Saic Q 1017

Diunggah oleh

Hussain Nasser Al- NowiesserDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Saic Q 1017

Diunggah oleh

Hussain Nasser Al- NowiesserHak Cipta:

Format Tersedia

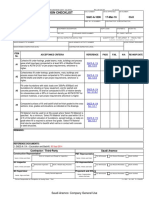

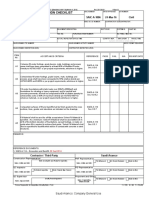

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - August 2004)

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Cast-In-Place Concrete Final Acceptance Inspection SAIC-Q-1017 18-May-05 CIVIL-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

All concrete surfaces in direct contact with earth shall be coated with two

coats of coal tar or bitumen coating consisting of two coats APCS-3 Coal

SAES-Q-001

A1 Tar Epoxy Coating System for Immersion Service or APCS-10

Sec. 11.4

Bituminous Paint for Moderate Temperatures in Buried or Immersion

Service. Overall dry coating thickness shall be from 325µm to 605µm.

All surface defects such as cracks or honey-combing shall be filled with

mortar consisting of 1 part Portland Cement of the type specified for the

job and 2.5 parts fine sand and ground in smooth with a trowel or

SAES-Q-001

A2 carborundum grind stone float. (ACI 515.1R, Sec. 3.2.1)

Sec. 3.2

Note: Proprietary compounds may be used in lieu of mortar in

accordance with the manufacturer's recommendations and with prior

approval of the S. ARAMCO representative.

After being cleaned and thoroughly dampened, tie holes should be SAES-Q-001

A3

completely filled with patching mortar. (ACI 515.1R, Sec. 3.2.2) Sec. 3.2

Finns, protrusions or similar irregularities projecting from the concrete

SAES-Q-001

A4 shall be removed back to the surface by chipping, brushhamering,

Sec. 3.2

needlegunning or wire brushing. (ACI 515.1R, Sec. 3.2.4)

Sharp offsets in the concrete caused by formwork misalignment, shall be

SAES-Q-001

A5 mechanically abraded to provide gradual and smooth transitions between

Sec. 3.2

offset surfaces. (ACI 515.1R, Sec. 3.4.2)

After finishing and curing operations all exposed construction joints,

control joints, expansion-contraction joints or other types shall blend into SAES-Q-001

A6

and match with the existing adjacent concrete finishes. Sec. 3.2

(ACI 301, Sec. 5.3.3)

If the surface is weak and more material can be removed by hand with a

knife; more material shall be removed down to a sound surface and SAES-Q-001

A7

patching performed as needed to bring the concrete surface back up to a Sec. 3.2

smooth, even surface. (ACI 515.1R, Sec. 3.4.3.3)

REMARKS:

REFERENCE DOCUMENTS:

1- SAES-Q-001 -- Criteria for Design and Construction of Concrete Structures, 29 October 2003

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Work is Complete and Ready for Inspection: T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Inspector PID Representative

Performed Inspection Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Completion of Quality Work / Test Y = YES N = NO F = FAILED

Page 1 of 1

Anda mungkin juga menyukai

- Saic Q 1007Dokumen2 halamanSaic Q 1007Hussain Nasser Al- NowiesserBelum ada peringkat

- Saic A 1005Dokumen2 halamanSaic A 1005Hussain Nasser Al- Nowiesser0% (1)

- Saic M 1043Dokumen1 halamanSaic M 1043Hussain Nasser Al- NowiesserBelum ada peringkat

- Saic M 1008Dokumen1 halamanSaic M 1008Hussain Nasser Al- NowiesserBelum ada peringkat

- Saic M 1047Dokumen1 halamanSaic M 1047Hussain Nasser Al- NowiesserBelum ada peringkat

- Saic Q 1016Dokumen2 halamanSaic Q 1016Hussain Nasser Al- NowiesserBelum ada peringkat

- Saic M 1044Dokumen2 halamanSaic M 1044Hussain Nasser Al- Nowiesser100% (1)

- Saic M 1060Dokumen1 halamanSaic M 1060Hussain Nasser Al- NowiesserBelum ada peringkat

- Saic M 1014Dokumen3 halamanSaic M 1014Hussain Nasser Al- NowiesserBelum ada peringkat

- Saic L 1002Dokumen2 halamanSaic L 1002Hussain Nasser Al- NowiesserBelum ada peringkat

- Handling and Storage of FBE Coated BarsDokumen2 halamanHandling and Storage of FBE Coated BarsMo'tasem SerdanehBelum ada peringkat

- Saic M 1006Dokumen2 halamanSaic M 1006Hussain Nasser Al- NowiesserBelum ada peringkat

- Saic M 1009Dokumen3 halamanSaic M 1009Hussain Nasser Al- NowiesserBelum ada peringkat

- SaicDokumen8 halamanSaicKhurram Shehzad100% (1)

- Saic A 1003Dokumen2 halamanSaic A 1003Hussain Nasser Al- NowiesserBelum ada peringkat

- Saic M 1053Dokumen1 halamanSaic M 1053Hussain Nasser Al- NowiesserBelum ada peringkat

- Saic M 2021Dokumen6 halamanSaic M 2021Hussain Nasser Al- NowiesserBelum ada peringkat

- Saic Q 1015Dokumen2 halamanSaic Q 1015Hussain Nasser Al- Nowiesser100% (1)

- Saic M 1012Dokumen2 halamanSaic M 1012Hussain Nasser Al- NowiesserBelum ada peringkat

- Saic A 1004Dokumen2 halamanSaic A 1004Hussain Nasser Al- Nowiesser0% (1)

- Saic L 1004Dokumen2 halamanSaic L 1004Hussain Nasser Al- NowiesserBelum ada peringkat

- Satip M 100 07Dokumen10 halamanSatip M 100 07munnaBelum ada peringkat

- Saic M 2004Dokumen6 halamanSaic M 2004Hussain Nasser Al- NowiesserBelum ada peringkat

- SAUDI ARAMCO CAST-IN-PLACE CONCRETE FORMWORK INSPECTION CHECKLISTDokumen5 halamanSAUDI ARAMCO CAST-IN-PLACE CONCRETE FORMWORK INSPECTION CHECKLISTNaushad AlamBelum ada peringkat

- Saic M 1070Dokumen1 halamanSaic M 1070Hussain Nasser Al- NowiesserBelum ada peringkat

- Saudi Aramco Inspection Checklist: Cast-In-Place Concrete Formwork Stripping Inspection SAIC Q-1016 15-Nov-17 MAH-SA-CDokumen3 halamanSaudi Aramco Inspection Checklist: Cast-In-Place Concrete Formwork Stripping Inspection SAIC Q-1016 15-Nov-17 MAH-SA-CAbdul HannanBelum ada peringkat

- Saic Q 1012Dokumen2 halamanSaic Q 1012Hussain Nasser Al- Nowiesser100% (2)

- Saudi Aramco waterproofing inspectionDokumen3 halamanSaudi Aramco waterproofing inspectionSatheesh Rama SamyBelum ada peringkat

- Saic M 1031Dokumen1 halamanSaic M 1031Hussain Nasser Al- NowiesserBelum ada peringkat

- Saic Q 1004Dokumen2 halamanSaic Q 1004Hussain Nasser Al- Nowiesser100% (1)

- Saic M 1067Dokumen2 halamanSaic M 1067Hussain Nasser Al- Nowiesser100% (2)

- Saic Q 1011Dokumen2 halamanSaic Q 1011Hussain Nasser Al- NowiesserBelum ada peringkat

- Saic-Q-1035 Sub-Base & Base CourseDokumen4 halamanSaic-Q-1035 Sub-Base & Base CourseAbdul HannanBelum ada peringkat

- Saic Q 1001Dokumen2 halamanSaic Q 1001Hussain Nasser Al- NowiesserBelum ada peringkat

- Satip Q 001 03Dokumen10 halamanSatip Q 001 03munnaBelum ada peringkat

- Saic M 1039Dokumen4 halamanSaic M 1039Hussain Nasser Al- Nowiesser100% (1)

- Saic M 1049Dokumen3 halamanSaic M 1049Hussain Nasser Al- NowiesserBelum ada peringkat

- SATIP-Q-001-03 Pre-Cast Concrete Fence Posts at Fabrication YardsDokumen2 halamanSATIP-Q-001-03 Pre-Cast Concrete Fence Posts at Fabrication YardsAbdul HannanBelum ada peringkat

- Saudi Aramco Soil Sampling ChecklistDokumen3 halamanSaudi Aramco Soil Sampling ChecklistTayyab KhanBelum ada peringkat

- Saudi Aramco Inspection ChecklistDokumen5 halamanSaudi Aramco Inspection ChecklistAbdul HannanBelum ada peringkat

- SATIP-Q-006-01rev4 (Asphalt Paving - Batch Plant & 3rd Party Lab) PDFDokumen3 halamanSATIP-Q-006-01rev4 (Asphalt Paving - Batch Plant & 3rd Party Lab) PDFRamziAhmedBelum ada peringkat

- Saic Q 1028Dokumen2 halamanSaic Q 1028Qays YousefBelum ada peringkat

- Saic M 1064Dokumen3 halamanSaic M 1064Hussain Nasser Al- NowiesserBelum ada peringkat

- SAIC-H-2007 Rev 7Dokumen5 halamanSAIC-H-2007 Rev 7isslam elhoussanyBelum ada peringkat

- SATIP-H-002-01 Rev 7Dokumen4 halamanSATIP-H-002-01 Rev 7Satheesh Rama SamyBelum ada peringkat

- Saic D 2024Dokumen9 halamanSaic D 2024Md ShariqueBelum ada peringkat

- Saudi Aramco Inspection Checklist: Concrete Fireproofing Final Inspection SAIC-B-1004 1-Nov-09 CivilDokumen1 halamanSaudi Aramco Inspection Checklist: Concrete Fireproofing Final Inspection SAIC-B-1004 1-Nov-09 CivilWaleed MedhatBelum ada peringkat

- Saudi Aramco Inspection Checklist: Geotechnical Investigation Requirements SAIC-A-1007 30-Apr-13 CivilDokumen2 halamanSaudi Aramco Inspection Checklist: Geotechnical Investigation Requirements SAIC-A-1007 30-Apr-13 CivilJeffrey Lipata Jr.Belum ada peringkat

- Saudi Aramco checklist for buttering jointsDokumen1 halamanSaudi Aramco checklist for buttering jointskarioke mohaBelum ada peringkat

- Saic M 1041Dokumen1 halamanSaic M 1041Hussain Nasser Al- NowiesserBelum ada peringkat

- SAUDI ARAMCO INSPECTION CHECKLISTDokumen1 halamanSAUDI ARAMCO INSPECTION CHECKLISTJagdishBelum ada peringkat

- Saic A 1006Dokumen1 halamanSaic A 1006QCI MYOUSIFBelum ada peringkat

- Saic A 1006Dokumen1 halamanSaic A 1006Niel TanedoBelum ada peringkat

- Saudi Aramco Inspection Checklist: Condensate Drain Installation SAIC-K-4007 15-Dec-09 HvacDokumen2 halamanSaudi Aramco Inspection Checklist: Condensate Drain Installation SAIC-K-4007 15-Dec-09 HvacMSK2112Belum ada peringkat

- SAIC-A-1006 - Final Fill InspectionDokumen1 halamanSAIC-A-1006 - Final Fill InspectionwalidBelum ada peringkat

- Surface Preparation ChecklistDokumen2 halamanSurface Preparation ChecklistWaleed MedhatBelum ada peringkat

- Saic A 1006Dokumen1 halamanSaic A 1006Hussain Nasser Al- NowiesserBelum ada peringkat

- Saic A 1006Dokumen1 halamanSaic A 1006Saragadam DilsriBelum ada peringkat

- Linolium Sheet Pre-Inspection ChecklistDokumen1 halamanLinolium Sheet Pre-Inspection Checklistmoytabura96Belum ada peringkat

- Saic H 1004Dokumen4 halamanSaic H 1004NASIR SYEDBelum ada peringkat

- Saic Q 1016Dokumen2 halamanSaic Q 1016Hussain Nasser Al- NowiesserBelum ada peringkat

- Saic Q 1013Dokumen5 halamanSaic Q 1013Hussain Nasser Al- NowiesserBelum ada peringkat

- Saic Q 1015Dokumen2 halamanSaic Q 1015Hussain Nasser Al- Nowiesser100% (1)

- Saic Q 1017Dokumen1 halamanSaic Q 1017Hussain Nasser Al- Nowiesser100% (2)

- Saic Q 1011Dokumen2 halamanSaic Q 1011Hussain Nasser Al- NowiesserBelum ada peringkat

- Saic Q 1014Dokumen2 halamanSaic Q 1014Hussain Nasser Al- NowiesserBelum ada peringkat

- Saic Q 1012Dokumen2 halamanSaic Q 1012Hussain Nasser Al- Nowiesser100% (2)

- Handling and Storage of FBE Coated BarsDokumen2 halamanHandling and Storage of FBE Coated BarsMo'tasem SerdanehBelum ada peringkat

- Saic Q 1001Dokumen2 halamanSaic Q 1001Hussain Nasser Al- NowiesserBelum ada peringkat

- Saic Q 1006Dokumen2 halamanSaic Q 1006Hussain Nasser Al- Nowiesser100% (1)

- Saic Q 1017Dokumen1 halamanSaic Q 1017Hussain Nasser Al- Nowiesser100% (2)

- Saic Q 1002Dokumen1 halamanSaic Q 1002Hussain Nasser Al- NowiesserBelum ada peringkat

- Saic Q 1017Dokumen1 halamanSaic Q 1017Hussain Nasser Al- Nowiesser100% (2)

- Saic Q 1004Dokumen2 halamanSaic Q 1004Hussain Nasser Al- Nowiesser100% (1)

- Saudi Aramco Inspection ChecklistDokumen2 halamanSaudi Aramco Inspection ChecklistDeepakBelum ada peringkat

- Saic Q 1017Dokumen1 halamanSaic Q 1017Hussain Nasser Al- Nowiesser100% (2)

- Saic o 1004Dokumen1 halamanSaic o 1004Hussain Nasser Al- NowiesserBelum ada peringkat

- Saic M 2004Dokumen6 halamanSaic M 2004Hussain Nasser Al- NowiesserBelum ada peringkat

- Saic o 1004Dokumen1 halamanSaic o 1004Hussain Nasser Al- NowiesserBelum ada peringkat

- Saic o 1004Dokumen1 halamanSaic o 1004Hussain Nasser Al- NowiesserBelum ada peringkat

- Saic M 1073Dokumen6 halamanSaic M 1073Hussain Nasser Al- NowiesserBelum ada peringkat

- Saic o 1001Dokumen1 halamanSaic o 1001Hussain Nasser Al- NowiesserBelum ada peringkat

- Saic o 1004Dokumen1 halamanSaic o 1004Hussain Nasser Al- NowiesserBelum ada peringkat

- Saudi Aramco Inspection ChecklistDokumen2 halamanSaudi Aramco Inspection ChecklistDeepakBelum ada peringkat

- Saic o 1004Dokumen1 halamanSaic o 1004Hussain Nasser Al- NowiesserBelum ada peringkat

- Saic M 2021Dokumen6 halamanSaic M 2021Hussain Nasser Al- NowiesserBelum ada peringkat

- Saic M 1072Dokumen5 halamanSaic M 1072Hussain Nasser Al- Nowiesser100% (2)

- Saudi Aramco Inspection Checklist: Structural Re-Instatement Punchlisting SAIC-M-1074 18-May-05 CivilDokumen5 halamanSaudi Aramco Inspection Checklist: Structural Re-Instatement Punchlisting SAIC-M-1074 18-May-05 Civil(*KaT*)Belum ada peringkat

- New Epdm MixingDokumen6 halamanNew Epdm MixingKAMAL BEHLBelum ada peringkat

- Perundurai SIPCOT Industries ListDokumen2 halamanPerundurai SIPCOT Industries ListShakth Creations50% (2)

- Shigleys Mechanical Engineering Design 10th Edition Budynas and Nisbett Solution ManualDokumen26 halamanShigleys Mechanical Engineering Design 10th Edition Budynas and Nisbett Solution Manualmark100% (23)

- Review On Metal Matrix Composites For Marine Applications: SciencedirectDokumen8 halamanReview On Metal Matrix Composites For Marine Applications: SciencedirectDavid MejiaBelum ada peringkat

- Belzona 1121 InstrustionsDokumen2 halamanBelzona 1121 Instrustionssh4kesBelum ada peringkat

- ASTM A193: GradesDokumen1 halamanASTM A193: GradesRamon MendozaBelum ada peringkat

- Incoterms Chart of ResponsibilityDokumen3 halamanIncoterms Chart of ResponsibilityRashoni JoswaBelum ada peringkat

- JST Crimp Quality ManualDokumen13 halamanJST Crimp Quality ManualChung LeBelum ada peringkat

- Failure Behavior of Honeycomb Sandwich Corner Joints and InsertsDokumen14 halamanFailure Behavior of Honeycomb Sandwich Corner Joints and InsertsConstantinescu MateiBelum ada peringkat

- HuberCrete Ground Calcium Carbonate For Precast Concrete ProductsDokumen6 halamanHuberCrete Ground Calcium Carbonate For Precast Concrete ProductsKalindaMadusankaDasanayakaBelum ada peringkat

- Notes On ExcavationDokumen3 halamanNotes On Excavationvegaangelika1Belum ada peringkat

- Construction Joint SealantDokumen4 halamanConstruction Joint SealantKhizar HayatBelum ada peringkat

- Properties Spec Typical: Technical Data Sheets For Al-99 and Al-90Dokumen2 halamanProperties Spec Typical: Technical Data Sheets For Al-99 and Al-90Haydee ContrerasBelum ada peringkat

- RITEMIX AS Anti-Shrinkage Powder Admixture Technical Data SheetDokumen2 halamanRITEMIX AS Anti-Shrinkage Powder Admixture Technical Data SheetMaria Aiza Maniwang CalumbaBelum ada peringkat

- BoQ Boundary Wall (Second Contract)Dokumen3 halamanBoQ Boundary Wall (Second Contract)surendramaharjanBelum ada peringkat

- Epma Introduction To PM MimDokumen38 halamanEpma Introduction To PM MimFilipe Schuck De LemosBelum ada peringkat

- Abrasive Paper RollsDokumen1 halamanAbrasive Paper Rollsherysyam1980Belum ada peringkat

- Tolonate™ IDT 70 B: Product Data SheetDokumen2 halamanTolonate™ IDT 70 B: Product Data SheetKay ChenBelum ada peringkat

- Production Methods of Aluminium Foam A Brief ReviewDokumen4 halamanProduction Methods of Aluminium Foam A Brief ReviewJuan SarmientoBelum ada peringkat

- Design and Automation of Plastic Injection Molding Machine: Under The Valuable Guidance ofDokumen49 halamanDesign and Automation of Plastic Injection Molding Machine: Under The Valuable Guidance ofAniket ChavanBelum ada peringkat

- Crouse Hinds TMC Catalog PageDokumen1 halamanCrouse Hinds TMC Catalog PageYofre Moreno CobeñaBelum ada peringkat

- Aluminum 2024-O Data SheetDokumen2 halamanAluminum 2024-O Data SheetAnonymous mq0U43UsPBelum ada peringkat

- Metal Forming 1 PDFDokumen6 halamanMetal Forming 1 PDFAlpha WolfBelum ada peringkat

- Sto Therm Classic BrochureDokumen12 halamanSto Therm Classic BrochureМомчило МитићBelum ada peringkat

- CE 415 - CMaT - Module 1 - Lesson 2Dokumen12 halamanCE 415 - CMaT - Module 1 - Lesson 2Enzo Ivan TILANDOCABelum ada peringkat

- TDS Nitoflor Lithurin 2 SEADokumen3 halamanTDS Nitoflor Lithurin 2 SEACharles FernandesBelum ada peringkat

- Standard Mechanical SealsDokumen115 halamanStandard Mechanical SealsArpit Verma50% (2)

- Mechanical AnchorsDokumen68 halamanMechanical AnchorsX800XLBelum ada peringkat

- 64-2103 Tweco Smoke Master MIGDokumen4 halaman64-2103 Tweco Smoke Master MIGcarlosBelum ada peringkat

- Aditya Birla Group Profile: PositionDokumen10 halamanAditya Birla Group Profile: PositionManohar NagillaBelum ada peringkat