 PDFDokumen89 halamanMeehanite Handbook2 PDFRichard ChávezBelum ada peringkat

- Foxboro Imv25timv30t PDFDokumen86 halamanFoxboro Imv25timv30t PDFestebanBelum ada peringkat

- Manual Controlador 8720a y 8730aDokumen12 halamanManual Controlador 8720a y 8730aAlejandro Robles HernandezBelum ada peringkat

- PLP P 13 2003, Stabilizing ForDokumen67 halamanPLP P 13 2003, Stabilizing Forivanov5559Belum ada peringkat

- DCU2 and VCU Data TransmitterDokumen157 halamanDCU2 and VCU Data Transmitterกิจรุ่งเรือง โพจัน100% (3)

- Victrex PEEK™ UHP Ultra High Purity Polyetheretherketone (PEEK)Dokumen3 halamanVictrex PEEK™ UHP Ultra High Purity Polyetheretherketone (PEEK)dipanBelum ada peringkat

- STRENGTHDokumen16 halamanSTRENGTHJoshBarnacheaBelum ada peringkat

- This Study Resource Was: MIDTERM ACTIVITIES: Pressure Vessels (Problem Set)Dokumen2 halamanThis Study Resource Was: MIDTERM ACTIVITIES: Pressure Vessels (Problem Set)osas pasas100% (1)

- Concrete - Concrete StrengthsDokumen1 halamanConcrete - Concrete Strengthslance lancelottiBelum ada peringkat

- 412 Ipb CH01 PDFDokumen18 halaman412 Ipb CH01 PDFPanca Xp100% (1)

- PETE 411: Well DrillingDokumen43 halamanPETE 411: Well DrillingCHO ACHIRI HUMPHREYBelum ada peringkat

- Air Valve 460Dokumen6 halamanAir Valve 460amrezzatBelum ada peringkat

- 210 Bevel Gear SetsDokumen1 halaman210 Bevel Gear SetsFika PorieskaBelum ada peringkat

- Adder 1Dokumen2 halamanAdder 1Macarena GuzmanBelum ada peringkat

- Analysis of Loads on Buried Pipe Track CrossingDokumen6 halamanAnalysis of Loads on Buried Pipe Track CrossingDivesh rahul50% (2)

- LS PEKK CF HT23 Material Datasheet 201705Dokumen1 halamanLS PEKK CF HT23 Material Datasheet 201705Angel LagrañaBelum ada peringkat

- Metric Conversions: To Convert From TO Multiply by Symbol Unit Symbol Unit LengthDokumen1 halamanMetric Conversions: To Convert From TO Multiply by Symbol Unit Symbol Unit LengthJosué Emmanuel Blásquez ContrerasBelum ada peringkat

- Astm e 670Dokumen10 halamanAstm e 670frengki jmBelum ada peringkat

- Nu Bolt Techdata A4 PDFDokumen2 halamanNu Bolt Techdata A4 PDFMatthew ButlerBelum ada peringkat

- ST 3000 and SFC User Manual 34-St-32-02d Aug 1993-OcrDokumen180 halamanST 3000 and SFC User Manual 34-St-32-02d Aug 1993-OcrAnonymous zdCUbW8Hf100% (1)

- Minggu Ke-13, Pertemuan Ke-25, Sifat Fluida Murni Dan Steam TabelDokumen19 halamanMinggu Ke-13, Pertemuan Ke-25, Sifat Fluida Murni Dan Steam TabelNurhamida 4701Belum ada peringkat

- Bohler-Uddeholm SUPERIOR® H13 Hot Work Tool SteelDokumen2 halamanBohler-Uddeholm SUPERIOR® H13 Hot Work Tool SteelAgustine SetiawanBelum ada peringkat

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsDari EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsBelum ada peringkat

- Transformed: Moving to the Product Operating ModelDari EverandTransformed: Moving to the Product Operating ModelPenilaian: 4 dari 5 bintang4/5 (1)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureDari EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CulturePenilaian: 4.5 dari 5 bintang4.5/5 (2)

- Design Thinking and Innovation Metrics: Powerful Tools to Manage Creativity, OKRs, Product, and Business SuccessDari EverandDesign Thinking and Innovation Metrics: Powerful Tools to Manage Creativity, OKRs, Product, and Business SuccessBelum ada peringkat

- Nir Eyal's Hooked: Proven Strategies for Getting Up to Speed Faster and Smarter SummaryDari EverandNir Eyal's Hooked: Proven Strategies for Getting Up to Speed Faster and Smarter SummaryPenilaian: 4 dari 5 bintang4/5 (5)

- Delft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsDari EverandDelft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsBelum ada peringkat

- Design for How People Think: Using Brain Science to Build Better ProductsDari EverandDesign for How People Think: Using Brain Science to Build Better ProductsPenilaian: 4 dari 5 bintang4/5 (8)

- Design Is The Problem: The Future of Design Must Be SustainableDari EverandDesign Is The Problem: The Future of Design Must Be SustainablePenilaian: 1.5 dari 5 bintang1.5/5 (2)

- Understanding Automotive Electronics: An Engineering PerspectiveDari EverandUnderstanding Automotive Electronics: An Engineering PerspectivePenilaian: 3.5 dari 5 bintang3.5/5 (16)

- Operational Amplifier Circuits: Analysis and DesignDari EverandOperational Amplifier Circuits: Analysis and DesignPenilaian: 4.5 dari 5 bintang4.5/5 (2)

- Electrical Principles and Technology for EngineeringDari EverandElectrical Principles and Technology for EngineeringPenilaian: 4 dari 5 bintang4/5 (4)

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tDari EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tPenilaian: 4.5 dari 5 bintang4.5/5 (27)

- The Maker's Field Guide: The Art & Science of Making Anything ImaginableDari EverandThe Maker's Field Guide: The Art & Science of Making Anything ImaginableBelum ada peringkat

- Iconic Advantage: Don’t Chase the New, Innovate the OldDari EverandIconic Advantage: Don’t Chase the New, Innovate the OldPenilaian: 4 dari 5 bintang4/5 (1)

- Articulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceDari EverandArticulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperiencePenilaian: 4 dari 5 bintang4/5 (19)

- The Box: How the Shipping Container Made the World Smaller and the World Economy Bigger - Second Edition with a new chapter by the authorDari EverandThe Box: How the Shipping Container Made the World Smaller and the World Economy Bigger - Second Edition with a new chapter by the authorPenilaian: 4 dari 5 bintang4/5 (7)

- What to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationDari EverandWhat to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationPenilaian: 4.5 dari 5 bintang4.5/5 (2)

- The User's Journey: Storymapping Products That People LoveDari EverandThe User's Journey: Storymapping Products That People LovePenilaian: 3.5 dari 5 bintang3.5/5 (8)

- Basic Electric Circuit Theory: A One-Semester TextDari EverandBasic Electric Circuit Theory: A One-Semester TextPenilaian: 1.5 dari 5 bintang1.5/5 (2)

- Top-Down Digital VLSI Design: From Architectures to Gate-Level Circuits and FPGAsDari EverandTop-Down Digital VLSI Design: From Architectures to Gate-Level Circuits and FPGAsBelum ada peringkat

- UX: Simple and Effective Methods for Designing UX Great Products Using UX Programming TheoriesDari EverandUX: Simple and Effective Methods for Designing UX Great Products Using UX Programming TheoriesBelum ada peringkat