Improving Dichromated Gelatin Sensitivity

Diunggah oleh

Arash RohaniDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Improving Dichromated Gelatin Sensitivity

Diunggah oleh

Arash RohaniHak Cipta:

Format Tersedia

Improving the holographic sensitivity of

dichromated gelatin in the blue–green part of the

spectrum by sensitization with xanthene dyes

Dejan Pantelić and Branka Murić

The holographic properties of dichromated gelatin 共DCG兲 sensitized with various xanthene dyes were

studied, and results are reported. The sensitivity of dyed DCG in the green part of the spectrum

compared with that of pure DCG 共215 mJ兾cm2兲 was significantly improved by addition of Rhodamine 6G

共140 mJ兾cm2兲 or Erythrosin B 共90 mJ兾cm2兲. Diffraction gratings were recorded with a He–Ne laser at

543.5 nm. The maximum diffraction efficiency was found to be 32% at normal incidence of the readout

beam; it was 80% at the Bragg angle. © 2001 Optical Society of America

OCIS codes: 090.2900, 050.1950.

1. Introduction holographic silver halide emulsions.8 Therefore re-

Gelatin sensitized with ammonium dichromate cording a hologram requires a powerful and expen-

关dichromated gelatin 共DCG兲兴 is one of the best holo- sive laser such as Ar-ion or He–Cd and large exposure

graphic recording materials because of its well- times.

known properties: high diffraction efficiency, large It was our intention to improve the sensitivity of

capacity for refractive-index modulation, high reso- DCG in the green part of the spectrum by adding a

lution 共as much as 5000 lines兾mm兲, high signal-to- dye such that a cheaper and simpler green He–Ne

noise ratio, and good environmental stability 共with a laser could be used. In this paper we present results

cover plate or a thin protective coating兲.1,2 A major of using various xanthene dyes 共Rhodamine 6G and

shortcoming of DCG is that its spectral sensitivity is Erythrosin B兲 and describe their influence on the

limited to the UV兾blue– green part of the spectrum.1,3 holographic properties of DCG.

The majority of reported papers concentrate on in-

2. Experiment

creasing the spectral sensitivity of DCG to the red

part of spectrum by addition of appropriate dyes 共for Chemically, gelatin is a polymer, which is composed

example, Methylene Blue4兲 to the DCG solution 共a of a number of ␣-amino acids and has a complex

sensitivity of 150 – 400 mJ兾cm2 at 632.8 nm was re- molecular structure. The molecular weight of gela-

ported兲.5 Only a few papers have been concerned tin ranges from 768 to 96,000, with an average value

with the increase of sensitivity in the green part of of approximately 27,000.9 DCG possesses good holo-

the spectrum.6,7 graphic characteristics. The mechanism of holo-

Although the sensitivity in the blue– green part of gram formation in DCG has been described in the

the spectrum is much higher than that in the red literature.1,10,11

part, it is still low compared with that of materials In our experiments, a 2–20% by weight aqueous

such as silver halogenide. That is, DCG is approxi- gelatin suspension was prepared by the procedure

mately 102–105 times slower photographically than outlined in Table 1. Various concentrations 共from 5

to 50% by weight of dry gelatin兲 of ammonium dichro-

mate were tested. The DCG film was prepared by

the gravity settling method12; nonphotographic qual-

D. Pantelić 共e-mail: pantelic@phy.bg.ac.yu兲 and B. Murić 共e-mail:

ity gelatin 共manufacturer trademark Gelatin-ALBA-

muric@phy.bg.ac.yu兲 are with the Institute of Physics, Pregrevica,

118, 11080 Zemun, Belgrade, Yugoslavia. Ph. Jug IV兲 was used. A DCG solution of constant

Received 26 October 2000; revised manuscript received 26 Feb- volume was poured onto a precisely leveled and well-

ruary 2001. cleaned microscope glass substrate. Thus we were

0003-6935兾01兾172871-05$15.00兾0 able to make DCG films with thicknesses that varied

© 2001 Optical Society of America from 15 to 60 m 共thickness of dried films兲.

10 June 2001 兾 Vol. 40, No. 17 兾 APPLIED OPTICS 2871

Table 1. Procedure for Preparing Dyed DCG Film Table 2. Procedure for Developing a Dyed DCG Platea

Step Description Step Description

1. Swell gelatin in deionized water for 60 min. 1. Wash in water for 5 min.

2. Heat the suspension in a thermostated water 2. Dehydrate in a 50:50% isopropyl alcohol and water

bath at 50 °C, stirring for 10 min. solution, stirring for 3 min.

3. Add an adequate amount 共see text兲 of ammonium 3. Dehydrate in a 70:30% isopropyl alcohol and water

dichromate, by weight of dry gelatin, and heat solution, stirring for 3 min.

in a thermostated water bath at 50 °C, stirring 4. Dehydrate in 100% isopropyl alcohol for 1.5 min.

for 10 min. 5. Dry plate with flowing hot air for 5 min and then

4. Add an appropriate amount of xanthene dye 共see in a chamber containing a desiccant.

Fig. 3 below for the optimum value兲 to the a

DCG solution. Deionized water was used. All steps were at a temperature of

25 °C.

5. Pipette out a known volume of dyed DCG solu-

tion onto a leveled glass microscope plate.

6. Dry the plate overnight.

type of hologram, were recorded by interference of

two expanded divergent laser beams that had equal

intensities and optical path lengths. A green He–Ne

The DCG plates were dried in the dark, for 24 h, in laser operating at ⫽ 543.5 nm 共with an output

relatively stable environmental conditions 共the tem- power of 1 mW兲 was used as a light source. The total

perature fluctuated in the 25–27 °C range, and the energy density of the recording light beams was 0.3

relative humidity was 50 – 60%兲. The best results mJ兾cm2. The angle between beams was approxi-

were obtained with a film made from a 5% aqueous mately 35° and, consequently, the spatial frequency

solution of gelatin, with 10% ammonium dichromate of the transmission gratings was ⬃1000 lines兾mm.

共by weight of dry gelatin兲 and a thickness of 30 m. The hologram area was 0.8 cm2. A readout beam at

One of the dyes used for DCG sensitization was 632.8 nm was used to measure the diffraction effi-

Rhodamine 6G, which belongs to the group of xan- ciency.

thene dyes 共absorption range, 500 –700 nm兲.13,14 During development, an exposed plate was washed

The addition of the dye can be accomplished in any of immediately in deionized water and dehydrated in

a number of ways.15 In our case, various quantities several baths of isopropyl alcohol with increasing

of a 0.1% aqueous solution of Rhodamine 6G were concentrations 共see Table 2兲.

introduced into a DCG solution. We found that the Also, we measured the diffraction efficiency in real

best results were obtained with a dye concentration of time as a function of exposure. A schematic dia-

7.5 mg兾l of DCG solution. gram of the real-time holographic setup is shown in

Using the same experimental conditions 共thickness Fig. 2. As can be seen, the measurements were not

of the DCG film, dichromate and dye concentrations performed at the Bragg angle. Instead, reconstruc-

unchanged兲, we investigated the influence of tion was done at normal incidence of a 632.8-nm

Erythrosin B 共another xanthene dye兲 on the holo- beam. We found that this configuration is easier to

graphic properties of DCG. position accurately and gives better reproducible re-

The absorption spectra of pure DCG and dyed DCG sults 共a slight deviation from the Bragg angle signif-

films 共Fig. 1兲 were measured with a UV–visible spec- icantly influenced our measurements兲.

trophotometer. The three spectra have approxi-

mately the same shape. As expected, at 543.5 nm

the absorption values of dyed DCG films increased

significantly compared with those of pure DCG film.

Transmission diffraction gratings, as the simplest

Fig. 2. Real-time holographic experimental setup: B.S., beam

Fig. 1. Absorption spectra of pure DCG film and dyed DCG films. splitter; MS, mirrors; Ls, lenses.

2872 APPLIED OPTICS 兾 Vol. 40, No. 17 兾 10 June 2001

Fig. 3. Relation of diffraction efficiency to concentration of Rho-

damine 6G for a 30-m-thick film with a constant exposure density

of 140 mJ兾cm2. Fig. 4. Relation of diffraction efficiency to exposure for a 30-m-

thick film with a constant concentration of Rhodamine 6G of 7.5

mg兾L.

3. Results and Discussion

Diffraction efficiency, as one of the most important holo-

The increase in holographic sensitivity depends

graphic parameters for judging the performance of DCG

only on properties of the chemical composition and

holograms, has been measured. Diffraction efficiency is

processing of DCG films. Although previous mea-

defined as the ratio between the intensities of the first-

surements were made at normal incidence, it is im-

order diffracted light and the incident light.16

portant to determine the maximum diffraction

Our measurements were made at normal incidence

efficiency at the Bragg angle. We did that for the

of the laser beam, both in real time and after devel-

most favorable circumstances for chemical process-

opment. Again, we found this configuration favor-

ing, as previously established 共at normal incidence兲.

able with respect to ease of positioning and

We found a maximum of 80% diffraction efficiency.

reproducibility. Besides, the purpose of our mea-

We found it hard to determine exactly whether our

surements was to determine holographic sensitivity gratings are of a thin, a thick, or an intermediate

of DCG 共DCG ⫹ sensitizer兲, which depends on chem- type.17,18 Because such a determination is not

ical composition and processing and not on the angle within the scope of our research, we give here only a

of the readout beam. For the sake of completeness, brief and incomplete analysis.

we include here our measurement of the maximum Strictly speaking, one can determine the type of

diffraction efficiency that can be obtained with our grating by calculating the so-called Q⬘ and ␥ factors

technique at the Bragg angle 共at wavelengths of both defined in Refs. 19 and 20. Along with other param-

543.5 and 632.8 nm兲. eters 共DCG emulsion thickness, wavelength, grating

The dependence of diffraction efficiency on the con- period, angle of incidence of the readout beam兲, Q⬘

centration of Rhodamine 6G is shown in Fig. 3. As depends on the refractive index of gelatin, which we

the concentration of Rhodamine 6G increases, the did not measure. Therefore we were able only to

diffraction efficiency increases; it reaches a maximum estimate that the parameter value is 77 by assuming

when the dye concentration is 7.5 mg兾l. After the that the refractive index of gelatin is 1.55.21 Like-

maximum concentration is attained, the diffraction wise, the ␥ factor depends on film thickness, wave-

efficiency decreases because Rhodamine 6G precipi- length, angle of incidence, and amplitude of the

tates at higher concentrations in the presence of the

dichromate ion.

The dependence of diffraction efficiency on expo-

sure for pure DCG and for DCG with Rhodamine 6G

is shown in Fig. 4. It is obvious that holographic

sensitivity increases in the presence of Rhodamine

6G. The maximum diffraction efficiency was found

to be 32% for both DCG and DCG with Rhodamine

6G, but the energy densities required for maximum

efficiency were 215 and 140 mJ兾cm2, respectively.

An increase in sensitivity was also observed after

we added Erythrosin B to the DCG solution 共Fig. 5兲.

We can see that the maximum value of the diffraction

efficiency for DCG sensitized with Erythrosin B was

32%, too. Moreover, in the presence of Erythrosin B,

maximum efficiency was obtained at an energy den- Fig. 5. Relation of diffraction efficiency to exposure for a 30-m-

sity of 90 mJ兾cm2, which is less than for both DCG thick film with a constant concentration of Erythrosin B of 7.5

sensitized with Rhodamine 6G and pure DCG. mg兾l.

10 June 2001 兾 Vol. 40, No. 17 兾 APPLIED OPTICS 2873

Fig. 7. Sensitivity 共filled squares, reported values24 –26; open

square, circle, and triangle, our results兲 of DCG as a function of

wavelength.

100% because of scattering, absorption, and Fresnel

losses.

We measured diffraction efficiency at 543.5 nm and

found only slight differences from that at 632.8 nm

共apart from a change of Bragg angle兲.

It is well known that pure DCG is sensitive to

UV兾blue– green light and that this sensitivity is

greater at shorter wavelengths 共the sensitivity ratio

at 488 and 514.5 nm is approximately 5:1兲.16,24 To our

knowledge, sensitivity measurements at 543.5 nm

Fig. 6. Energy distribution among various diffraction orders at were not performed, so we measured this value and

normal incidence and at the Bragg angle. Distribution was mea- found it to be 215 mJ兾cm2.

sured on the same DCG film, optimally exposed and processed. We wanted to correlate our results with the pre-

viously published measurements of DCG sensi-

tivity.24 –26 Therefore in Fig. 7 we illustrate the

refractive-index modulation. The last parameter

sensitivity of DCG 共defined as the energy density

was not measured; instead we took the value ⌬n ⫽

required for the maximum diffraction efficiency兲 as

0.00135 from Ref. 21 and found that ␥ ⫽ 0.2.

a function of wavelength. It is obvious that sensi-

Because of the unpredictable properties of gelatin

tization of DCG results in significant improvement

and of processing peculiarities, ⌬n can have various

of sensitivity at 543.5 nm.

values.22,23 That is, the refractive index of DCG and

We also found that the sensitivity of DCG at 543.5

its variation depend on many parameters, such as

nm 共He–Ne laser兲 in the presence of xanthene dyes—

humidity, temperature, concentration of ammonim

Rhodamine 6G and Erythrosin B—is approximately

dichromate, polarization, birefringence of gelatin,

the same as the sensitivity of pure DCG at 514.5 nm

nonuniformity, and exposure level. Therefore the

共Ar-ion laser兲.

values that we obtained should be taken with a de-

In Fig. 8, we show the real-time diffraction effi-

gree of caution.

At any rate, if the Q⬘ and ␥ values are correct,

according to Ref. 19 our gratings will be on the border

between the Bragg and the Raman–Nath regimes.

To support this conclusion we illustrate the distribu-

tion of energy among various diffraction orders at

normal incidence and at the Bragg angle 共Fig. 6兲. As

can be seen, there is a significant amount of energy

distributed outside 0th and ⫺1st orders at the Bragg

angle. This means that the grating is not purely

Bragg. Also, the grating is not Raman–Nath be-

cause the 0th order should have a higher intensity

than other orders 共for ␥ ⫽ 0.2, as in our case兲. Ad-

ditionally, the diffraction efficiency should not de-

pend significantly on the angle of incidence in an

angular range of ⫾20° 共whereas in our case the dif-

fraction efficiency was 32% at normal incidence,

reaching a maximum of 80% at an angle of ⬃10°兲.

The total diffracted energy 共all orders兲 does not add to Fig. 8. Real-time diffraction efficiency as a function of exposure.

2874 APPLIED OPTICS 兾 Vol. 40, No. 17 兾 10 June 2001

ciency as a function of exposure for pure DCG and for 7. G. Manivannan, R. Changkakoti, R. A. Lessard, G. Maihot,

dyed DCG. The real-time effects confirm the im- and M. Bolte, “Dichromated poly共vinyl alchohol兲–xanthene dye

provement in sensitivity of dyed DCG films. Also, systems: holographic characterization and electron spin res-

onance spectroscopic study,” in Photopolymers and Applica-

we can see that presence of Rhodamine 6G or

tions in Holography, Optical Data Storage, Optical Sensors,

Erythrosin B in DCG, besides increasing the sensi- and Interconnects, R. A. Lessard, ed., Proc. SPIE 2042, 87–97

tivity of DCG, enhances the real-time diffraction ef- 共1993兲.

ficiency. Maxima of 0.004% for pure DCG, 0.008% 8. K. S. Pennington and J. S. Harper, “New phototechnology for

for DCG with Erythrosin B, and 0.012% for DCG with recording phase holograms and similar information in hard-

Rhodamine 6G were obtained. ened gelatin,” Appl. Phys. Lett. 18, 80 – 84 共1971兲.

9. L. Stroebel, J. Compton, I. Current, and R. Zaria, Photographic

4. Conclusions Materials and Processes 共Focal, Boston, Mass., 1985兲.

The aim of our research was to improve the holo- 10. S. Sjöllender, “Dichromated gelatin and light sensitivity,” J.

graphic sensitivity of DCG in the green part of the Imaging Sci. 30, 151–154 共1986兲.

spectrum by sensitization with various xanthene 11. C. Lafond, C. Pizzocaro, R. A. Lessard, and M. Bolte, “Primary

dyes. Although we used a rather simple method for photochemical process in films of dichromated gelatin: a

quantitative approach,” Opt. Eng. 39, 610 – 615 共2000兲.

preparation and development of pure DCG, our re-

12. T. Keinonen, P. Riihola, K. Huttu, and S. Parkkonen, “Dye

sults are in good agreement with those of previous

films for optical demonstrations in the undergraduate labora-

research. The sensitivity of DCG was significantly tory,” Opt. Mater. 11, 79 – 86 共1998兲.

improved by addition of Rhodamine 6G and 13. M. Maeda, Laser Dyes 共Academic, London, 1984兲, p. 22.

Erythrosin B. The improvement in the sensitivity of 14. K. P. B. Moosad, T. M. A. Rasheed, and V. P. N. Nampoori,

dyed DCG was confirmed by real-time measure- “Optical phase conjugation in dyes embedded in polymer

ments. films,” Opt. Eng. 29, 47–51 共1990兲.

The photochemical reaction processes of DCG sen- 15. A. Graube and C. Park, “Dye sensitized dichromated gelatin

sitized with xanthene dyes are complex and not yet holographic materials,” U.S. patent 3,963,490 共15 June 1976兲.

clear. Therefore additional research should be done 16. R. J. Collier, C. B. Burchhart, and L. H. Lin, Optical Hologra-

in order to elucidate the chemical mechanisms in phy 共Academic, New York, 1971兲, p. 295.

more detail. 17. R. R. A. Syms, Practical Volume Holography 共Clarendon, Ox-

ford, 1990兲, p. 49.

References 18. R. Magnusson and T. K. Gaylord, “Diffraction regimes of trans-

1. B. J. Chang and C. D. Leonard, “Dichromated gelatin for the mission gratings,” J. Opt. Soc. Am. 68, 809 – 814 共1978兲.

fabrication of holographic optical elements,” Appl. Opt. 18, 19. M. G. Moharam, T. K. Gaylord, and R. Magnusson, “Criteria

2407–2417 共1979兲. for Raman–Nath regime diffraction by phase gratings,” Opt.

2. C. G. Stojanoff, O. Brasseur, S. Tropartz, and H. Schuette, Commun. 32, 19 –23 共1980兲.

“Conceptual design and practical implementation of dichro- 20. M. G. Moharam, T. K. Gaylord, and R. Magnusson, “Criteria

mated gelatin films as an optimal holographic recording ma- for Bragg regime diffraction by phase gratings,” Opt. Commun.

terial for large-format holograms,” in Photopolymers and 32, 14 –18 共1980兲.

Applications in Holography: Optical Data Storage, Optical 21. T. A. Shankoff, “Phase holograms in dichromated gelatin,”

Sensors, and Interconnects, R. A. Lessard, ed., Proc. SPIE Appl. Opt. 7, 2101–2105 共1968兲.

2042, 301–311 共1993兲. 22. G. Campbell, T. J. Kim, and R. K. Kostok, “Comparison of

3. T. Mizuno, T. Goto, M. Goto, K. Matsui, and T. Kubota, “Meth- methods for determining the bias index of a dichromated gel-

ylene Blue sensitized dichromated gelatin holograms: influ- atin hologram,” Appl. Opt. 34, 2548 –2555 共1995兲.

ence of the moisture on their exposure and diffraction 23. V. M. Rzhevski and N. G. Rupchev, “Influence of photochem-

efficiency,” Appl. Opt. 29, 4757– 4760 共1990兲. istry processes on the refractive index and thickness on layers

4. M. Sun, J. Wang, J. Zhao, and M. Li, “Methylene-Blue- of dichromated gelatin,” Opt. Spectrosc. USSR 68, 1378 –1380

sensitized gelatin holograms,” Appl. Opt. 35, 5776 –5779 共1980兲, in Russian.

共1996兲. 24. L. H. Lin, “Hologram formation in hardened dichromated gel-

5. T. Kubota and T. Ose, “Methods of increasing the sensitivity of atin films,” Appl. Opt. 8, 963–966 共1969兲.

Methylene Blue sensitized dichromated gelatin,” Appl. Opt. 25. K. Kurokawa, S. Koike, S. Samba, T. Mizuno, and T. Kubota,

18, 2538 –2539 共1979兲. “Simplified method for preparing Methylene-Blue-sensitized

6. R. A. Myers, T. L. Helg, T. H. Barnes, A. D. Woolhouse, and dichromated gelatin,” Appl. Opt. 37, 3038 –3043 共1998兲.

T. G. Haskell, “Characterization of dye-doped media for real- 26. V. A. Baracevski, New Recording Materials for Holography

time holography,” Opt. Commun. 137, 223–228 共1997兲. 共Nauka, Leningrad, 1983兲, in Russian, p. 22.

10 June 2001 兾 Vol. 40, No. 17 兾 APPLIED OPTICS 2875

Anda mungkin juga menyukai

- Hans Bjelkhagen New Recording Materials For HolographyDokumen12 halamanHans Bjelkhagen New Recording Materials For HolographyAABDAHMEDBelum ada peringkat

- Investigations On The Theory of The Photographic Process - Sheppard and MeesDokumen366 halamanInvestigations On The Theory of The Photographic Process - Sheppard and MeesJorgeCamachoBelum ada peringkat

- The Photographic Industry 1Dokumen65 halamanThe Photographic Industry 1HagosMebrahtuBelum ada peringkat

- Fourier OpticsDokumen9 halamanFourier Opticssal.paradise.1Belum ada peringkat

- Ultra RealisticimagingDokumen665 halamanUltra RealisticimaginggffgfgBelum ada peringkat

- High Precision Laser Interferometer Feedback SystemsDokumen24 halamanHigh Precision Laser Interferometer Feedback SystemsSandeep RaiBelum ada peringkat

- Photosensitized Singlet Oxygen and Its Applications: Maria C. Derosa, Robert J. CrutchleyDokumen21 halamanPhotosensitized Singlet Oxygen and Its Applications: Maria C. Derosa, Robert J. CrutchleyHarsha VempatiBelum ada peringkat

- Ferric GumDokumen13 halamanFerric GumMichal SlavíčekBelum ada peringkat

- Holographics Intl - No7Dokumen36 halamanHolographics Intl - No7alkislemBelum ada peringkat

- Advanced Holography - Metrology and ImagingDokumen384 halamanAdvanced Holography - Metrology and Imagingzaryab khanBelum ada peringkat

- Hodges A Course in Scientific German (1887) PDFDokumen200 halamanHodges A Course in Scientific German (1887) PDFMarcelo Silvano de Camargo100% (1)

- Photographic Objectives And Photo-Optical Auxiliary AppliancesDari EverandPhotographic Objectives And Photo-Optical Auxiliary AppliancesBelum ada peringkat

- !kannala Brandt CalibrationDokumen15 halaman!kannala Brandt CalibrationpchistBelum ada peringkat

- Laser InterferometerDokumen33 halamanLaser InterferometerShree Ram PandeyBelum ada peringkat

- Agfa Beginners Book IIDokumen35 halamanAgfa Beginners Book IIGabriel Ma del CaBelum ada peringkat

- HolographyDokumen17 halamanHolographymanoj kumar rout100% (2)

- Talbot's Rouen WindowDokumen9 halamanTalbot's Rouen Windowwalkerevans439Belum ada peringkat

- Light HeadsDokumen60 halamanLight HeadsJosé NBelum ada peringkat

- M Ware, New Argyrotype ProcessDokumen4 halamanM Ware, New Argyrotype Processluis guevaraBelum ada peringkat

- Moon Revealed SR 50 (10) 12-18 PDFDokumen0 halamanMoon Revealed SR 50 (10) 12-18 PDFbimanbasuBelum ada peringkat

- The Holography Times Issue 22Dokumen20 halamanThe Holography Times Issue 22CHANDER SHEKHAR JEENABelum ada peringkat

- Transition and Turbulence: Proceedings of a Symposium Conducted by the Mathematics Research Center, the University of Wisconsin–Madison, October 13–15, 1980Dari EverandTransition and Turbulence: Proceedings of a Symposium Conducted by the Mathematics Research Center, the University of Wisconsin–Madison, October 13–15, 1980Belum ada peringkat

- Art of PhotographyDokumen31 halamanArt of PhotographyIvanof VioletaBelum ada peringkat

- Reactions of Non-Metallic Inorganic CompoundsDari EverandReactions of Non-Metallic Inorganic CompoundsBelum ada peringkat

- A Guide to the Wet Plate Process of Photography - Camera Series Vol. XVIII. - A Selection of Classic Articles on Development, Fixing, Chemicals andDari EverandA Guide to the Wet Plate Process of Photography - Camera Series Vol. XVIII. - A Selection of Classic Articles on Development, Fixing, Chemicals andBelum ada peringkat

- Adaptive Optics for Vision Science: Principles, Practices, Design, and ApplicationsDari EverandAdaptive Optics for Vision Science: Principles, Practices, Design, and ApplicationsBelum ada peringkat

- Seminar Report Sem 4Dokumen15 halamanSeminar Report Sem 4Adith KSBelum ada peringkat

- Applications of Holography and Optical Data Processing: Proceedings of the International Conference, Jerusalem, August 23-26, 1976Dari EverandApplications of Holography and Optical Data Processing: Proceedings of the International Conference, Jerusalem, August 23-26, 1976E. MaromBelum ada peringkat

- An Introduction to Solid State DiffusionDari EverandAn Introduction to Solid State DiffusionPenilaian: 4 dari 5 bintang4/5 (6029)

- Computer Generated Holograms, An Historical ReviewDokumen10 halamanComputer Generated Holograms, An Historical ReviewJano Gil LópezBelum ada peringkat

- "Leith & Upatnieks" Holograms PDFDokumen8 halaman"Leith & Upatnieks" Holograms PDFRichurajanBelum ada peringkat

- Photograms & ScanographyDokumen33 halamanPhotograms & ScanographyaborleisBelum ada peringkat

- Issue Vol. 10, 04 2012Dokumen163 halamanIssue Vol. 10, 04 2012Rogério CavalcanteBelum ada peringkat

- Nikon L35af PDFDokumen21 halamanNikon L35af PDFJessica HmcBelum ada peringkat

- Blue Printing PDFDokumen3 halamanBlue Printing PDFanjuBelum ada peringkat

- Agfa Professional FilmsDokumen12 halamanAgfa Professional FilmsdprakelBelum ada peringkat

- William Eggleston - The Life and WorksDokumen9 halamanWilliam Eggleston - The Life and Worksapi-356541788Belum ada peringkat

- Brought To You by Mac Torrent Download: Important NotesDokumen1 halamanBrought To You by Mac Torrent Download: Important NotesAhmediqraBelum ada peringkat

- Cyanotype ProcessDokumen22 halamanCyanotype Processgg100% (3)

- Moire and Fringe Projection Techniques PDFDokumen34 halamanMoire and Fringe Projection Techniques PDFMay VargasBelum ada peringkat

- Holographics Intl - No5Dokumen36 halamanHolographics Intl - No5alkislemBelum ada peringkat

- Photography - HistoryDokumen27 halamanPhotography - HistoryMiguelVinci100% (1)

- Color Space KoenderinkDokumen1 halamanColor Space KoenderinkdavidrojasvBelum ada peringkat

- Web Darkroom Chem 2014Dokumen34 halamanWeb Darkroom Chem 2014caro sturgesBelum ada peringkat

- Munsell A0Dokumen1 halamanMunsell A0Ar Raj YamgarBelum ada peringkat

- Carbon RSDokumen15 halamanCarbon RSSandra SinuésBelum ada peringkat

- Negatives Poster BookletDokumen36 halamanNegatives Poster BookletFernando GarcíaBelum ada peringkat

- DAYLABDokumen26 halamanDAYLABMassimo PedrinaBelum ada peringkat

- Agfa Book of Photographic Formulae - 1910Dokumen136 halamanAgfa Book of Photographic Formulae - 1910JorgeCamachoBelum ada peringkat

- Blur 39 PDFDokumen225 halamanBlur 39 PDFMilosJovanovicBelum ada peringkat

- An Analytical Study On The Modern History of Digital Photography - Dr. Amr Mohamed GalalDokumen13 halamanAn Analytical Study On The Modern History of Digital Photography - Dr. Amr Mohamed GalalRodrigo AlcocerBelum ada peringkat

- Osbahr ReversalDokumen35 halamanOsbahr Reversalcool_dd100% (1)

- Crystal GrowthDokumen96 halamanCrystal GrowthArif Istiaque FarhanBelum ada peringkat

- Kodak Professional Apparatus 1936Dokumen62 halamanKodak Professional Apparatus 1936ajsikelBelum ada peringkat

- 206 Darkroom HazardsDokumen3 halaman206 Darkroom Hazardsskynyrd75Belum ada peringkat

- Spatial Disorientation in AviationDokumen12 halamanSpatial Disorientation in AviationT-CAS0% (1)

- Marvel Mcq's 3rd PaperDokumen5 halamanMarvel Mcq's 3rd Paper384varunjoshiBelum ada peringkat

- Y12 Chemistry Initial AssessmentDokumen58 halamanY12 Chemistry Initial AssessmentGeorge DrakeBelum ada peringkat

- Pirs509a BeamnrcDokumen289 halamanPirs509a BeamnrcskcomhackerBelum ada peringkat

- Diseño Cercha Metalica Tipo I VerificadoDokumen36 halamanDiseño Cercha Metalica Tipo I VerificadoJosé Mario Blacutt AléBelum ada peringkat

- Model 549: General & Small Parts PhantomDokumen3 halamanModel 549: General & Small Parts PhantomMiguel De Los Santos PavisicBelum ada peringkat

- Makalah Akhir Pressure MaintenanceDokumen13 halamanMakalah Akhir Pressure MaintenanceBarbara_LFCBelum ada peringkat

- The Physics of VolleyballDokumen2 halamanThe Physics of VolleyballMary Grace Arcayan LoberianoBelum ada peringkat

- Midterm Exam Fall 2012Dokumen5 halamanMidterm Exam Fall 2012Asanka RodrigoBelum ada peringkat

- Zoncare-Q7: Full Digital Color Doppler Ultrasound Diagnostic SystemDokumen3 halamanZoncare-Q7: Full Digital Color Doppler Ultrasound Diagnostic SystemyeniBelum ada peringkat

- 2 & 3 Wheeler Lab ManualDokumen36 halaman2 & 3 Wheeler Lab ManualKarthi100% (1)

- Wolfson Eup3 Ch18 Test BankDokumen18 halamanWolfson Eup3 Ch18 Test BankifghelpdeskBelum ada peringkat

- Modified Windkessel Model Applied in A Tubular Pulsation Dampener AnalysisDokumen11 halamanModified Windkessel Model Applied in A Tubular Pulsation Dampener AnalysisFrancesca CoattiBelum ada peringkat

- UBD Physics Unit 2 - Energy and The EnviornmentDokumen5 halamanUBD Physics Unit 2 - Energy and The EnviornmentAlfred Melvin SolivaBelum ada peringkat

- Burns & Mayne (S&F 2002) PiezoDissipationDokumen7 halamanBurns & Mayne (S&F 2002) PiezoDissipationJesus GonzalezBelum ada peringkat

- EE5103/ME5403 Lecture Two Computer Control and Discrete-Time SystemsDokumen49 halamanEE5103/ME5403 Lecture Two Computer Control and Discrete-Time SystemsFeiBelum ada peringkat

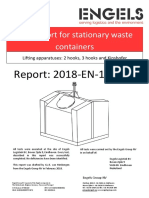

- Report 2018-En-1 en 13071-1-3 Aero EnglishDokumen16 halamanReport 2018-En-1 en 13071-1-3 Aero EnglishSlikCostaBelum ada peringkat

- A.7.a.1CE Mark - KS1150 FR - Panou Perete Rez Foc 180 Min C2Dokumen1 halamanA.7.a.1CE Mark - KS1150 FR - Panou Perete Rez Foc 180 Min C2Agnes SzaboBelum ada peringkat

- 1 s2.0 S0267726121000427 MainDokumen14 halaman1 s2.0 S0267726121000427 MainMarco Castro MayorBelum ada peringkat

- II B. Tech II Semester Regular Examinations April/May - 2013 Electrical Machines - IiDokumen8 halamanII B. Tech II Semester Regular Examinations April/May - 2013 Electrical Machines - IiAR-TBelum ada peringkat

- Introduction To SR and GR by Hans Stephani PDFDokumen418 halamanIntroduction To SR and GR by Hans Stephani PDFDvij252580% (5)

- Separation of Drugs by Packed-Column Supercritical Fluid ChromatographyDokumen18 halamanSeparation of Drugs by Packed-Column Supercritical Fluid ChromatographySameh QanadiloBelum ada peringkat

- Basic Data Viper40 15066 enDokumen10 halamanBasic Data Viper40 15066 enArmando RiveraBelum ada peringkat

- Astrology WebcourseDokumen310 halamanAstrology Webcoursexlearner100% (18)

- Drawing Numbering System: Client: ProjectDokumen23 halamanDrawing Numbering System: Client: ProjectPrasanna kumar subudhiBelum ada peringkat

- Charles Law Strategic Intervention Material in ChemistryDokumen11 halamanCharles Law Strategic Intervention Material in ChemistryDwell Joy Armada78% (9)

- AcousticsDokumen7 halamanAcousticscancan25Belum ada peringkat

- The Core-Periphery Model With Three Regions and MoreDokumen25 halamanThe Core-Periphery Model With Three Regions and MoreJomit C PBelum ada peringkat

- MAG8000 Manual PDFDokumen137 halamanMAG8000 Manual PDFHanks EpphBelum ada peringkat

- Nonlinear Modeling With OpenSeesDokumen71 halamanNonlinear Modeling With OpenSeesManu Vega100% (1)