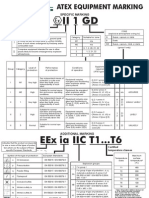

ATEX Rating Chart

Diunggah oleh

Ashish JoshiDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

ATEX Rating Chart

Diunggah oleh

Ashish JoshiHak Cipta:

Format Tersedia

Extronics Products • Explosion Proof & Pressurised Solutions • Engineered Solutions, Bespoke Certification and Development • Training &

Engineered Solutions, Bespoke Certification and Development • Training & Certification Services

ATEX Certification Definitions

Zoning Definitions Categories Non-electrical Equipment (concepts) Conformity Assessment ‘Quality Modules’

Zones ATEX Typical Zone EN 13463-1 Basic methods & requirements Module Annex Equipment Category *3 Protective

Gas Dust Definitions *1 *2 M1 M2 M2 1 2 2 3 System

Cat. Suitability EN 13463-2 Flow restricting enclosure fr

(E) (N) (E) (N)

EN 60079-10 EN 61241-10

EN 13463-3 Flame-proof enclosure d

A place in which an explosive 1G Equip. suitable for zone 0

0 20 1D Equip. suitable for zone 20 Design Phase

atmosphere is continually present EN 13463-5 Constructional safety c

EN 13463-6 Control of ignition sources b EC-Type Examination B III ✔ ✔ ✔ ✔ ✔

A place in which an explosive 2G Equip. suitable for zone 1 EN 13463-7 Pressurisation p Internal Control of Production A VIII ✔*4 ✔*4 ✔

1 21 atmosphere is likely to occur in normal 2D Equip. suitable for zone 21

operation occasionally EN 13463-8 Liquid immersion k

Unit Verification G IX O O O O O O O O

A place in which an explosive atmosphere 3G Equip. suitable for zone 2

2 22 Conformity Assessment ‘Quality Modules’ Table Production Phase

is not likely to occur in normal operation, 3D Equip. suitable for zone 22

but if it does only occurs for short periods * Notes:

1 “Global Approach” OJEC No.L220, 1993 Production Quality Assurance D IV Y Y Y

2 ATEX Directive 94/9/EC

3 Suffix (E) refers to electrical equipment and Product Quality Assurance E VII Y Y

IP Code Dusts internal combustion engines

Suffix (N) refers to non-electrical equipment

4 Technical Files to be deposited with a notified Product Verification F V Y Y Y

1st Numerical 2nd Numerical IP

Zone ATEX Category body

Protection against Solid Bodies Protection against Liquid Rating Conformity to Type C VI Y Y

KEY

0 No protection 0 No protection ✔ = mandatory unless Unit Verification is used

20 Requires 1D equipment IP6X

1 Objects > 50mm 1 Vertically dripping water O = optional as an alternative to other modules Internal Control of Production A VIII ✔ ✔ ✔

Y = one of two production phase modules for

2 Objects > 12mm 2 Drops of liquid (75° to 90°) the equipment category to be chosen by the

21 Requires 1D or 2D equipment IP6X Unit Verification G IX O O O O O O O O

3 Objects > 2.5mm 3 Sprayed water manufacturer

4 Objects > 1mm 4 Splashed water

5 Dust-protected 5 Water jets 22 Requires 3D, 2D or 1D equipment IP5X*

6 Dust-tight 6 Heavy seas Groups

7 Effects of immersion * Must be IP6X if dust is electrically conductive

8 Indefinite immersion I Electrical equipment intended for use in mines susceptible

to firedamp

US Enclosure Ratings NEMA 7 to 10 Hazardous Area Enclosures Types of Protection II Electrical equipment intended for use in places with an

explosive gas atmosphere other than mines susceptible to

NEMA, UL Approximate GAS ATEX DUST ATEX firedamp

& CSA IEC/IP Abbreviated Protection Description Standard Standard

type rating classification Type of Protection Code Type of Protection Code III Electrical equipment intended for use in places with an

1 IP20 Indoor, from contact with contents General Requirements – EN 60079-0 General Requirements – EN 61241-0:2006 explosive dust atmosphere other than mines susceptible to

firedamp*

2 IP22 Indoor, limited, falling dirt and water Intrinsic Safety Ex ia & ib EN 60079-11 Protection by Enclosures tD EN 61241-1:2004

3 IP55 Outdoor, from rain, sleet, windblown dust & ice damage

Increased Safety Ex e EN 60079-7 Protection pD EN 61241-4:2006

3R IP24 Outdoor, from rain, sleet & ice damage Gas Groups Dust Groups*

4 IP66 Indoor & outdoor, from windblown dust, rain, splashing Flameproof Ex d EN 60079-1 Intrinsic Safety iD EN 61241-11:2006

& hose directed water & ice damage IIA Propane IIIA Combustible Flyings

Pressurisation Ex p EN 60079-2 Encapsulation mD EN 61241-18:2004

4X IP66 Indoor & outdoor, from corrosion, windblown dust, rain, IIB Ethylene IIIB Non-conductive Dust

Powder Filling Ex q EN 60079-5

splashing & hose directed water & ice damage Type n EN60079-15 IIC Hydrogen/Acetylene IIIC Conductive Dust

6 IP67 Indoor & outdoor, from hose directed water, water entry Encapsulation Ex ma & mb EN 60079-18 Enclosed break device nC

Non-incendive component nC *Taken from the new IEC60079-0 2007

during submersion & ice damage Oil Immersion Ex o EN 60079-6 Hermetically sealed device nC

Sealed device nC

Type n Ex n EN 60079-15 Encapsulated device nC Simple Apparatus

Mechanical Impacts (UK) Code EN50102 Energy limited apparatus & circuits nL

Restricted breathing enclosure nR

Passive components

IK Code IK00 IK01 IK02 IK03 IK04 IK05 IK06 IK07 IK08 IK09 IK10 Temperature Non sparking nA

Impact

Energy * 0.14 0.2 0.35 0.5 0.7 1 2 5 10 20 T-Class Max surface Other Useful Standards

(Joules) temp in °C Well defined sources of

BS6656 Assessment of inadvertent ignition of flammable atmospheres stored energy considered

T1 450 by radio frequency radiation (guide) in safety analysis

T2 300

EN1127-1 Explosive atmospheres - Explosion prevention and protection.

T3 200 Part 1, Basic concepts & methodology for surface industry

Cable Gland Selection T4 135 EN1127-2 Explosive atmospheres - Explosion prevention and protection.

START T5 100 Part 2, Basic concepts & methodology for mining Sources of generated energy not

more than *1.5V, 100mA & 25mW

T6 85 EN60079-10 Classification of hazardous areas

EN60079-14 Electrical installations in hazardous areas (other than mines)

EN60079-17 Electrical installations inspection and maintenance

NOT

Yes No EN60079-19 Equipment repair, overhaul and reclamation piezoelectric crystal

Is area zoned?

EN60079-28 Protection of equipment and transmission systems using protected components

optical radiation voltage or current enhancement

Is equipment Is equipment 5V in

No No Zone 1? No Zone 2

Ex i concept? Ex d concept? Marking for

Gas Hazards XXXX

II 2 G Ex d IIC T4 * Note: North America still

Yes Yes Yes

Complies with Equipment Gas Type of Temperature

uses 1.2V and 20 microjoules

European Group Protection Gas Group* Class

EC Mark A, B or C

Directive Explosion (T1-T6)

*If omitted suitable

Use non-certified Refer to Ex d Notified Body Equipment Protection for all gas groups

Ex n* or N Number Category

cable glands cable selector Ex e concept Ex e concept

*refer to note 1 concept

chart

Marking for

Note 1: Non certified cable glands

Dust or Flyings XXXX

III 2 D Ex tD A21 IP66 T80°C

may be used provided that they and Fibres

maintain the minimum IP rating on Complies with Equipment Dust Type of

Use non-certified Hazards European Group Protection

the certified equipment of IP54 for cable glands Directive

EC Mark

Ingress protection

Explosion

outdoors and IP20 for indoor *refer to note 2 Notified Body Equipment Protection and max. surface

Gland type Brass temperature

equipment. Number Category

Note 2: Non certified cable glands

may be used provided they meet

the requirements of EN60079-0 and

Plastic

Radio Frequency Sources

EN60079-7 or EN60079-15. Use certified The threshold power of radio frequency (10 kHz to 300 GHz) for continuous transmissions and for pulsed

cable glands

Note 3: Internal sources of ignition transmissions whose pulse durations exceed the thermal initiation time shall not exceed the values shown in Table 4.

include sparks or equipment Programmable or software control intended for setting by the user shall not be permitted.

temperatures occurring in normal

operation which can cause ignition. Does this For pulsed radar and other transmissions where the pulses are short compared with the thermal initiation time, the

An enclosure containing terminals enclosure threshold energy values Zth shall not exceed those given in Table 5.

only or an indirect entry enclosure is Yes contain an No

internal source

considered not to constitute an

of ignition?

Table 4 from IEC 60079-0 Table 5 from IEC 60079-0

internal source of ignition.

*refer to note 3 Radio Frequency Power Thresholds Radio-frequency Energy Thresholds

Does the

Yes

hazardous No

gas require IIC Equipment Threshold power Thermal Initiation Time Equipment Threshold Energy Zth

apparatus? for (W) (averaging period) for (µJ)

(µs)

Is the area of

Yes installation of No Use a suitable Group I 6.0 200 Group I 1500

Zone 1? flameproof cable

gland with a Group IIA 6.0 100 Group IIA 950

Is the sealing ring.

volume of (Gland with

Group IIB 3.5 80 Group IIB 250

Use a barrier Yes No

enclosure elastomeric

gland

greater than Group IIC 2.0 20 Group IIC 50

seals)

2 dm3?

Group III 6.0 200 Group III 1500

Extronics Ltd · Meridian House · Roe Street · Congleton · Cheshire · CW12 1PG · Tel: +44 (0)1260 292651 · Fax: +44 (0)1260 297280 · www.extronics.com · info@extronics.com

The information in this wall chart is for guidance only. For detailed information see relevant Directives and Regulations. © Extronics Ltd 2008 07/08

Anda mungkin juga menyukai

- Procom Ex certified antennas for hazardous environmentsDokumen8 halamanProcom Ex certified antennas for hazardous environmentsBao Quoc Mai100% (1)

- Atex ChartDokumen1 halamanAtex ChartShinoj B.c.100% (2)

- ATEXDokumen90 halamanATEXRinjal Banerjee80% (5)

- DS59 IEC 60079 0 2011 The Differences and The ConsequencesDokumen3 halamanDS59 IEC 60079 0 2011 The Differences and The ConsequencesGlen AshwellBelum ada peringkat

- Hazardous Area ClassificationDokumen63 halamanHazardous Area Classificationhtetwin100% (3)

- ATEX Guide to Explosive Atmosphere ProtectionDokumen44 halamanATEX Guide to Explosive Atmosphere Protectionminah22100% (4)

- Principles of Explosion Protection 30080001258Dokumen68 halamanPrinciples of Explosion Protection 30080001258HoangBelum ada peringkat

- Equipment For Explosive AtmospheresDokumen33 halamanEquipment For Explosive AtmospheresGreggBaeten0% (1)

- ATEX DirectiveDokumen11 halamanATEX Directiveasimozma100% (2)

- iUPS101: XXXX Ii 2 G Ex D (E) Iib T6 GBDokumen1 halamaniUPS101: XXXX Ii 2 G Ex D (E) Iib T6 GBAdemola Olajide TejumolaBelum ada peringkat

- Atex GuideDokumen6 halamanAtex GuideValiBelum ada peringkat

- Ex Essential Explosion Protection Rstahl B enDokumen56 halamanEx Essential Explosion Protection Rstahl B encruzleeno100% (1)

- AtexDokumen60 halamanAtexWendi Junaedi100% (1)

- Conference IEC 60079-14Dokumen79 halamanConference IEC 60079-14arturoncBelum ada peringkat

- (TC31) IEC 60079-0 Edition 6.0 (2011-06-22)Dokumen9 halaman(TC31) IEC 60079-0 Edition 6.0 (2011-06-22)Shirish100% (1)

- IEC 60079-18 - 2009 - Encapsulated Protection - Ex M PDFDokumen35 halamanIEC 60079-18 - 2009 - Encapsulated Protection - Ex M PDFRadu Babau100% (1)

- ATEX ExplainedDokumen1 halamanATEX ExplainedDonal O'SullivanBelum ada peringkat

- ATEX Standards Instrumentation ToolsDokumen5 halamanATEX Standards Instrumentation ToolsAbarajithan RajendranBelum ada peringkat

- Hazardous Area Classification - Dust AtmospheresDokumen23 halamanHazardous Area Classification - Dust AtmospheresMohd Lutfi MahaliBelum ada peringkat

- Rockwell Machine Safety ISO 13849-1Dokumen17 halamanRockwell Machine Safety ISO 13849-1Arun BabuBelum ada peringkat

- Hazardous Area Table IEC & NEC (NEMA) Cooper Crouse Hinds PDFDokumen1 halamanHazardous Area Table IEC & NEC (NEMA) Cooper Crouse Hinds PDFAgustinus Made Theo Dwijaya100% (3)

- Intrinsic SafetyDokumen85 halamanIntrinsic Safetycaigithe852456100% (2)

- IECDokumen1 halamanIECJay Jay100% (1)

- Hazardous Area Classification of Natural Gas Installations PDFDokumen11 halamanHazardous Area Classification of Natural Gas Installations PDFEko Poerwanto0% (4)

- Cable Glands in Hazardous Areas CCG PresentationDokumen59 halamanCable Glands in Hazardous Areas CCG PresentationAwotiku Abimbola100% (2)

- Very Good Presentation - ATEX IchemEDokumen109 halamanVery Good Presentation - ATEX IchemEkomalrana2007100% (8)

- Explosive Atmospheres Brochure 3AUA0000037223 REVC en LowresDokumen24 halamanExplosive Atmospheres Brochure 3AUA0000037223 REVC en Lowresckwei0910Belum ada peringkat

- Potentially Explosive Atmospheres ATEX Ignition Source ClassificationDokumen1 halamanPotentially Explosive Atmospheres ATEX Ignition Source ClassificationDANE80Belum ada peringkat

- Risk Analysis ATEXDokumen14 halamanRisk Analysis ATEXbaaziz2015Belum ada peringkat

- Guidelines in Support To IEC 60079-17 PDFDokumen124 halamanGuidelines in Support To IEC 60079-17 PDFMichael100% (4)

- Dsen 60079-10-1 & Uk PDFDokumen29 halamanDsen 60079-10-1 & Uk PDFNISO9001Belum ada peringkat

- Hazardous Area ClassificationsDokumen1 halamanHazardous Area ClassificationsAndrew Bull100% (2)

- IEC 60079-29-1 Gas Detectors - Performance Requirements of Detectors For Flammable Gases-2007Dokumen104 halamanIEC 60079-29-1 Gas Detectors - Performance Requirements of Detectors For Flammable Gases-2007Mohd Lutfi MahaliBelum ada peringkat

- Test Your Knowledge-DeepexDokumen23 halamanTest Your Knowledge-DeepexvishnudasBelum ada peringkat

- ATEX IECEx Certification Training Compliance StandardsDokumen1 halamanATEX IECEx Certification Training Compliance Standardshafnium99100% (1)

- ISA-61241 Electrical Aparatus To Use in Zone21y22Dokumen26 halamanISA-61241 Electrical Aparatus To Use in Zone21y22nicolascsBelum ada peringkat

- Iec 60079-13Dokumen11 halamanIec 60079-13nazaruddinmBelum ada peringkat

- 10-1 2018 3Dokumen9 halaman10-1 2018 3Efari BahcevanBelum ada peringkat

- Safety Instrumented System A Complete Guide - 2020 EditionDari EverandSafety Instrumented System A Complete Guide - 2020 EditionBelum ada peringkat

- ISO 12100 The Ultimate Step-By-Step GuideDari EverandISO 12100 The Ultimate Step-By-Step GuidePenilaian: 1 dari 5 bintang1/5 (1)

- Major Accidents to the Environment: A Practical Guide to the Seveso II-Directive and COMAH RegulationsDari EverandMajor Accidents to the Environment: A Practical Guide to the Seveso II-Directive and COMAH RegulationsBelum ada peringkat

- Explosion Hazards in the Process IndustriesDari EverandExplosion Hazards in the Process IndustriesPenilaian: 5 dari 5 bintang5/5 (2)

- Atex MarkingDokumen1 halamanAtex Markinggangotri05Belum ada peringkat

- Cable Sealing Solutions: For Hazardous AreasDokumen12 halamanCable Sealing Solutions: For Hazardous AreasArun VaideeswaranBelum ada peringkat

- Proiector Si CIL Atmosfera Potential ExplozivaDokumen14 halamanProiector Si CIL Atmosfera Potential ExplozivaMuzeul LampilorBelum ada peringkat

- IECEx Motors Check List - ED03 - 13aDokumen9 halamanIECEx Motors Check List - ED03 - 13atopendwarriorBelum ada peringkat

- SirenaDokumen6 halamanSirenaLuiza OcheanaBelum ada peringkat

- Fire ZoneDokumen12 halamanFire ZoneMehman NasibovBelum ada peringkat

- Topic III Hazardous Area ClassificationDokumen22 halamanTopic III Hazardous Area ClassificationJulius ChavezBelum ada peringkat

- HazLoc Guide To Zoned EquipmentDokumen8 halamanHazLoc Guide To Zoned EquipmentDzeminSinBelum ada peringkat

- Atex ExplainedDokumen3 halamanAtex ExplainedErica LindseyBelum ada peringkat

- EX AT: Equipment CategoriesDokumen2 halamanEX AT: Equipment CategoriesAminBelum ada peringkat

- CMP E1fwDokumen1 halamanCMP E1fwHen Drix LevaBelum ada peringkat

- Hazardous Area Classification and Control of Ignition SourcesDokumen9 halamanHazardous Area Classification and Control of Ignition SourcesKHALID HUBBAHBelum ada peringkat

- Ex Plakat enDokumen1 halamanEx Plakat enFarshid Ahmadian YazdiBelum ada peringkat

- 100V-Line 15 Watt Horn Speaker With Series Blocking Capacitor For Use in Hazardous areasBEXL15D-inDokumen26 halaman100V-Line 15 Watt Horn Speaker With Series Blocking Capacitor For Use in Hazardous areasBEXL15D-inEufemiano Noble JrBelum ada peringkat

- Dhirubhai AdviseDokumen6 halamanDhirubhai AdviseAshish JoshiBelum ada peringkat

- Reminiscences of The Nehru Age by M O Mathai Part 1of2Dokumen170 halamanReminiscences of The Nehru Age by M O Mathai Part 1of2satya194785% (13)

- CAPA - IntroductionDokumen6 halamanCAPA - IntroductionAshish JoshiBelum ada peringkat

- Physics EquationsDokumen5 halamanPhysics Equationsanon-992211100% (64)

- CAPA - IntroductionDokumen6 halamanCAPA - IntroductionAshish JoshiBelum ada peringkat

- Iit-Jee 1998Dokumen50 halamanIit-Jee 1998Ashish JoshiBelum ada peringkat

- A05 1032 PDFDokumen2 halamanA05 1032 PDFArgile-assholeBelum ada peringkat

- Siemens 2017Dokumen26 halamanSiemens 2017Varun PatelBelum ada peringkat

- Hazardous Area Classifications and ProtectionsDokumen8 halamanHazardous Area Classifications and ProtectionsUday GokhaleBelum ada peringkat

- ABS SVR - Part4 - 2006Dokumen748 halamanABS SVR - Part4 - 2006kman548Belum ada peringkat

- 310SV User's Guide PDFDokumen188 halaman310SV User's Guide PDFabhishek murarka100% (1)

- Ni 9205Dokumen26 halamanNi 9205Service MMIBelum ada peringkat

- Mini AllDokumen562 halamanMini Allkevin_lim90100% (1)

- Arp0108 2018Dokumen75 halamanArp0108 2018justin.kochBelum ada peringkat

- ABB Pressure Transmitter3Dokumen13 halamanABB Pressure Transmitter3Supawat RangsiwongBelum ada peringkat

- TDTG Bucket ElevatorDokumen20 halamanTDTG Bucket ElevatorVictor Julio Torres Daza0% (1)

- 462393-21 VJ DF 6320 - Operator Manual PDFDokumen91 halaman462393-21 VJ DF 6320 - Operator Manual PDFHayk PichikyanBelum ada peringkat

- 4 To 20 Ma Remote Indicator: Instructions, Operation Maintenance ManualDokumen24 halaman4 To 20 Ma Remote Indicator: Instructions, Operation Maintenance ManualsancakemreBelum ada peringkat

- Foxboro 873EC AnalyzerDokumen102 halamanFoxboro 873EC AnalyzerTimothy RingwoodBelum ada peringkat

- Operating Instructions Compact Piston and Diaphragm Pressure Switches Series 8000Dokumen4 halamanOperating Instructions Compact Piston and Diaphragm Pressure Switches Series 8000Ronaldo CordeiroBelum ada peringkat

- Ma0311 Ul Eu enDokumen2 halamanMa0311 Ul Eu enNal FivefivetwooneBelum ada peringkat

- Purged-Pressurized EnclosuresDokumen1 halamanPurged-Pressurized EnclosuresKennedy K'OdoyoBelum ada peringkat

- Storage and Dispensing of High Blend Ethanol Fuels Inc E 85 PDFDokumen15 halamanStorage and Dispensing of High Blend Ethanol Fuels Inc E 85 PDFMurli RamchandranBelum ada peringkat

- ISO PUR Oil Purification Operators ManualDokumen60 halamanISO PUR Oil Purification Operators ManualDivakar DecaBelum ada peringkat

- MN 06135Dokumen94 halamanMN 06135Sardar PerdawoodBelum ada peringkat

- FLUKE 87 V EX IndustrialDokumen2 halamanFLUKE 87 V EX IndustrialAKZTRABelum ada peringkat

- Mobile Offshore Drilling Units 2008: Rules For Building and ClassingDokumen40 halamanMobile Offshore Drilling Units 2008: Rules For Building and ClassingAmanda MartinezBelum ada peringkat

- UK Experience - European Standards ImplementationDokumen266 halamanUK Experience - European Standards ImplementationEnrico ManfrinatoBelum ada peringkat

- Explosion Proof Visual Signal 5-20 Joule Series FL60Dokumen6 halamanExplosion Proof Visual Signal 5-20 Joule Series FL60grenjithBelum ada peringkat

- Presentation - DNV Rey MorenoDokumen68 halamanPresentation - DNV Rey MorenoRey-an A. MorenoBelum ada peringkat

- RSC ProfileDokumen35 halamanRSC ProfileSathishBelum ada peringkat

- Rosemount 144-PCDokumen8 halamanRosemount 144-PCAnonymous YSA8CZ0Tz5Belum ada peringkat

- Risk Assessment: Method Statement Painting ActivitiesDokumen11 halamanRisk Assessment: Method Statement Painting ActivitiesWalid Amdouni100% (1)

- 02 Behavioural Safety Audit Site Inspection NCMTDokumen6 halaman02 Behavioural Safety Audit Site Inspection NCMTbabudevanandBelum ada peringkat

- Biffi ICON 3000: Electric ActuatorDokumen64 halamanBiffi ICON 3000: Electric Actuatorgdor1973Belum ada peringkat

- 34 Samss 625 PDFDokumen23 halaman34 Samss 625 PDFFlorin Daniel AnghelBelum ada peringkat