Gast Pump 10x1040-2 - 11x1740-2a Manual

Diunggah oleh

Tom MeyerDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Gast Pump 10x1040-2 - 11x1740-2a Manual

Diunggah oleh

Tom MeyerHak Cipta:

Format Tersedia

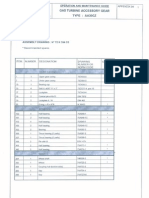

70-600 G420 (Rev.

B)

PARTS LIST and

OPERATING and MAINTENANCE

INSTRUCTIONS FOR MODELS

10x1040-2

11x1740-2A

LUBRICATED DUAL

CHAMBER AIR PUMPS

KEEP THIS DOCUMENT FOR FUTURE REFERENCE

REF PART REF PART

DESCRIPTION 10X1040-2 DESCRIPTION 10X1040-2

NO QTY NO QTY

•

1 BODY 1 AC361A 18 END CAP GASKET, DEAD 1 AB126A

2 END PLATE, DRIVE 1 AC362 19 OILER CAP 3 AA6-1

3 END PLATE, DEAD 1 AC363 20 FAN PULLEY 1 AC374

4 R OTOR 2 AC365 21 DRIVE KEY 1 AB136D

5 SHAFT 1 AC377 22 SIPHON OILER 1 AA930D

•

6 SHAFT KEY (ROTOR) 4 AE519 23 COVER GASKET 2 AA932

• •

7 VANE 8 AB125E 24 WICK 2 AA934

•

8 BEARING, DRIVE 1 AB918 25 SIPHON OILER 1 AA930B

•

9 BEARING, DEAD 1 AA755D 26 INTAKE FILTER-MUFFLER 3 AB600

•

10 LOCK NUT, DRIVE 1 AB920 27 COVER GASKET 3 AA405

•

11 LOCKWASHER, DRIVE 1 AB919 28 GLASS JAR 3 AA805

• •

12 SHAFT SEAL 3 AC370 29 FELT - 50 MICRON 4 AB342

•

13 SNAP RING 1 AG900 30 MUFFLER (METAL JAR) 1 AB665

• •

14 BODY SPACER GASKET 2 AC371 31 COVER GASKET 1 AA404

15 END CAP, DRIVE 1 AC372 32 GLASS JAR 1 AA75

16 END CAP, DEAD 1 AB127A 33 CARTRIDGE 1 AC393

•

17 END CAP GASKET, DRIVE 1 AC373

•

Denotes parts included in Service Kit K244. If unit is 1279 or older indicate when ordering repair kit.

2

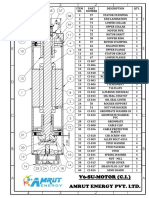

REF PART REF PART

DESCRIPTION 11X1740-2A DESCRIPTION 11X1740-2A

NO QTY NO QTY

1 BODY 1 AC621C 20 FAN PULLEY 1 AC374B

2 END PLATE 2 AC622 21 DRIVE KEY 1 AB136

3 ROTOR (SHORT 21/2") 1 AC623 22 CONSTANT LEVEL OILER (DRIVE) 1 AD125E-6

•

4 ROTOR (LONG 31/2") 1 AC624 23 COVER GASKET 2 AA932

•

5 ROTOR SHAFT 1 AC625 24 WICK 2 AA934

6 SHAFT KEY 4 AE525 25 JAR 2 AA935A

•

7 VANE (LONG 31/2") 4 AC411 26 OIL RESERVOIR 2 AD117

• •

8 VANE (SHORT 21/2") 4 AC412 27 O-RING 2 AD157

•

9 BEARING, DRIVE 1 AB917 28 CONSTANT LEVEL OILER (DEAD) 1 AD125D-6

•

10 BEARING, DEAD 1 AB918 29 FILTER/MUFFLER 3 AA900J

• •

11 LOCKWASHER* 1 AB919 30 COVER GASKET 3 AA405

12 LOCK NUT* 1 AB920 31 GLASS JAR (1 QT) 3 AA401

•

13 SHAFT SEAL, DRIVE 1 AC626 32 INNER FILTER ASSEMBLY 3 AA905G

• •

14 SHAFT SEAL, CENTER 2 AG627 33 FELT 3 D344B

•

15 BODY (SPACER) GASKET 2 AC629 34 EXHAUST MUFFLER 1 AB650

•

16 END CAP, DRIVE 1 AC630 35 COVER GASKET 1 AA404

17 END CAP, DEAD 1 AC631 36 FILTER ASSEMBLY 1 AB340G

•

18 END CAP GASKET 2 AC373 37 FELT 1 AB342

19 OILER CAP 3 AA6-1

•

Denotes parts included in Service Kit K245. If unit is 1279 or older indicate when ordering repair kit.

3

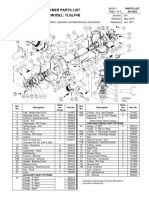

OPERATION INSPECTION FILTER MUFFLER

Regular inspection and maintenance may prevent Elements covered with dust or oil will cause loss in

expensive repairs. High vacuum or pressure operation will vacuum, pressure, and overheating of the pump. Wash the

shorten pump’s life. Oil fog from the exhaust indicates elements with cleaning solvent and dry before replacing.

overheating. Keep external surfaces clean for proper heat

dissipation. SERVICING

Most failures to build up pressure or vacuum are due to

LUBRICATION leaks in connecting lines, damaged filter jar threads,

Use of correct and proper amount of oil is important. collapsed air lines, dirty filtering elements, or sluggish

Excessive lubrication rarely does as much harm as vanes in the pump. See “Cleaning” for care of the filter

inadequate lubrication. elements and vanes, which may stick in the rotor slots due

to lack of oil or carbonized (burnt) oil deposits. The latter

Gast AD220 Oil is available in convenient quart is generally caused from the pump being operated above

containers from the factory or through Gast stocking its recommendations and getting too hot.

representatives. Order by part #AD220. As a substitute, a

high detergent SAE #10 weight oil may be used. A 20 CLEANING

weight oil should be used in high ambient locations. Remove the filters and muffler to flush the pump of dirt,

viscous or carbonized oil. Permit a cupful of solvent* to be

m WARNING Always disconnect power source

slowly drawn into each chamber at intake while pump is

before servicing. The motor may be

thermally protected and can running. If foreign particles cannot be removed by this

automatically restart when the method, an experienced mechanic may remove the end

protector resets. plates to clean the interior or to replace the vanes.

Reusing oil is not recommended. m CAUTION Avoid damaging the internal machined

surfaces and paper shim gaskets.

SIPHON OILER Flush unit in a well-ventilated area.

The jar’s oil level, oil viscosity and temperature governs Eye protection is recommended. Keep

the oil feed rate. The air breather hole in the connector face away from exhaust port and do

fitting should not be restricted. Clean or replace wick not flush unit with flammable solvent.

(pipe cleaner) when dirty. One filing will last 20 to 40 Wash pump interior with

hours. recommended solvent*.

Rebuild as dissembled, end clearance for each chamber is

BEARING SEAL OILERS 0.006" to 0.008"; top clearance is 0.0015". Rebuilding with

Stop pump. Remove cap. Fill with 4 or 5 drops of oil excessive clearance will cause a loss of efficiency.

(same as used for pump) daily. Empty muffler And/or Insufficient clearances will cause overheating and internal

drain tank. Replace caps before starting pump again. pump damage.

m WARNING DO NOT replace Bearing-Seal caps Recommended solvent is Gast Flushing Solvent part

with grease fittings or grease any

#AH255.

part of the pump.

Due to complexity of setting clearances and machining we recommend you send this unit

to an authorized service facility for rebuilding.

AUTHORIZED SERVICE FACILITIES

Gast Manufacturing Inc. Gast Manufacturing Inc. Brenner Fiedler & Assoc Gast Manufacturing Co., Ltd.

2300 Highway M-139 505 Washington Avenue 13824 Bentley Place Beech House, Knaves Beech

Benton Harbor, MI 49022 Carlstadt, NJ 07072 Cerritos, CA 90701 Business Centre, Loudwater

TEL: 616-926-6171 TEL: 201-933-8484 TEL: 800-843-5558 High Wycombe, Bucks HP 10 9SD

FAX: 616-925-8288 FAX: 201-933-5545 TEL: 310-404-2721 England

www.gastmfg.com FAX: 310-404-7975 TEL: 44 628 532600

Wainbee Limited FAX: 44 628 532470

Wainbee Limited 5789 Coopers Avenue Japan Machinery Co., Ltd

215 Brunswick Blvd. Mississauga, Ontario Central PO Box 1451 NOTE: General correspondence should be

Pointe Claire, Quebec Canada L4Z 3S6 Tokyo, 100-91 Japan sent to—

Canada H9R 4R7 TEL: 416-213-7202 TEL: 81-3-3573-5421 Gast Mfr. Inc./A Unit of IDEX Corporation

TEL: 514-697-8810 FAX: 416-213-7207 FAX: 81-3-3571-7865 P O Box 97

FAX: 514-697-3070 or: 81-3-3571-7896 Benton Harbor, MI 49023-0097

Anda mungkin juga menyukai

- Drilling Fluids Processing HandbookDari EverandDrilling Fluids Processing HandbookPenilaian: 4.5 dari 5 bintang4.5/5 (4)

- Anglo–American Microelectronics Data 1968–69: Manufacturers A–PDari EverandAnglo–American Microelectronics Data 1968–69: Manufacturers A–PBelum ada peringkat

- 65 Series Lubricated OmDokumen1 halaman65 Series Lubricated OmSaul EscalanteBelum ada peringkat

- (04-02) - AlternatorDokumen3 halaman(04-02) - AlternatoreduardoBelum ada peringkat

- Numeros de ParteDokumen8 halamanNumeros de ParteJulio GarciaBelum ada peringkat

- Curtis RS100D Parts ListDokumen28 halamanCurtis RS100D Parts ListrobertBelum ada peringkat

- (04-01) - StarterDokumen3 halaman(04-01) - StartereduardoBelum ada peringkat

- LIT2409 R1 PD15B Parts (05852) 9-2008Dokumen10 halamanLIT2409 R1 PD15B Parts (05852) 9-2008Andres Florentin Pizarro LazarteBelum ada peringkat

- ZH5CR0005H1000001 21/03/2017: VIN Nmber: ReleaseDokumen41 halamanZH5CR0005H1000001 21/03/2017: VIN Nmber: ReleaseMassi's ShedBelum ada peringkat

- 2100s-2110s Yedek Parça KatalogDokumen251 halaman2100s-2110s Yedek Parça KatalogЧанко ДеневBelum ada peringkat

- Motor Assy - Swing Case CX330Dokumen3 halamanMotor Assy - Swing Case CX330Comassur SA de CV0% (1)

- Pump, Tandem (Rear) 404281a2Dokumen3 halamanPump, Tandem (Rear) 404281a2Lenin GullapalliBelum ada peringkat

- Ur1021a01s 1Dokumen3 halamanUr1021a01s 1MARTIN GONZALEZBelum ada peringkat

- Hydraulics - TransmissionDokumen3 halamanHydraulics - TransmissionJESUSBelum ada peringkat

- FS-5005A July 2011Dokumen19 halamanFS-5005A July 2011MarioRuizBelum ada peringkat

- SQ100Dokumen3 halamanSQ100Solrac Nauj Ogaitnas100% (1)

- Catalogues$tata 207 Di RX Bs-IiDokumen182 halamanCatalogues$tata 207 Di RX Bs-Iiveeresh100% (1)

- 03 MastDokumen12 halaman03 MastAngel JhosesitoBelum ada peringkat

- Coolant Radiator, Hydraulic Fluid and Transmission OilDokumen2 halamanCoolant Radiator, Hydraulic Fluid and Transmission OilFRANCISCO BURELO CASTILLOBelum ada peringkat

- 590 - Turbo Loader Backhoe (01/88 - 12/91) 06 - Power Train 6-10 - Torque Converter Housing, Pump and Output ShaftDokumen4 halaman590 - Turbo Loader Backhoe (01/88 - 12/91) 06 - Power Train 6-10 - Torque Converter Housing, Pump and Output ShaftJESUS100% (1)

- Sistema de Exaustão - BobcatDokumen3 halamanSistema de Exaustão - BobcatObras AjuricabaBelum ada peringkat

- FMC PumpDokumen3 halamanFMC PumpIllofi Ajie0% (1)

- New Holland Eh215 Crawler ExcavatorDokumen653 halamanNew Holland Eh215 Crawler ExcavatorcarlosBelum ada peringkat

- Pump Assy Yn10v00043f1 (Hc405) Page 1 of 2Dokumen4 halamanPump Assy Yn10v00043f1 (Hc405) Page 1 of 2Michael EstupiñanBelum ada peringkat

- 2 MainstreetDokumen25 halaman2 MainstreetyoBelum ada peringkat

- Material List: PD12C HoistDokumen8 halamanMaterial List: PD12C HoistFakhar F.Belum ada peringkat

- SC430 - Scrubber-Dryer - Parts Lists DiagramsDokumen18 halamanSC430 - Scrubber-Dryer - Parts Lists DiagramsDimitris ThanasopoulosBelum ada peringkat

- 580M Siii Eje 2daDokumen4 halaman580M Siii Eje 2daALEX DIEGOBelum ada peringkat

- Part List FG Gearbox AA 30 CZDokumen6 halamanPart List FG Gearbox AA 30 CZirwcsohBelum ada peringkat

- Estimation TCI Sanmar - EDC Vent Condenser Tag No E-102Dokumen5 halamanEstimation TCI Sanmar - EDC Vent Condenser Tag No E-102Raviraj Shashikant PatilBelum ada peringkat

- WheelHorse GT 14 Parts Manual 1-7451 - A-5260Dokumen10 halamanWheelHorse GT 14 Parts Manual 1-7451 - A-5260Kevins Small Engine and Tractor Service100% (1)

- Cylinder Assy - Bucket PDFDokumen3 halamanCylinder Assy - Bucket PDFJESUSBelum ada peringkat

- Report 3685246303879574056Dokumen4 halamanReport 3685246303879574056Wilmer CarreroBelum ada peringkat

- Blackmer Parts List Pump Model: Hxl6GDokumen2 halamanBlackmer Parts List Pump Model: Hxl6Gherbin hutabaratBelum ada peringkat

- Vortec 4,3L PSI Control PeçasDokumen19 halamanVortec 4,3L PSI Control PeçasFrancisco JúniorBelum ada peringkat

- S12 PartsDokumen150 halamanS12 PartsG.L. ZortmanBelum ada peringkat

- Visio 200Dokumen93 halamanVisio 200Jaroslav IvanBelum ada peringkat

- 580sn - Loader Backhoe - Tier 3 (04/10 - 07/15) 35 - Hydraulic Systems 35.732.01 (06) - Cylinder - Backhoe Stabilizer (580sn)Dokumen3 halaman580sn - Loader Backhoe - Tier 3 (04/10 - 07/15) 35 - Hydraulic Systems 35.732.01 (06) - Cylinder - Backhoe Stabilizer (580sn)JORGEBelum ada peringkat

- Catalogue Index Chassis R954 #736 15951Dokumen85 halamanCatalogue Index Chassis R954 #736 15951b.maurincomeBelum ada peringkat

- Tlglf4b 09 09 MarkedDokumen2 halamanTlglf4b 09 09 MarkedyuanBelum ada peringkat

- Amrut Energy Pvt. Ltd. V6-SU-MOTOR (C.I.) V6-SU-MOTOR (C.I.)Dokumen1 halamanAmrut Energy Pvt. Ltd. V6-SU-MOTOR (C.I.) V6-SU-MOTOR (C.I.)IMTB MumbaiBelum ada peringkat

- Radiador y Sus Partes, Motor Diesel 504BDTDokumen3 halamanRadiador y Sus Partes, Motor Diesel 504BDTRamón ManglesBelum ada peringkat

- Ruggerini RD180-280Dokumen18 halamanRuggerini RD180-280ruralhermit0% (1)

- Blackmer Parts List Pump Model: Tlglf4BDokumen2 halamanBlackmer Parts List Pump Model: Tlglf4BRAUL ARMANDO PALOMO CAMPOSBelum ada peringkat

- (02-26) - Crankshaft - 4-390 4T-390 Emissions Certified EngineDokumen3 halaman(02-26) - Crankshaft - 4-390 4T-390 Emissions Certified EngineeduardoBelum ada peringkat

- 520 Estimation ABC Tag No E-132Dokumen6 halaman520 Estimation ABC Tag No E-132RavirajBelum ada peringkat

- Craftsman CompressorDokumen8 halamanCraftsman CompressorhorseriderintexasBelum ada peringkat

- Jackleg WebDokumen1 halamanJackleg WebNgười Chiến Sĩ ẤyBelum ada peringkat

- 82b 25bed PartsDokumen67 halaman82b 25bed PartsYOSETH VASQUEZBelum ada peringkat

- Cylinder Assy - Backhoe SwingDokumen3 halamanCylinder Assy - Backhoe SwingivaldodanielBelum ada peringkat

- 6S 1701Dokumen16 halaman6S 1701richard44927Belum ada peringkat

- Engine InstallationDokumen5 halamanEngine InstallationAnonymous cS9UMvhBqBelum ada peringkat

- Tilt Cylinder (RH) (538,7mm - 21.21 - Tube Length) (38,1mm - 1.5 - OD) (W - Piston Collar) - (S - N A3NT15431 & Above, A3NU12267 & Above) - S630Dokumen2 halamanTilt Cylinder (RH) (538,7mm - 21.21 - Tube Length) (38,1mm - 1.5 - OD) (W - Piston Collar) - (S - N A3NT15431 & Above, A3NU12267 & Above) - S630Romero JhonBelum ada peringkat

- DECOY CF TECHNICAL INFORMATION CUSTOMER5dfa08337022dDokumen4 halamanDECOY CF TECHNICAL INFORMATION CUSTOMER5dfa08337022dlukaradrienBelum ada peringkat

- Parts 44a 44b 12.5-9.4 BTDB 15.0 - 12.0 BTDCDokumen102 halamanParts 44a 44b 12.5-9.4 BTDB 15.0 - 12.0 BTDCnyaungzinBelum ada peringkat

- Power Shuttle, Valve Assembly Without Pto PDFDokumen3 halamanPower Shuttle, Valve Assembly Without Pto PDFRetropartes AcevedoBelum ada peringkat

- JCB 3DX Super BSIII Backhoe Loader 2Dokumen116 halamanJCB 3DX Super BSIII Backhoe Loader 2abhibawa89% (19)

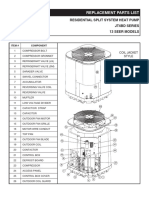

- Nordyne JT4BD-048K AC HVAC Heat Pump Parts ListDokumen2 halamanNordyne JT4BD-048K AC HVAC Heat Pump Parts ListRichard PhillipsBelum ada peringkat

- PINDokumen4 halamanPINVladimirCarrilloBelum ada peringkat

- Newnes Workshop Engineer's Pocket BookDari EverandNewnes Workshop Engineer's Pocket BookPenilaian: 4.5 dari 5 bintang4.5/5 (2)

- ECU - Engine Control Unit Diagnostic Trouble Codes (6135 JD Control Unit, Level 15)Dokumen5 halamanECU - Engine Control Unit Diagnostic Trouble Codes (6135 JD Control Unit, Level 15)Anonymous V9fdC6Belum ada peringkat

- Circuit Description: Refer To DTC P0412 On PageDokumen9 halamanCircuit Description: Refer To DTC P0412 On PageAndres AriasBelum ada peringkat

- ME8694 HydraulicsandPneumaticsQuestionBank PDFDokumen15 halamanME8694 HydraulicsandPneumaticsQuestionBank PDFVikram mBelum ada peringkat

- General Characteristics: DescriptiveDokumen4 halamanGeneral Characteristics: DescriptiveAsif MahmoodBelum ada peringkat

- CL#2 Maintenance Schedule 7 - 18 REDDokumen5 halamanCL#2 Maintenance Schedule 7 - 18 REDRicky WrightBelum ada peringkat

- Kawasaki Parts LISTING V15 6Dokumen40 halamanKawasaki Parts LISTING V15 6Kudanthai Senthilkumar100% (1)

- Bf40D - Bf50D Remote Control Type Wiring DiagramDokumen1 halamanBf40D - Bf50D Remote Control Type Wiring DiagramJoe75% (4)

- Bj175alfph W175-W175 Se (2018-20)Dokumen75 halamanBj175alfph W175-W175 Se (2018-20)Albert Depano100% (8)

- Job Cost in V 03112012Dokumen52 halamanJob Cost in V 03112012govindvbBelum ada peringkat

- Serv1855 (345D) - TXTDokumen202 halamanServ1855 (345D) - TXTeng_ebrahim_2000100% (3)

- Project On Protable Grass Cutter MachineDokumen11 halamanProject On Protable Grass Cutter MachineNayon HalderBelum ada peringkat

- Asko Dryer Service Manual T-700 SeriesDokumen65 halamanAsko Dryer Service Manual T-700 SeriesTom Senberg100% (1)

- Wheeled Excavator: Generation Operating Weight EngineDokumen24 halamanWheeled Excavator: Generation Operating Weight Enginepebi liveBelum ada peringkat

- High Pressure Ball Valves 150119Dokumen5 halamanHigh Pressure Ball Valves 150119Nilesh MistryBelum ada peringkat

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Dokumen25 halamanInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Kike HernandezBelum ada peringkat

- Kawasaki NINJA ZX-10R 2015-2017-106-109Dokumen4 halamanKawasaki NINJA ZX-10R 2015-2017-106-109Nathan CrestaniBelum ada peringkat

- WI62EX: Model TypeDokumen23 halamanWI62EX: Model TypePredrag MarkovicBelum ada peringkat

- 6.375-4 Amm Buttress ThreadDokumen4 halaman6.375-4 Amm Buttress Threadnoe juarezBelum ada peringkat

- Powershift ElectrDokumen17 halamanPowershift ElectrAdamBelum ada peringkat

- Axial Vibration Input Data List, July 2019Dokumen2 halamanAxial Vibration Input Data List, July 2019Monglen Z. CasiñoBelum ada peringkat

- BUCHAS ART 0500 - G - 00192B InstruçoesDokumen5 halamanBUCHAS ART 0500 - G - 00192B InstruçoesAnderson FonsecaBelum ada peringkat

- Motores Hidráulicos Tipo Oms - Omt - Sauer DanfossDokumen84 halamanMotores Hidráulicos Tipo Oms - Omt - Sauer DanfossFlávio Hanauer100% (1)

- EUS NT800 ManualDokumen24 halamanEUS NT800 ManualDilakartikaBelum ada peringkat

- Mec623 Scotch Yoke Technical ReportDokumen39 halamanMec623 Scotch Yoke Technical ReportAhmad AfieszBelum ada peringkat

- XQ80 and XQ100 Generator Set Electrical System With EMCP3: Back Panel of Emcp3 BoxDokumen2 halamanXQ80 and XQ100 Generator Set Electrical System With EMCP3: Back Panel of Emcp3 Boxtommy lanyonBelum ada peringkat

- Atlas Copco TEX12PS - Parts ManualDokumen24 halamanAtlas Copco TEX12PS - Parts ManualSergio Raul BaezBelum ada peringkat

- Wheel Bearings Cups and Cones: Faa-Pma Approved!Dokumen2 halamanWheel Bearings Cups and Cones: Faa-Pma Approved!Fernando CentenoBelum ada peringkat

- !drilling Machine Geared Head InstructionDokumen5 halaman!drilling Machine Geared Head InstructionTiago PaivaBelum ada peringkat

- Idle RelearnDokumen2 halamanIdle RelearnSutiknoBelum ada peringkat

- D75KS Manual Servicio PDFDokumen748 halamanD75KS Manual Servicio PDFSara100% (1)