CH 44 - Subsoil Drainage

Diunggah oleh

Lit Phen TuDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

CH 44 - Subsoil Drainage

Diunggah oleh

Lit Phen TuHak Cipta:

Format Tersedia

44 SUBSOIL DRAINAGE

44.1 INTRODUCTION ............................................................................................................. 44-1

44.1.1 Purpose ............................................................................................................ 44-1

44.1.2 Scope of this Manual......................................................................................... 44-1

44.2 THEORETICAL PRINCIPLES............................................................................................. 44-1

44.2.1 General Principles ............................................................................................. 44-1

44.2.2 Other Design Considerations.............................................................................. 44-1

44.3 DRAIN TYPES................................................................................................................. 44-1

44.4 LAYOUT ......................................................................................................................... 44-2

44.5 DESIGN CONSIDERATIONS ............................................................................................ 44-3

44.5.1 Drain Dimensions and Spacings......................................................................... 44-3

44.5.2 Design of Conduits ............................................................................................ 44-4

44.5.3 Pipe Gradient.................................................................................................... 44-4

44.5.4 Drain Envelopes ................................................................................................ 44-4

44.6 INSTALLATION............................................................................................................... 44-5

44.6.1 General............................................................................................................. 44-5

44.6.2 Embedment ...................................................................................................... 44-5

44.6.3 Monitoring Wells ............................................................................................... 44-6

Urban Stormwater Management Manual 44-i

Subsoil Drainage

44.1 INTRODUCTION head of the conduit is less than that of the soil to be

drained (ASCE, 1998). The hydraulic head differential

44.1.1 Purpose creates a hydraulic gradient towards the flow channel,

depressing the phreatic line (also called the free water

The purpose of this Chapter is to provide a general surface) in the vicinity of the conduit. Water is removed

introduction to the topic of subsoil drainage for the urban from the conduit at its downstream end, thus maintaining

stormwater engineer. a flow system. It can therefore be seen that subsurface

drainage involves principles of hydraulics and flow through

Subsoil drainage systems are provided to drain away

porous media. The hydraulic gradient and the hydraulic

subsurface water in order to:

conductivity of the soil govern the rate of subsurface

• increase the stability of the ground and footings of drainage.

buildings by inducing a more stable moisture regime

and reducing foundation movements due to the 44.2.2 Other Design Considerations

variations in the soil moisture content;

In evaluating the need to remove subsurface water,

• mitigate surface water ponding and waterlogging of consideration must be given to surface water runoff from

soils by lowering watertables; buildings, road pavements and subgrades, and other

• alleviate ground water pressures likely to cause impervious surfaces which is allowed to enter subsurface

dampness in below-ground internal parts of buildings zones and contribute to soil saturation.

or damage to foundations of buildings, other

structures, or pavements; and/or In clay soils, subsoil drains can alter long-term soil

• increase soil strength by reducing the moisture moisture regimes so that building foundations can be

content. adversely affected by removing water, or some cases, by

introducing water. In such conditions, subsoil drains

Subsoil drainage is an important part of road construction. should only be used where there are no other options for

Vehicular traffic on pavement with a saturated subbase solving a dampness problem.

results in rapid deterioration of the pavement. Entrapped

water that is subject to vehicular loadings creates large Consideration should be given to the possible effects of

hydrostatic and hydrodynamic pressures within the intermittent or permanent reduction in groundwater levels

subbase, reducing its ability to provide stable support for on adjacent lands when designing subsoil drainage. In

the pavement. Correctly designed roads and paved areas soils with clay content exceeding 20%, lowering

have a highly permeable base or subbase construction and watertables can cause soil shrinkage and damage to

may include subsoil drains to promote the rapid outflow of structures. It is recommended that subsoil drains should

subsurface water. not be placed too close to buildings on clayey sites.

One important factor indicating a need for subsoil drainage 44.3 DRAIN TYPES

is the presence of a watertable high enough to have an

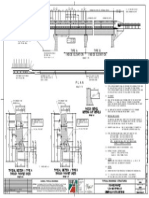

adverse effect on buildings and infrastructure within urban The types of subsoil drains that are commonly used are

developments. Subsoil drainage is particularly important in shown in Figure 44.1. These may be installed on flat

hillside areas due to the potential to create land instability ground, in a sag or depression, or on sloping ground. The

(Chapter 47). Drains behind retaining walls are designed basic parts of a subsoil drain are shown in Figure 44.1(a)

using similar principles as other subsoil drains. which is a trench with fill or filter material (commonly sand

or gravel). This simple arrangement is called a rubble

44.1.2 Scope of this Manual drain or French drain.

The design principles and methods set out herein will be Figure 44.1(b) shows the addition of a geotextile lining to

useful for many applications. However, this Chapter does prevent external fine soil particles being washed into the

not provide detailed advice for all situations. Specialist filter material and clogging it. Both this and the unlined

advice should be obtained for large or complex rubble drain have only limited effectiveness due to their

applications. Some applications, such as road and highway limited ability to convey water.

subsoil drainage, are covered in more detail in other

Manuals or publications. Figure 44.1(c) shows the addition of a pipe to promote

more rapid drainage. This is the most common type of

44.2 THEORETICAL PRINCIPLES subsoil drain. The pipe is perforated to allow easy entry of

water and can be rigid or flexible. Figure 44.1(d) shows

44.2.1 General Principles two further variations – an impervious cap for situations

where the drain is intended to collect only subsurface

Subsurface drainage is accomplished by placing an artificial flows, and bedding material for cases where the base of

conduit or flowpath below the water table so the hydraulic the excavation is unsuitable as a pipe support.

Urban Stormwater Management Manual 44-1

Subsoil Drainage

Pervious Back Fill Impervious Cap

Fill or

Filter

Material

Trench

(a) Basic System (b) Geotextile Filter (c) Pipe Drain (d) Pipe Drain with Capping

to Exclude Surface Water

Pipe Wrapped

in Geotextile

Vertical Horizontal

Geocomposite Geocomposite

Drain Drain

Pervious Filter Layer

on Trench Sides

(e) Geotextile (f) Geocomposite Drain (g) Geocomposite Drain (h) Soil Filter Layer to Avoid

Around Pipe in Narrow Trench in Shallow Trench Clogging of Geotextile

Figure 44.1 Types of Subsoil Drains

Figures 44.1(e), (f), and (g) show more elaboration. The depressions. Subsoil drains should connect to a

pipe can be wrapped in geotextile to prevent piping and stormwater pit or a point of connection, and be consistent

loss of filter material. Geocomposite drains of various with the layouts for the site stormwater drain and the

configurations and manufacture can be provided. These external stormwater drainage network.

are usually of plastic wrapped in geotextile and various

proprietary systems are available. Finally, Figure 44.1(h) Relevant layouts for the types of subsoil drainage systems

shows an external layer of filter material provided around covered in this chapter include:

the geotextile encompassing the filter material. This might

• subsoil drains on one or more sides of a building or

be used where there is a likelihood of fine particles or

cutting, including cut-off drains for interception of

deposits, e.g. iron precipitates, clogging the geotextile.

groundwater flows from higher land;

In general, subsoil drains connect either into a stormwater • drainage systems for mitigating waterlogging or

pit (Chapter 24) or an open channel which is part of a lowering watertables on small to medium areas of

surface water drainage system, with the subsoil drain pipe land, e.g. less than 500 m2

or strip drain penetrating the pit wall. Weepholes with a

suitable geotextile filter may also be used to admit water These layouts may involve branch subsoil drains

from the filter materials into the pit. connecting to a main subsoil drain. Manholes (Chapter 24)

should be provided at main junction points to facilitate

inspection and cleaning.

44.4 LAYOUT

Suggested maximum spacings for branch subsoil drains are

The layout is directly related to the topography, the as given in Table 44.1.

location of buildings and access points, the geology (nature

of subsoil and level of groundwater) and area of a

property. Main subsoil drains often follow natural

44-2 Urban Stormwater Management Manual

Subsoil Drainage

Table 44.1 Maximum Spacing of Branch Subsoil Drains • Where the subsoil drain is intended to lower the

general groundwater level, the determination of the

depth of drain depends on whether there is a single or

Depth of Invert of a multi-drain system as shown in Figure 44.2.

Main Subsoil Drains

Soil Type Analysis in these cases depends on knowledge of the

0.8 to 1.0 m 1.0 to 1.5 m hydraulic properties of the soil, and on theoretical

solutions. A professional engineer with geotechnical

Maximum Spacing (m) expertise should carry out the design work in critical

cases.

Sand — 45 – 90

For less critical situations, the drawdown curve for a

Sandy loam — 30 – 45

single drain can be assumed to have the

Loam 16 – 20 20 – 30 characteristics given in Table 44.2.

Clay loam 12 – 16 15 – 20 For multi-drain systems, the drain spacings given in

Sandy clay 6 – 12 — Table 44.3 can be used in less critical applications.

Clay 2–6 — Clay soils present particular problems as they may be

too impermeable for any drawdown to occur and

Source: BS 8301 (1985) expert geotechnical advice should be sought.

• Trench widths shall be a minimum of 300 mm where

circular pipes are used. A minimum width of 450 mm

44.5 DESIGN CONSIDERATIONS is required where human access is required. Where a

trench is deeper than 1.5 m, shoring as specified by

The design and investigation of subsoil drainage systems relevant construction safety acts and regulations shall

are uncertain processes. Only in a very limited number of be used.

situations can the need for subsoil drainage be identified

For geocomposite drains set vertically, as shown in

without detailed subsurface investigations involving

Figure 44.1(f), the minimum trench width shall be

excavations, field observations, and soil tests. This Manual

100 mm.

provides an introduction only. For many applications,

specialist advice should be obtained. • Drains should be constructed with the base of the

trench at an even slope, so that the trench acts as a

44.5.1 Drain Dimensions and Spacings rubble drain even if the pipe or geocomposite drain is

blocked.

The depth of a subsoil drain is dictated by the groundwater • Where a subsoil drain pipe or geocomposite drain

conditions, the amount by which the groundwater level is connects to a pit or a pump-out sump, access for easy

to be lowered, and the available hydraulic gradient. The inspection of flows should be provided so that the

following requirements are recommended: performance of the subsoil drain can be monitored.

For drains in critical locations, a means of backflushing

• Interceptor drains that aim to remove flows from a

should be provided to clear blockages.

particular soil stratum or an aquifer should clearly

penetrate the stratum and should extend to a depth of

150 mm to 300 mm into the impervious strata below.

Zone of Influence Drain Spacing

Original

Groundwater

Level

Drawdown

Curve

Underlying

Stratum

Figure 44.2 Water Table Drawdown to Single and Multi-Drain Systems

Urban Stormwater Management Manual 44-3

Subsoil Drainage

Table 44.2 Typical Single Drain Drawdown Values from a professional engineer with geotechnical

expertise.

• Rigid or flexible pipes must be designed and installed

Zone of Typical Gradient to suit the relevant loading condition. Rigid pipes

Soil Type Influence of Drawdown transmit most of the applied load through the pipe

(m) Curve wall to the bedding material. Flexible pipes transfer

the load to the backfill material by deflection. Design

Coarse gravel 150 — principles are the same as for stormwater pipes

Medium gravel 50 1:200 – 1:100 (Chapter 25).

Coarse sand 40 1:100 – 1:33

44.5.3 Pipe Gradient

Medium sand 15 – 30 1:50 – 1:20

Fine sand 8 – 15 1:20 – 1:5 The gradients of subsoil drains shall be determined by the

Silt/clay Variable 1:5 – 1:2.5 topography of the site. Subsoil pipe drains shall be

designed with a fall toward the outlet. High points must

Source: AS/NZ 3500.3.2 (1998) be avoided because they will trap air, causing an air

blockage.

44.5.4 Drain Envelopes

Table 44.3 Typical Drain Spacings (a) General

Drain envelopes are placed around a subsoil drain such as

Soil Type Depth (m) Spacing (m) a pipe, for several purposes. These purposes include

(ASCE, 1998):

Sand 1–2 50 –90

• to prevent excessive movement of soil material into

Sandy loam 1 – 1.5 30 – 40

the drain;

Clay loam

0.5 – 1 12 – 16 • to increase the permeability and hydraulic

(i.e. a clayey silt)

performance of the material near the subsoil drain;

Source: AS/NZ 3500.3.2 (1998) • to increase the effective surface area of the drain;

• to stabilise the soil in which the drain is being placed;

and

44.5.2 Design of Conduits • to support and provide structural bedding for the pipe

or conduit.

Pipes or other conduits are often provided in subsoil drains

for two purposes: (i) for collection and (ii) for conveyance. The use of drain envelopes avoids the risk of high

A range of geocomposite materials, many of proprietary hydraulic gradients close to the subsoil drain pipe, which

design, is also available and can be used for the same can cause soil instability. It also increases the

purpose. effectiveness of the drain by increasing its surface area.

Pipes or other conduits associated with subsoil drains

should meet the following requirements: The material in the drain envelope is often called a filter,

although this is not strictly correct. It is not necessary for

• The size of the conduits is to be related to the the envelope to retain all soil material. Such a filter would

expected flows through them. These flows will be rapidly become clogged. Nevertheless, the term “filter” is

very small in fine-grained soils, but will be larger widely used and it has been adopted in this Chapter.

where:

° the drain is located in a pervious stratum such as (b) Filter Material

a sand that is permanently fed by a nearby water

body or by heavy rainfall over a prolonged period Filter material consisting of natural clean washed sands

° the drain cuts off flow in an aquifer that is and gravels and screened crushed rock should be:

carrying a significant flow • well graded with a mix of different sizes of sand

• Where circular pipes are used in subsurface drains, particles and an adequate permeability with:

normally, a minimum pipe size of 100 mm is ° natural sand, less than 5% passing a 75 µm sieve

employed, with larger sizes required for long runs of

° screened crushed rock, sizes 3 mm to 20 mm

drains or in situation such as those described above.

In cases of the larger flows, advice shall be sought • sufficiently coarse not to wash into the subsoil drain,

or through pores in a geotextile cover to such drain;

44-4 Urban Stormwater Management Manual

Subsoil Drainage

• chemically stable and inert to possible actions of soil unpaved finished surface, and terminate with a

and groundwater screw cap legibly marked ‘SS’

Manholes may be constructed of concrete or other

(c) Geotextile Filters approved material. Manhole construction requirements are

outlined in Chapter 24. Pipe to manhole connections

The permeability of geotextiles used in subsoil drains should allow flexibility at the interface. Manholes on

should be greater than that of the native soil. The subsoil drains are normally capped with a metal casting

following general requirements should be considered: that has a removable lid, or with a concrete cover. It is

• a desirable permeability for geotextiles is 10 times that desirable for manholes on subsoil drains to be identified as

of the native soil such, for example by the marking ‘SS’ on the cover.

• there is a tendency for geotextiles to clog at some

44.6.2 Embedment

locations, particularly where iron salts are present,

e.g. scoria. Oxidation and biologically related actions

(a) Materials

can cause plate-like deposits of ferruginous particles

on filter surfaces, rapidly clogging them. In such

The material for bedding, haunch support, side support,

areas, carefully selected granular filters should be

and overlay is determined by:

used instead of geotextiles. Advice from a

professional engineer with geotechnical expertise • the characteristics of the ground in which the subsoil

should be sought in such situations. drain is located

• the type of geotextile material used (if applicable)

44.6 INSTALLATION

Where the conduit consists of a pipe, the embedment

44.6.1 General material shall be crushed hard rock or natural gravel with

not less than 90% by mass retained on a 9.5 mm sieve.

Any pipes, conduits and fittings in such drains shall be: Where the conduit is a geocomposite drain the material

may be a coarse washed sand.

• cleaned internally prior to installation and

commissioning Requirements for sizing and determining arrangements of

• continuously supported by embedment (see filter material are as follows:

Section 44.6.2)

(i) For proper performance, the filter material (or backfill)

• jointed with elastomeric seals, solvent cement or joints should usually surround the drain, under as well as

complying with the manufacturer’s recommendations over. However, this will depend on the nature of the

and/or requirements of the Local Authority strata being drained and the depth of drain.

If a drain penetrates a water-bearing layer, and is

Installation of subsoil drains may include either of the

socketed into an impervious zone below, then the filter

following:

material only needs to be placed in contact with the

• pre-wrapping of the pipes or geocomposite drains with pervious soil and a suitable pipe bedding material

geotextile material prior to placement of the could surround the pipe.

embedment, or

If a drain only partially penetrates a pervious layer

• wrapping of all or part of the embedment with such that water would be expected to flow into a drain

geotextile material over its entire depth, then the filter material would

need to surround the pipe and also to act as the pipe

The manufacturer’s recommendations should be followed bedding material.

where applicable. Joint overlaps for geotextile material

should not be less than 300 mm. (ii) Where pipe bedding is a different material to the filter

material, it should be coarser grained than the filter

Subsoil drains shall be laid: material and its particles have to be greater in size

• so any pipe or geocomposite drain employed can be than the perforations in the pipe unless a geotextile

flushed out wrapping is provided. Ideally, the grain size

distribution of the bedding material should be chosen

• with clean-out points for pipes or geocomposite

so that it itself acts as a filter to the filter zone.

drains:

Common practice is to choose a free-draining, stable

) located at their topmost ends (or heads) and at

and inert material with a larger grain size than the

each change of direction greater than 700

filter, such as good quality, screened, crushed rock.

) constructed so that they intersect the drain at an

angle not greater than 450, extend vertically to

the top of paved surfaces or within 300 mm of an

Urban Stormwater Management Manual 44-5

Subsoil Drainage

(iii) A coarse washed sand should be used as a backfill 44.6.3 Monitoring Wells

when geocomposite subsurface drains are used. The

coarse sand acts as the primary filter and the On large or important installations, provision should be

geotextile wrap on the drain as a secondary filter. made to monitor subsurface water levels by installing

monitoring wells or piezometers. Monitoring wells allow

(b) Installation both the level and water quality of the subsurface water to

be checked. Piezometers can consist of a length of plastic

Subsoil drains shall be laid: tube, 25 mm to 38 mm in diameter, with holes to admit

water. Both monitoring wells and piezometers should be

• with embedment installed so that a subsoil drain is

capped to exclude surface water.

neither dislodged nor damaged

• so as to prevent the ingress of embedment and trench

fill

44-6 Urban Stormwater Management Manual

Anda mungkin juga menyukai

- Pipe Culvert Design Calculations PDFDokumen3 halamanPipe Culvert Design Calculations PDFRohit Kumar BeheraBelum ada peringkat

- Reinforced Concrete Reservoir AssignmentDokumen7 halamanReinforced Concrete Reservoir AssignmentKuza AnasBelum ada peringkat

- Design of New EarthworksDokumen20 halamanDesign of New EarthworksMilyanBelum ada peringkat

- Hydrological ReportDokumen27 halamanHydrological ReportAmos MutoroBelum ada peringkat

- U of I Facilities Standards - Control ValvesDokumen25 halamanU of I Facilities Standards - Control Valvesforevertay2000Belum ada peringkat

- Gabion Design Spreadsheet-WorkingDokumen7 halamanGabion Design Spreadsheet-WorkingDeependra Subedi0% (1)

- Subsoil Drainage DesignDokumen4 halamanSubsoil Drainage Designbirajr78Belum ada peringkat

- MarineDokumen16 halamanMarineNguyễn Thị Kim PhượngBelum ada peringkat

- Shift of Centre of Gravity (C.o.G.) during LiftingDokumen6 halamanShift of Centre of Gravity (C.o.G.) during LiftingLit Phen TuBelum ada peringkat

- Hackney Community Centre Condition SurveyDokumen42 halamanHackney Community Centre Condition SurveyFederico OrtizBelum ada peringkat

- Wind Tunnel Designs and Their Diverse Engineering Applications (PDFDrive)Dokumen228 halamanWind Tunnel Designs and Their Diverse Engineering Applications (PDFDrive)iman jabbar100% (1)

- Estimating Design Flood Hydrographs Using Clark MethodDokumen64 halamanEstimating Design Flood Hydrographs Using Clark MethodAgungNurFauziBelum ada peringkat

- Estimating relief loads using conventional, steady-state and dynamic simulation techniquesDokumen9 halamanEstimating relief loads using conventional, steady-state and dynamic simulation techniquessgrsth100% (5)

- ASTM A283 GR C PDFDokumen3 halamanASTM A283 GR C PDFDiego Alonso100% (2)

- NDOR Hydraulic Analysis GuidelinesDokumen22 halamanNDOR Hydraulic Analysis GuidelinesMahmoud Breama100% (1)

- Sulphate Attack and Chloride PenetrationDokumen8 halamanSulphate Attack and Chloride PenetrationMahmood MuftiBelum ada peringkat

- Natural Gas Infrastructure InvestmentDokumen32 halamanNatural Gas Infrastructure InvestmentLit Phen TuBelum ada peringkat

- Fatfree User ManualDokumen33 halamanFatfree User ManualLit Phen TuBelum ada peringkat

- 2 Design of Causeways in Developing CountriesDokumen8 halaman2 Design of Causeways in Developing CountriesMichael100% (1)

- Chapter5 Drainage of Highway PavementDokumen26 halamanChapter5 Drainage of Highway Pavementmehul_cl045032Belum ada peringkat

- Lamella Clarifier Leopold TexlerDokumen4 halamanLamella Clarifier Leopold TexlerAntony ThanosBelum ada peringkat

- Wet Retention Ponds: AdvantagesDokumen7 halamanWet Retention Ponds: AdvantagesEugene MarcoBelum ada peringkat

- Hydraulic Calculation of Box Culvert: Bekri Primary Canal ##+### BBK1a 3-Barrel BoxDokumen1 halamanHydraulic Calculation of Box Culvert: Bekri Primary Canal ##+### BBK1a 3-Barrel BoxelfitaBelum ada peringkat

- BS en 12390 8 2009 Testing Hardened Concrete Depth of Penetration of Water Under Pressure PDFDokumen10 halamanBS en 12390 8 2009 Testing Hardened Concrete Depth of Penetration of Water Under Pressure PDFKING OF VIDEO GAMES xBelum ada peringkat

- Design and Analysis of Exhaust Diffuser of Gas Turbine Afterburner Using CFDDokumen6 halamanDesign and Analysis of Exhaust Diffuser of Gas Turbine Afterburner Using CFDMASOUDBelum ada peringkat

- Route 123 Flexible Overlay Design ExampleDokumen4 halamanRoute 123 Flexible Overlay Design ExamplePODBelum ada peringkat

- SUDS Design and Adoption GuideDokumen114 halamanSUDS Design and Adoption GuideEgia YosepBelum ada peringkat

- Design Flexible ATJ 5I85 2013 2022Dokumen33 halamanDesign Flexible ATJ 5I85 2013 2022Leediya AfrinaBelum ada peringkat

- FERTIGATIONDokumen96 halamanFERTIGATIONNohaAbdulWarthBelum ada peringkat

- Open Channel Flow Types and StatesDokumen41 halamanOpen Channel Flow Types and StatesdibaelleyaBelum ada peringkat

- Concrete Joint Types: Construction, Expansion, Contraction & IsolationDokumen7 halamanConcrete Joint Types: Construction, Expansion, Contraction & IsolationbotchBelum ada peringkat

- Water RecDokumen22 halamanWater RecKavi MaranBelum ada peringkat

- Land and Highway Drainage DrainageDokumen16 halamanLand and Highway Drainage DrainageIcen AlincastreBelum ada peringkat

- 2018 Distillation NoteDokumen120 halaman2018 Distillation NoteemmanuelBelum ada peringkat

- Botswana Borehole Completions CertificateDokumen3 halamanBotswana Borehole Completions CertificateRICHARDBelum ada peringkat

- My Second Tutorial in WaterCad Modeling PDFDokumen26 halamanMy Second Tutorial in WaterCad Modeling PDFEdBelum ada peringkat

- Sewer DesignDokumen14 halamanSewer DesignDevendra Sharma100% (3)

- Lecture3 - Uniform Flow 2Dokumen18 halamanLecture3 - Uniform Flow 2Kaaviyan ThirunyanamBelum ada peringkat

- Concrete Information - Design of Concrete Pavement For City StreetsDokumen8 halamanConcrete Information - Design of Concrete Pavement For City Streetsoscargon19100% (1)

- Rotarex - Changeover ManifoldDokumen60 halamanRotarex - Changeover ManifoldLit Phen TuBelum ada peringkat

- 17 - Repairing Internal Corrosion Defects in Pipelines - A Case Study PDFDokumen26 halaman17 - Repairing Internal Corrosion Defects in Pipelines - A Case Study PDF김원재100% (4)

- EMCO Floating Suctions enDokumen2 halamanEMCO Floating Suctions enAnonymous yQ7SQrBelum ada peringkat

- SS 531-1-2006 (2013) - Preview PDFDokumen11 halamanSS 531-1-2006 (2013) - Preview PDFTai Huynh100% (1)

- Below Ground DrainageDokumen9 halamanBelow Ground Drainagepatrick kivutiBelum ada peringkat

- Step (1) : Determine Storage Volume RequiredDokumen12 halamanStep (1) : Determine Storage Volume RequiredYANIshaBelum ada peringkat

- Types of ManholesDokumen6 halamanTypes of ManholesEvonYongBelum ada peringkat

- Piano WeirDokumen14 halamanPiano WeirDheeraj ThakurBelum ada peringkat

- Development Design Specification D4Dokumen10 halamanDevelopment Design Specification D4Timothy KimemiaBelum ada peringkat

- Guidance Note On The Design of Thrust BlocksDokumen1 halamanGuidance Note On The Design of Thrust BlocksLi Tsz ChunBelum ada peringkat

- Lecture 2 Storage Structures ReservoirDokumen33 halamanLecture 2 Storage Structures ReservoirNguyen Hong HaiBelum ada peringkat

- Calculations For Head Loss Using Hazen William EquationDokumen2 halamanCalculations For Head Loss Using Hazen William EquationHussan AliBelum ada peringkat

- Rock Sizing For Culvert Outlets PDFDokumen0 halamanRock Sizing For Culvert Outlets PDFwrobinsonf2scomBelum ada peringkat

- Introduction To GeotehnicalDokumen15 halamanIntroduction To GeotehnicalAnna CristinaBelum ada peringkat

- Microsoft Word - PART 2-SRK Project Report 2017Dokumen28 halamanMicrosoft Word - PART 2-SRK Project Report 2017daprcBelum ada peringkat

- Intersection Control and Design IDokumen30 halamanIntersection Control and Design IKwaku SoloBelum ada peringkat

- Watershed Management Field ManualDokumen196 halamanWatershed Management Field ManualAnonymous U6pIEKQgh100% (1)

- 2000 06 PDFDokumen16 halaman2000 06 PDFBlack MesaBelum ada peringkat

- Weir Dsign and LayoutDokumen5 halamanWeir Dsign and LayoutBehar Abduraheman100% (1)

- Pet Hi Ya God ADokumen10 halamanPet Hi Ya God AShashika IreshBelum ada peringkat

- IWK - Recommended PEDokumen1 halamanIWK - Recommended PECalvin KewBelum ada peringkat

- Table 60001 Concrete DurabilityDokumen1 halamanTable 60001 Concrete DurabilityZaid JamilBelum ada peringkat

- AqueductDokumen36 halamanAqueductAnonymous r63bVFCc0% (1)

- Drainage Design FundamentalsDokumen49 halamanDrainage Design FundamentalskarthikuddBelum ada peringkat

- Check DamDokumen7 halamanCheck Damahtan99Belum ada peringkat

- Stormwater Analysis and Solution of Waterlogging in Kothrud Region, PuneDokumen11 halamanStormwater Analysis and Solution of Waterlogging in Kothrud Region, PuneIJRASETPublicationsBelum ada peringkat

- HP16 MasmaDokumen28 halamanHP16 MasmaAsyraf MalikBelum ada peringkat

- Structural Engineering NotesDokumen5 halamanStructural Engineering NotesRishabh LalaBelum ada peringkat

- Civil Engineering Technology - Higher National Diploma (HND) : Transportation: Transportation Engineering - 1597859336315Dokumen4 halamanCivil Engineering Technology - Higher National Diploma (HND) : Transportation: Transportation Engineering - 1597859336315Stephen TorwoedzorBelum ada peringkat

- 66 AMH - Module 4 On Spring Development PDFDokumen39 halaman66 AMH - Module 4 On Spring Development PDFEfremWakjiraHodeBelum ada peringkat

- v2 TD S P 1002 1 F Shape Parapet 1 22m High Type A B General Layout and SectionsDokumen1 halamanv2 TD S P 1002 1 F Shape Parapet 1 22m High Type A B General Layout and SectionsSudathipTangwongchaiBelum ada peringkat

- Clay BlanketDokumen2 halamanClay BlanketAhmed Tarek100% (1)

- Design of Hydraulic Structures: B.Tech Civil Credit Hours: 03Dokumen16 halamanDesign of Hydraulic Structures: B.Tech Civil Credit Hours: 03Suleman FaisalBelum ada peringkat

- Old Exam 4307Dokumen6 halamanOld Exam 4307rizwan ghafoorBelum ada peringkat

- Dam Seepage ExplainedDokumen12 halamanDam Seepage ExplainedCzar Alexis FernandezBelum ada peringkat

- Manning's N ValuesDokumen5 halamanManning's N ValuesSuraj Mani LamichhaneBelum ada peringkat

- Ecohydrology: Vegetation Function, Water and Resource ManagementDari EverandEcohydrology: Vegetation Function, Water and Resource ManagementBelum ada peringkat

- CHP 0840Dokumen5 halamanCHP 0840Rocky SaseleBelum ada peringkat

- d07 Subsurface Drainage DesignDokumen19 halamand07 Subsurface Drainage DesignKaushal RijalBelum ada peringkat

- Installation and Operation Guide for 4-20IQ Sensor TransmittersDokumen12 halamanInstallation and Operation Guide for 4-20IQ Sensor TransmittersLit Phen TuBelum ada peringkat

- MPcontroller ManualDokumen24 halamanMPcontroller ManualLit Phen TuBelum ada peringkat

- Connection From The Fexible Hose To The On Site Piping System As Following ShownDokumen1 halamanConnection From The Fexible Hose To The On Site Piping System As Following ShownLit Phen TuBelum ada peringkat

- Installation Manual - BM-BE - 1212Dokumen2 halamanInstallation Manual - BM-BE - 1212Lit Phen TuBelum ada peringkat

- LED Light - Datasheet (Philips LED Panel 600x600) PDFDokumen2 halamanLED Light - Datasheet (Philips LED Panel 600x600) PDFLit Phen TuBelum ada peringkat

- Vinyl Floor - BrochureDokumen6 halamanVinyl Floor - BrochureLit Phen TuBelum ada peringkat

- Operating Manual BM BE 55-56-2U 1115Dokumen18 halamanOperating Manual BM BE 55-56-2U 1115Lit Phen TuBelum ada peringkat

- Instruction For Use BM55-2U (Simplified Version)Dokumen2 halamanInstruction For Use BM55-2U (Simplified Version)Lit Phen TuBelum ada peringkat

- Vinyl Floor - DatasheetDokumen1 halamanVinyl Floor - DatasheetLit Phen TuBelum ada peringkat

- Vinyl Floor - Declaration of PerformanceDokumen1 halamanVinyl Floor - Declaration of PerformanceLit Phen TuBelum ada peringkat

- Broschuere GCS 2018-05Dokumen8 halamanBroschuere GCS 2018-05Lit Phen TuBelum ada peringkat

- Rin JaniDokumen23 halamanRin JaniLit Phen TuBelum ada peringkat

- How Best To Repair The World's Ageing PipelinesDokumen3 halamanHow Best To Repair The World's Ageing PipelinesLit Phen TuBelum ada peringkat

- Section Description Section Length (M)Dokumen9 halamanSection Description Section Length (M)Lit Phen TuBelum ada peringkat

- Flip Flop Hostel - Main StationDokumen1 halamanFlip Flop Hostel - Main StationLit Phen TuBelum ada peringkat

- Aviva PCP Blue Clinic Listing 201401Dokumen11 halamanAviva PCP Blue Clinic Listing 201401Lit Phen TuBelum ada peringkat

- Salman Offshore Facilities Laybarge Welding SpecificationDokumen45 halamanSalman Offshore Facilities Laybarge Welding SpecificationLit Phen TuBelum ada peringkat

- Jurnal 1 PDFDokumen10 halamanJurnal 1 PDFFauzan RahmanBelum ada peringkat

- Jurnal 1 PDFDokumen10 halamanJurnal 1 PDFFauzan RahmanBelum ada peringkat

- Complete 15-minute permit application form for proposed reconstruction worksDokumen1 halamanComplete 15-minute permit application form for proposed reconstruction worksLit Phen TuBelum ada peringkat

- First Coach 1-6-2014Dokumen1 halamanFirst Coach 1-6-2014Lit Phen TuBelum ada peringkat

- Introduction To Wind Forces and Wind Effects On Buildings and StructuresDokumen16 halamanIntroduction To Wind Forces and Wind Effects On Buildings and StructuresallenBelum ada peringkat

- Re90220 01 - 2011 10Dokumen6 halamanRe90220 01 - 2011 10Parmasamy SubramaniBelum ada peringkat

- Re27518 0203 - (WWW - Isva.co)Dokumen6 halamanRe27518 0203 - (WWW - Isva.co)AdrianaBelum ada peringkat

- Empirical Process ControlDokumen12 halamanEmpirical Process ControlrahulBelum ada peringkat

- AP PGECET Chemical Engg 2015 Question Paper - Answer Key DownloadDokumen16 halamanAP PGECET Chemical Engg 2015 Question Paper - Answer Key DownloadpavaniBelum ada peringkat

- Control Surges with Ross ECV Electronic Check ValveDokumen6 halamanControl Surges with Ross ECV Electronic Check ValveHassan HaiderBelum ada peringkat

- Experiment CSTRDokumen20 halamanExperiment CSTRqilahBelum ada peringkat

- BLACK GOLD DISSOLVABLE FRAC PLUG Technical Sales Brochure PDFDokumen3 halamanBLACK GOLD DISSOLVABLE FRAC PLUG Technical Sales Brochure PDFImadBelum ada peringkat

- Siphon EffectDokumen12 halamanSiphon EffectKhalid AnwarBelum ada peringkat

- Calculation of Height of The Siphon SystemDokumen2 halamanCalculation of Height of The Siphon SystemHsein WangBelum ada peringkat

- Turbine StatorDokumen18 halamanTurbine StatorAli KamranBelum ada peringkat

- Mass Transfer II Prof. Nishith Verma Department of Chemical Engineering Indian Institute of Technology, Kanpur Lecture No. # 04Dokumen23 halamanMass Transfer II Prof. Nishith Verma Department of Chemical Engineering Indian Institute of Technology, Kanpur Lecture No. # 04Anitha RajBelum ada peringkat

- Fluid Mechanics Worksheet 2Dokumen8 halamanFluid Mechanics Worksheet 2anon_293092329Belum ada peringkat

- Final Project (Team)Dokumen5 halamanFinal Project (Team)bintangBelum ada peringkat

- Design and Validation of Bellows As Per EJMA-FEA (White Paper) PDFDokumen5 halamanDesign and Validation of Bellows As Per EJMA-FEA (White Paper) PDFJaveed A. KhanBelum ada peringkat

- Pompe GasoilDokumen2 halamanPompe Gasoilday rachidBelum ada peringkat

- Product Bulletin - PC-77Dokumen3 halamanProduct Bulletin - PC-77Aymen Hentati100% (1)

- Netzsch-ARC en Web PDFDokumen20 halamanNetzsch-ARC en Web PDFdarksideministryBelum ada peringkat

- PVC Pressure Pipes and Fittings Catalogue (Pannon Pipe)Dokumen8 halamanPVC Pressure Pipes and Fittings Catalogue (Pannon Pipe)vuthy prakBelum ada peringkat

- Input parameters and energy savings comparison of galvanized sheet duct and SMART PIR panelsDokumen3 halamanInput parameters and energy savings comparison of galvanized sheet duct and SMART PIR panelsMahesh KhadeBelum ada peringkat