Descaling Tube Heat Exchangers

Diunggah oleh

arajamani780 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

92 tayangan2 halamanJudul Asli

DescalingTubeHeatExchangers

Hak Cipta

© Attribution Non-Commercial (BY-NC)

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Attribution Non-Commercial (BY-NC)

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

92 tayangan2 halamanDescaling Tube Heat Exchangers

Diunggah oleh

arajamani78Hak Cipta:

Attribution Non-Commercial (BY-NC)

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 2

DESCALING TUBULAR HEAT

EXCHANGERS

Guidance notes

CHOICE OF

DESCALING flow and return tubing

CHEMICAL AND Tapping /

QUANTITY pressure gauge fitting

REQUIRED: flow

reverser

For mild steel HEAT

heat exchangers, EXCHANGER

even with copper, Drain

valve DESCALING

brass or bronze PUMP

ancillary flow and

components, use return tubing

SCALEBREAKER

HD.

NB. When descaling with any acid, there is the

If the heat exchanger utilises any stainless

possibility of hydrogen being evolved.

steel in the construction, SCALEBREAKER HD

Hydrogen is a flammable gas, and the working

should not be used. Either SCALEBREAKER

area should be well ventilated. Avoid smoking

SR or SCALEBREAKER FX should be used, nearby, or any other means of ignition.

dependent on the type of fouling.

PROCEDURE:

1. Check the volume / capacity of the section

to be descaled (usually the water-side), and 1. Ensure an adequate water supply to dilute

calculate the amount of descaling chemical or neutralise any chemical leaks, or the

required. spent descaling chemical, so that disposal

does not contravene local regulations.

2. As a guide, for a 250 litre capacity heat

exchanger, use 1 x 25 litre of descaling 2. Isolate water inlet and outlet pipework, by

chemical (ie. a 10% solution by volume). A valve, or blanking plates if necessary.

weaker solution may be used, but will take

longer to remove a given amount of scale. 3. Couple flow and return hoses from descaling

pump to the inlet and outlet of the heat

3. In the above example, a C30 descaling exchanger to be descaled.

pump of 35 litre tank capacity will allow all

the descaling chemical to be placed directly 4. The pump connection to the lower point of

in the pump tank, without first draining out the heat exchanger should always be

a corresponding volume of water from the through a valve, as a precaution. Failing

heat exchanger. this, power failure to the pump would result

in the head of water in a larger heat

4. A descaling pump with a smaller tank would exchanger overflowing the pump tank,

require some water to be run out of the unless prevented by closing the valve.

heat exchanger before commencing, and

the tank of the pump would need to be filled 5. Connections should be made so that there

with descaling chemical two or more times, is a closed circuit between the pump output

each time operating the pump briefly to hose, through the heat exchanger to the

transfer the chemical into the heat return hose.

exchanger before commencing normal

circulation. The chemical will rapidly dilute 6. Venting of the carbon dioxide gas evolved is

to the working strength on commencing achieved through the pump tank filler cap

circulation. aperture. The cap should be screwed on by

no more than one quarter of a turn. This is

© Kamco Limited 2004 Descaling Tubular Heat Exchangers: Guidance Notes

sufficient to vent the gas, but at the same SCALEBREAKER descaling chemicals contain a

time reduces fumes and prevents splashes. built-in colour change to monitor strength.

An alternative simple check may be made

7. Connect the pump to a suitable earthed by dropping a sample of limescale into the

power supply (220 or 110 volt, according to solution, and observing if there is any

model). As the pump will be used in a effervescence.

damp location, we recommend that a

residual current circuit breaker plug top be 14. Alternatively, a pH meter, or pH indicator

used. paper, may be used to check the pH of the

descaling solution. Once the pH has risen to

8. The flow reverser handle points in the 3.5 to 4, its ability to dissolve limescale and

direction of flow of the liquid. Turn the corrosion deposits is effectively spent, and

handle so that it initially points towards the more descaling chemical or a fresh solution

hose going to the lower heat exchanger will be required.

connection. The hose from the top of the

heat exchanger will then be the return to 15. After draining off the spent descaling

the pump tank. chemical, flush the heat exchanger with

fresh water. Many natural waters are

9. Prior to adding descaling chemical to pump slightly alkaline, and water flushing may be

tank, first 'prove' the circuit with fresh all that is required. Alternatively, circulate a

water alone. Add water to pump tank to 0.5 to 1% solution of NEUTRALISING

approx. 8cm. above minimum liquid level, CRYSTALS through the heat exchanger for

switch on pump, and immediately open the 15 minutes, drain, and then flush with clean

valve detailed in point 4 above, to allow water.

circulation to commence. If water level

drops initially, add more water to pump 16. Operators may prefer to neutralise the

tank, and check that all connections are spent descaling solution "in situ" whilst the

tight. liquid is still circulating, by carefully adding

neutralising crystals to the solution until the

10. To commence descaling, slowly add pH is brought up to a value of 7, and then

descaling chemical into pump tank, waiting flushing to drain. If foaming is excessive,

until liquid is returning into the descaling carefully add a little FOAMBREAKER to the

pump tank from the heat exchanger, and descaling pump tank.

check to see if there is a rapid build up of

foam on top of the liquid in the pump. This IMPORTANT: WHEN WORKING WITH

may happen when there is a large build up ACIDIC DESCALING CHEMICALS, ALWAYS

of reactive limescale in the heat exchanger. WEAR SUITABLE PROTECTIVE CLOTHING

If this is excessive, add a little AND GOGGLES, AND CHECK AND OBSERVE

FOAMBREAKER carefully to the tank. INSTRUCTIONS WITH DESCALING

CHEMICALS.

11. As pumping commences, bubbles and

foaming will be seen in the return hose to Caps should be kept securely on all chemical

the pump, indicating that limescale is being containers whilst not in use. As a matter of

dissolved. If foam formation is excessive, prudence, and to avoid splashes, operators

carefully remove descaling pump tank cap, should avoid standing directly over the open

and add FOAMBREAKER to the pump tank neck of either chemical containers or the filling

to stop the foaming. neck of the descaling pump whilst pouring or

adding chemicals.

12. Reverse the direction of flow periodically,

checking all connections for tightness and Legal disclaimer: It is stressed that these are

absence of leaks. guidance notes only, and the above

information is based on the present state of

13. Scale removal can be considered complete our knowledge of tubular heat exchangers in

when bubbles are no longer seen in the general. It is given in good faith, but due to

return pipe, and yet the descaling solution is the diverse and varied nature of such

still sufficiently strong to remove hard water equipment, the user must satisfy himself that

deposits. the above procedure is viable in the prevailing

situation.

© Kamco Limited 2004 Descaling Tubular Heat Exchangers: Guidance Notes

Anda mungkin juga menyukai

- Lesson Plan TemplateDokumen1 halamanLesson Plan Templatearajamani78Belum ada peringkat

- Fall Protection ProceduresDokumen14 halamanFall Protection Proceduresarajamani78Belum ada peringkat

- TPM 8 PillarsDokumen6 halamanTPM 8 Pillarsarajamani78Belum ada peringkat

- Motivation 1Dokumen29 halamanMotivation 1arajamani78Belum ada peringkat

- Power Press Operator TrainingDokumen40 halamanPower Press Operator TrainingpandaprasadBelum ada peringkat

- Building Standards HandbookDokumen170 halamanBuilding Standards Handbookarajamani78Belum ada peringkat

- 5s 7 Housekeeping Wastes Kanban 1233776462169799 2 PDFDokumen26 halaman5s 7 Housekeeping Wastes Kanban 1233776462169799 2 PDFMario Alberto Hernandez HerreraBelum ada peringkat

- Powder MixingDokumen1 halamanPowder Mixingarajamani78Belum ada peringkat

- GM 750Dokumen40 halamanGM 750arajamani78Belum ada peringkat

- Asian Paints LTD UPDokumen14 halamanAsian Paints LTD UParajamani78Belum ada peringkat

- Skill Matrix For ChemistsDokumen4 halamanSkill Matrix For Chemistsarajamani78Belum ada peringkat

- 5s 7 Housekeeping Wastes Kanban 1233776462169799 2 PDFDokumen26 halaman5s 7 Housekeeping Wastes Kanban 1233776462169799 2 PDFMario Alberto Hernandez HerreraBelum ada peringkat

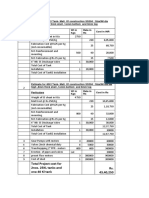

- Ss Tank EstimateDokumen1 halamanSs Tank Estimatearajamani78Belum ada peringkat

- Is 3043 1987Dokumen95 halamanIs 3043 1987suresh kumarBelum ada peringkat

- Plant Engineers Guide To Agitation Design and FundamentalsDokumen33 halamanPlant Engineers Guide To Agitation Design and FundamentalsMark MacIntyre100% (1)

- Test Paper-For Paint Plant OperatorDokumen1 halamanTest Paper-For Paint Plant Operatorarajamani78Belum ada peringkat

- Blackmer Paint and Coatings BrochureDokumen4 halamanBlackmer Paint and Coatings Brochurearajamani78Belum ada peringkat

- Bearing Housing PDFDokumen1 halamanBearing Housing PDFarajamani78Belum ada peringkat

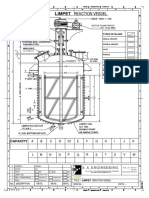

- Limpet Coil Reactor VesselDokumen1 halamanLimpet Coil Reactor Vesselarajamani78Belum ada peringkat

- Limpet Reaction Vessel PDFDokumen1 halamanLimpet Reaction Vessel PDFarajamani78Belum ada peringkat

- Fire Safety Training: Presented by Environmental Safety Services, Division of Public Safety, Georgia Southern UniversityDokumen36 halamanFire Safety Training: Presented by Environmental Safety Services, Division of Public Safety, Georgia Southern Universityarajamani78Belum ada peringkat

- Rs. 4,340,250 Total Project Cost For 2nos. 25KL Tanks and One 40 KL TankDokumen1 halamanRs. 4,340,250 Total Project Cost For 2nos. 25KL Tanks and One 40 KL Tankarajamani78Belum ada peringkat

- API70 Spec PDFDokumen1 halamanAPI70 Spec PDFarajamani78Belum ada peringkat

- Total Project Cost For 2nos. 25KL Tanks and One 40 KL Tank Rs. 43,40,250Dokumen1 halamanTotal Project Cost For 2nos. 25KL Tanks and One 40 KL Tank Rs. 43,40,250arajamani78Belum ada peringkat

- Estimate For 25 KL TankDokumen1 halamanEstimate For 25 KL Tankarajamani78Belum ada peringkat

- Air DryersDokumen85 halamanAir Dryersarajamani78Belum ada peringkat

- Air DryersDokumen85 halamanAir Dryersarajamani78Belum ada peringkat

- DimensionsDokumen4 halamanDimensionsarajamani78Belum ada peringkat

- 26 Health Benefits of Cinnamon - Cinnamon VogueDokumen5 halaman26 Health Benefits of Cinnamon - Cinnamon Voguearajamani78Belum ada peringkat

- Resin Pipeline CalibrationDokumen1 halamanResin Pipeline Calibrationarajamani78Belum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (72)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- J Matpr 2021 06 081Dokumen8 halamanJ Matpr 2021 06 081SREEJITH S NAIR100% (1)

- A AaaaaaaDokumen8 halamanA AaaaaaaVani VaniBelum ada peringkat

- Alternate Fuels For IC EnginesDokumen2 halamanAlternate Fuels For IC Enginesharshasai123456Belum ada peringkat

- Workshop AssignmentDokumen23 halamanWorkshop AssignmentMr. NasrullahBelum ada peringkat

- Technical Information Sheet: Stay Silv 5 Brazing Filler MetalDokumen1 halamanTechnical Information Sheet: Stay Silv 5 Brazing Filler MetalMind´s EyesBelum ada peringkat

- Isi Handbook For Structural Engineers PDFDokumen124 halamanIsi Handbook For Structural Engineers PDFRoyer JuarezBelum ada peringkat

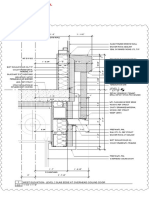

- Overhead Door Head DetailDokumen1 halamanOverhead Door Head Detaildata copyBelum ada peringkat

- TOOLCORD MMA Electrodes for HardfacingDokumen1 halamanTOOLCORD MMA Electrodes for HardfacingbrunizzaBelum ada peringkat

- Creep and Shrinkage Calculation Using The Model Code 2010: Benchmark Example No. 1Dokumen9 halamanCreep and Shrinkage Calculation Using The Model Code 2010: Benchmark Example No. 1Sri RamBelum ada peringkat

- Snowy The Baby Polar Bear Set: NotesDokumen7 halamanSnowy The Baby Polar Bear Set: NotesMiriam Beñose100% (2)

- TDS - Total - Lubrilam S 40 L - 1as - 201412 - enDokumen1 halamanTDS - Total - Lubrilam S 40 L - 1as - 201412 - enVelibor KaranovicBelum ada peringkat

- Construction and Application of Clay-Swelling Diagrams by Use of XRD MethodsDokumen1 halamanConstruction and Application of Clay-Swelling Diagrams by Use of XRD MethodsFarzad sadeghzadBelum ada peringkat

- Learning Naming Through Guided Inquiry - KeyDokumen15 halamanLearning Naming Through Guided Inquiry - KeyAshton StinsonBelum ada peringkat

- How To Get High Quality Weldoflange or NipoflangeDokumen7 halamanHow To Get High Quality Weldoflange or NipoflangeYaneYangBelum ada peringkat

- Cambridge IGCSE: Combined Science 0653/42Dokumen24 halamanCambridge IGCSE: Combined Science 0653/42Hin Wa LeungBelum ada peringkat

- Felted Makeup Bag: Buy Yarn and Supplies HereDokumen5 halamanFelted Makeup Bag: Buy Yarn and Supplies HereLangónéBaloghJuditBelum ada peringkat

- Arcol PPG 2000 - en - 05486688 13017894 13552551Dokumen2 halamanArcol PPG 2000 - en - 05486688 13017894 13552551Fairmont Ind Quality DivisionBelum ada peringkat

- Sodium Chlorate - Properties and Reactions PDFDokumen5 halamanSodium Chlorate - Properties and Reactions PDFangelofglory100% (1)

- Grade 11-Platinum Smaw 3RD Quarter ExamDokumen3 halamanGrade 11-Platinum Smaw 3RD Quarter ExamemmabentonioBelum ada peringkat

- Sigma Marine Coatings Manual - Part113Dokumen2 halamanSigma Marine Coatings Manual - Part113Tommy2020Belum ada peringkat

- Terry Adams Construction/ HVAC ResumeDokumen3 halamanTerry Adams Construction/ HVAC ResumeTerry AdamsBelum ada peringkat

- Pipe Dimensions Imperial/Metric Pipe Chart: Nominal Pipe Size MM OD MM Wall Thickness MM KG/MDokumen6 halamanPipe Dimensions Imperial/Metric Pipe Chart: Nominal Pipe Size MM OD MM Wall Thickness MM KG/MJaydev ChakrabortyBelum ada peringkat

- Att - 2-1 - DS-103-0001-1 - Engineering Specification For Pressure VesselsDokumen78 halamanAtt - 2-1 - DS-103-0001-1 - Engineering Specification For Pressure VesselsDinh Nguyen DaoBelum ada peringkat

- Chemistry-Science 2 Solved by MeDokumen8 halamanChemistry-Science 2 Solved by MeMrunank R ReddyBelum ada peringkat

- Mcode and Mname Commercial and Alternate Designations: Material - Cross - IndexDokumen33 halamanMcode and Mname Commercial and Alternate Designations: Material - Cross - IndexMohamedBelum ada peringkat

- Lintel Design Manual: Design and Analysis of Concrete Masonry and Precast Concrete LintelsDokumen72 halamanLintel Design Manual: Design and Analysis of Concrete Masonry and Precast Concrete LintelsReinaldo Andrei SalazarBelum ada peringkat

- Fabrication of Nanomaterials by Top-Down and Bottom-Up Approaches - An OverviewDokumen5 halamanFabrication of Nanomaterials by Top-Down and Bottom-Up Approaches - An OverviewApexa SharmaBelum ada peringkat

- DENSITY VALUES OF PLASTICSDokumen4 halamanDENSITY VALUES OF PLASTICSAbdullah Al AsikBelum ada peringkat

- CHAPTER SIX EXPLAINS DISINFECTION METHODSDokumen33 halamanCHAPTER SIX EXPLAINS DISINFECTION METHODSSolomon DesalegnBelum ada peringkat

- 05892E02Dokumen39 halaman05892E02adelBelum ada peringkat